Diethyl ether purification method, and method for improving purity of nitrogen-containing organic matter by using diethyl ether

A purification method and a technology of organic matter, applied in ether separation/purification, chemical instruments and methods, organic chemistry, etc., can solve problems such as failure to fundamentally prevent the formation of iodine element, loss of raw materials, and inability to prevent the oxidation of precursor AX, etc. Achieve low cost, reduce the generation of halogen elemental substances, and overcome the effects of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

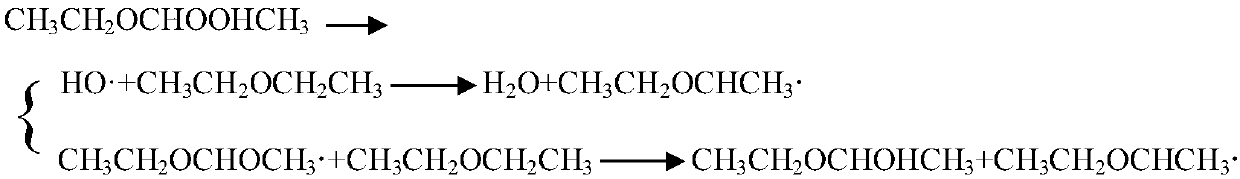

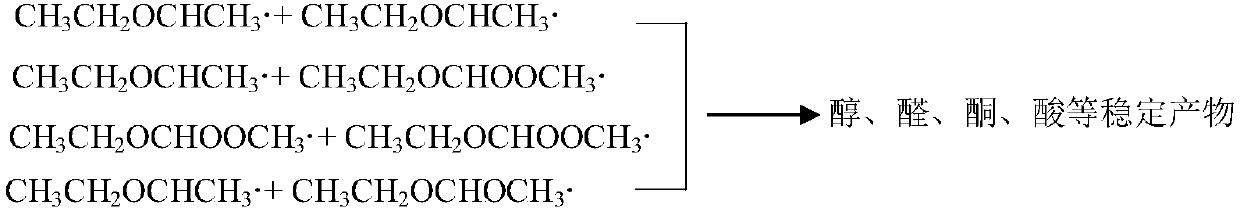

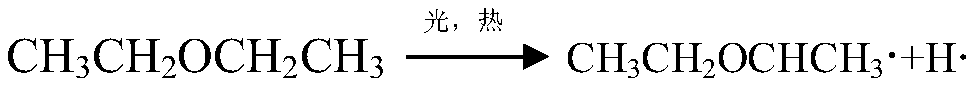

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] 11). Weigh 0.05mol free radical scavenger pentaerythritol tetrakis(3,5-di-tert-butyl-4-hydroxy)phenylpropionate, and dissolve it in 50 mL of chloroform.

[0089] 12). Weigh 0.05mol hydroperoxide decomposer tris(2,4-di-tert-butylphenyl)phosphite and dissolve it in 50mL of acetone.

[0090] 13). Mix the above two solutions, add 100mL of the mixed solution to 2L of ether, oscillate, mix well, place it in a sealed room at room temperature and avoid light for more than a week, and react completely, remove free radicals and peroxyethyl ether in ether, and obtain purified mixed solution of diethyl ether.

[0091] 14). Weigh 10g of methylammonium iodide powder into a beaker, pour 100mL of absolute ethanol, and stir until completely dissolved. Then gradually add the purified diethyl ether mixed solution into the beaker with a separating funnel until the methyl ammonium iodide crystals no longer precipitate, that is, stop the diethyl ether injection, and fully stir for 15 minute...

Embodiment 2

[0097] 21). Weigh 0.1 mol of free radical scavenger 3-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate, 0.1 mol of hydroperoxide decomposer thiobis Didodecyl propionate, add them to 10L ether, oscillate, mix well, place in airtight and dark place at room temperature for more than one week, complete reaction to remove free radicals and peroxyethyl ether in ether.

[0098] 22). Add 10g of formamidine ammonium iodide powder into the beaker, pour into 100mL of anhydrous methanol, and stir until completely dissolved. Then gradually add the purified diethyl ether mixed solution into the beaker with a separating funnel until the formamidine ammonium iodide crystals no longer separate out, that is, stop the diethyl ether injection, and fully stir for 15 minutes. Suction filtration with a Buchner funnel yielded formamidine ammonium iodide as a solid.

[0099] 23). Repeat step 22) three times to obtain high-quality formamidine ammonium iodide crystals.

[0100] 24). Disperse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com