Patents

Literature

50 results about "Hydroperoxide decomposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for the preparation of phenol and cyclohexanone

InactiveUS20120157718A1EfficiencyGood choiceOxygen-containing compound preparationOrganic compound preparationCyclohexanoneCyclohexene

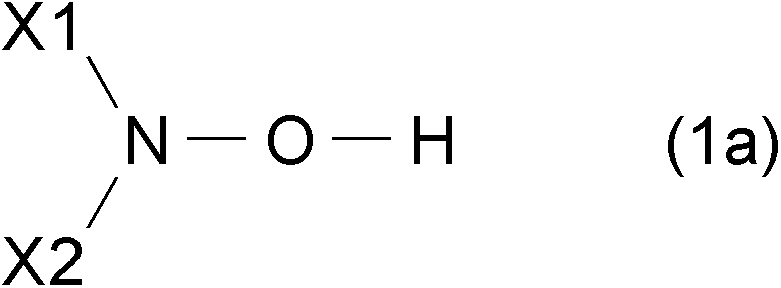

Process for the preparation of phenol and cyclohexanone which comprises:a. the synthesis of cyclohexylbenzene by the hydro-alkylation of benzene by contact with hydrogen or the alkylation of benzene with cyclohexene using Y zeolites;b. the selective aerobic oxidation of cyclohexylbenzene to the corresponding hydroperoxide catalyzed by N-hydroxy-derivatives in the presence of polar solvents; andc. the scission of the hydroperoxide of cyclohexylbenzene to phenol and cyclohexanone by homogeneous or heterogeneous acid catalysts;characterized in that the synthesis of cyclohexylbenzene takes place in the presence of a catalytic system comprising a Y zeolite and an inorganic ligand wherein the Y zeolite has a crystalline structure with openings consisting of 12 tetrahedra and the inorganic ligand is γ-alumina, and wherein said catalytic composition is characterized by a pore volume, obtained by adding the mesoporosity and macroporosity fractions, greater than or equal to 0.7 cm3 / g, wherein at least 30% of said volume consists of pores with a diameter greater than 100 nanometers.

Owner:POLIMERI EUROPA SPA

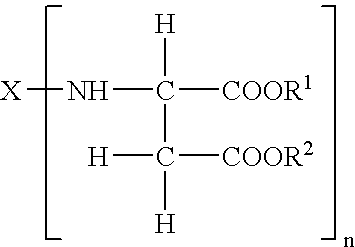

Durable coating compositions containing aspartic compounds

InactiveUS20040147648A1Synthetic resin layered productsPolyurea/polyurethane coatingsPolymer scienceO-Phosphoric Acid

A coating composition comprising a binder of a. polyisocyanate crosslinking agent; b. an isocyanate-reactive component having at least one compound having the following formula: wherein X is an aliphatic or cycloaliphatic group, R<1 >and R<2 >are the same or different organic groups that are inert to isocyanate groups, and n is 2 to 4, and c. optionally, a polymeric component having a number average molecular weight of 5,000 to 50,000 having reactive groups that crosslink with an isocyanate, where the reactive groups are hydroxyl, carboxyl, glycidyl, amine and any mixtures thereof; and d. optionally, an oligomeric component having a number average molecular weight of 300 to 3,000 having reactive groups that crosslink with an isocyanate, where the reactive groups are hydroxyl, carboxyl, glycidyl, amine, aldimines, phosphoric acid, ketimine and any mixtures thereof; and contains the following additives: disubstituted phenol antioxidant or a hydroperoxide decomposer, an ultraviolet light absorber, and a hindered amine light stabilizer.

Owner:AXALTA COATING SYST IP CO LLC

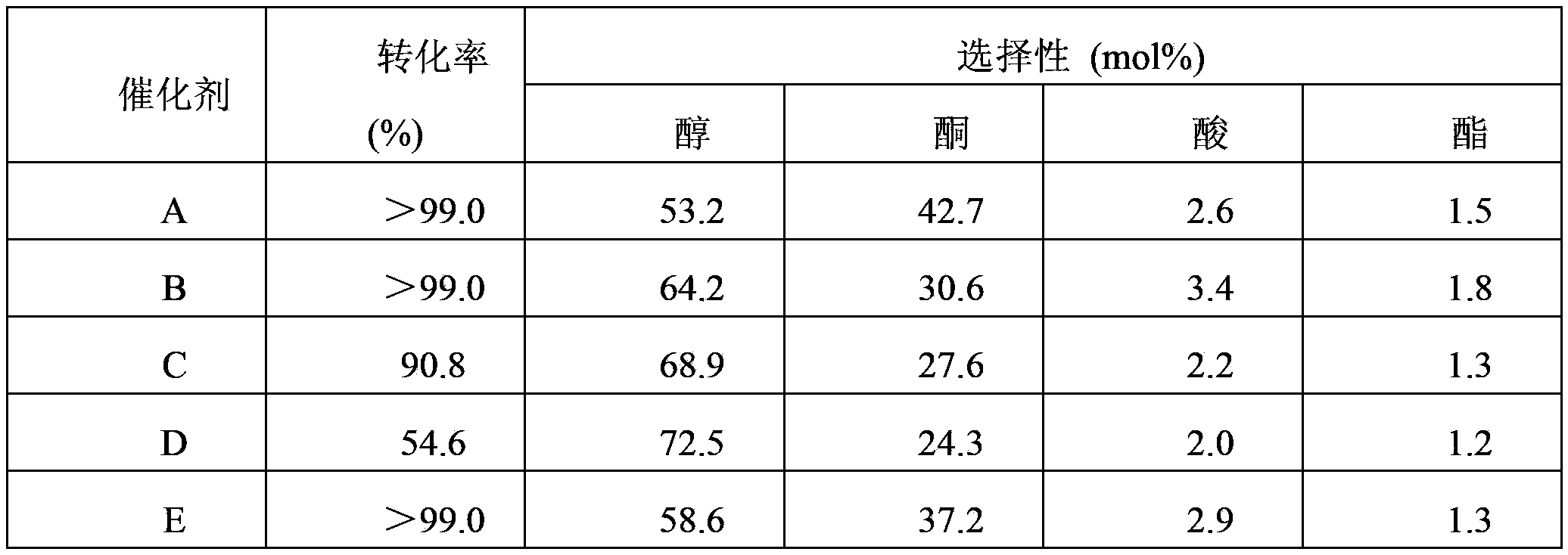

Preparation method and application of metal organic framework material loaded with Schiff base complex

ActiveCN107056649AHigh catalytic performance and very stableWon't be lostOxygen-containing compound preparationOrganic compound preparationCyclohexanoneHydrogen peroxide breakdown

The invention discloses a preparation method and an application of a metal organic framework material loaded with a Schiff base complex. Salen is formed by introducing salicylic aldehyde onto an amino functionalization metal organic framework material, then, Salen and transition metal ions form a complex, the metal organic framework material loaded with the Schiff base complex is prepared, and the material is applied to a cyclohexyl hydroperoxide decomposition reaction. The prepared catalyst is high in catalytic performance, the catalytic activity of the catalyst is basically not reduced after being recycled repeatedly, the catalyst is stable in performance and is applied to catalysis of the cyclohexyl hydroperoxide decomposition reaction, the decomposition conversion rate can reach 97%, the total selectivity of alcohol ketone can reach 99.8%, the good decomposition effect can be obtained without alkaline liquor, the environmental problem caused by the waste liquor is effectively avoided, the environmental pollution is significantly reduced, and meanwhile, the proportion of cyclohexanol to cyclohexanone is significantly increased.

Owner:XIANGTAN UNIV

Preparation method of metal organic framework material and application of metal organic framework material in cyclohexyl hydroperoxide decomposition reaction

ActiveCN105712867AEasy to makeShort synthesis cycleOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSodium acetateAlkali free

The invention discloses a preparation method of a metal organic framework material and application of the metal organic framework material in a cyclohexyl hydroperoxide decomposition reaction. Transition metal salt and terephthalic acid or a derivative thereof are subjected to a hydrothermal synthesis reaction in a sodium acetate solution to obtain the metal organic framework material, then the metal organic framework material serving as a catalyst is added into industrial cyclohexane uncatalysed oxidation liquid, the temperature is controlled to be 50-150 DEG C, the time is controlled to be 0.1-5 h, cyclohexyl hydroperoxide decomposition is carried out to obtain hexamethylene and cyclohexanone, the conversion rate of cyclohexyl hydroperoxide is larger than 95%, and the selectivity of alcohol ketone reaches up to 100%; the activity of the repeatedly-recycled catalyst is kept unchanged basically. Compared with other catalysts containing metal active components, the catalyst is high in catalytic efficiency, recyclable and stable in reusability; when the catalyst is applied to the cyclohexyl hydroperoxide decomposition reaction, the decomposition process is conducted under the alkali-free condition, the catalytic efficiency is very high, and pollution caused by waste alkali liquor to the environment is avoided.

Owner:XIANGTAN UNIV

High temperature stabilization of UV systems

ActiveUS20050043450A1Improve high temperature stabilityReduced stabilityImpression capsInksGreek letter betaOligomer

A composition comprising one or more radiation curable monomers and / or oligomers and one or heat stable composition comprising at least one radiation-curable alpha, beta-ethylenically unsaturated compound, at least one phenolic stabilizer, and at least one non-phenolic stabilizer selected from the group consisting of hydroperoxide decomposers and free radical traps. The compositions and methods are useful in applications such as radiation curable ink jet systems where viscosity is reduced by heating.

Owner:ARKEMA FRANCE SA

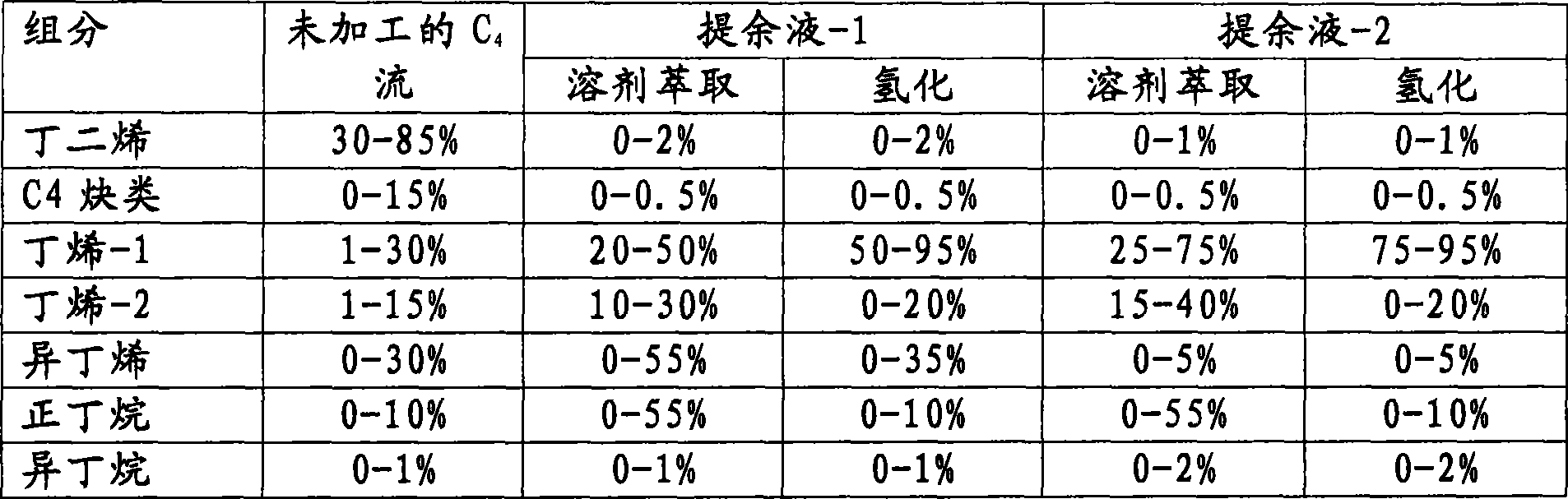

Process for producing phenol and methyl ethyl ketone

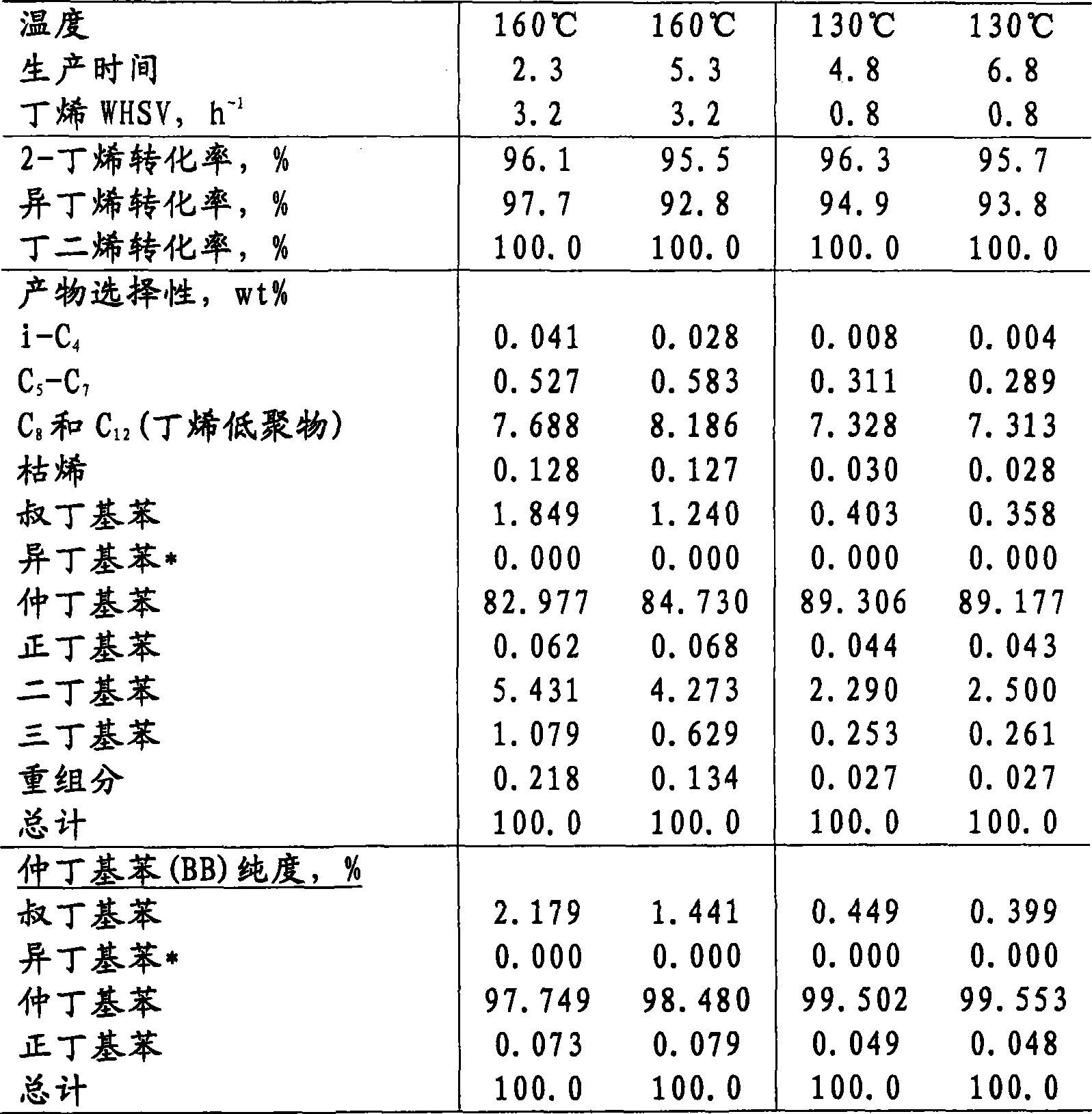

A process for producing phenol and methyl ethyl ketone comprises contacting benzene with a C4 alkylating agent under aklylation conditions with catalyst comprising zeolite beta or a molecular sieve having an X-ray diffraction pattern including d-spacing maxima at 12.4+-0.25, 6.9+-0.15, 3.57+-0.07 and 3.42+-0.07 Angstrom to produce an alkylation effluent comprising sec-butylbenzene. The sec-butylbenzene is then oxidized to produce a hydroperoxide and the hydroperoxide is decomposed to produce phenol and methyl ethyl ketone.

Owner:EXXONMOBIL CHEM PAT INC

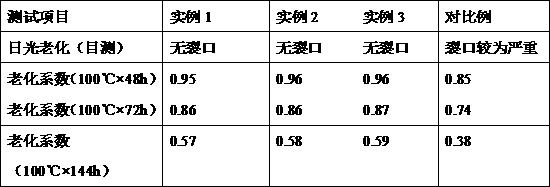

Method for preparing cyclohexanone and cyclohexanol by decomposition of cyclohexane oxidation liquid

ActiveCN106946678AReduce consumptionPreparation by oxidation reactionsOrganic compound preparationCyclohexanoneHydrogen peroxide breakdown

The invention discloses a method for preparing cyclohexanone and cyclohexanol by decomposition of a cyclohexane oxidation liquid. The method comprises the following steps: a cyclohexane oxidation liquid is subjected to a homogeneous decomposition reaction in the presence of an oil-soluble catalyst isooctyl chromate at the reaction temperature of 100-160 DEG C at the pressure of 0.3-0.8 Mpa for 1.0-5 h; after the decomposition reaction, the decomposition liquor is cooled and then washed with alkali lye, followed by standing and alkali separation; then, an organic phase and an inorganic phase are obtained; and the organic phase is separated and refined so as to obtain cyclohexanone and cyclohexanol. By using the oil-soluble catalyst isooctyl chromate, the traditional thinking of using aqueous alkali for heterogeneous decomposition is broken through. By changing the catalytic system and reaction condition, cyclohexyl hydroperoxide decomposition rate reaches 99.8% and above, yield of cyclohexanone and cyclohexanol obtained after the decomposition is 98% and above, and ketone-to-alcohol ratio is 1.3:1 and above and far higher than the ratio of 1:1 in traditional basic decomposition. As the cyclohexyl hydroperoxide decomposition reaction needn't be carried out under the alkaline condition, consumption of alkali is also greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

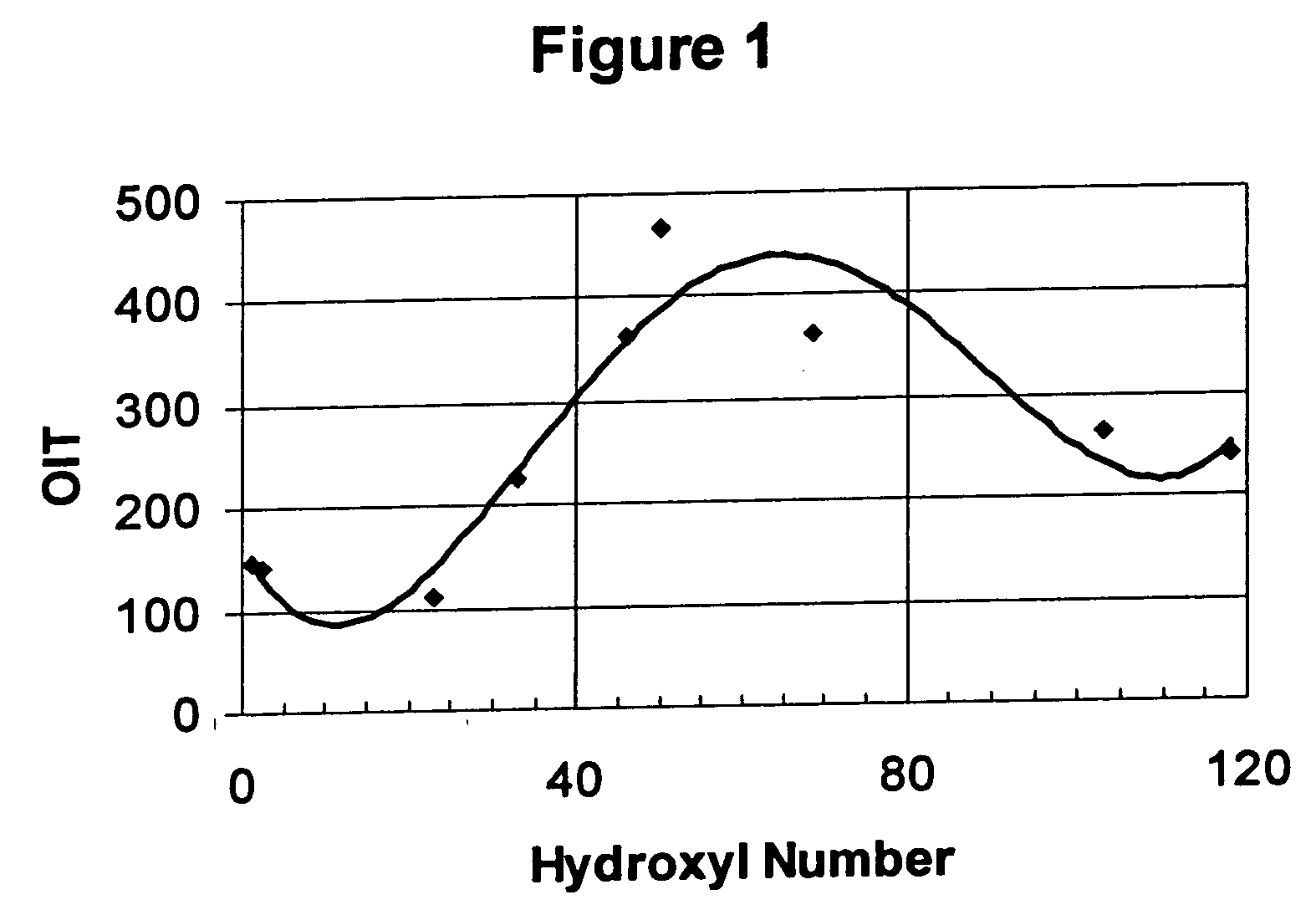

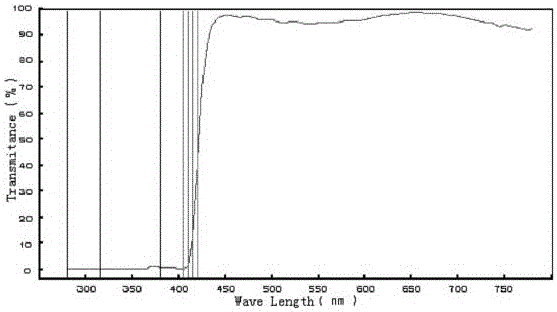

Light adjusting film and preparation method thereof

InactiveCN105759487AStop or delay the photoaging processExtend your lifeNon-macromolecular adhesive additivesNon-linear opticsChemical reactionSinglet oxygen

The invention provides a light adjusting film and a preparation method thereof.The light adjusting film comprises a first conductive layer, an adhesion layer, a polymer dispersing liquid crystal layer and a second conductive layer, wherein the adhesion layer is arranged on the surface of the first conductive layer, and light stabilizer is dispersed in the adhesion layer; the polymer dispersing liquid crystal layer is arranged on the surface, away from the first conductive layer, of the adhesion layer, and the second conductive layer is arranged on the surface, away from the adhesion layer, of the polymer dispersing liquid crystal layer.The light stabilizer is added to the adhesion layer of the light adjusting film, the light stabilizer has the functions of shielding or absorbing energy of ultrasonic rays, eliminating singlet oxygen, decomposing hydroperoxide into innactivated substances and the like, photochemical reaction can be avoided or relieved when the light adjusting film is under light radiation, the light ageing process of the light adjusting film is prevented or delayed, and the service life of the light adjusting film is prolonged.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Preparation method of bimetal organic framework material and application of bimetal organic framework material in decomposition reaction of cyclohexyl hydroperoxide

ActiveCN107082892AEasy to makeStable in natureOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen peroxide breakdownAlkali free

The invention discloses a preparation method of a bimetal organic framework material and an application of the bimetal organic framework material in decomposition reaction of cyclohexyl hydroperoxide. The method comprises the steps of adopting a metal-organic framework material MIL-101 (Cr) as a carrier, introducing a second metal ion to obtain the bimetal organic framework material, and applying the material to a cyclohexyl hydroperoxide decomposition system as a catalyst under an alkali-free condition. The obtained catalyst is simple in preparation process, the catalyst is stable in property and not easy to go bad, the catalytic performance is high and stable, and the catalytic activity is essentially constant through multiple times of recycling. The catalyst is used for catalyzing the decomposition reaction of the cyclohexyl hydroperoxide; the conversion rate of the cyclohexyl hydroperoxide can reach over 96%, the overall selectivity of alcohol ketone can reach over 100%, and meanwhile, the ratio of cyclohexanol to cyclohexanone in the product is significantly increased.

Owner:XIANGTAN UNIV

High temperature stabilization of UV systems

ActiveUS7312254B2Improve high temperature stabilityReduced stabilityImpression capsInksOligomerViscosity

A composition comprising one or more radiation curable monomers and / or oligomers and one or heat stable composition comprising at least one radiation-curable alpha, beta-ethylenically unsaturated compound, at least one phenolic stabilizer, and at least one non-phenolic stabilizer selected from the group consisting of hydroperoxide decomposers and free radical traps. The compositions and methods are useful in applications such as radiation curable ink jet systems where viscosity is reduced by heating.

Owner:ARKEMA FRANCE SA

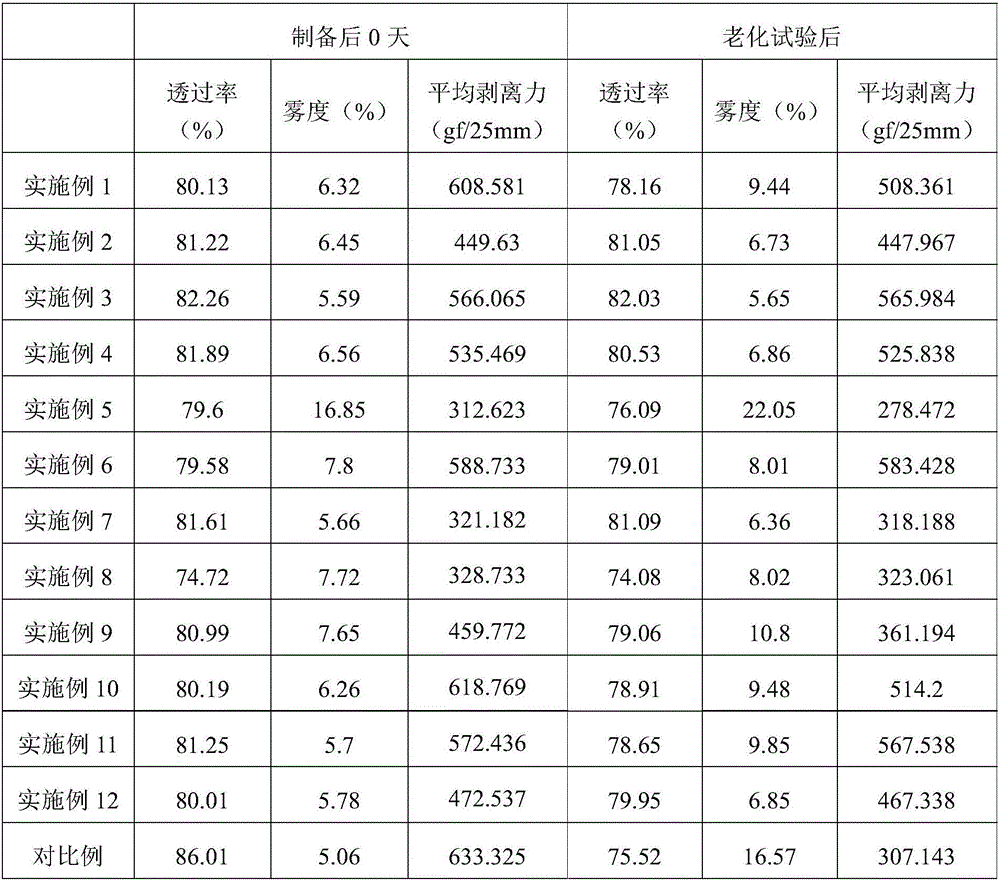

Antioxidants and antioxidant boosters capable of producing hydroperoxyl radicals

InactiveUS20050145831A1Good curative effectImprove Oxidation StabilityOrganic chemistryLiquid carbonaceous fuelsLeaving groupPolyol

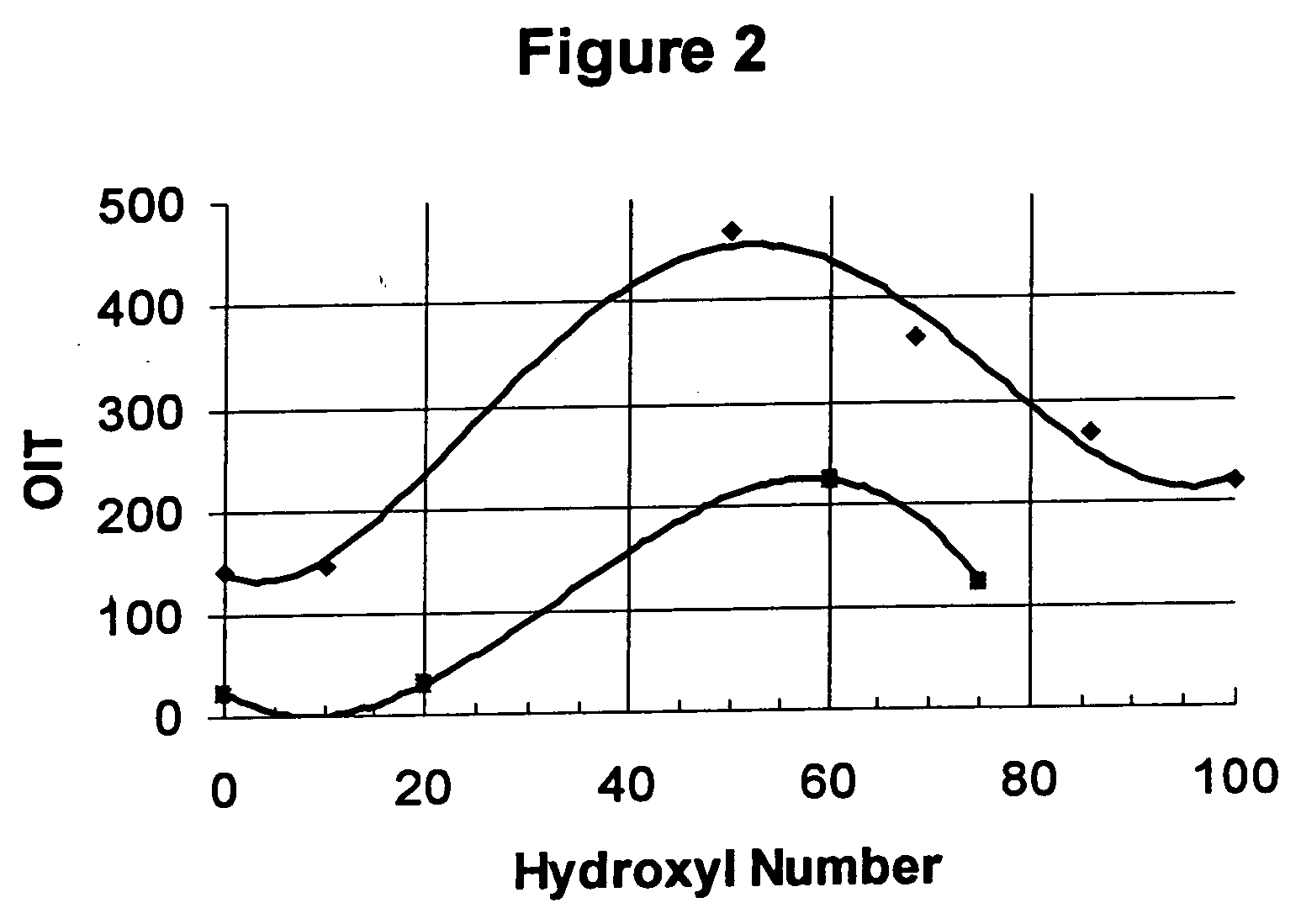

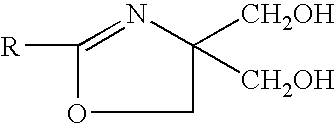

An antioxidant which comprises a primary aliphatic hydroxyl group linked to an organic backbone such that upon oxidation a hydroperoxyl moiety capable of boosting the efficacy of free radical scavengers and hydroperoxide decomposer type antioxidants is generated in situ. The antioxidant is preferably a high hydroxyl polyol ester having a hydroxyl number ranging from about 30 to about 180 which ester is the reaction product of polyol and an acid which is at least fifty percent branched carboxylic acid, wherein the unconverted hydroxyl group is reacted with a facile leaving group, thereby producing free —CH2OH groups upon hydrolysis or oxidation.

Owner:EXXON RES & ENG CO

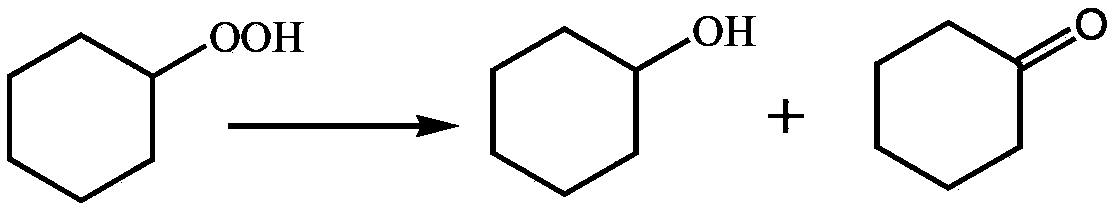

Decomposition method of cyclohexyl hydrogen peroxide

InactiveCN1443742ANo generationMaterial no special requirementsOxygen-containing compound preparationOrganic compound preparationReaction temperatureHydroperoxide decomposition

The decomposition method of cyclodexyl hydrogen peroxide is characterized by that under the heterogeneous condition intermittently or continuously adding solid alklouli catalyst whose PKa=10-47 in decomposition reactor, controlling the weight ratio of the solid alkali catalyst and cyclodexane oxide product in 1:20-1:300, reaction temp. is 10 deg.C-170 deg.C, reaction time is 5-200 min. and can decompose the cyclodexyl hydrogen peroxide into cyclodexanone and cyclodexanol.

Owner:BALING PETRO CHEM CO LTD SINOPEC

Method for preparation of cyclohexanone and cyclohexanol by decomposition of cyclohexyl hydroperoxide

InactiveCN104177222AOxygen-containing compound preparationOrganic compound preparationCyclohexanoneKetone

The invention relates to a method for preparation of cyclohexanone and cyclohexanol by decomposition of cyclohexyl hydroperoxide in a cyclohexane oxidation liquid, and the method is characterized in that, a sodium hydroxide solution and a cobalt acetate solution are added in different feeding ports of a tubular reactor, cobalt ion concentration of the inorganic phase is 1.5-10ppm, the volume ratio of organic phase to inorganic phase in the decomposition reactor is 5.0-7.0: 1, and the basicity is 0.7-3.0mol / kg. The decomposition reactor temperature is controlled at 85-120 DEG C, the cyclohexyl hydroperoxide decomposition rate is greater than or equal to 99.5%, the cyclohexanone and cyclohexanol yield is greater than or equal to 90%, and the ketone-alcohol ratio is more than 1.0.

Owner:CHINA PETROLEUM & CHEM CORP +1

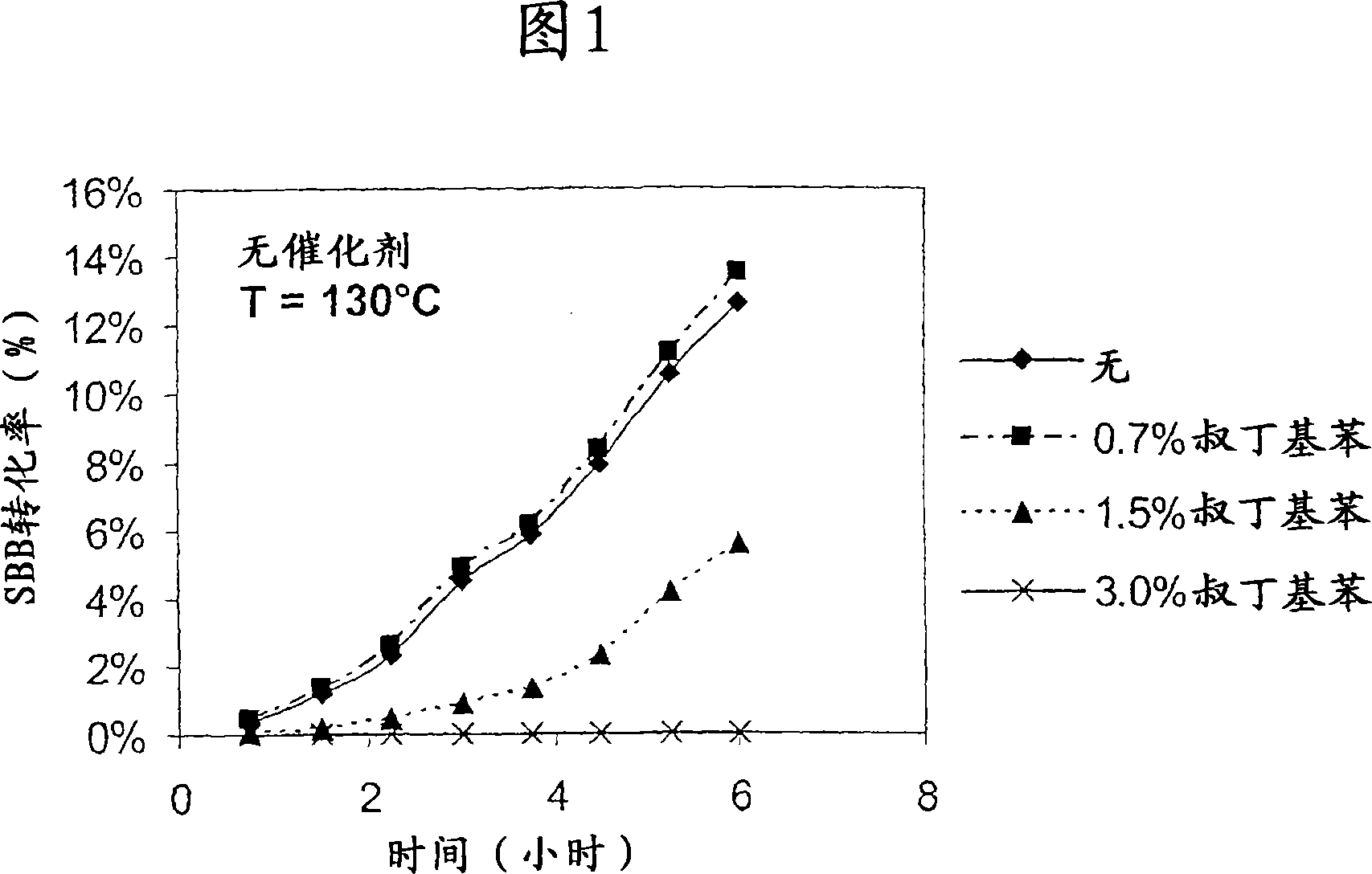

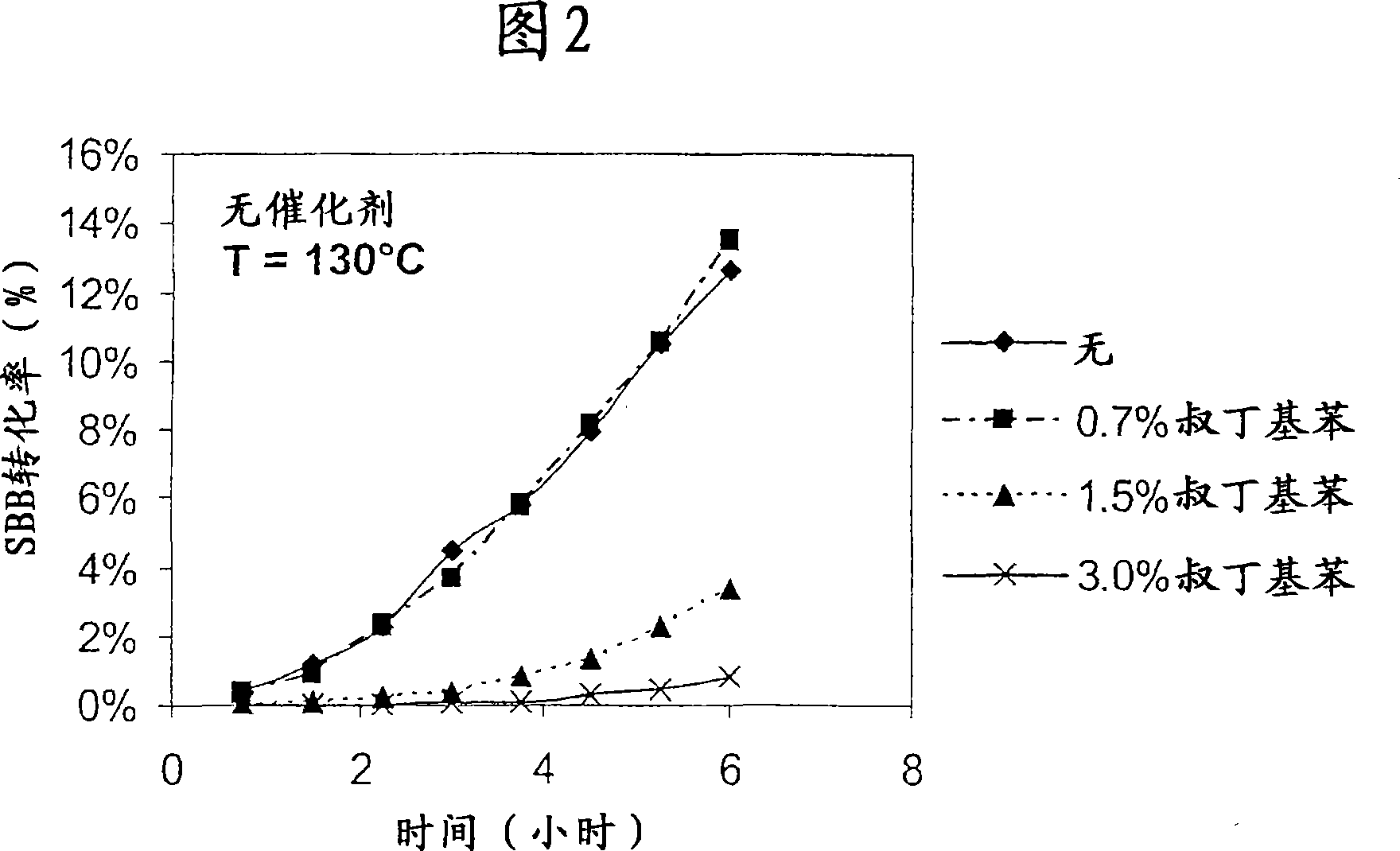

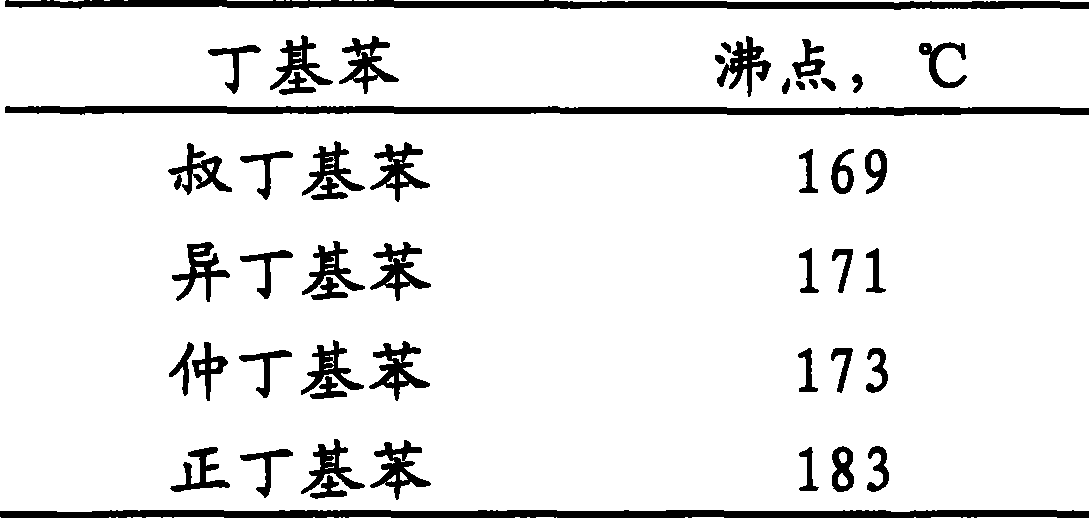

Process for producing sec-butylbenzene

A process for producing sec-butylbenzene comprises contacting a feed comprising benzene and a C4 alkylating agent under alkylation conditions comprising a temperature of about 110 DEG C to about 150 DEG C with a catalyst comprising at least one molecular sieve having an X-ray diffraction pattern including d-spacing maxima at 12.4+-0.25, 6.9+-0.15, 3.57+-0.07 and 3.42+-0.07 Angstrom. The sec-butylbenzene can be then oxidized to produce a hydroperoxide and the hydroperoxide decomposed to produce phenol and methyl ethyl ketone.

Owner:EXXONMOBIL CHEM PAT INC

Hydroperoxide decomposition process

An improved process for decomposing alkyl or aromatic hydroperoxides to form a decomposition reaction mixture containing the corresponding alcohol and ketone is disclosed. The improvement relates to adding water to a starting hydroperoxide containing mixture, then removing the bulk of said water by a means such that water-soluble impurities are removed along with the water, then decomposing the hydroperoxide by contacting the hydroperoxide with a catalytic amount of a heterogeneous catalyst of Au, Ag, Cu or a sol-gel compound containing particular combinations of Cr, Co, Zr, Ta, Si, Mg, Nb, Al and Ti wherein certain of those metals have been combined with an oxide, such as an inorganic matrix of hydroxides or oxides, or combinations thereof. The catalysts may also optionally be supported on a suitable support member.

Owner:EI DU PONT DE NEMOURS & CO

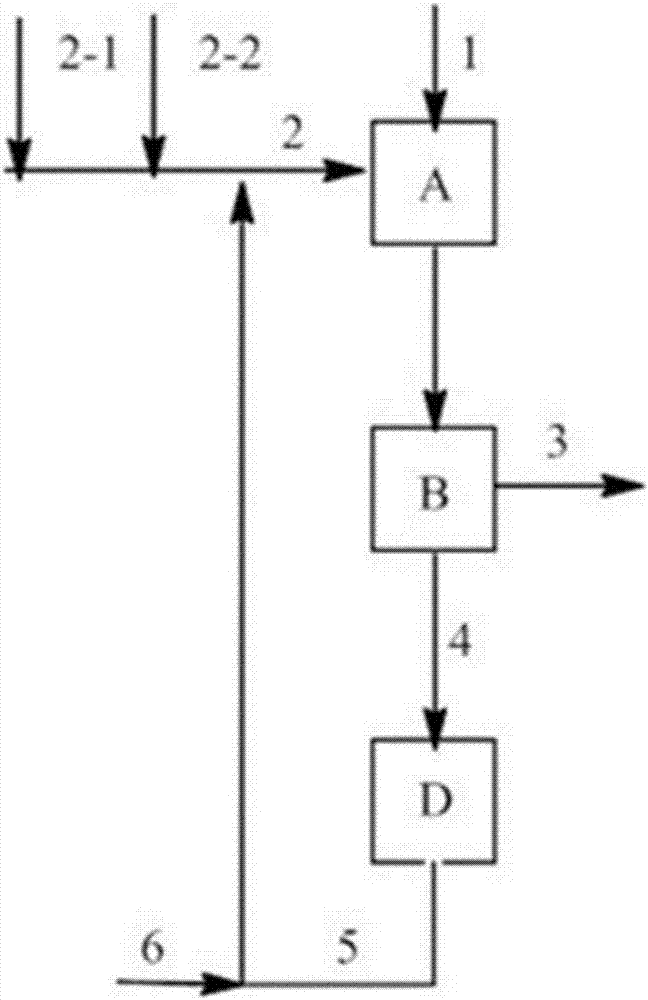

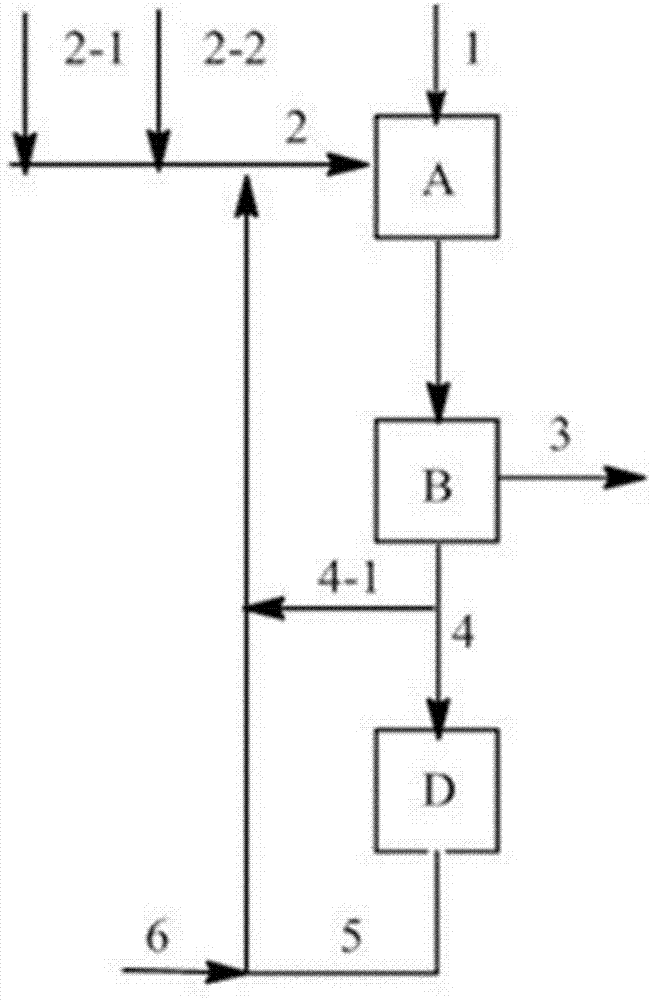

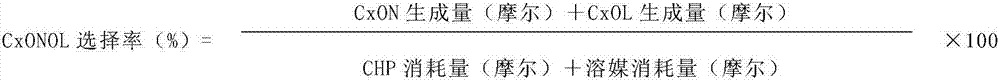

Method for producing ketone and/or alcohol, and system thereof

InactiveCN107108424AEfficient recyclingCheap to prepareOrganic compound preparationOrganic chemistry methodsCarbon numberAlkaline earth metal

In order to rapidly and highly selectively decompose a hydroperoxide of a hydrocarbon compound, and to produce a target ketone and / or alcohol, this method for producing a ketone and / or alcohol involves decomposing a hydroperoxide in a reaction solution obtained by oxidizing a hydrocarbon compound using molecular oxygen, and producing a ketone and / or alcohol having the same carbon number as the hydrocarbon compound, wherein: a hydroperoxide decomposition step for bringing the reaction solution into contact with an aqueous solution containing a carbonate of an alkaline earth metal or a carbonate of an alkali metal and a transition metal compound, and decomposing the hydroperoxide into a ketone and / or alcohol; a separation step for separating the resulting liquid into an oil phase including the ketone and / or alcohol, and an aqueous phase containing the carbonate of an alkaline earth metal or the carbonate of an alkali metal and the transition metal compound; a recovery step for burning the aqueous phase and recovering the carbonate of an alkali metal or the carbonate of an alkaline earth metal and the transition metal compound; and a recycling step for dissolving at least the carbonate of an alkali metal or the carbonate of an alkaline earth metal among the recovered substances obtained in the recovery step, in water, and recycling to the hydroperoxide decomposition step.

Owner:UBE IND LTD

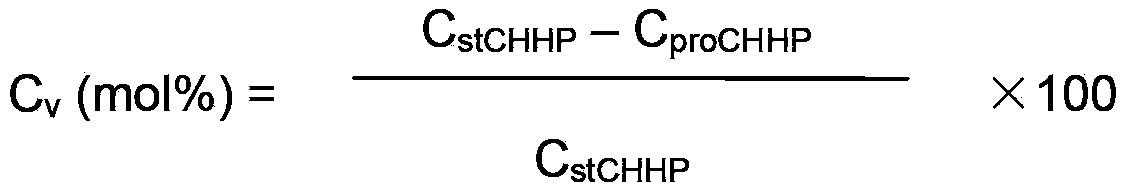

Method of high yield cyclohexyl hydroperoxide decomposition

InactiveCN1659122AHigh yieldReduce adverse effectsOxygen-containing compound preparationOrganic compound preparationAqueous solutionHydroperoxide decomposition

Disclosed is a process for cyclohexyl hydroperoxide (CHHP) decomposition using in aqueous alkaline solution in presence of cobalt catalyst.

Owner:INVISTA TECHNOLOG IES S A R L

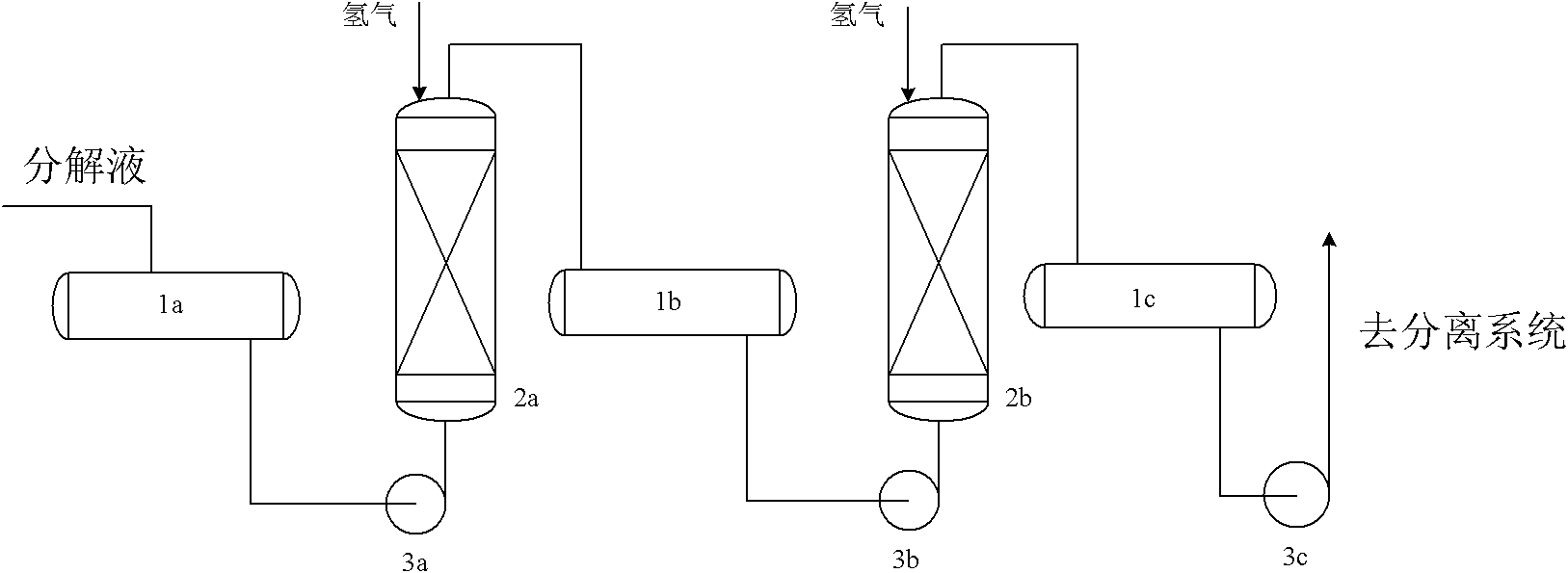

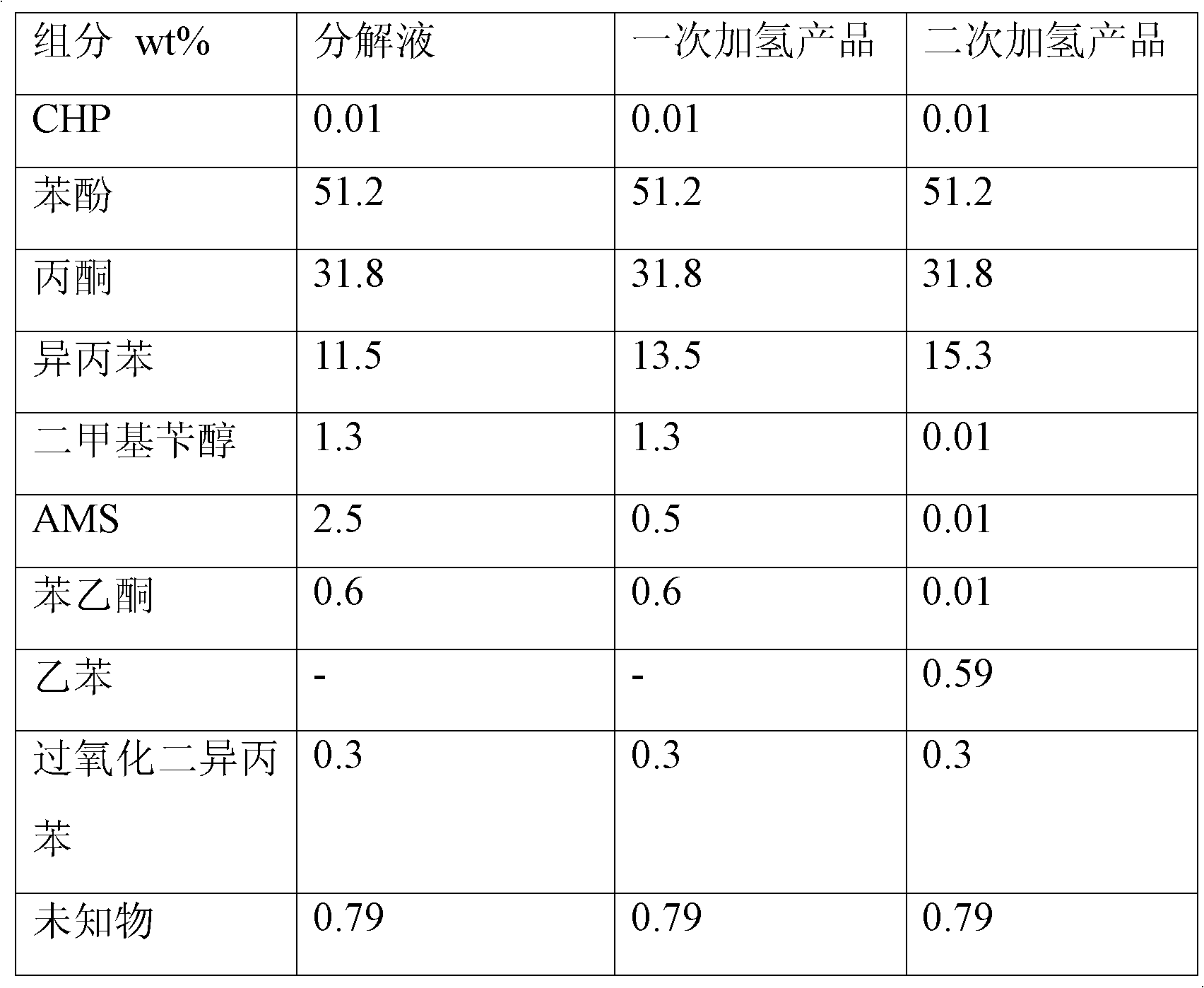

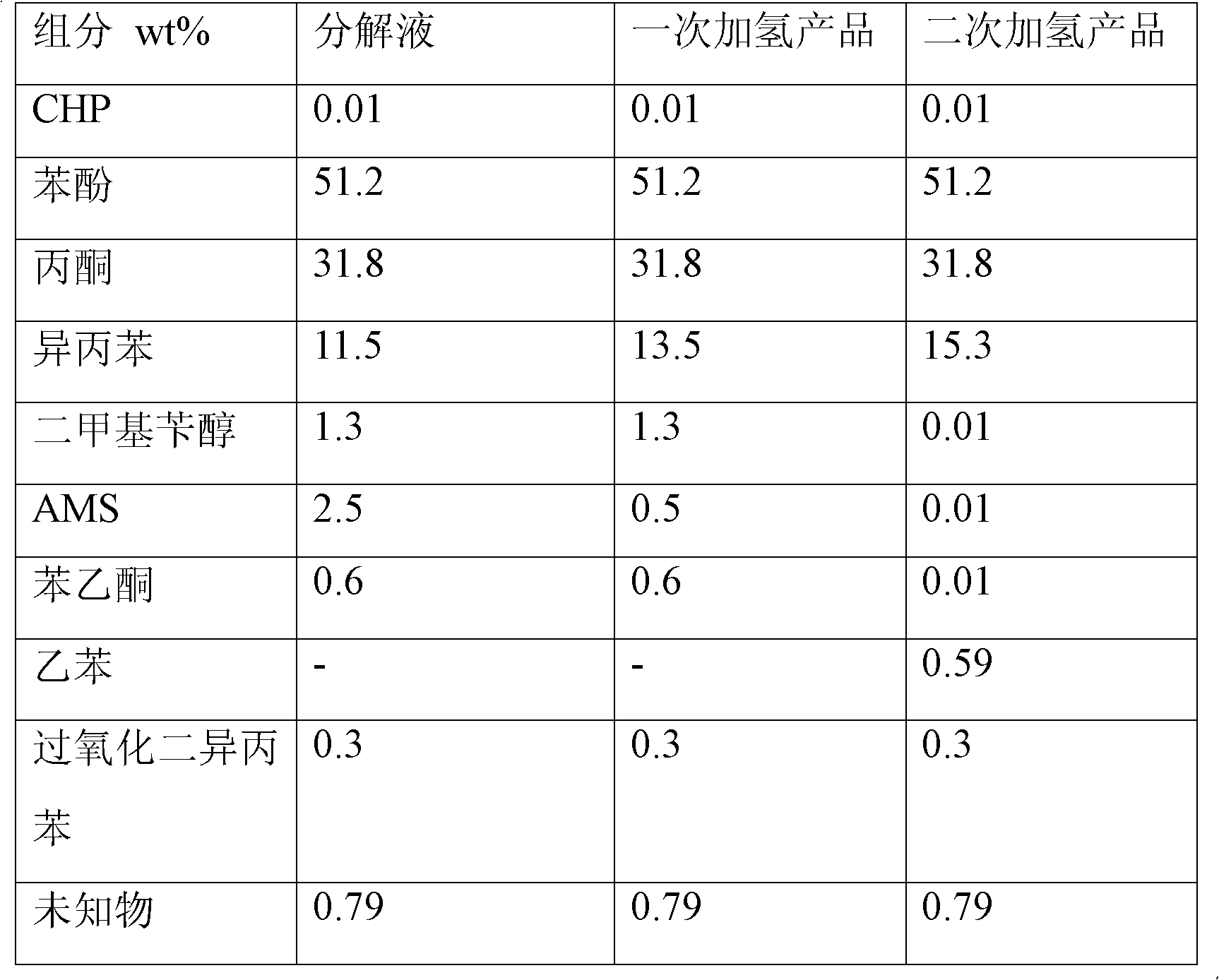

Method for treating products of alkylbenzene hydroperoxide decomposition reaction

InactiveCN102146021AReduce loadOrganic compound preparationCarbonyl compound separation/purificationCeriumAcetophenone

The invention discloses a method for treating products of the alkylbenzene hydroperoxide decomposition reaction, belongings to the technical field of alkylbenzene hydroperoxide decomposition. The method comprises the following steps: adding decomposition liquid firstly to a first hydrogenation reactor with nickel-cerium-loaded hydrogenation catalyst, hydrogenating alpha-methyl styrene or alpha-ethyl styrene at 60-70 DEG C and constant atmospheric pressure to ensure that the weight content is reduced to the range from 0.4% to 0.5%; then enabling the obtained material to enter a second reactor,increasing temperature to 200 DEG C and increasing pressure to 0.5-1.0 MPa, continuously converting the rest of alpha-methyl styrene or alpha-ethyl styrene into isopropylbenzene or sec-butylbenzene and converting dimethyl benzyl alcohol or methyl ethyl benzyl alcohol, and acetyl benzene into isopropylbenzene or sec-butylbenzene, and ethylbenzene synchronously, wherein the catalyst is a palladium-loaded hydrogenation catalyst with higher activity. By adopting the treatment method, three phenol / acetone technological by-products can be converted in one process step and the load of the subsequentseparation process can be reduced.

Owner:BEIJING UNIV OF CHEM TECH

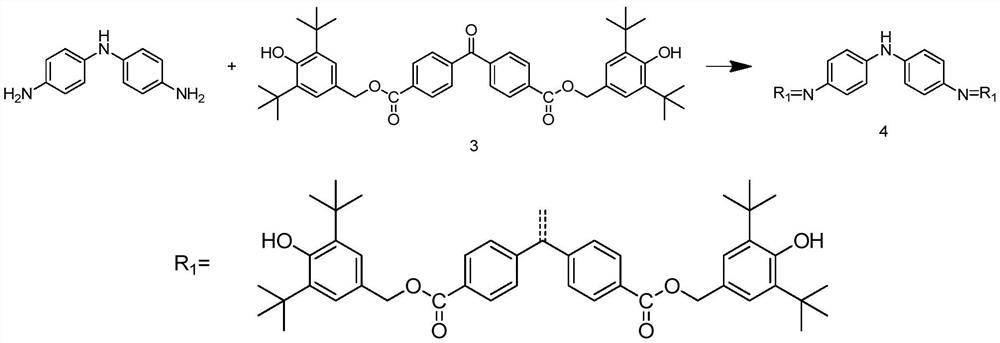

Blue-light-resistant resin and preparation method thereof

InactiveCN106674438AEvenly distributedPrevent or delay agingOptical elementsOrganic solventUltraviolet lights

The invention provides blue-light-resistant resin. The blue-light-resistant resin comprises the following raw materials: mixed resin, an organic solvent, a light stabilizer and a blue light absorber, wherein the mass ratio of the organic solvent to the mixed resin is 1 to (4-5); the mass of the light stabilizer is 1000-5000ppm of that of the mixed resin; the mass of the blue light absorber is 3000-5000ppm or 15000-20000ppm of that of the mixed resin. Through the blue-light-resistant resin, the distribution of the blue light absorber is more uniform; the refractive index is adjusted by adjusting the mass ratio of the mixed resin and the organic solvent; the resin prepared by adding the light stabilizer is capable of shielding or absorbing energy of ultraviolet light; the resin also has the functions of quenching singlet oxygen and decomposing hydroperoxide into inactive substances and is also capable of eliminating or delaying possibility of photochemical reaction and preventing or delaying light aging process; the service life of the blue-light-resistant resin is greatly prolonged.

Owner:JIANGSU CONANT OPTICS

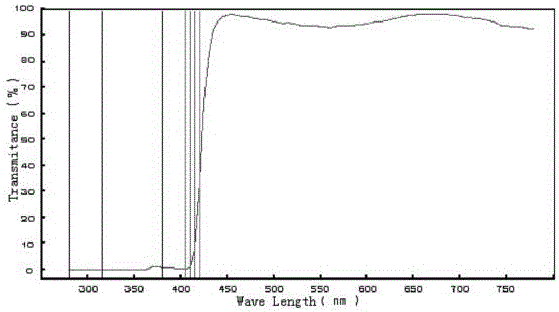

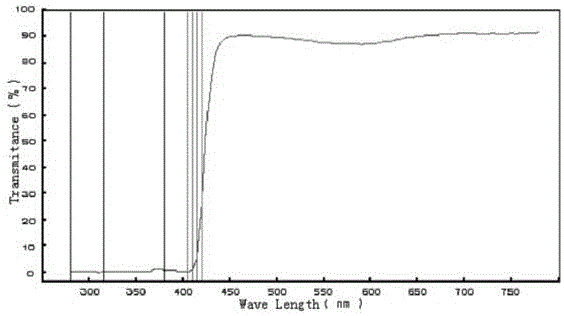

Functionalized mid-pore silica material and preparation and application thereof

InactiveCN104056649AHigh activityReduce dosageOxygen-containing compound preparationMolecular sieve catalystsHydrogen peroxide breakdownRoom temperature

The invention discloses a functionalized hexagonal mid-pore silica (HMS) material used in decomposition reaction of cyclohexyl hydroperoxide, the surface of functionalized hexagonal mid-pore silica material is superficial immobilized with one or a plurality of metal elements with cyclohexyl hydroperoxide decomposition ability. The material can be synthesized at room temperature by the sol-gel method. At a relatively low temperature, the material can be used as a catalyst for the catalytic liquid phase decomposition of the cyclohexyl hydroperoxide, and the material has high catalytic activity. Compared with catalysts in the prior art, the catalyst used in the invention has the advantages of being high in efficiency, cheap, convenient to use and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

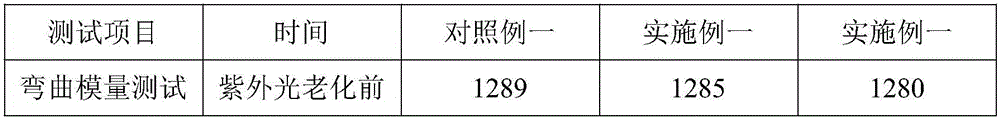

Anti-ultraviolet honeycomb composite board and manufacturing method thereof

ActiveCN106626549AStrong UV Absorbing PropertiesReduce negative impactSynthetic resin layered productsLaminationGlass fiberScavenger

The invention discloses an anti-ultraviolet honeycomb composite board. The honeycomb composite board comprises a honeycomb board core material, a honeycomb board panel and a honeycomb board panel basebottom film, wherein the honeycomb board panel is compounded together with the honeycomb board core material through the honeycomb board panel base bottom film; the honeycomb board panel is made of the following components in parts by weight: 40 to 100 parts of thermoplastic material, 0.5 to 1.5 parts of coupling agent, 0.5 to 2 parts of dispersing agent, 0.1 to 5 parts of ultraviolet light absorber and 0.1 to 5 parts of radical scavenger; the honeycomb board panel base bottom film is made of the following components in parts by weight: 90 to 100 parts of glass fiber cloth material, 0.5 to 1.5 parts of coupling agent, 0.5 to 2 parts of dispersing agent and 0.1 to 5 parts of quenching agent; the honeycomb board core material is made of the following components in parts by weight: 40 to 100 parts of thermoplastic material, 0.5 to 1.5 parts of coupling agent, 0.5 to 2 parts of dispersing agent, 0.1 to 3 parts of hydroperoxide decomposer and 0.1 to 3 parts of radical scavenger. In the honeycomb composite board, different light stabilizers are added, so that the honeycomb composite board has an ultraviolet absorption capability, the negative effect of ultraviolet radiation on the honeycomb composite board is lowered, and the service life of the honeycomb composite board is prolonged.

Owner:GUANGZHOU TOPU COMPOSITE MATERIALS

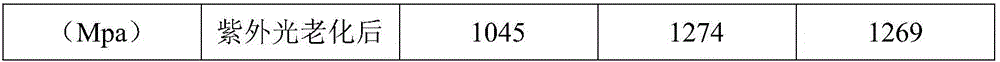

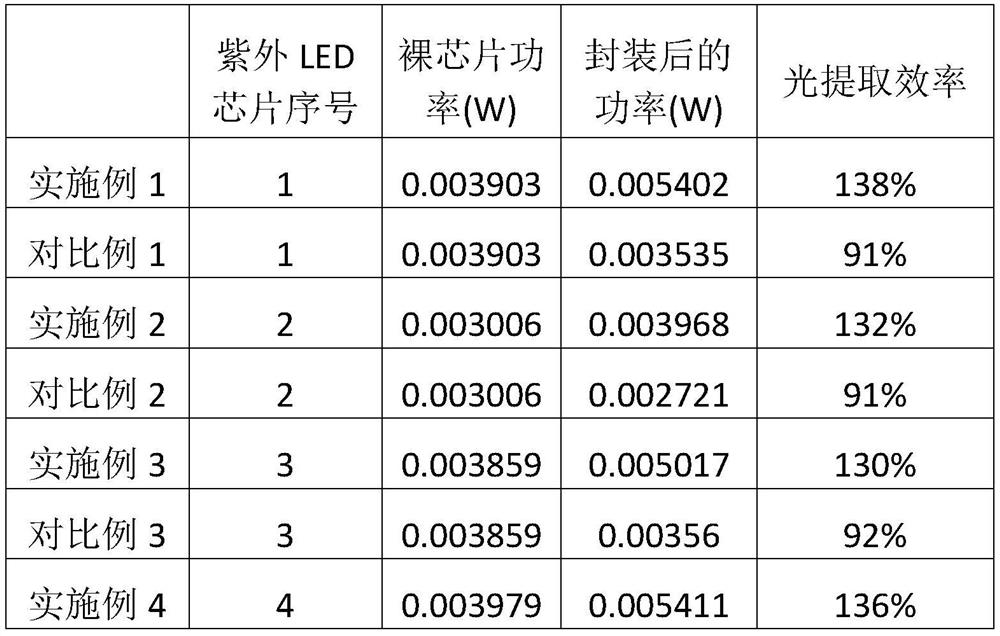

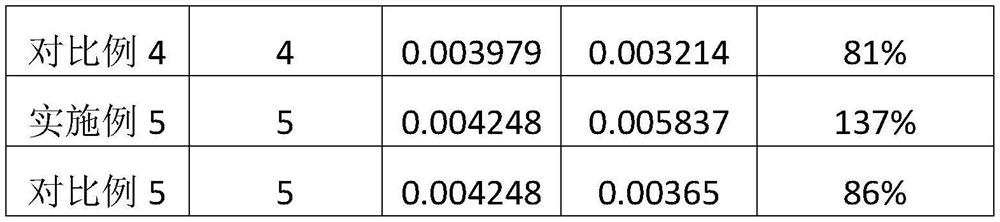

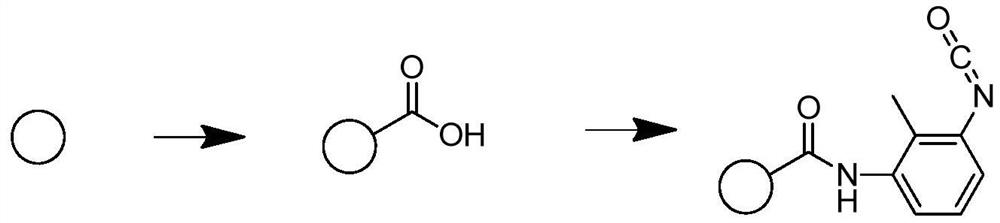

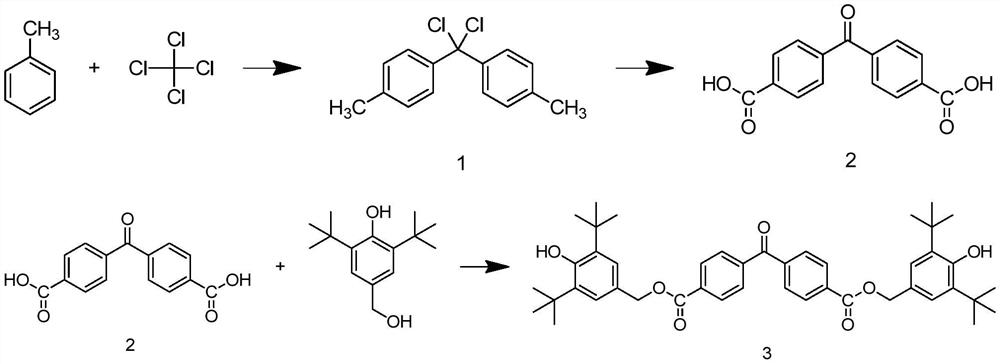

Ultraviolet LED packaging adhesive with high light extraction efficiency and light aging resistance and packaging structure

The invention provides an ultraviolet LED packaging adhesive with high light extraction efficiency and light aging resistance. The adhesive comprises the following components in percentage by mass: colloid containing Si-O, C-F and Si-F bonds, a quencher accounting for 0.1-10% of the colloid, a hydroperoxide decomposer accounting for 0.1-10% of the colloid, a free radical scavenger accounting for 0.1-15% of the colloid, a hindered amine light stabilizer accounting for 0.1-15% of the colloid, a coupling agent accounting for 0.5-5% of the mass of the colloid, and a dispersing agent accounting for1-5% of the mass of the colloid. The invention further provides a packaging structure. According to the packaging adhesive and the packaging structure, the degradation and aging time of the polymer can be prolonged, the long-term stable light aging resistance effect is achieved, the total reflection light loss generated in the ultraviolet refraction process is effectively reduced, and the light extraction efficiency of the packaging material is improved.

Owner:TIANJIN ZHONGHUAN ELECTRONICS LIGHTING TECH

Processing technology of low-energy-consumption environment-friendly carbon black

ActiveCN113897078AReduce energy consumptionGuaranteed to be greenPigmenting treatmentOrganic chemistryVulcanizationPolyvinyl alcohol

The invention discloses a processing technology of low-energy-consumption environment-friendly carbon black. Pre-treated carbon black and graphene are compounded by taking polyvinyl alcohol 600 as a binder to prepare environment-friendly carbon black, in this way, other toxic binders are avoided, greenness and environmental protection of the carbon black preparation technology are ensured, and meanwhile, no high-power equipment is used for treatment, so that the energy consumption of the carbon black preparation is reduced, the modified carbon black and the reinforcing agent are prepared during the preparation process, the reinforcing agent molecule contains a large amount of hindered amine and hindered phenol structure, the generated free radical or hydroperoxide decomposition can be promoted, the chain reaction can be prevented and the free radical reaction can be eliminated when the reinforcing agent is blended with the rubber, free radicals can generate stable substances to achieve an anti-aging effect, and meanwhile, a mercaptobenzothiazole structure on a molecule can participate in a vulcanization cross-linking reaction of rubber, so that the interaction between the environment-friendly carbon black and rubber quality inspection is enhanced, the reinforcing effect is improved, and the dispersity of filler is promoted.

Owner:新疆德欣新材料有限公司

A kind of anti-ultraviolet honeycomb composite board and preparation method thereof

ActiveCN106626549BStrong UV Absorbing PropertiesReduce negative impactSynthetic resin layered productsLaminationScavengerUltraviolet lights

The invention discloses an anti-ultraviolet honeycomb composite board. The honeycomb composite board comprises a honeycomb board core material, a honeycomb board panel and a honeycomb board panel basebottom film, wherein the honeycomb board panel is compounded together with the honeycomb board core material through the honeycomb board panel base bottom film; the honeycomb board panel is made of the following components in parts by weight: 40 to 100 parts of thermoplastic material, 0.5 to 1.5 parts of coupling agent, 0.5 to 2 parts of dispersing agent, 0.1 to 5 parts of ultraviolet light absorber and 0.1 to 5 parts of radical scavenger; the honeycomb board panel base bottom film is made of the following components in parts by weight: 90 to 100 parts of glass fiber cloth material, 0.5 to 1.5 parts of coupling agent, 0.5 to 2 parts of dispersing agent and 0.1 to 5 parts of quenching agent; the honeycomb board core material is made of the following components in parts by weight: 40 to 100 parts of thermoplastic material, 0.5 to 1.5 parts of coupling agent, 0.5 to 2 parts of dispersing agent, 0.1 to 3 parts of hydroperoxide decomposer and 0.1 to 3 parts of radical scavenger. In the honeycomb composite board, different light stabilizers are added, so that the honeycomb composite board has an ultraviolet absorption capability, the negative effect of ultraviolet radiation on the honeycomb composite board is lowered, and the service life of the honeycomb composite board is prolonged.

Owner:GUANGZHOU TOPU COMPOSITE MATERIALS

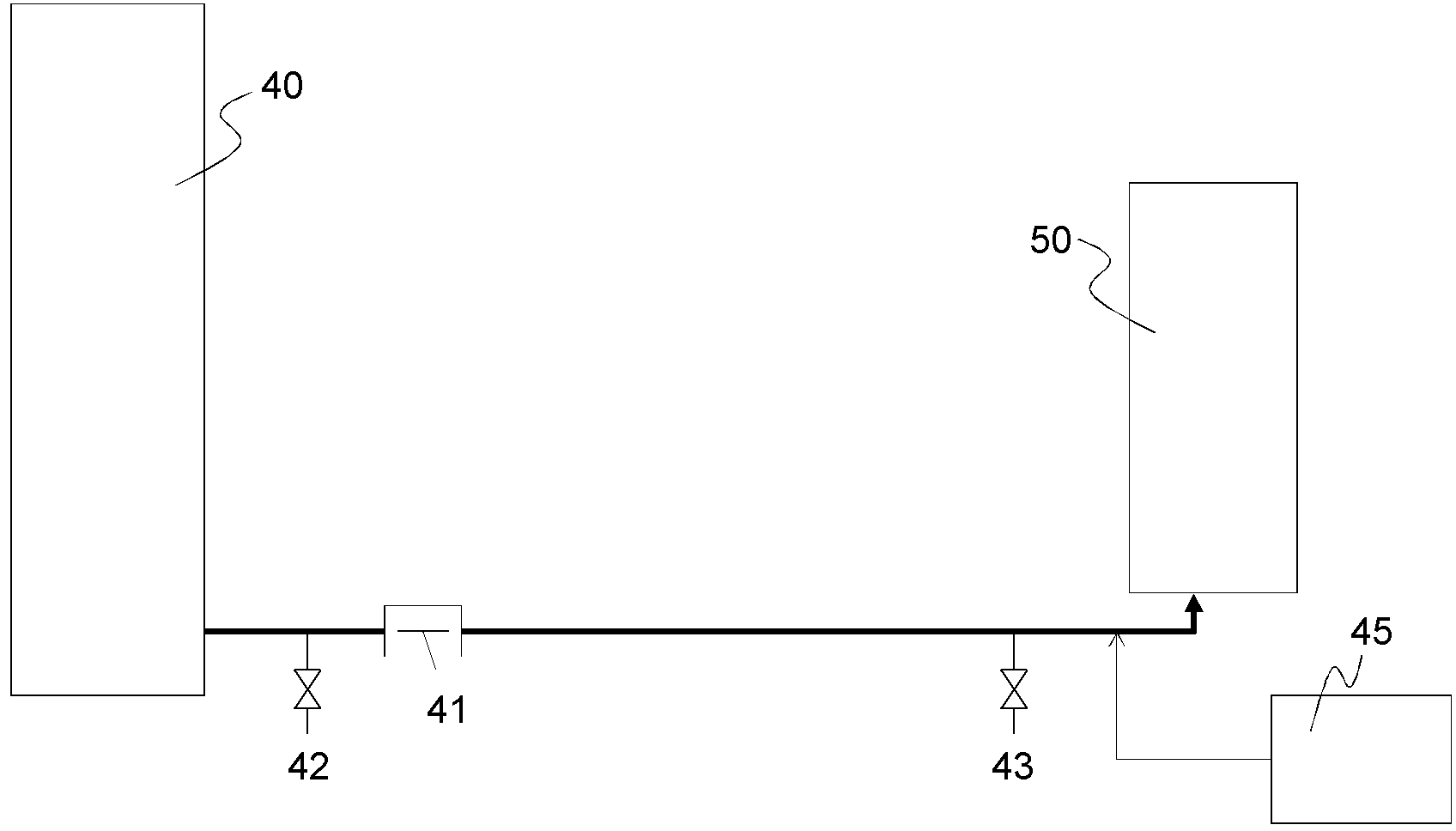

Oxidation catalyst for hydrocarbon compound, and method and apparatus for producing oxide of hydrocarbon compound using same

InactiveCN103140286AControl decompositionPreparation by oxidation reactionsOrganic compound preparationPhosphoric Acid EstersPtru catalyst

According to the first embodiment of the present invention, an oxide of a hydrocarbon compound can be produced with high yield and high productivity by oxidizing the hydrocarbon compound with molecular oxygen in the co-presence of an N-hydroxy compound, such as methyl ethyl ketone or N-hydroxysuccinimide, and a phosphate ester, such as dibutyl phosphate. According to another embodiment of the present invention, an oxide of a hydrocarbon compound can be produced with high yield by using an oxidation catalyst that comprises an oxime compound, such as methyl ethyl ketone. According to another embodiment of the present invention, an alcohol and / or a ketone can be produced with high yield by oxidizing the hydrocarbon compound at a temperature of 160 DEG C. or less, and by decomposing the resulting hydroperoxide, for example, in a unit having an inner surface formed by a material from which no transition metal ion is generated.

Owner:UBE IND LTD

Preparing method of anti-ageing rubber and plastic

The invention relates to the technical field of rubber and plastic preparation, and discloses a preparing method of anti-ageing rubber and plastic. The anti-ageing rubber and plastic is prepared from,by weight, 40-80 parts of natural rubber, 30-70 parts of butadiene styrene rubber, 5-10 parts of high styrene resin, 10-15 parts of dioctyl sebacate, 6-12 parts of phenolic resin, 3-5 parts of a vulcanization accelerator, 2-7 parts of an active agent, 0.1-0.5 part of an antioxidant and 5-10 parts of a light stabilizer. The antioxidant and the light stabilizer are added, the antioxidant can delayor restrain the oxidation process of the rubber and plastic material, prevent the ageing of the rubber and plastic material and prolong the service life of the rubber and plastic material, the light stabilizer can shield or absorb the energy of ultraviolet rays, quench singlet-state oxygen and decompose hydroperoxide into inert matter, and therefore high-molecular polymers under the irradiation oflight can eliminate or delay the photochemical reaction probability, prevent or delay the light ageing process and thus prolong the service life of the rubber and plastic product and effectively improve the anti-ageing performance of the rubber and plastic product.

Owner:亚罗斯建材(江苏)有限公司

Production process of T buckle

The invention discloses a production process of a T buckle. The T buckle is prepared from the following raw materials in parts by weight: 80 to 90 parts of polyformaldehyde, 10 to 20 parts of polyurethane, 0.3 to 0.7 part of an antioxidant 1010, 0.1 to 0.5 part of a phosphorous acid aid and 0.2 to 0.6 part of an anti-ultraviolet agent. According to the production process of the T buckle, the arranged antioxidant 1010 can react with free radicals generated by a polymer to interrupt the chain reaction of molecular chains, so that free formaldehyde is deactivated; hydroperoxide can be decomposedinto inactive products through the arranged phosphorous acid aid so as to inhibit the automatic catalytic action of the hydroperoxide, and the antioxidant 1010 and the phosphorous acid aid can generate a strong synergistic effect; the antioxidant is used together with an ultraviolet light absorber, so that active products formed by the antioxidant under illumination can be eliminated, the sulfideis prevented from being decomposed, and the antioxidant is a light-resistant and heat-resistant antioxidant stable system; and along with the time and the temperature rise, the thermal oxidative degradation of the plastic can be reduced, and the stability of the plastic during molding processing is improved.

Owner:马鞍山市聚能新材料科技有限公司

Preparation method of heat, oxygen and light-resistant antioxidant

The invention belongs to the technical field of production of rubber antioxidants, and concretely relates to a preparation method of a heat, oxygen and light-resistant antioxidant. Rare earth reacts with sodium ascorbate to form a complex, the surface of graphene oxide is grafted with snail mucus and a silane coupling agent KH-560, a free radical chain inhibitor and a hydroperoxide decomposing agent are added to prevent a chain reaction in order to protect rubber, the hydroperoxide decomposing agent decomposes the rubber to facilitate difficult aging of natural rubber, expandable graphite, borax and molybdenum disilicide are added, the graphite can expand a sheet to form a compact thermal insulation carbon layer in order to benefit the ageing resistance of the natural rubber, an o-hydroxyaromatic compound converts excitation energy into heat energy through intramolecular transfer and efficient radiation-free deactivation, and the borax and molybdenum disilicide are beneficial to preventing oxygen from invading and carbon from diffusing outwards to form a good shielding effect, and achieve the anti-oxidation effect in order to make the natural rubber probe no easy to age, so the antioxidant has a broad application prospect.

Owner:常州市万昌化工有限公司

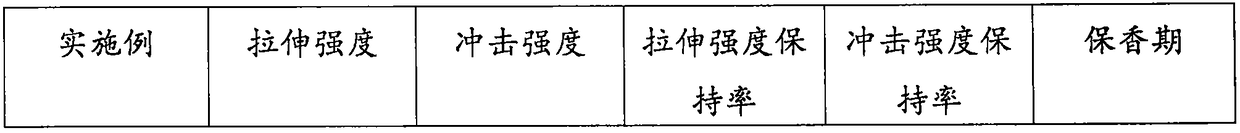

Simulated flower material with long effect fragrance and preparation method thereof

InactiveCN108530748AAchieve slow releaseReduce photosensitivityMicroballoon preparationMicrocapsule preparationPolyvinyl chloridePolypropylene

The invention discloses a simulated flower material with long effect fragrance and a preparation method thereof. The simulated flower material is prepared from the following raw materials in parts byweight: 25 to 40 parts of polypropylene, 20 to 25 parts of polyvinyl chloride, 20 to 30 parts of polyfluortetraethylene, 3 to 5 parts of tritolyl phosphate, 1.5 to 2.0 parts of zinc stearate, 1.5 to 2.0 parts of calcium stearate, 1.0 to 1.5 parts of 2-(2'-hydroxy-5'-methyl phenyl)benzotriazole, 1.0 to 1.5 parts of phenyl salicylate, 1 to 1.5 parts of liquid paraffin, 10 to 15 parts of talcum powder, 1.5 to 2.0 parts of aluminum oxide powder, 0.5 to 1.0 part of hydroperoxide decomposing agents, 1.5 to 3.0 parts of polyacrylamide, 5 to 10 parts of fragrance slow release agents, 0.1 to 0.5 part of coupling agents and 2 to 4 parts of color master batch. The fragrance slow release agent is added into a plastic substrate; the goal of slowly releasing the fragrance is achieved; the fragrance preservation period of a product is prolonged and can reach about two years.

Owner:覃洪洲

Synthesis method of oil-soluble catalyst isooctyl chromate

ActiveCN106995463AOrganic-compounds/hydrides/coordination-complexes catalystsGroup 6/16 organic compounds without C-metal linkagesSynthesis methodsReaction temperature

The invention provides a synthesis method of an oil-soluble catalyst isooctyl chromate, comprising the following steps of dissolving chromic oxide into water, dropwise adding an aqueous solution of the chromic oxide to isooctyl alcohol while stirring, controlling the reaction temperature to be 10 to 60 DEG C and the dropwise adding time to be 0.5 to 1.0h, after the adding is finished, continuously stirring to react for 0.5 to 1.5h, extracting an organic phase after the reaction is finished, wherein an obtained extract phase is the oil-soluble catalyst isooctyl chromate. When the obtained oil-soluble catalyst isooctyl chromate is applied to the cyclohexyl hydroperoxide decomposition reaction, the decomposition rate of the cyclohexyl hydroperoxide is greater than 99.0 percent, and the ketone-alcohol radio is greater than 1.2 to 1.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com