Functionalized mid-pore silica material and preparation and application thereof

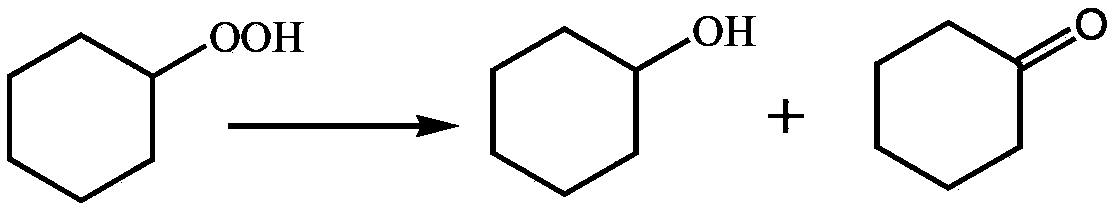

A mesoporous silica and functionalization technology, applied in the field of cyclohexane solution, can solve the problems of alkaline wastewater polluting the environment, high cost, corrosion equipment and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment one: the preparation of catalyst A

[0022] Take 2.61g hexadecylamine and dissolve in 50ml water and 20ml ethanol to prepare solution 1. Take 8.32g tetraethyl orthosilicate (TEOS) to obtain solution 2. Take 0.2gVOSO 4 (Molar ratio Si / V=50) solution in 10ml of water to prepare solution 3. Under vigorous stirring, solutions 2 and 3 were slowly added to solution 1. Aging for 24 hours, suction filtration, washing the precipitate, and drying at 80°C. Baked at 550°C for 5 hours in a muffle furnace. Catalyst A was prepared.

Embodiment 2

[0023] Embodiment two: catalytic decomposition cyclohexyl hydroperoxide active determination

[0024] Add 0.02g of catalyst A to a 50ml stainless steel reaction kettle with electromagnetic stirring, and then add 10ml of about (7.8g) cyclohexane solution containing 6% (0.5029mmol / g) of cyclohexyl hydroperoxide. Replace the reactor with nitrogen first, then close the gas inlet and outlet valves, heat to 120°C while stirring, keep the temperature constant for 30 minutes, cool down, and take out the reaction product.

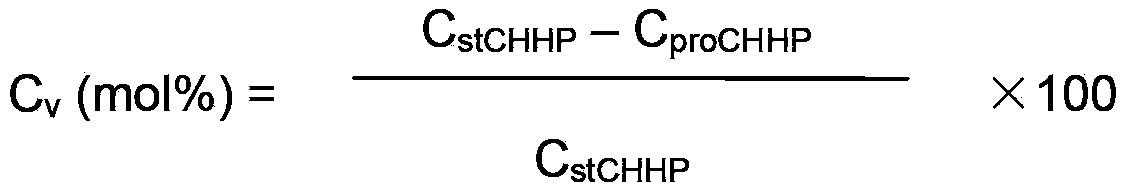

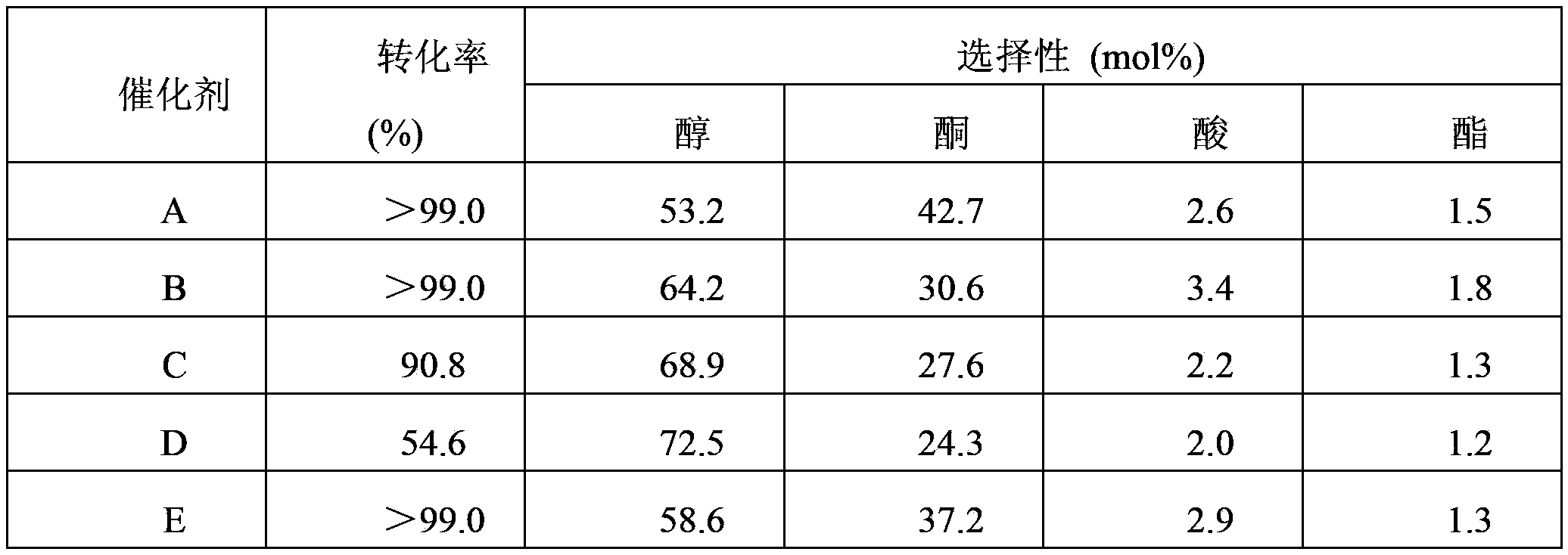

[0025] The content of cyclohexane hydrogen peroxide before and after the reaction was analyzed by iodine-sodium thiosulfate redox titration method, and the amount of cyclohexanol and cyclohexanone in the reaction solution and the generated solution before and after the reaction were analyzed by gas chromatography internal standard method. The test results are shown in Table 1.

Embodiment 3

[0026] Embodiment three: preparation and catalytic activity of catalyst B

[0027] Except that the type of transition metal is different, the catalyst preparation method is the same as that of Example 1. The transition metal source is Co(CH 3 COO) 2 . The method for testing the activity of the catalyst is the same as in Example 2, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com