Light adjusting film and preparation method thereof

A light-adjustable film and light-stabilizing technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as poor uniformity, high equipment precision requirements, and short service life of light-adjustable films, and achieve the effect of slowing down photochemical reactions and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] In yet another exemplary embodiment of the present application, a method for preparing a light-adjustable film is provided. The above-mentioned preparation method is implemented by using a roll-to-roll device. The above-mentioned preparation method includes: step S1, coating the first conductive layer 10 The adhesive layer composition with a solid content of 10-50% is thermally cured to form an adhesive layer 20, the first conductive layer 10 and the adhesive layer 20 form a first structure, wherein the adhesive layer composition A light stabilizer is dispersed; step S2, a polymer dispersed liquid crystal composition is coated on the second conductive layer 40, and cured to form a polymer dispersed liquid crystal layer 30. The second conductive layer 40 and the polymer dispersed liquid crystal layer 30 form a second The second structure, the polymer dispersed liquid crystal composition is a raw material for forming the polymer dispersed liquid crystal layer; and step S3, ...

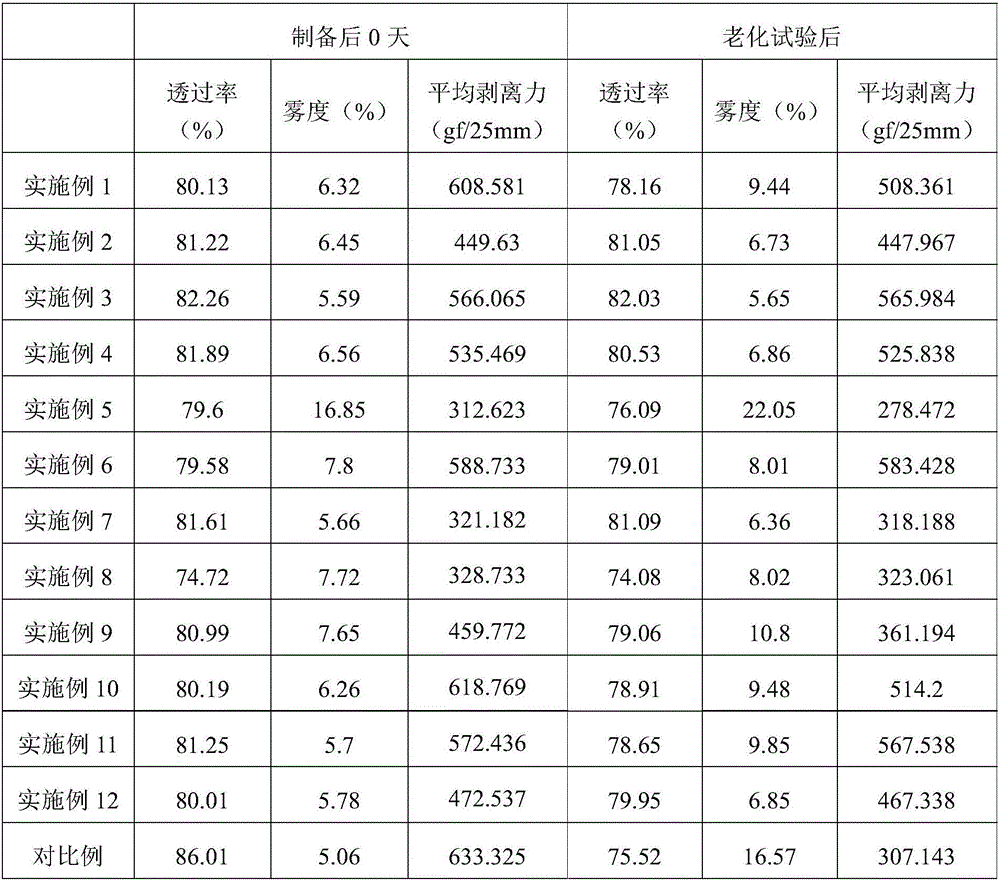

Embodiment 1

[0060] The light stabilizer is added to the adhesive glue and stirred at a constant speed, and the light stabilizer is dispersed in the adhesive glue and the solvent to form an adhesive layer composition, wherein the weight content of the light stabilizer is 1.825%. The weight content of the adhesive is 34.675%, the adhesive compound is a mixture of compound adhesive 303 and curing agent, the adhesive compound is compound adhesive 303, and the curing agent is vinyl triamine. In the adhesive compound, the weight content of curing agent is 5%; the weight content of the solvent is 63.5%, and the solvent is ethyl acetate. The light stabilizer is a compound light stabilizer of UV-327 and UV-531, the ratio of the two is 2:3, and the solid content of the adhesive layer composition is 36.5%.

[0061] The acrylic resin composition (aliphatic urethane acrylate, hexanediol diacrylate, acrylate, methacrylate, and octadecyl methacrylate=2.8:1.4:3.2:1.1:1.6) and the molecular weight are 200 T...

Embodiment 2

[0069] The light stabilizer is added to the pressure-sensitive adhesive 911P and stirred at a constant speed, and the light stabilizer is dispersed in the adhesive and solvent to form an adhesive layer composition. The weight content of the light stabilizer is 7.3%, and the weight of the pressure-sensitive adhesive is The weight content is 29.2%, the weight content of the solvent is 63.5%, the light stabilizer is 2-hydroxy-4-methoxybenzophenone and 2-[2-hydroxy-3,5-di(1,1-di (Methylpropylphenyl)]-2H-benzotriazole compound, and the ratio of the two is 3:7, benzophenone light-stable substance and benzotriazole light-stable substance are compounded , And the solid content of the adhesive layer composition is 36.5%.

[0070] The acrylic resin composition (aliphatic urethane acrylate, hexanediol diacrylate, acrylate, methacrylate and octadecyl methacrylate=2.8:1.4:3.2:1.1:1.6) and the molecular weight are 700 The liquid crystal is mixed and stirred at a constant speed, the stirring s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com