Functional resin and polyolefin material, and preparation methods and application thereof

A technology of functional resin and polyolefin, which is applied in the field of functional resin and its application in polyolefin materials, can solve the problems affecting the service life of photovoltaic modules affecting the reliability of packaging, affecting the product quality of polyolefin materials, and poor compatibility of additives. Achieve excellent anti-migration properties, slow down the possibility of photochemical reactions, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

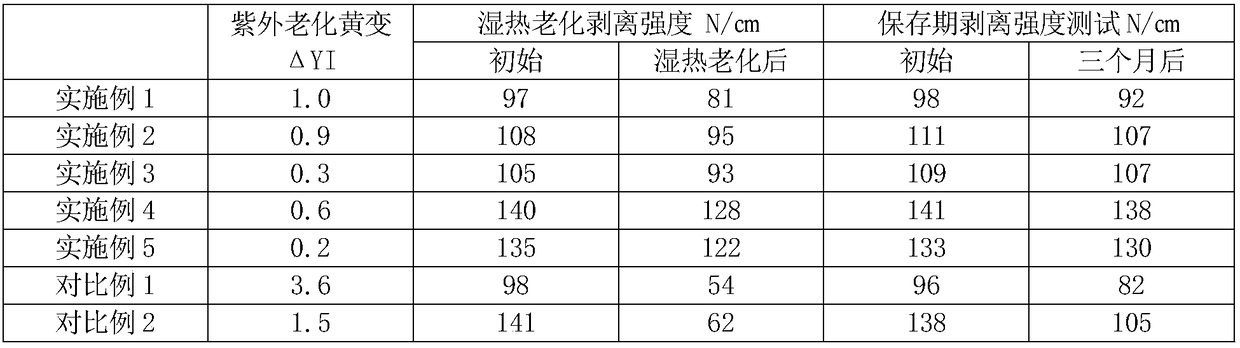

Examples

preparation example Construction

[0035] The preparation of above-mentioned functional resin is carried out in twin-screw extruder, and its steps are:

[0036] After mixing polyolefin resin, crosslinking agent and light stabilizer containing reactive groups uniformly in a mixer in proportion, they are extruded and granulated in a twin-screw extruder to obtain a functional resin. The twin-screw extruder The extrusion temperature of the machine is 160°C-240°C. If the extrusion temperature is lower than 160°C, the reaction rate will be too slow, the degree of reaction will be too low, and there may be more light stabilizer residues; if the extrusion temperature is higher than 240°C, the reaction rate will be too fast, and the resin will be cross-linked and burnt. There is a risk of burning.

[0037] In the components of the polyolefin material, 1-10 parts by mass of functional resin is added to 100 parts by mass of polyolefin resin, preferably 3-5 parts by mass. When the added amount of the functional resin is ...

Embodiment 1

[0045]0.1 parts by mass of di-tert-butyl peroxycumene (BIBP) as an organic peroxide crosslinking agent and 1 part by mass of 4-acryloyloxy-2,2,6,6-tetramethyl Piperidinol ester (ATMP) was added into 100 parts by mass of ethylene-octene copolymer (Dow Chemical ENGAGE 8407) as a light stabilizer and mixed evenly, and the mixture was added to a twin-screw extruder for grafting, and the temperature was controlled at At 240°C, the extruded product was pelletized and dried under water to obtain functional resin A.

[0046] 100 parts by mass of ethylene-octene copolymer (Dow Chemical ENGAGE 8137), 0.7 parts by mass of peroxy-3,5,5-trimethylhexanoic acid tert-butyl ester (TBPIN) as organic peroxide crosslinking agent and 0.7 parts by mass of triallyl isocyanurate (TAIC) are mixed uniformly as a cross-linking accelerator, and then 0.1 parts by mass of tris (2,4-di-tert-butylphenyl) phosphite (gas IRGAFOS-168) as an antioxidant, 0.2 parts by mass of vinyltrimethoxysilane (Dow Corning z...

Embodiment 2

[0048] 1 part by mass of di-tert-butylperoxycumene (BIBP) as an organic peroxide crosslinking agent and 10 parts by mass of 4-methacryloyloxy-2,2,6,6-tetra Methylpiperidinol ester (MTMP) was added as a light stabilizer to 100 parts by mass of ethylene-octene copolymer (Dow Chemical ENGAGE 8407) and mixed evenly, and the mixture was added to a twin-screw extruder for grafting, and the temperature The temperature is controlled at 195°C, and the extruded product is pelletized and dried under water to obtain functional resin B.

[0049] 100 parts by mass of ethylene-octene copolymer (Dow Chemical ENGAGE 8137), 0.7 parts by mass of peroxy-3,5,5-trimethylhexanoic acid tert-butyl ester (TBPIN) as organic peroxide crosslinking agent and 0.7 parts by mass of triallyl isocyanurate (TAIC) are mixed uniformly as a cross-linking accelerator, and then 0.1 parts by mass of tris (2,4-di-tert-butylphenyl) phosphite (gas IRGAFOS-168) as an antioxidant, 0.2 parts by mass of vinyltrimethoxysilan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yellowness index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com