Low-temperature alkaline soak solution and preparation method thereof

A soaking liquid and alkaline technology, which is applied in the field of low-temperature alkaline soaking liquid and its preparation, can solve problems such as complex process, high cost, and product corrosion, and achieve simple formula components, simple manufacturing process, and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A low-temperature alkaline soaking solution consists of 100 grams of potassium hydroxide, 50 grams of butyl glycol ether, 830 grams of pure water and 20 grams of surfactant (molecular weight: 2000). The preparation method is to put 100 grams of potassium hydroxide, 50 grams of ethylene glycol butyl ether, 830 grams of pure water and 20 grams of surfactant into a beaker, and heat the solution in the beaker to 20 ° C, and use a stirrer to fully Stir for 3 hours, filter the stirred mixed solution with 1um filter paper, and obtain 1000 grams of low-temperature alkaline soaking liquid finished product. The filter paper is easy to use and cheap, and can meet the needs of this product.

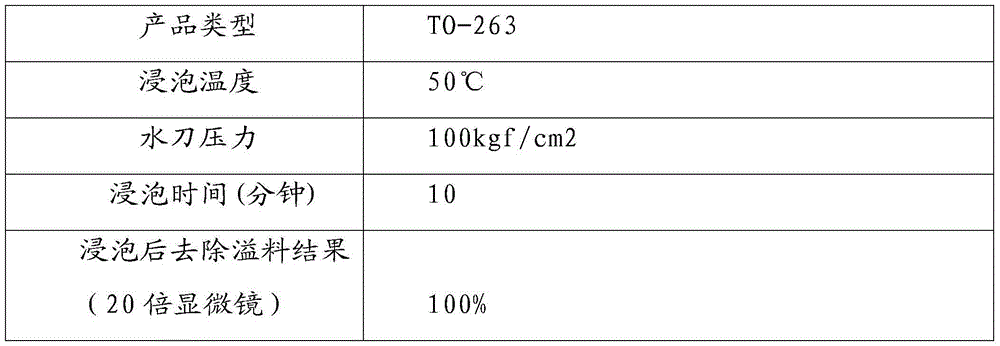

[0019] After soaking the obtained low-temperature alkaline soaking liquid with spilled products after packaging, the cleaning methods are as follows: 1. Soaking; 2. Washing; 3. High-pressure water washing; 4. Appearance inspection. And record the data in Table 1 below:

[0020]

Embodiment 2

[0022] A low-temperature alkaline soaking solution consists of 150 grams of potassium hydroxide, 100 grams of ethylene glycol butyl ether, 710 grams of pure water and 40 grams of surfactant (molecular weight: 4000). The preparation method is to put 150 grams of potassium hydroxide mass, 100 grams of ethylene glycol butyl ether mass, 710 grams of pure water and 40 grams of surfactant into a beaker, and heat the solution in the beaker to 30°C, and use a stirrer to fully Stir for 4 hours, filter the stirred mixed solution with 5um filter paper, and obtain 1000 grams of low-temperature alkaline soaking liquid finished product.

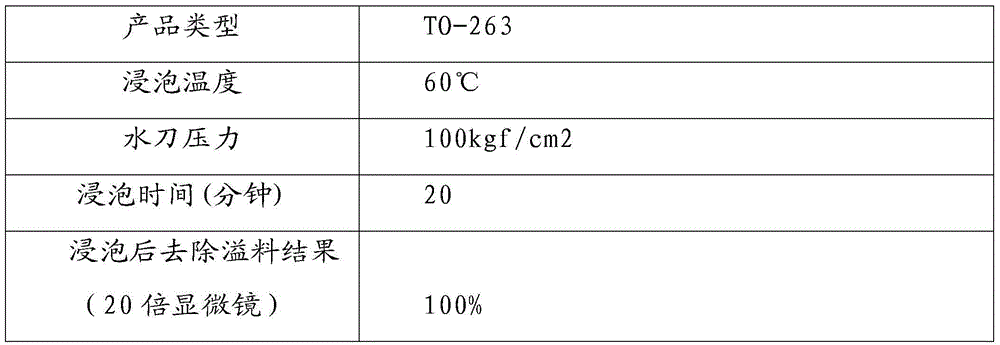

[0023] After soaking the obtained low-temperature alkaline soaking liquid with spilled products after packaging, the cleaning methods are as follows: 1. Soaking; 2. Washing; 3. High-pressure water washing; 4. Appearance inspection. And record the data as shown in Table 2 below

[0024]

Embodiment 3

[0026] A low-temperature alkaline soaking solution consists of 200 grams of potassium hydroxide, 150 grams of ethylene glycol butyl ether, 590 grams of pure water and 60 grams of surfactant (molecular weight: 6000). The preparation method is to put 200 grams of potassium hydroxide, 150 grams of ethylene glycol butyl ether, 590 grams of pure water and 60 grams of surfactant into a beaker, and heat the solution in the beaker to 40 ° C, and use a stirrer to fully Stir for 5 hours, filter the stirred mixed solution with 10um filter paper, and obtain 1000 grams of low-temperature alkaline soaking liquid finished product.

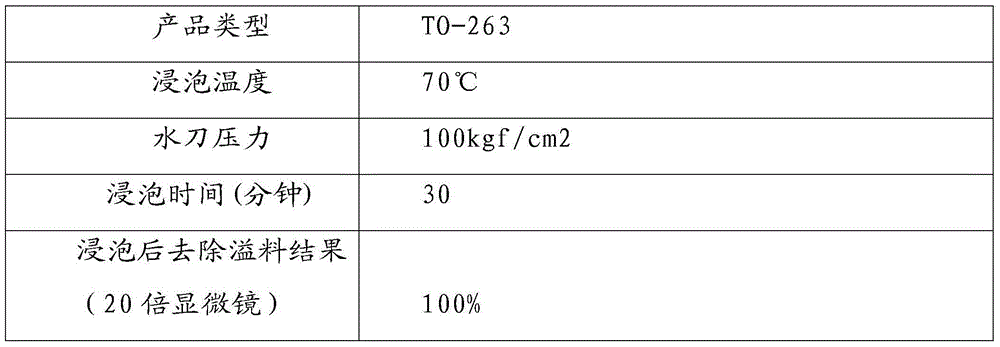

[0027] After soaking the obtained low-temperature alkaline soaking liquid with spilled products after packaging, the cleaning methods are as follows: 1. Soaking; 2. Washing; 3. High-pressure water washing; 4. Appearance inspection. And record the data as shown in Table 3 below

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com