Preparation method for TiO2/SiO2-Ag-SiO2 nanocomposite film

A sio2-ag-sio2 and nano-composite technology, applied in the field of optoelectronic materials, can solve the problems of low utilization rate of sunlight and achieve the effects of improving photocatalytic efficiency, low preparation cost, and reducing the probability of recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

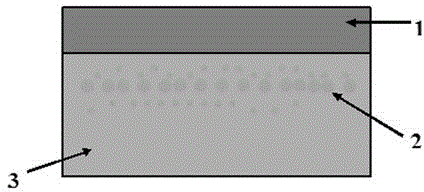

[0022] Ag with an energy of 20 kV + Implanted into the quartz glass substrate, the injection dose is 5×10 16 ions / cm 2 . Ag nanoparticles were formed in the silica substrate, the size of the nanoparticles was 3-15 nm, SiO 2 The thickness of the isolation layer is about 3 nm. The depth distribution range of Ag nanoparticles is relatively wide. TiO with a thickness of about 100 nm was deposited on the surface of the quartz glass substrate with Ag nanoparticles by DC reactive magnetron sputtering 2 Thin films were annealed at 500 oC for 2 hours in an oxygen atmosphere, and the temperature was naturally lowered after annealing. Anatase TiO 2 film. so as to get TiO2 / SiO 2 -Ag-SiO 2 nanocomposite films.

Embodiment 2

[0024] Ag with an energy of 40 kV + Implanted into the quartz glass substrate, the injection dose is 5×10 16 ions / cm 2 . Ag nanoparticles are formed in the silicon dioxide substrate, and the size of the nanoparticles is 20-30 nm. The size of the Ag nanoparticles is relatively uniform, and the depth distribution is roughly the same. SiO 2 The thickness of the isolation layer is about 7 nm. TiO with a thickness of about 100 nm was deposited on the surface of the quartz glass substrate with Ag nanoparticles by DC reactive magnetron sputtering 2 Thin films were annealed at 500 oC for 2 hours in an oxygen atmosphere, and the temperature was naturally lowered after annealing. Anatase TiO 2 film. so as to get TiO 2 / SiO 2 -Ag-SiO 2 Composite film.

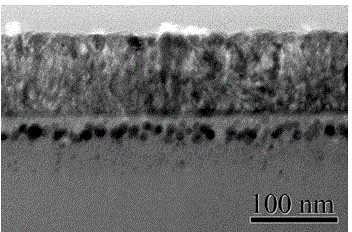

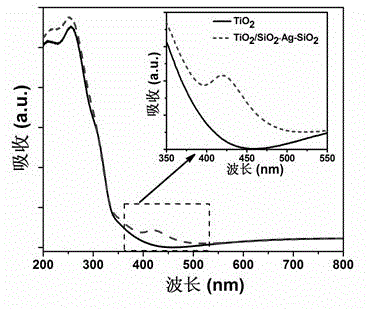

[0025] The sample prepared in this embodiment is analyzed

[0026] figure 2 For the prepared TiO 2 / SiO 2 -Ag-SiO 2 Cross-sectional image of the composite structure transmission electron microscope, it can be seen from th...

Embodiment 3

[0031] Ag with an energy of 60 kV + Implanted into the quartz glass substrate, the injection dose is 5×10 16 ions / cm 2 . Ag nanoparticles were formed in a silica substrate. TiO with a thickness of about 100 nm was deposited on the surface of the quartz glass substrate with Ag nanoparticles by DC reactive magnetron sputtering 2 film and annealed at 400 °C for 2 h in an oxygen atmosphere. so as to get TiO 2 / SiO 2 -Ag-SiO 2 Composite film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com