Conductive paste for electronic component

A technology of electronic components and conductive paste, which is applied in the field of conductive paste, can solve the problems of reduced conductivity, high price, short circuit of electrodes, etc., and achieve the effect of reducing sintering temperature, reducing production cost and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

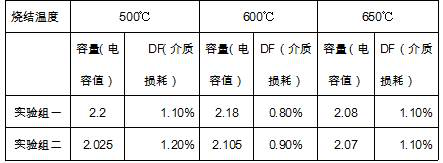

[0035] A conductive paste for electronic components, including components and the content of each component: by weight, 66 parts of conductive metal powder, 5 parts of glass, 1 part of dispersant, 2 parts of coupling agent, and 22.5 parts of solvent , 3.5 parts of ethyl cellulose. Among them, the conductive metal powder includes bronze and silver powder (0.2um), and the weight ratio of bronze and silver powder is 2:1. Using copper as the main metal can avoid the effect of atomic migration when silver metal is used as an electrode.

[0036]

[0037] It can be seen from the above that in this embodiment, when the manufacturing temperature is 600° C., the performance of the capacitor and the metal electrode is the best.

specific Embodiment 2

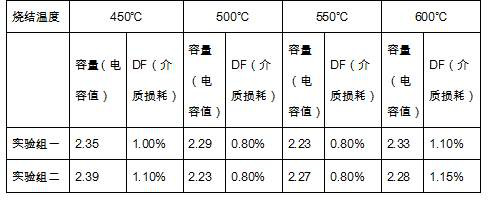

[0039] A conductive paste for electronic components, including components and the content of each component: in parts by weight, 66 parts of conductive metal powder, 6 parts of glass, 1 part of dispersant, 2 parts of coupling agent, and 21 parts of solvent , 4 parts of ethyl cellulose. Among them, the conductive metal powder includes bronze powder, silver-coated copper powder and tin powder, and the weight ratio of bronze powder, silver-coated copper powder and silver powder (< 0.2um) is 4:4:2. Copper powder and silver-coated copper powder are used as the main metal. In order to avoid oxidation, the surface of silver-coated copper powder is covered with silver metal as protection, so that it will not be oxidized during air sintering.

[0040]

[0041] It can be seen from the above that in this embodiment, when the manufacturing temperature is 500-550° C., the performance of the capacitor and the metal electrode is the best.

specific Embodiment 3

[0043] A conductive paste for electronic components, including components and the content of each component: in parts by weight, 64.2 parts of conductive metal powder, 5 parts of glass, 1 part of dispersant, 2 parts of coupling agent, and 24 parts of solvent , 3.8 parts of ethyl cellulose. Among them, the conductive metal powder includes cupronickel and silver powder (0.2um), and the weight ratio of cupronickel and silver powder is 5:1.

[0044]

[0045] It can be seen from the above that in this embodiment, when the manufacturing temperature is 650° C., the performance of the capacitor and the metal electrode is the best.

[0046] The beneficial effects of the conductive paste for electronic components of the present invention are:

[0047] 1. The sintering temperature of the conductive paste is reduced, saving energy and reducing production costs.

[0048] 2. When sintering in air, replacing part of the silver metal with copper can effectively reduce the material cost. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com