High-speed milling micro lubrication liquid supply nozzle structure and separation and recovery mechanism and system

A high-speed milling and micro-lubrication technology, used in metal processing machinery parts, metal processing equipment, maintenance and safety accessories, etc., can solve the problems of lubrication of parts not suitable for high-speed milling, cooling separation and collection device integration, etc., to achieve lubrication Good effect, reduce pollution, avoid splash effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

[0078] Such as Figure 1 to Figure 5 Shown is a structural diagram of a high-speed milling micro-lubrication liquid supply system.

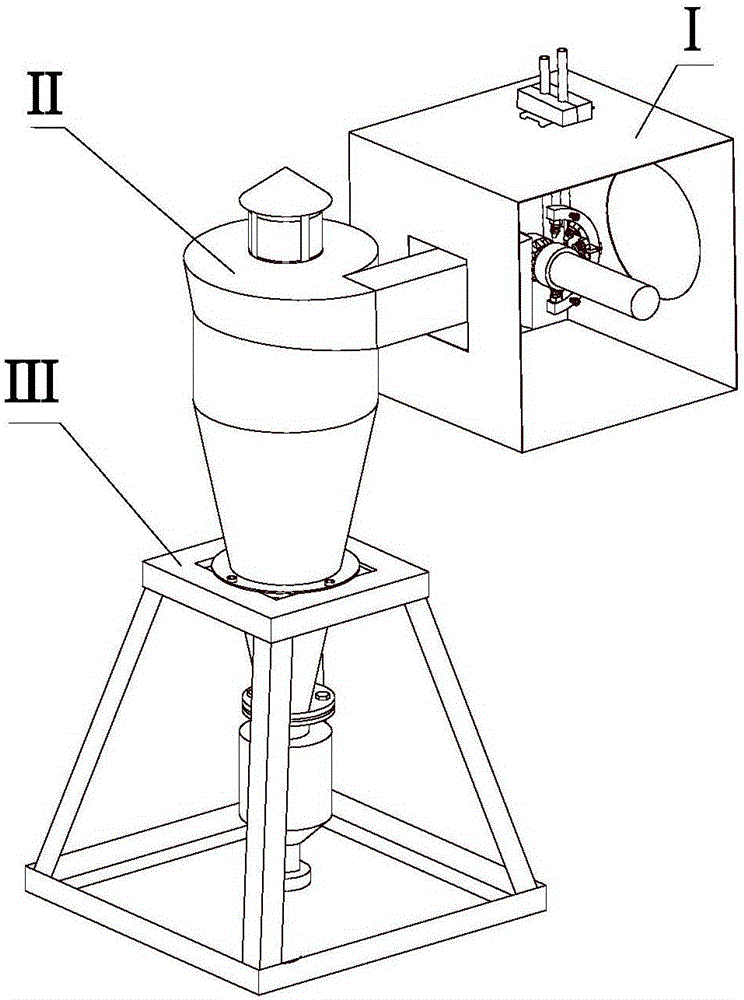

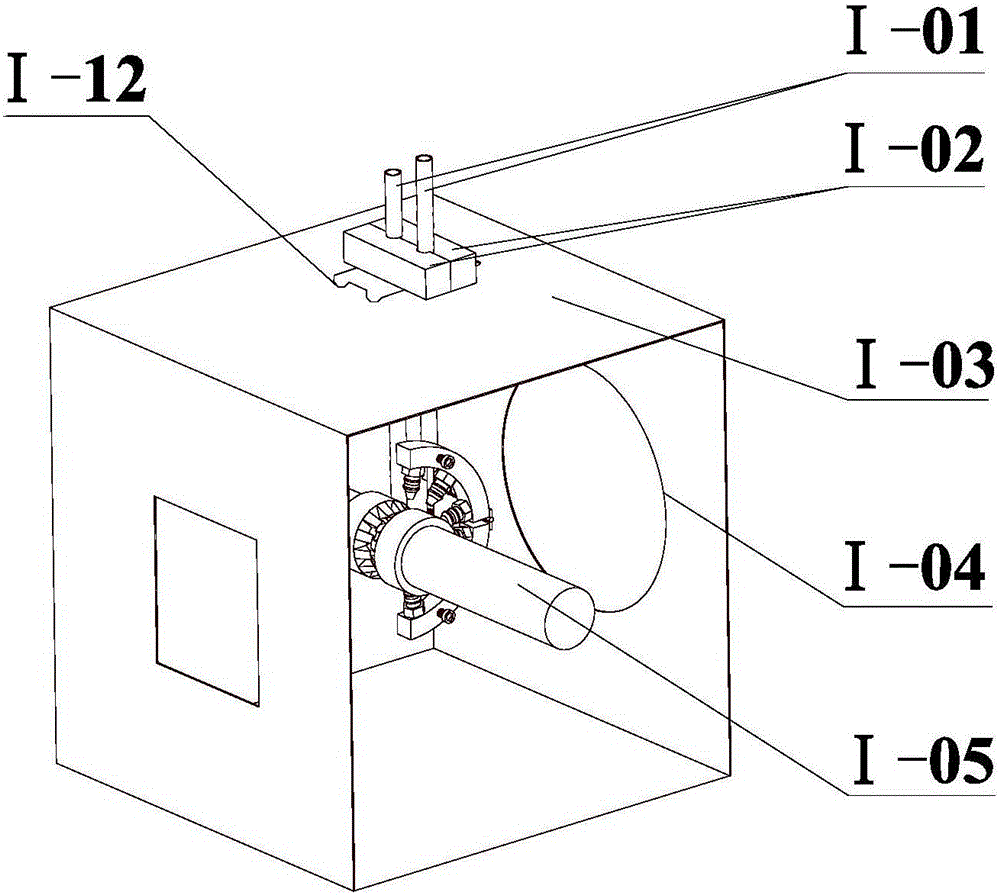

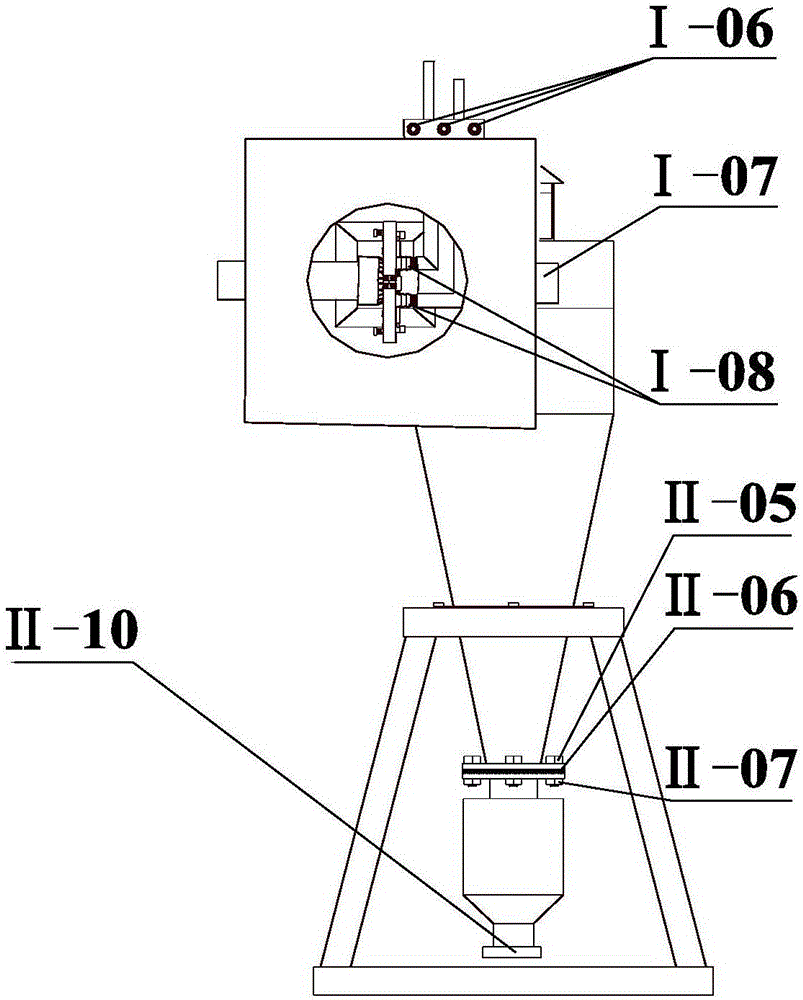

[0079] Such as figure 1 As shown, a high-speed milling micro-lubrication liquid supply system is divided into three parts, consisting of high-speed milling processing part I, oil-water-air chip collection part II, and oil-water-gas chip separation support part III.

[0080] Such as Figure 2 to Figure 5 , Figure 13 , Figure 14 As shown, the delivery pipe I-01 is connected to the pipeline casing through the serpentine universal joint I-08, and the two pipeline casings can form a semicircle, and are arranged up and down around the milling cutter. The nozzle is placed in the contact area between the workpiece and the high-speed milling cutter, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com