Wear-resistant reciprocating grate support structure

A support structure and reciprocating furnace technology, which is applied in the field of boiler grate, can solve the problems of short service life of grate pieces, blockage of grate pieces, decreased combustion efficiency, etc., and achieve the effects of reducing maintenance costs, improving use efficiency, and improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below through non-limiting embodiments and in conjunction with the accompanying drawings.

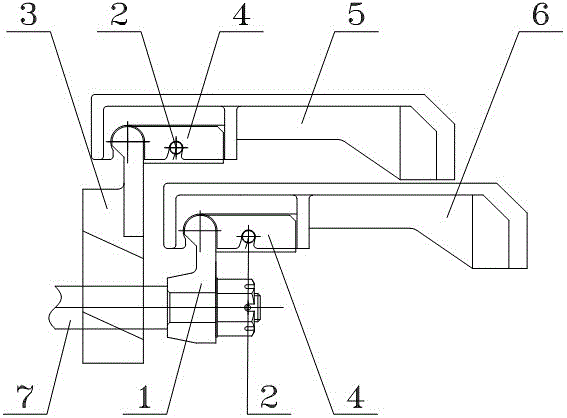

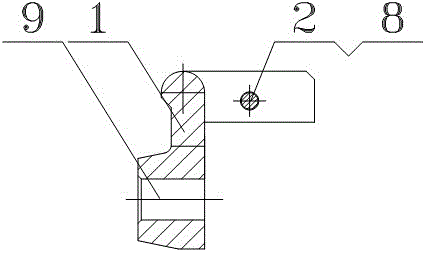

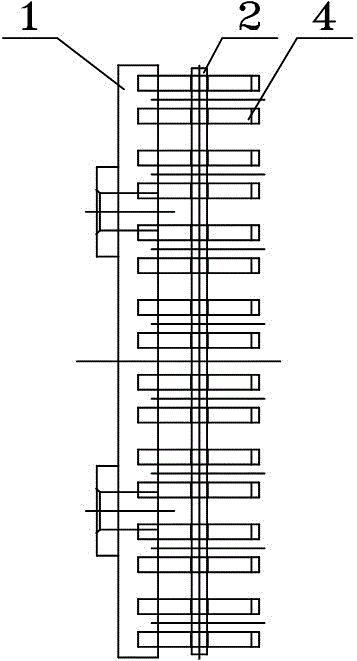

[0017] Such as Figure 1 to Figure 7 As shown, a wear-resistant reciprocating grate support structure includes movable grate 6, fixed grate 5, movable shelf 1 and fixed shelf 3, and the movable shelf is provided with a connecting hole 9, which is connected with Pull rod 7, pull rod 7 is connected with movable fire grate driving mechanism, movable fire grate piece 6 and fixed fire grate piece 5 are clamped on movable shelf 1 and fixed shelf 3 respectively through the card slot 12 thereon, after connection, movable furnace A gap of 3mm is reserved between the top and bottom of the row piece and the fixed grate piece; the positioning plate group corresponding to the movable fire grate piece 6 is fixedly connected to the movable shelf 1, and the positioning plate group is composed of two positioning plates 4, two The distance between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com