Discharge tube element which produce ozone

A discharge tube and component technology, which is applied in the field of ozone generator equipment, can solve problems such as leakage loss, dielectric breakdown, and lowering the dielectric constant of the dielectric, so as to avoid deviations in processing accuracy and reduce length and processing accuracy, the effect of no attenuation of ozone concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

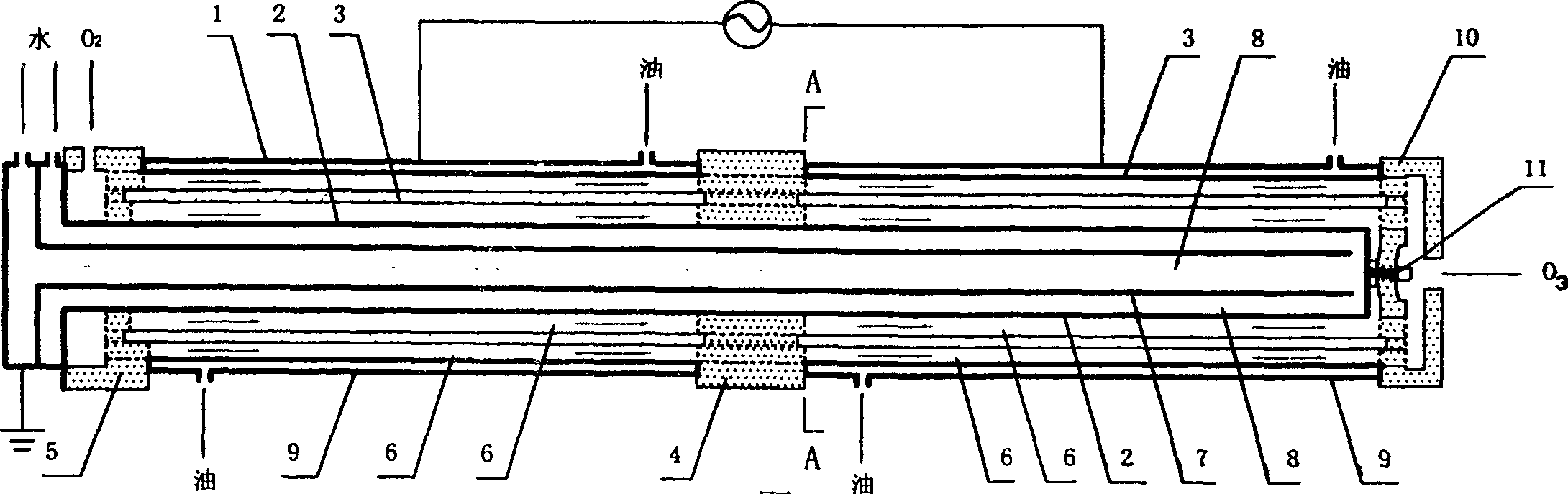

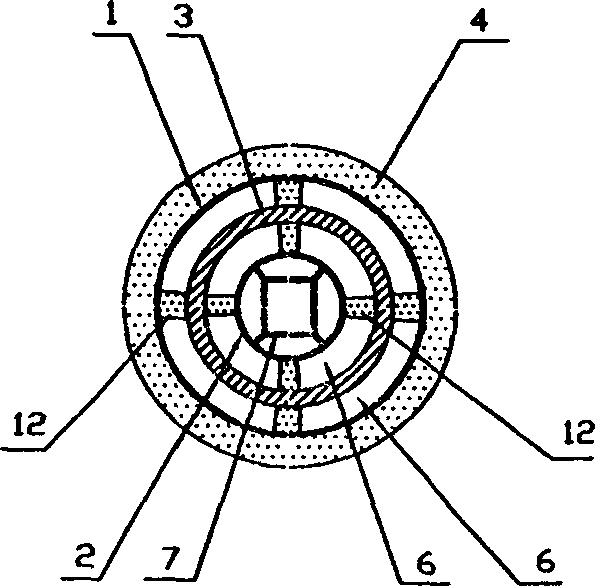

[0030] Embodiment 1, as figure 1 , figure 2 As shown, the discharge tube unit that generates ozone is provided with mutually insulated and symmetrical stainless steel casing high-voltage electrode groups (1) on the outer surface of the tubular dielectric body (3) to form a discharge tube unit, which is symmetrical and insulated from each other. They are respectively connected to two high-voltage input terminals of the high-frequency power supply, and a tubular dielectric body (3) is separated between the high-voltage electrode tube (1) and the stainless steel tube grounding electrode (2). The two high-voltage electrode groups (1) are separated from each other in the axial direction by insulating ring pads (4) to prevent short circuits between the two poles. Dielectric body positioning cards (12) and discharge electrodes are arranged on the insulating material ring pads (4). The air vent of the gap (6); place a coaxial stainless steel pipe grounding electrode (2) in the tubul...

Embodiment 2

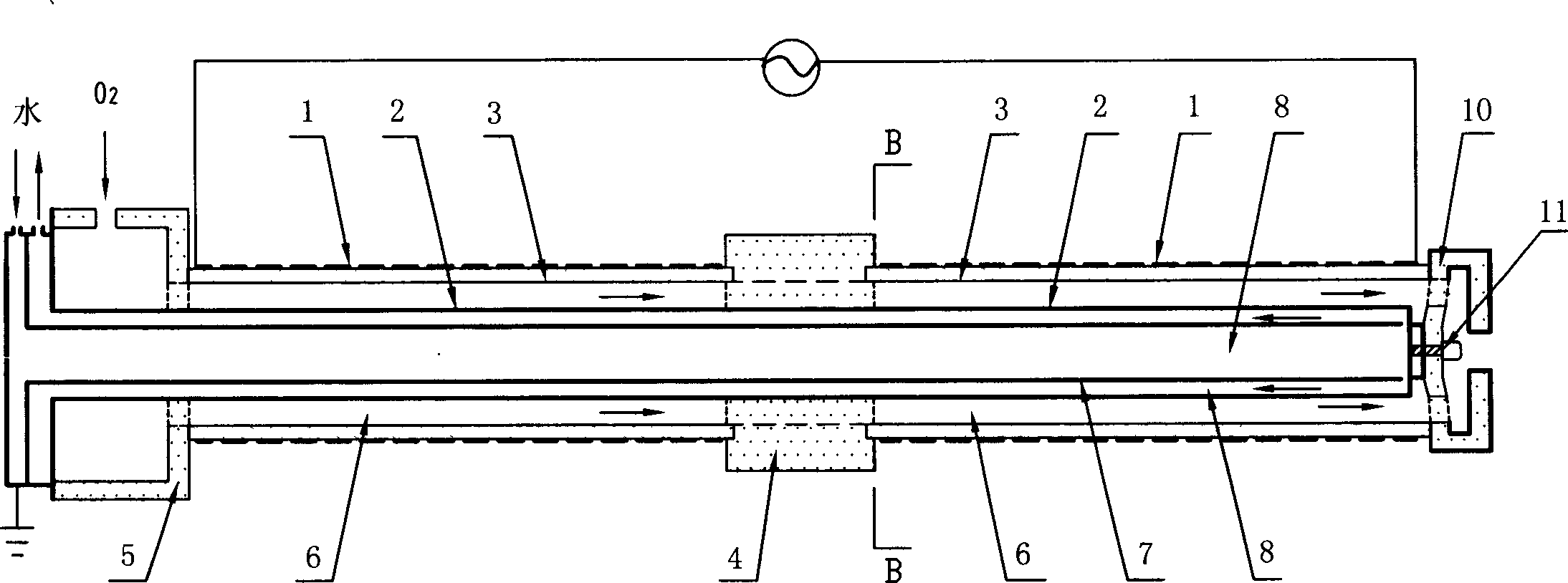

[0031] Embodiment 2, as image 3 , Figure 4 As shown, the ozone-generating discharge tube unit is directly coated or sintered on the outer surface of the tubular dielectric body (3) with ring-shaped conductive films that are symmetrical to each other and spaced more than 20mm apart from each other, forming two high-voltage electrodes (1) of the discharge tube element. Conductive film, high-voltage electrode (1) The conductive film is respectively connected to the two high-voltage input terminals of the power supply, and the conductive film of the two high-voltage electrodes (1) is made of insulating materials such as polytetrafluoroethylene and polyvinyl chloride along the axial direction. The ring gasket (4) is isolated to prevent short circuit between the two poles, and the positioning card (12) of the tubular dielectric body (3) and the vent hole of the discharge gap (6) are arranged on the insulating material ring gasket (4); Or the two high-voltage electrodes (1) formed...

Embodiment 3

[0032] Embodiment 3, as Figure 5 , Figure 6 As shown, the discharge tube unit that generates ozone consists of a high voltage pole (1), a ground pole (2), a tubular dielectric body (3), an insulating material gasket (4), a left insulating end cap (5), and a right insulating end cap (10), non-metal insulating pipe (13) constitutes. The high-voltage pole (1) is coated with two sets of conductive films that are symmetrical to each other and separated in the middle on the non-metallic insulating material tube (13). The conductive film is used as the high-voltage pole (1) and the ground pole (2). The body (3), the insulating material ring gasket (4) and the positioning card (12) play a fixed role, so that the discharge gap between the high voltage pole (1), the tubular dielectric body (3) and the grounding pole (2) (6) Equal, when the discharge tube is working, the medium oil with good insulation is passed into the non-metallic insulating material tube (13) to cool the two high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com