Process for spraying and treating percolate

A treatment process and leachate technology, which is applied in the field of landfill leachate treatment process, can solve pollution and other problems, achieve the effects of improving economic benefits, prolonging the operation cycle, and reducing coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make readers understand the present invention more clearly, the present invention will be further elaborated below in conjunction with specific examples.

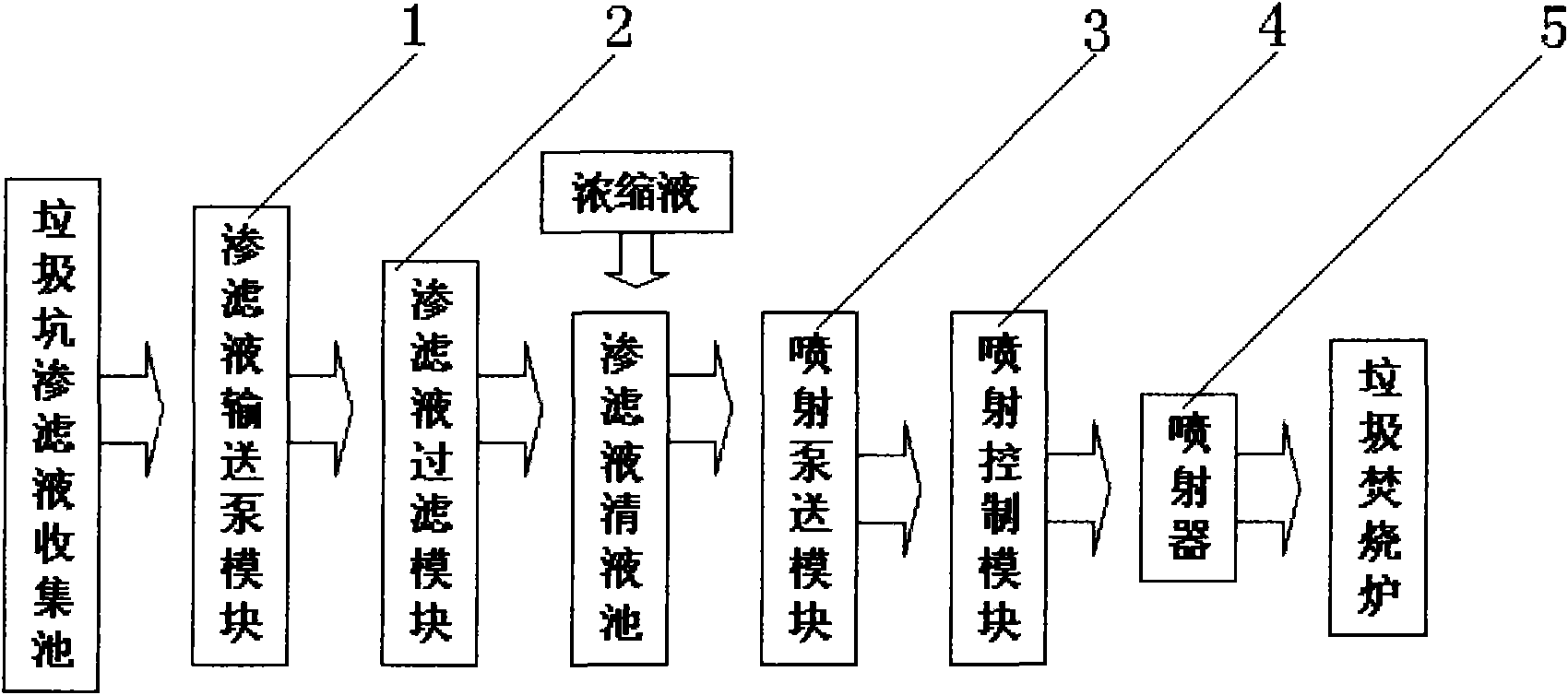

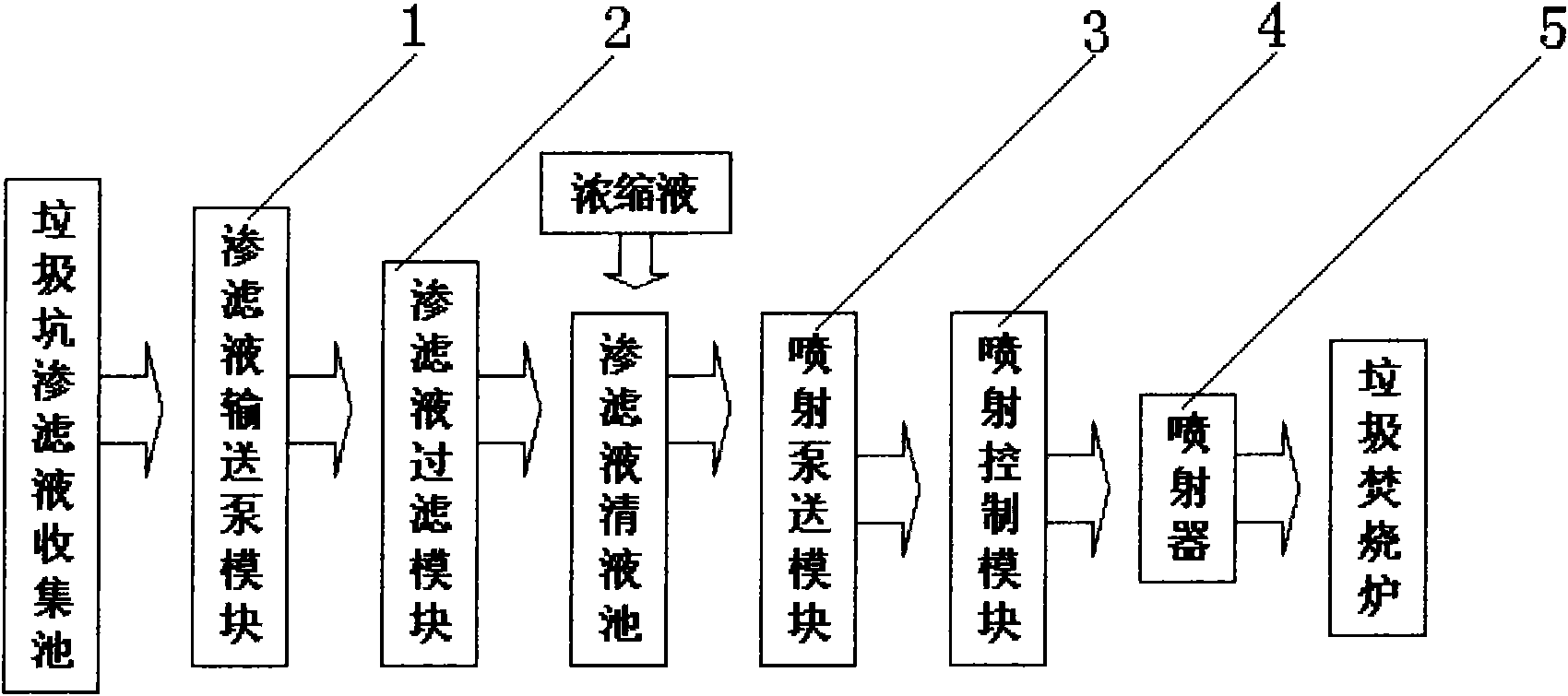

[0024] 1. Principle of leachate backspray treatment process

[0025] First, the leachate to be treated is transported through a high-precision mechanical filter through a water pump (filter pump). After filtration, the suspended particles of the leachate are significantly reduced, and the fluidity is enhanced, which meets the injection requirements. Then it is pumped to the furnace of the incinerator through the water pump (jet pump). According to the real-time combustion situation of the incinerator and the change of the flue gas composition, the appropriate spray volume is calculated, adjusted by the flow regulating device, and finally passed through the gas installed on the furnace. After the mist injector is fully atomized, it is sprayed into the appropriate position of the furnace for uniform evapora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com