Patents

Literature

31results about How to "Slow down the speed of coking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

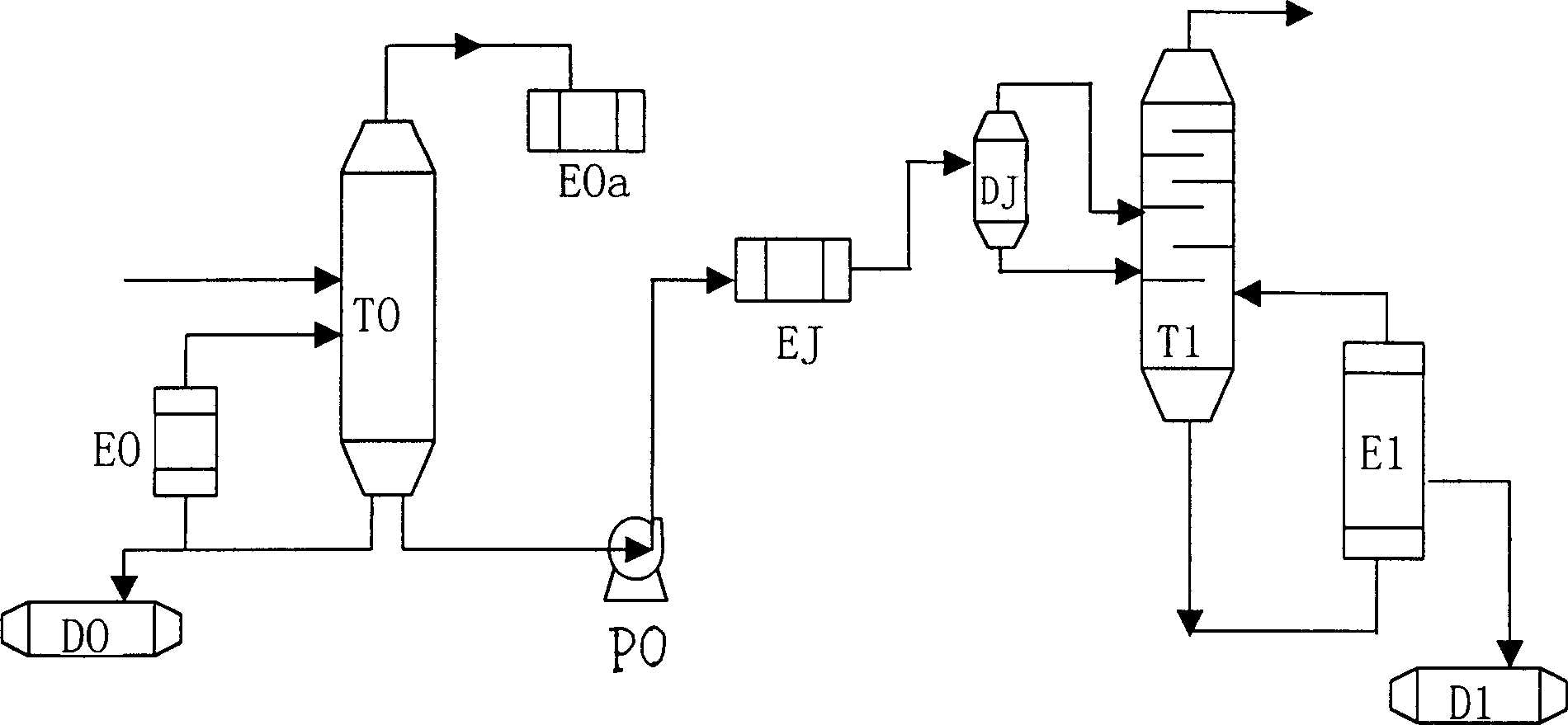

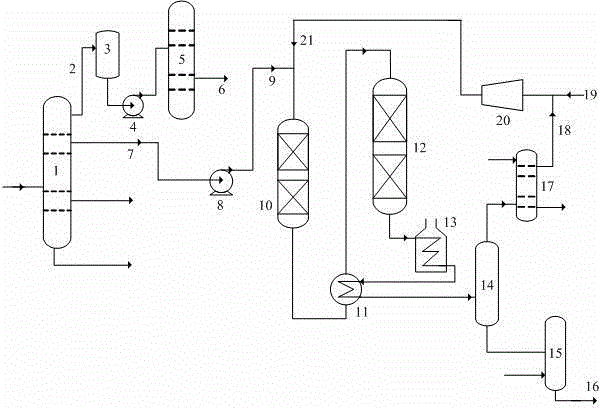

Hydrogenation and refining method of gasoline with poor quality

ActiveCN101591565AThe method flow is simpleEasy and flexible operationTreatment with hydrotreatment processesSolventPoor quality

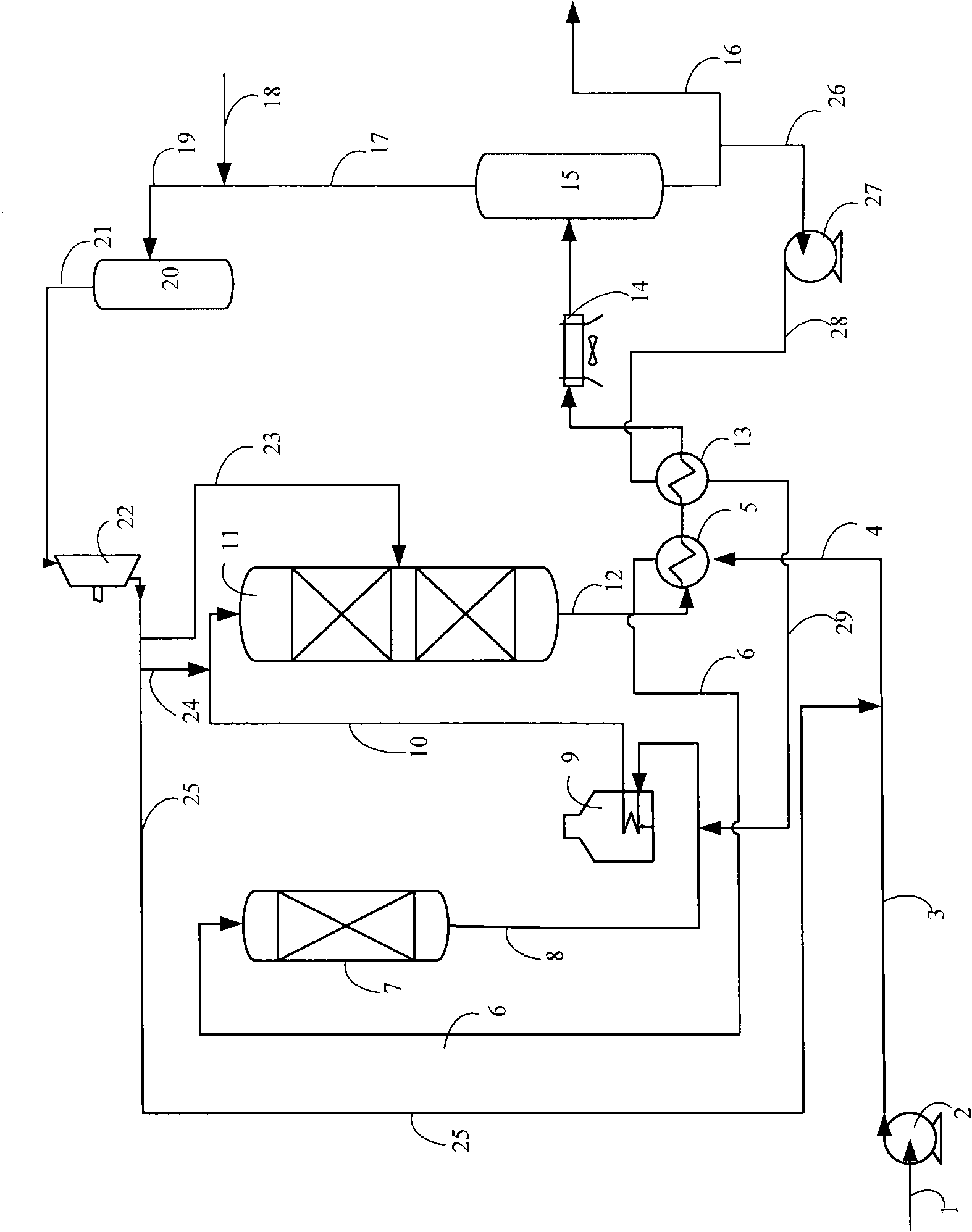

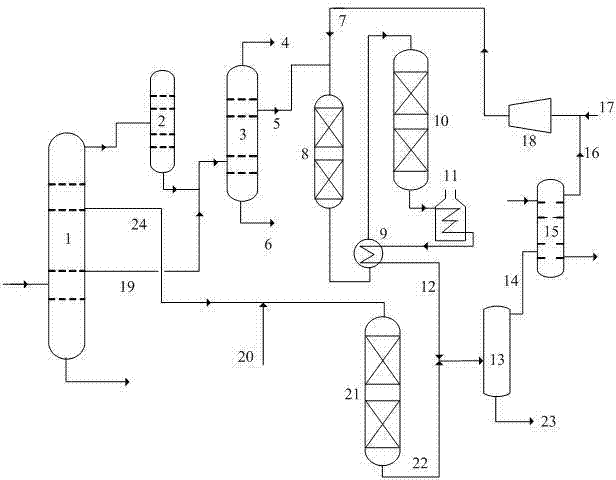

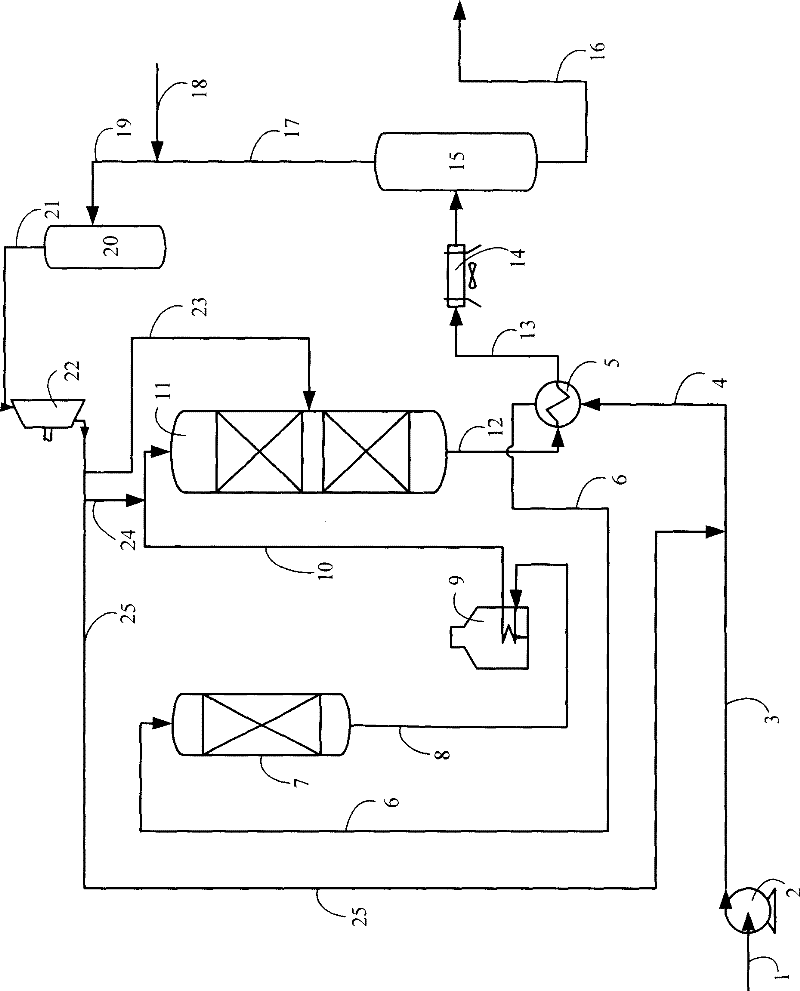

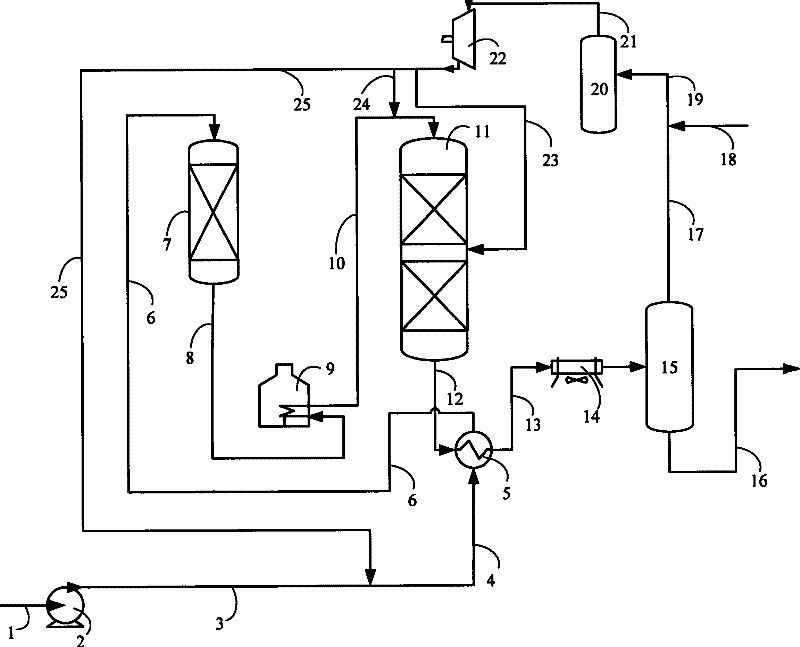

The invention discloses a hydrogenation and refining method of gasoline with poor quality, comprising the following steps: the base oil of gasoline contacts and reacts with hydrogenation protective agent at low temperature; after reaction effluent is mixed with circulation oil, the mixture sequentially contacts and reacts with hydrogenation desilication solvent and hyrorefining catalyst at high temperature; the reaction product is cooled and separated to obtain hydrogen-rich gas and refined gasoline fraction; and parts of refined gasoline fraction serves as circulation oil to return to the outlet of a first hydrogenation reaction area. The method can handle coker gasoline with high content of sulphur, nitrogen and olefin, and refined gasoline fraction can satisfy charging requirements of reforming pre-hydrogenation devices and steam cracking ethene preparing devices. The method of the invention can effectively slow coking speed of heating furnace tubes, greatly lowers pressure drop generation frequency of a main hydrogenation reactor, improves the operating severity of the main hydrogenation reactor and retards the deactivation speed of catalyst at the bottom of a refined reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

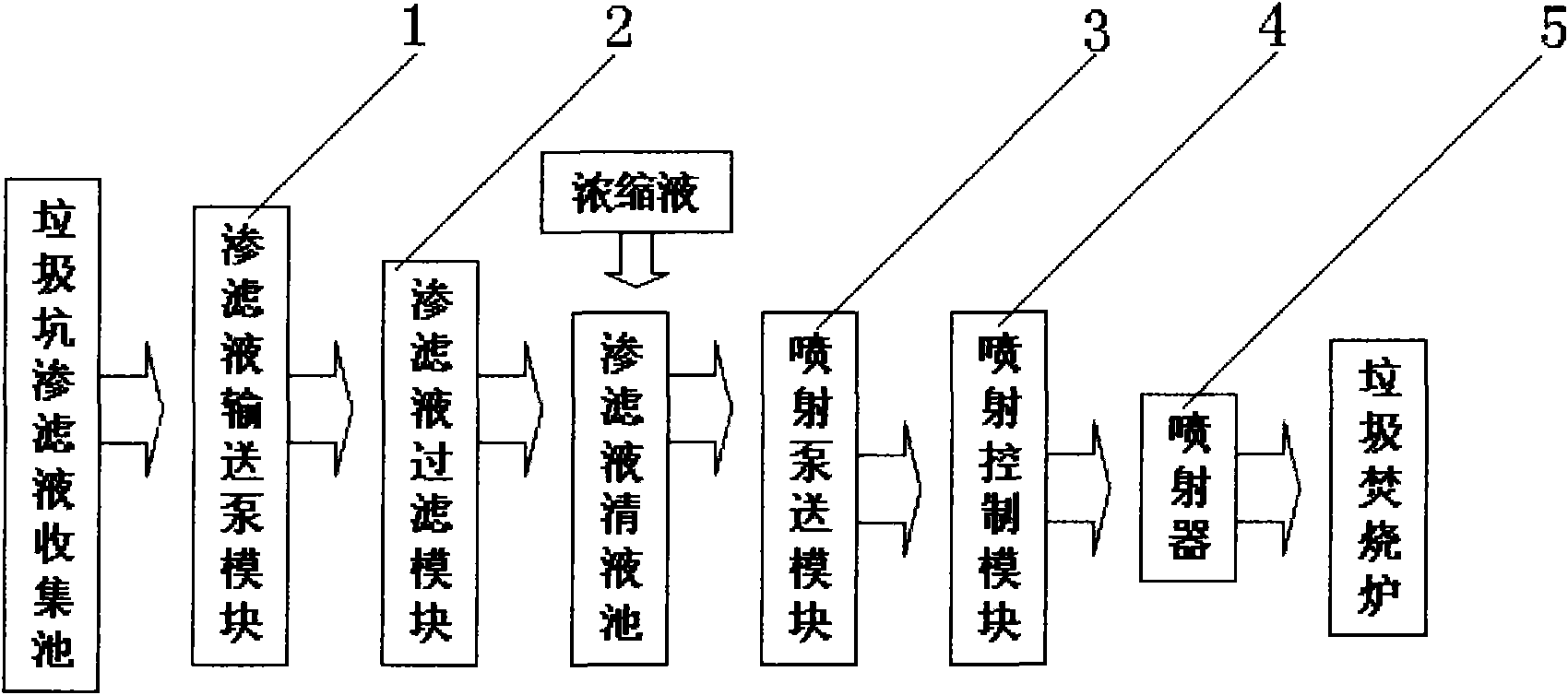

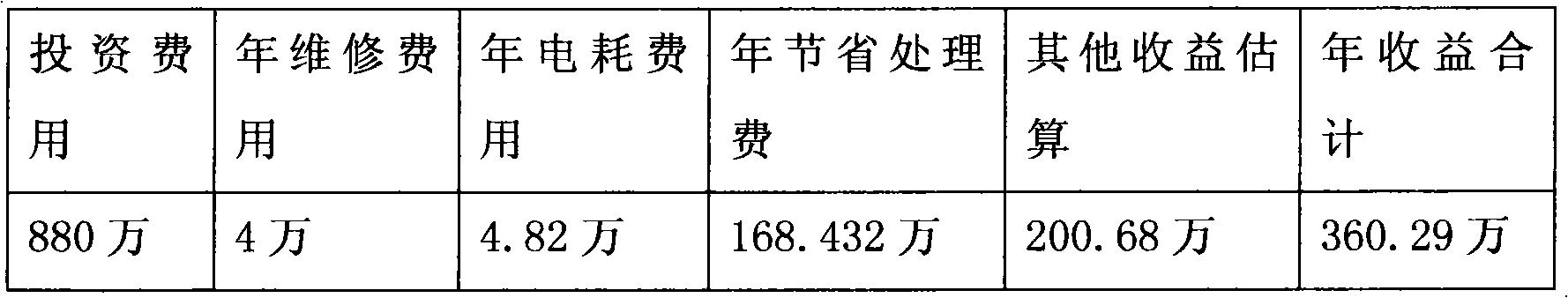

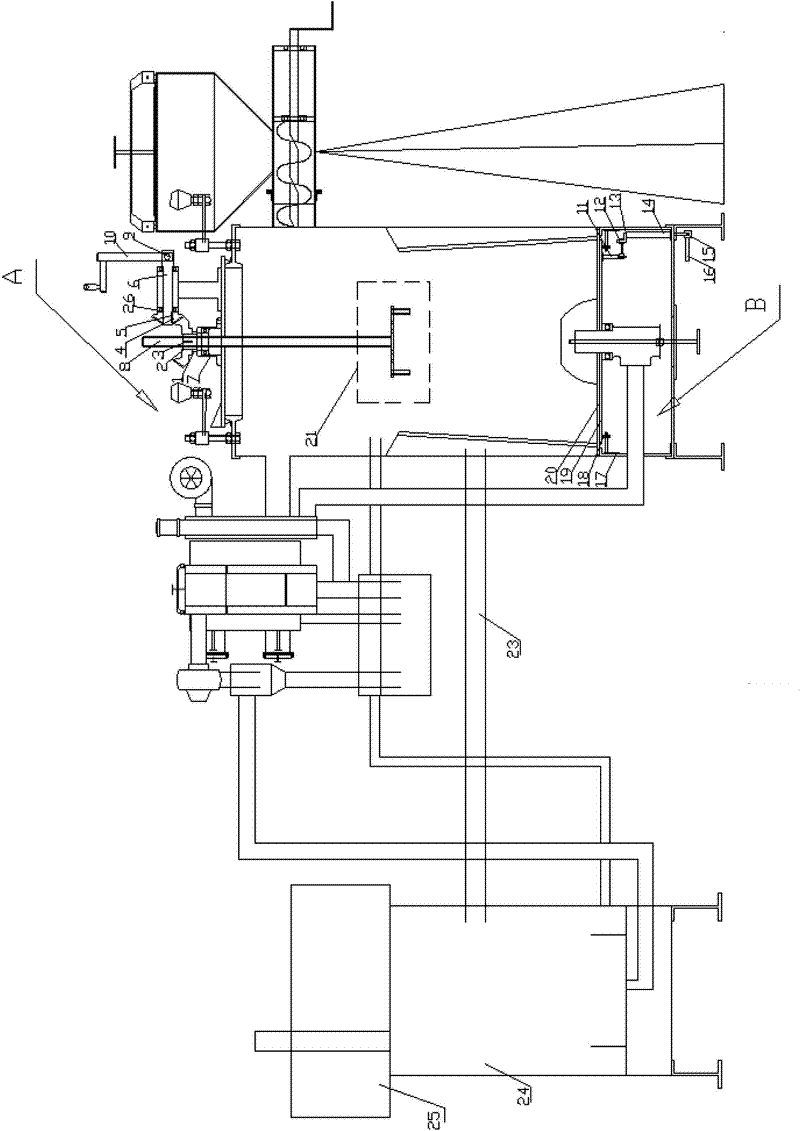

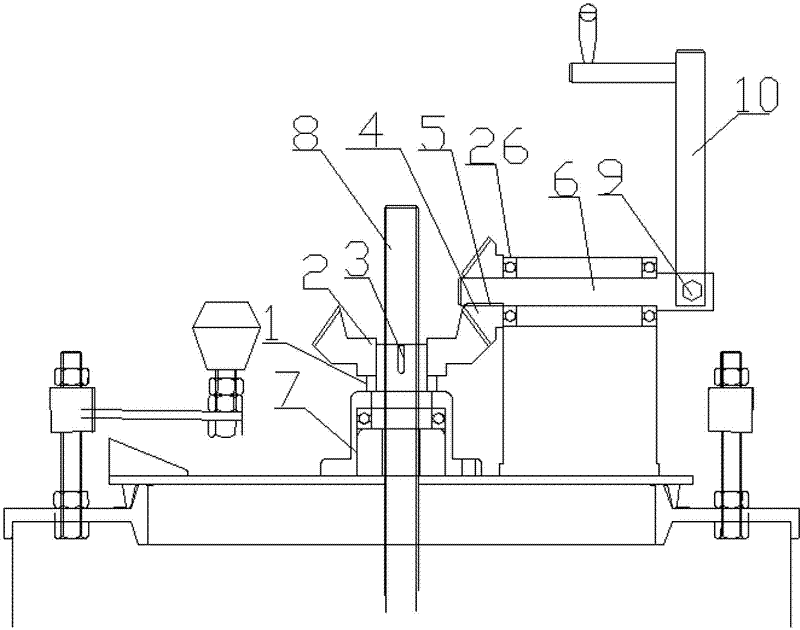

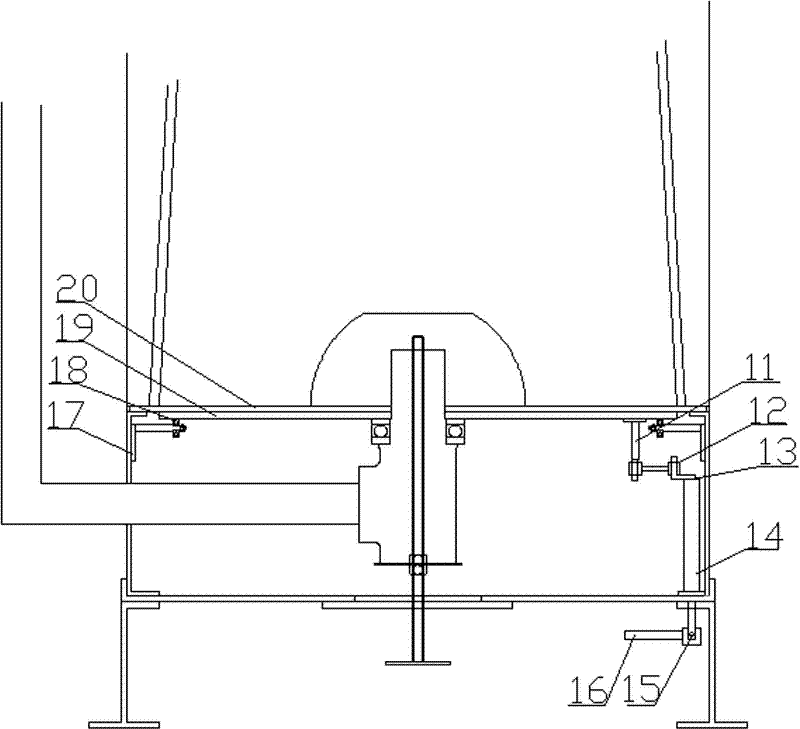

Process for spraying and treating percolate

ActiveCN101979921AExtended operating cycleReduce cokingIncinerator apparatusAutomatic controlBurn treatment

The invention relates to a process for treating garbage percolate, in particular to a process for spraying and treating percolate and aims to provide a reliable and efficient garbage percolate treatment method for spraying the garbage percolate for burning treatment. The garbage percolate can be prevented from polluting the environment and the pollution problem can be solved completely. In order to fulfill the aim, the process for spraying and treating the percolate is provided and comprises the following steps of: collecting the percolate; filtering the percolate; and spraying the percolate. A technical process for spraying, burning and treating the percolate is simple and is convenient to operate. Stock garbage percolate can be decomposed fully or concentrated solution produced in other treatment modes can be treated simultaneously and secondary pollution is avoided; and compared with other treatment modes, the process has low construction, operation and maintenance costs, small floor area and high automatic control degree and is convenient to operate.

Owner:SHANGHAI TECHSPRAY ENG

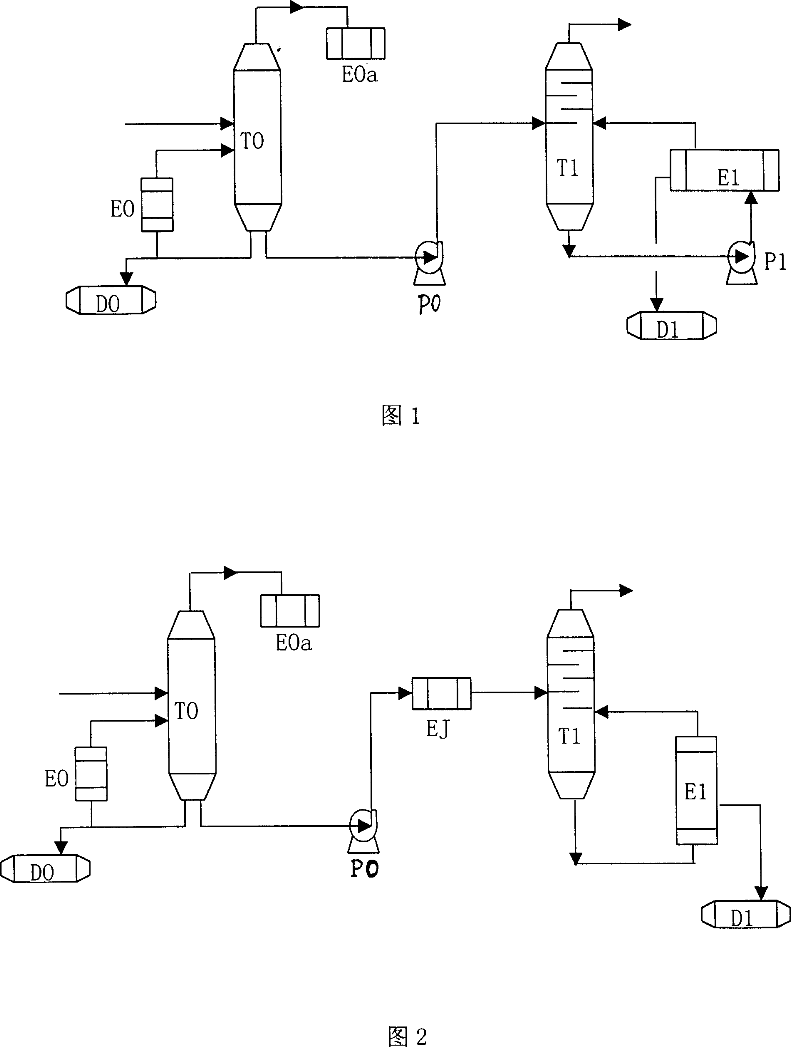

Coal tar processing method

ActiveCN101892065ALow ashReduce concentrationHydrocarbon distillationCoking carbonaceous materialsProcess engineeringEngineering

The invention relates to a coal tar processing method, which comprises the following steps of: feeding coal tar into a fractionating tower T, setting a washing section at a position above a coal tar feeding hole of the fractionating tower T, discharging washing section outside throwing oil from the washing section, and discharging residual oil from the bottom of the fractionating tower T; and further heating the washing section outside throwing oil to a temperature T1, and coking the heated washing section outside throwing oil and the residual oil at a temperature T2 together, wherein the temperature T1 is higher than the temperature T2. The coal tar processing method has the advantages of improving the flexibility of controlling the asphalt content of lightweight distillate oil and effectively reducing the exit temperature of a residual oil heating furnace.

Owner:何巨堂

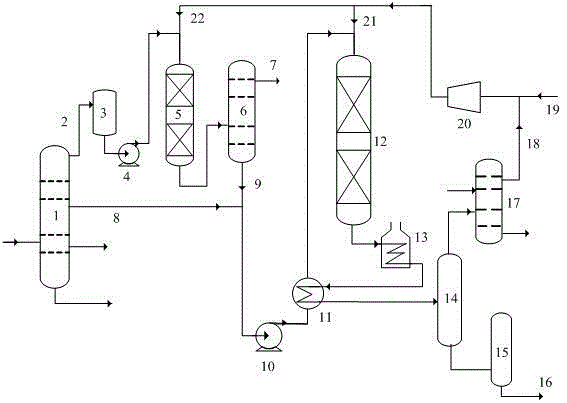

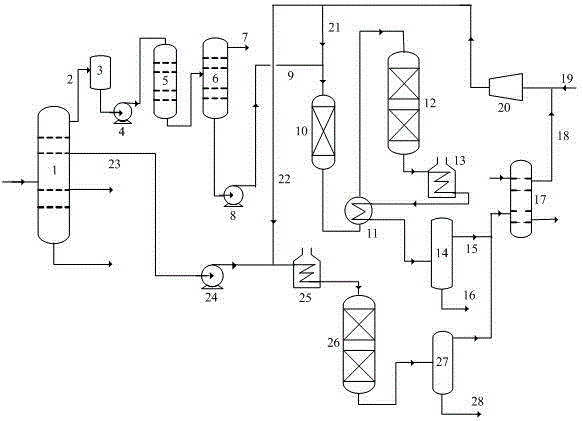

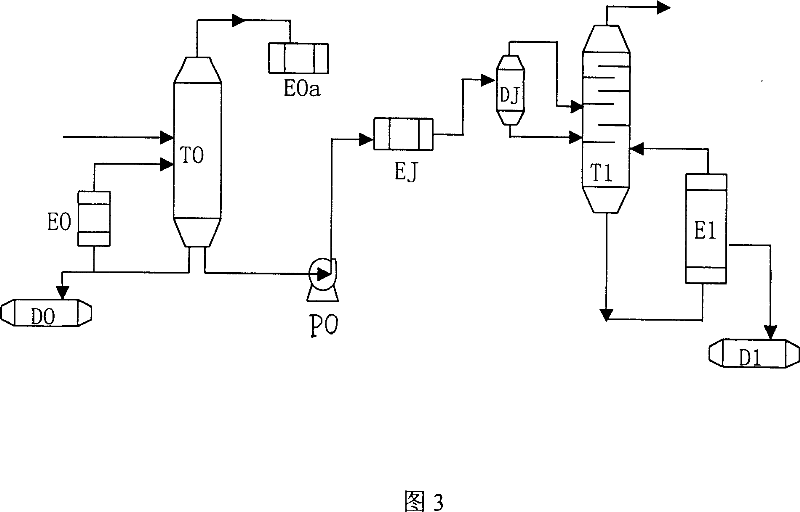

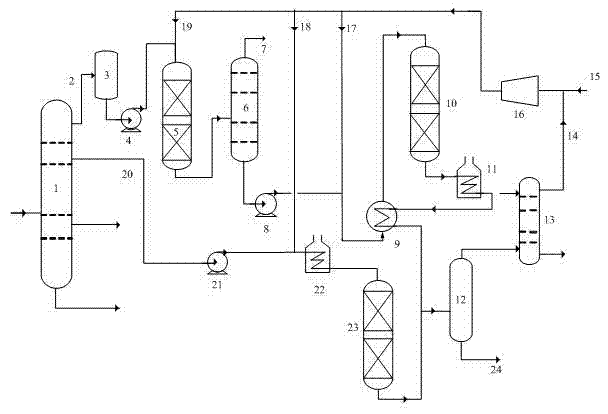

Low-energy consumption catalytic gasoline hydrodesulfurization method

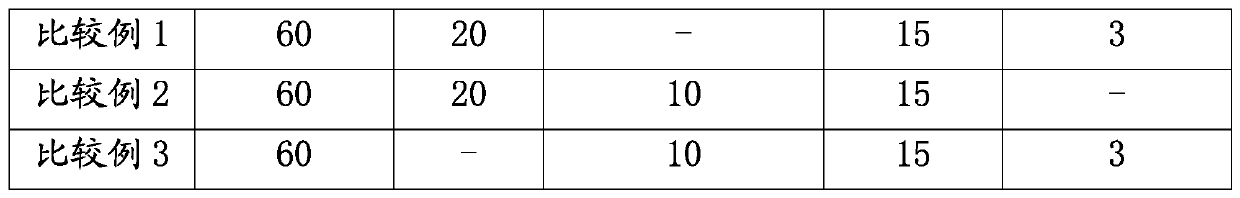

ActiveCN103059957AAchieve pre-separationLow investment costTreatment with hydrotreatment processesHydrogenHydrodesulfurization

The invention discloses a low-energy consumption catalytic gasoline hydrodesulfurization method. The method comprises: adjusting the operating conditions of a catalytic cracking device fractionating tower, and adopting an appropriate cutting point to perform pre-separation in an FCC (fluid catalytic cracking) fractionating tower so as to obtain light fractions and heavy fractions; subjecting the mercaptan in the light fractions to hydroconversion to form a heavy sulfide, making the treated light fractions enter a hydrogenation prefractionator to fractionate light gasoline and medium gasoline, mixing the medium gasoline with the heavy fractions generated by the FCC fractionating tower, letting the mixture enter a hydrodesulfurization reactor to undergo deep desulfurization, conducting steam stripping on the obtained refined heavy gasoline, and mixing it with the light gasoline, thus obtaining a clean gasoline product or a blending component. Compared with the existing catalytic gasoline hydrodesulfurization technologies, the method provided in the invention has the advantages that: the equipment energy consumption is significantly reduced, the gasoline octane number loss is small, the gasoline product quality can meet the quality requirement for a sulfur content of less than 10 micrograms / g, and the economic benefits of oil refining enterprises are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

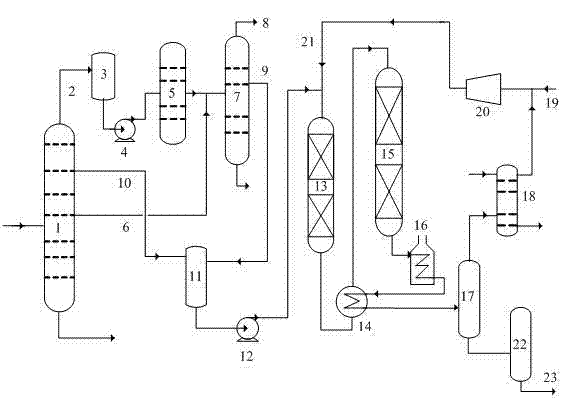

Catalytic gasoline hydrodesulfurization method

ActiveCN103059950AAchieve pre-separationLow investment costTreatment with hydrotreatment processesHydrodesulfurizationProcess engineering

The invention discloses a catalytic gasoline hydrodesulfurization method. The method comprises: adjusting the operating conditions of a catalytic device fractionating tower, adding a lateral line, conducting cutting at an appropriate cutting temperature so as to obtain light fractions at the tower top and heavy fractions at the lateral line; subjecting the light fractions to an alkali extraction treatment, and then separating light gasoline and medium gasoline through a hydrogenation prefractionator; and carrying out moderate selective hydrodesulfurization on the medium gasoline, and carrying out deep selective hydrodesulfurization on the heavy gasoline, subjecting the obtained two refined products to gas stripping, and then mixing them with alkali extracted light gasoline, thus obtaining a clean gasoline product. Compared with the existing catalytic gasoline hydrodesulfurization technologies, the method provided in the invention can significantly reduce equipment energy consumption, the gasoline octane number loss is small, the obtained gasoline product quality can meet the quality requirement for a sulfur content of less than 10 micrograms / g, and the economic benefits of oil refining enterprises are substantially improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

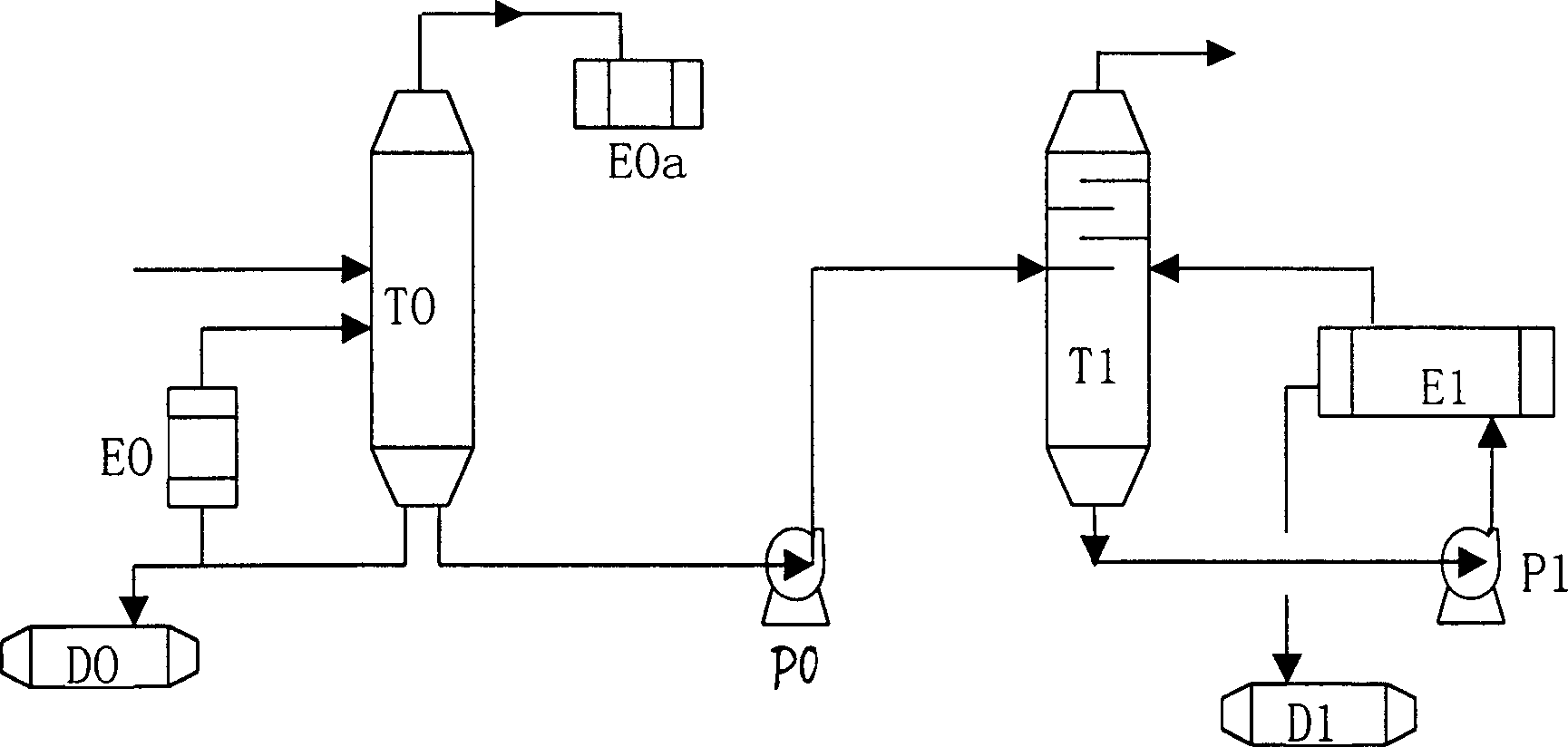

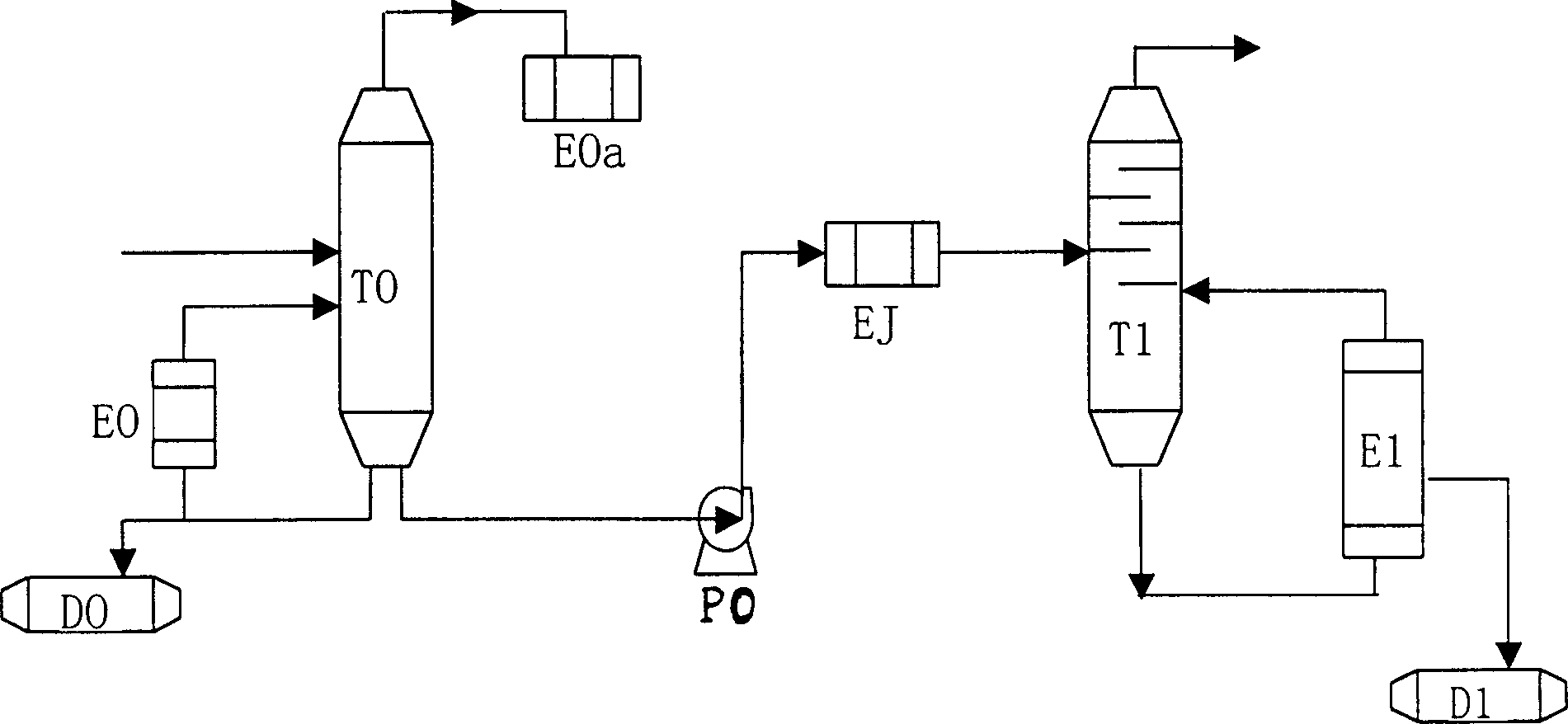

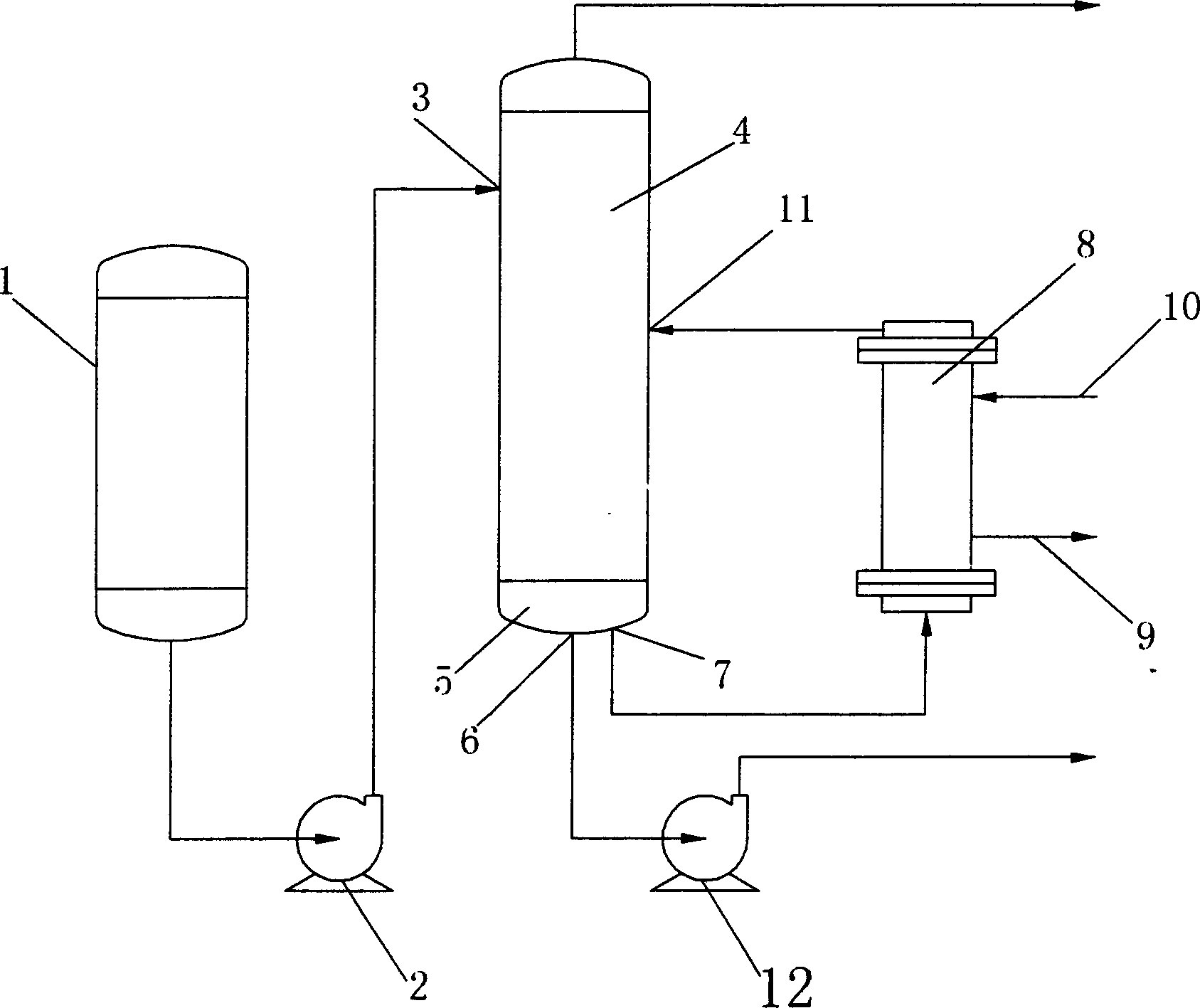

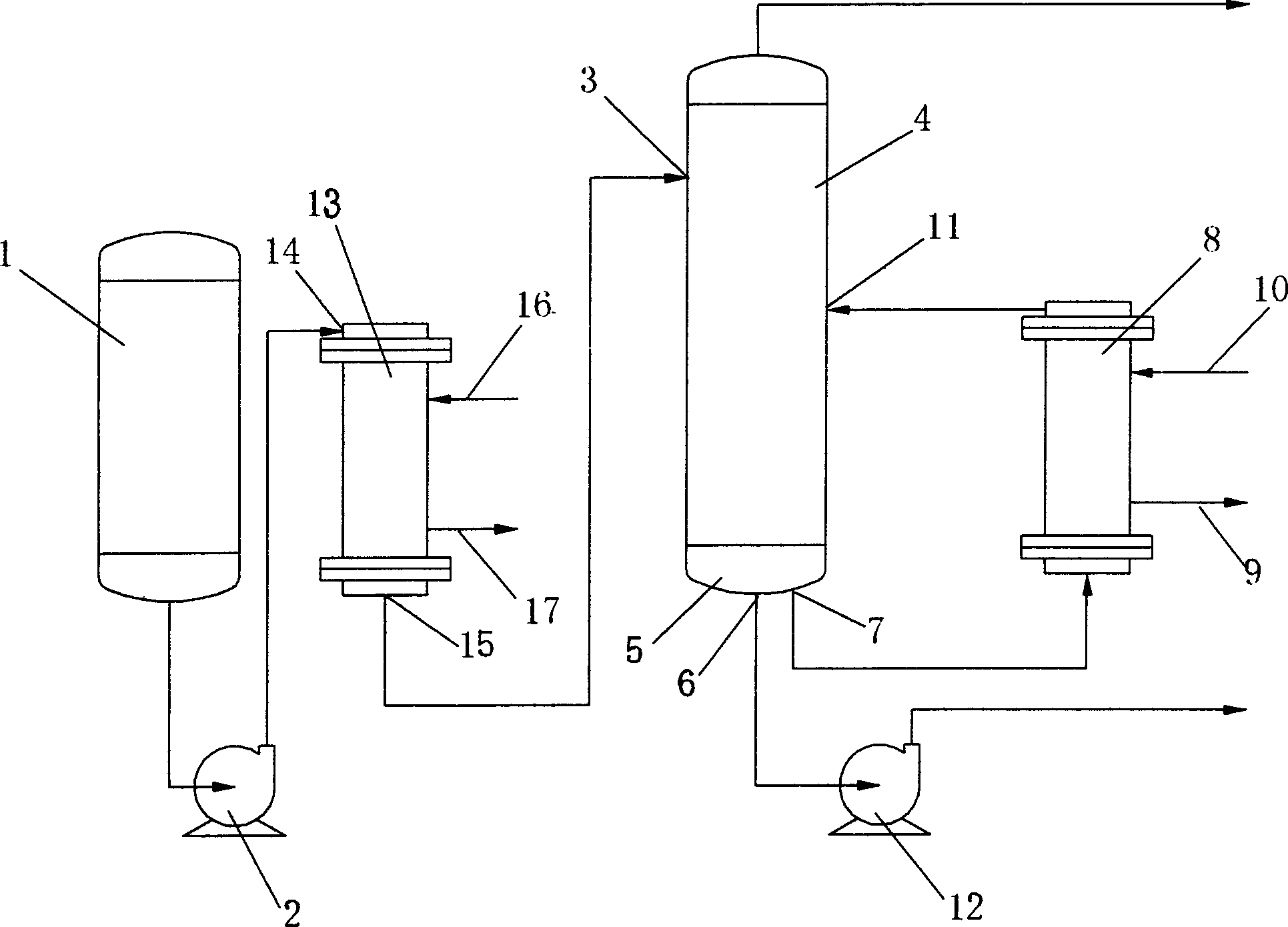

Treatment method of dehydration in ethylene glycol production

InactiveCN1807375ASlow down the speed of cokingExtended service lifeHydroxy compound separation/purificationChemistryReboiler

The invention discloses a method for dewatering treatment in glycol preparation. Wherein, heating the concentrated glycol aqueous solution obtained from multi-effect evaporation system in a preheater to its bubble point or higher; in dewatering tower, taking dewater treatment. This invention solves the problems of reboiler coking, prolongs service lifetime, and can increase the tower load more than 30% by adding a little piece of devices.

Owner:CHINA HUANQIU CONTRACTING & ENG CO LTD

Catalytic gasoline deep hydrodesulfurization method

ActiveCN103059965AAchieve pre-separationLow investment costTreatment with hydrotreatment processesAlkali freeHydrodesulfurization

The invention discloses a catalytic gasoline deep hydrodesulfurization method. The method comprises: adjusting the operating conditions of a catalytic device fractionating tower, adding a lateral line, adopting an appropriate cutting point to conduct cutting so as to obtain FCC (fluid catalytic cracking) gasoline light fractions at the tower top and FCC heavy fractions at the lateral line; subjecting FCC gasoline light fractions to alkali-free deodorization, and then separating light gasoline and medium gasoline through a hydrogenation prefractionator; and carrying out moderate selective hydrogenation on the medium gasoline, performing deep selective hydrogenation on the heavy gasoline, and mixing the obtained two parts of refined distillate oil with the light gasoline subjected to alkali-free deodorization, thus obtaining a clean gasoline product or a blending component. Compared with the existing catalytic gasoline hydrodesulfurization technologies, the method provided in the invention can significantly reduce equipment energy consumption, the gasoline octane number loss is small, the obtained gasoline product quality can meet the quality requirement for a sulfur content of less than 10 micrograms / g, and the economic benefits of oil refining enterprises are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking method of straight-run diesel oil

ActiveCN111607425ASmall crystalsMany orificesCatalytic crackingMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a catalytic cracking method of straight-run diesel oil. The method comprises the following steps that: step 1, an acidic substance is added into the straight-run diesel oil, sothat alkaline nitride removal pretreatment can be carried out; step 2, a ZSM-5 type nano molecular sieve catalyst is put into a reactor so as to perform pretreatment; 3, after pretreatment is finished, the straight-run diesel oil and inert diluent gas are introduced into the reactor at the same time, so that a catalytic cracking reaction is conducted, and low-carbon olefin is generated. The acidic substance is one or two of groups consisting of sodium dihydrogen phosphate and potassium dihydrogen phosphate; and the addition amount of the acidic substance is 1-5% of the mass of the straight-run diesel oil; the inert diluent gas is one or more of groups consisting of nitrogen, helium and argon; and the molar ratio of the straight-run diesel oil to the inert diluent gas is 1: (0.1-1). The catalytic cracking method of the direct-current diesel oil can improve the conversion rate of diesel oil and the yield of low-carbon olefins, and can prolong the one-way period of the catalyst.

Owner:PETROCHINA CO LTD

Method and device for dehydration of glycol by extending coking period of tower-drier reboiler

InactiveCN1557795AExtend the coking cycleIncrease heat loadHydroxy compound separation/purificationPreparation by hydrolysisReboilerPulp and paper industry

The glycol dewatering method for delaying the scaling period of reboiler in drying tower includes the control on the material temperature of drying tower, and features that the glycol solution temperature is 95-130 deg.c. The present invention also provides a glycol dewatering apparatus related to the method for delaying the scaling period of reboiler in drying tower. The method of the present invention can decrease the scaling speed of the reboiler obviously to reduce stop loss, lower cost in descaling, reduce drained sewage and protect environment.

Owner:北京东方石油化工有限公司

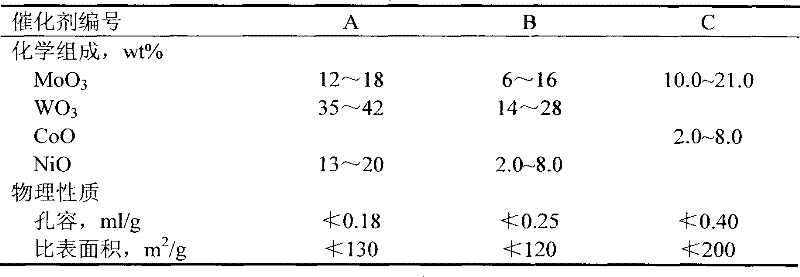

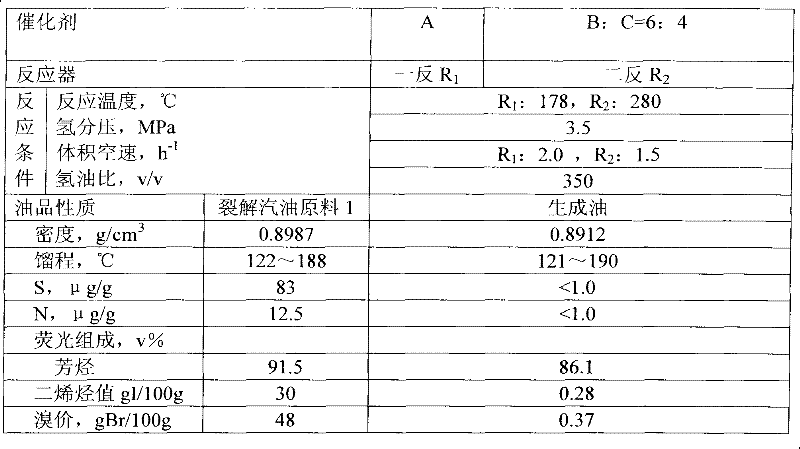

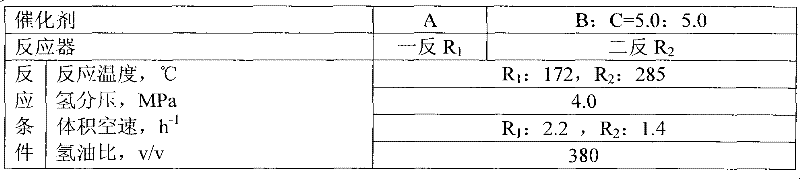

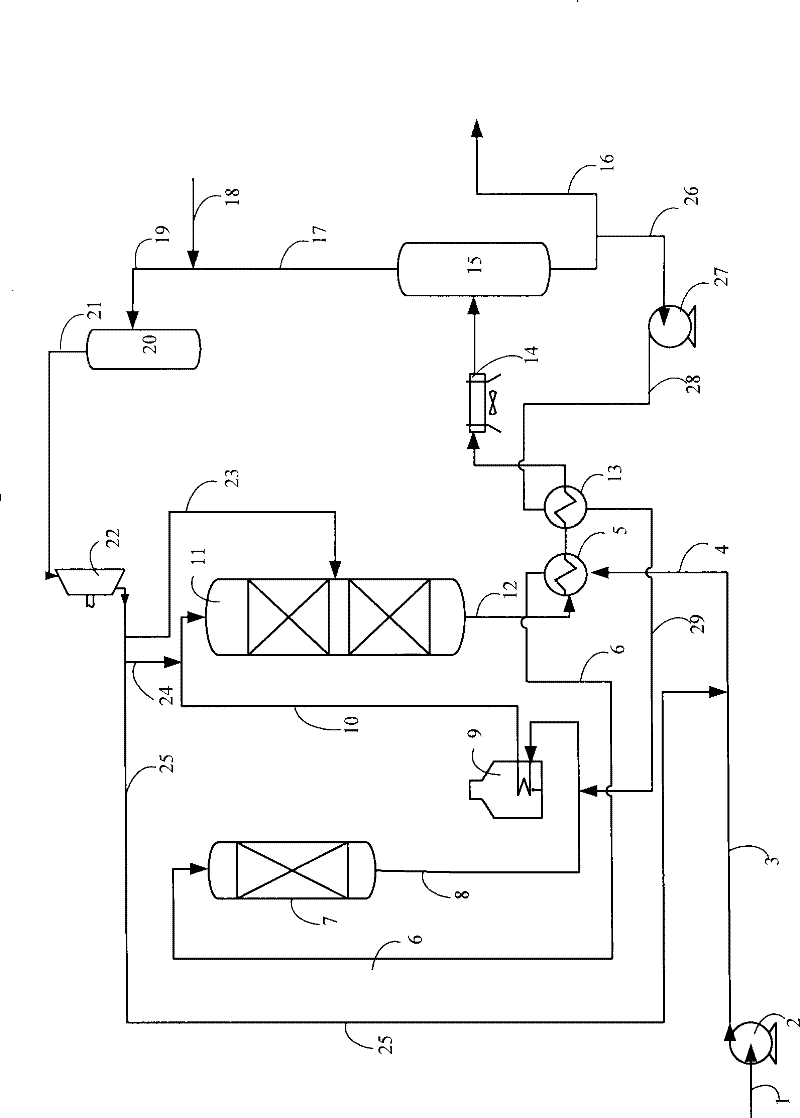

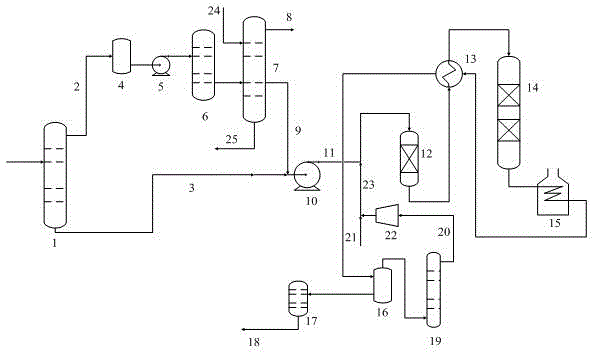

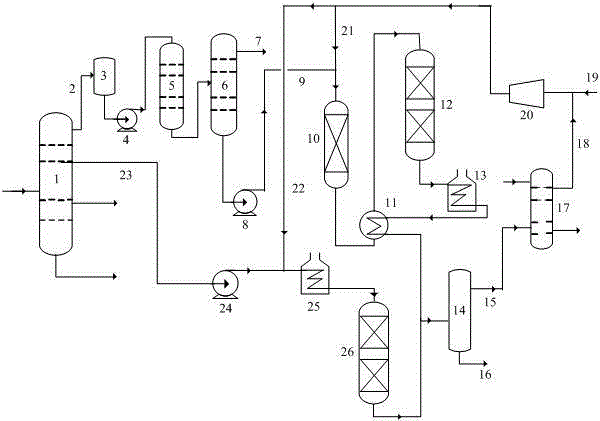

Method for hydrotreatment of heavy fraction of pyrolysis gasoline

ActiveCN101619239BIncrease lossIncrease coking speedTreatment with hydrotreatment processesHydrogenEconomic benefits

The invention relates to a method for hydrotreatment of heavy fraction of pyrolysis gasoline, which adopts the one-section series process flow, and particularly comprises the following steps that: raw materials of the heavy fraction of the pyrolysis gasoline and hydrogen gas are contacted with a first reactor hydrogenation catalyst first under the condition of hydrofining, and the W-Mo-Ni based hydrogenation catalyst with high content of active metal is used in the first reactor; and the product flowed out of the first reactor directly enters a second reactor to be contacted with two hydrogenation catalysts in the second reactor, the reaction materials are contacted with the W-Mo-Ni based hydrogenation catalyst first and then the Mo-Co based hydrogenation catalyst, and the reaction products are subjected to the separating treatment. Aiming at the pyrolysis gasoline C9 to C10 fractions which are difficultly treated by petrochemical enterprises, the economic benefits are improved by adopting the method; moreover, the method also has the advantages of simple process flow, stable operation and good product property, and the hydrogenation device used in the method can be newly built or improved from the old hydrogenation device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation and refining method of gasoline with poor quality

ActiveCN101591565BThe method flow is simpleEasy and flexible operationTreatment with hydrotreatment processesSolventPoor quality

The invention discloses a hydrogenation and refining method of gasoline with poor quality, comprising the following steps: the base oil of gasoline contacts and reacts with hydrogenation protective agent at low temperature; after reaction effluent is mixed with circulation oil, the mixture sequentially contacts and reacts with hydrogenation desilication solvent and hyrorefining catalyst at high temperature; the reaction product is cooled and separated to obtain hydrogen-rich gas and refined gasoline fraction; and parts of refined gasoline fraction serves as circulation oil to return to the outlet of a first hydrogenation reaction area. The method can handle coker gasoline with high content of sulphur, nitrogen and olefin, and refined gasoline fraction can satisfy charging requirements of reforming pre-hydrogenation devices and steam cracking ethene preparing devices. The method of the invention can effectively slow coking speed of heating furnace tubes, greatly lowers pressure drop generation frequency of a main hydrogenation reactor, improves the operating severity of the main hydrogenation reactor and retards the deactivation speed of catalyst at the bottom of a refined reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing aromatic hydrocarbons and light oil through catalytic conversion of straight-run diesel oil

ActiveCN111718751AImprove conversion rateImprove one-way cycleMolecular sieve catalystsCatalyst activation/preparationCatalytic transformationMolecular sieve

The invention provides a method for preparing aromatic hydrocarbons and light oil through catalytic conversion of straight-run diesel oil. The method comprises the following steps: 1) carrying out analkaline nitride removal pretreatment on straight-run diesel oil to obtain straight-run diesel oil without alkaline nitride; and 2) performing a catalytic conversion reaction on the straight-run diesel oil without alkaline nitride by taking a transition metal ion modified nano ZSM-5 molecular sieve catalyst as a reaction catalyst to obtain aromatic hydrocarbons and light oil. Straight-run diesel oil without alkaline nitride is used as a reaction raw material, and a modified nano ZSM-5 molecular sieve is used as a catalyst to carry out a catalytic conversion reaction; the activity of the catalyst is high, the reactions are more efficient, the conversion rate of diesel macromolecules is increased, the yield of aromatic hydrocarbons is increased, the generation of dry gas (byproduct) is inhibited, the coking speed of the catalyst is slowed down, and the one-way period is prolonged.

Owner:PETROCHINA CO LTD +1

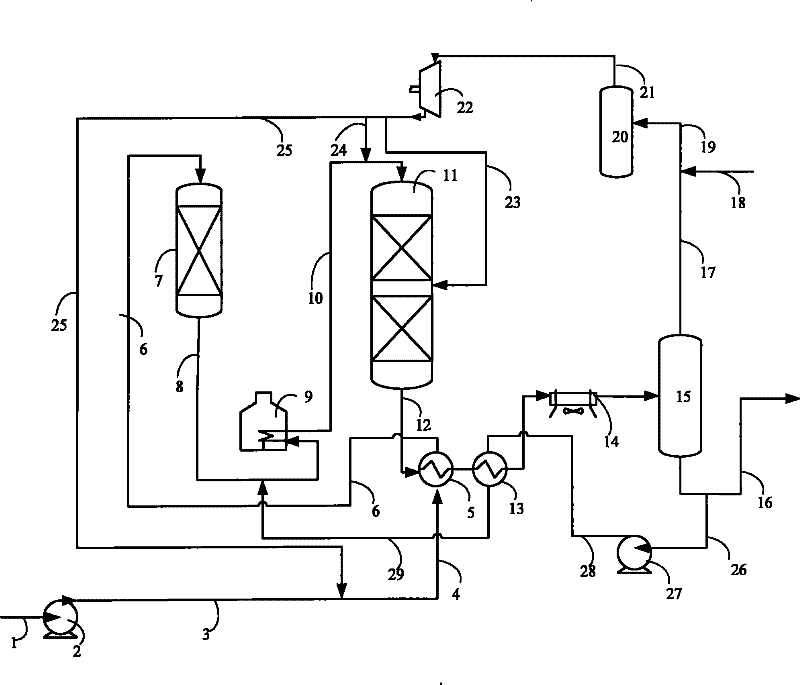

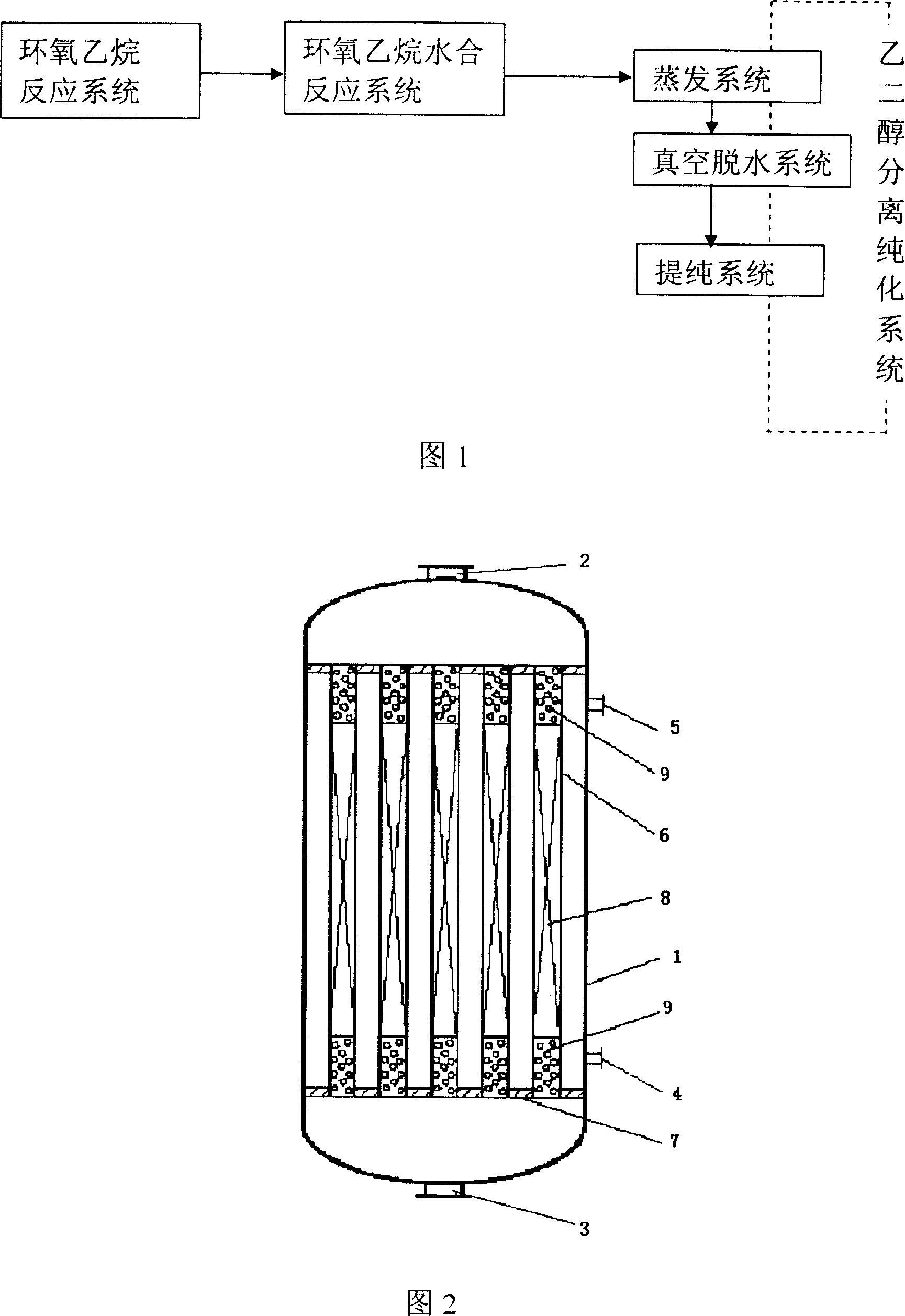

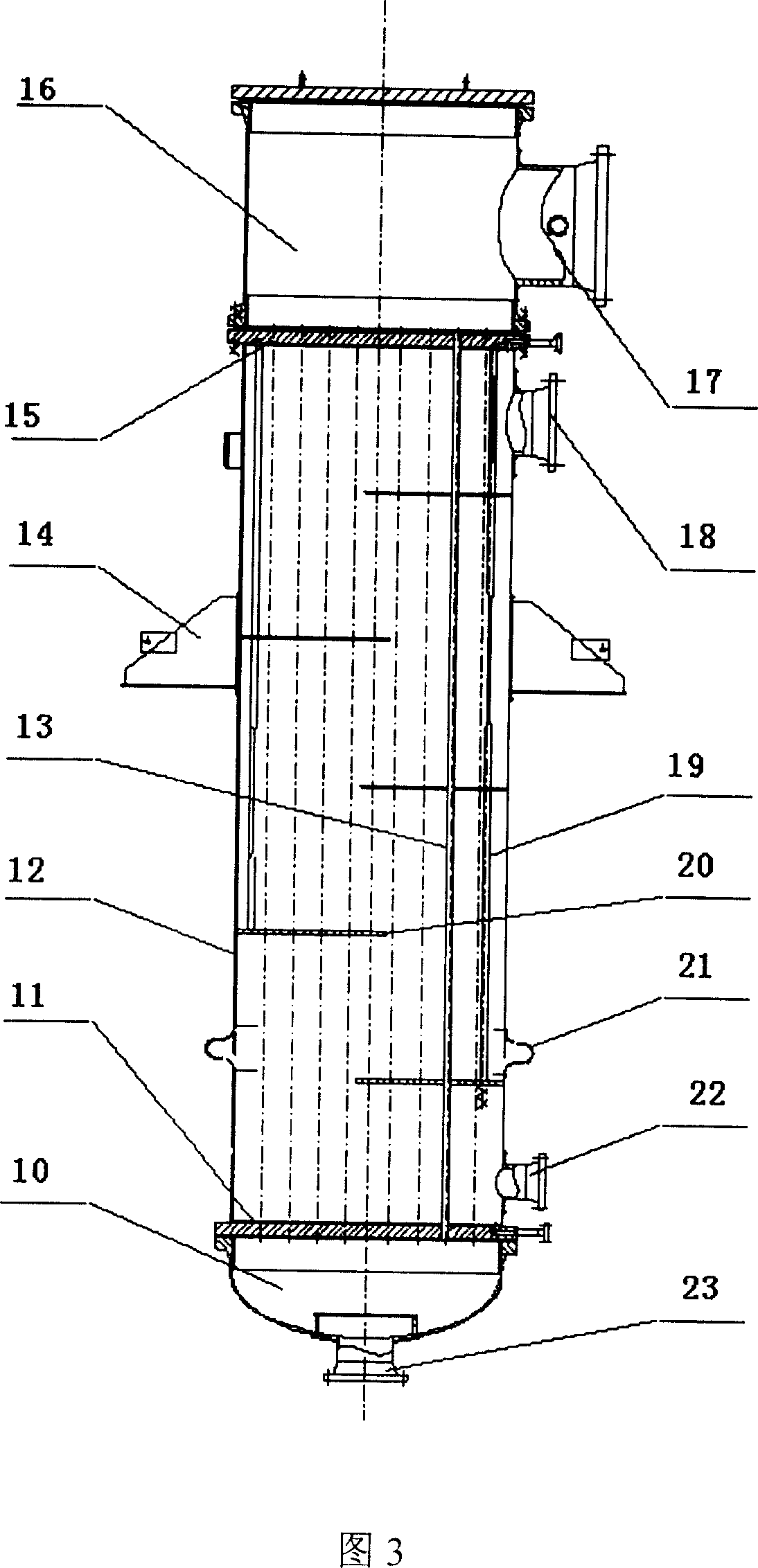

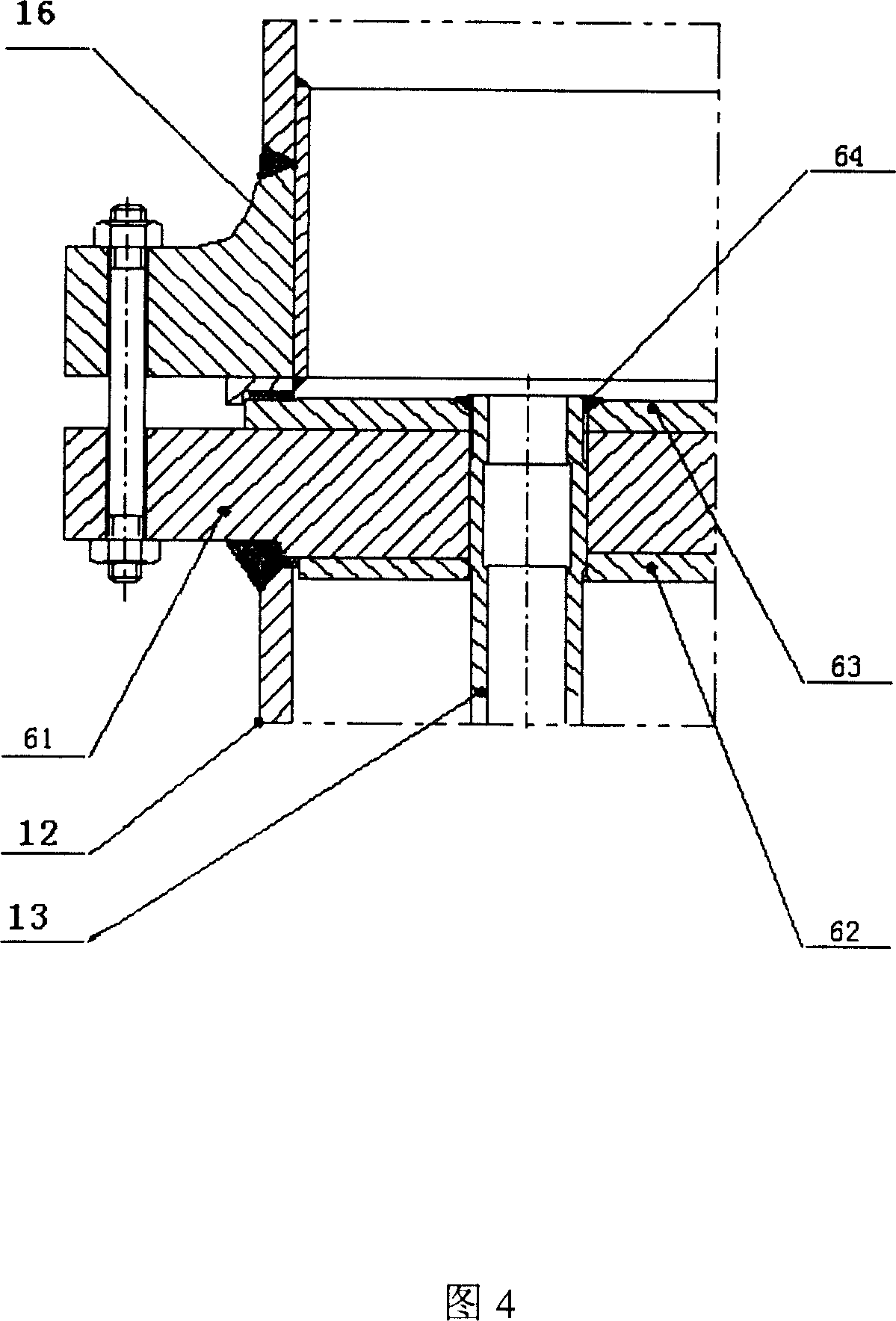

System for preparing ethylene glycol from ethane via epoxyethane

The invention provides a system to prepare glycol, which comprises: an oxirane reaction system with a tube-row fixed bed reactor with the tube size within 40~50mm, an oxirane hydration reaction system, a glycol evaporation system with a multi-effect evaporator system in series and a heat exchanger with low-pressure steam as heat source, and a vacuum dewatering system with a pre-heater arranged in front of the tower to heat the feeding solution to or more than its bubble point temperature; Wherein, the reboiler in the evaporation system has tube plate as dual-face composite structure steel plate, basic material layer as carbon steel, tube side composite layer as Monel alloy, and shell side composite layer as stainless steel. This invention takes small land, needs low investment, solves effectively the corrosion protection and coking problems for device, and has well economic benefit.

Owner:CHINA HUANQIU CONTRACTING & ENG CO LTD

Treatment method of dehydration in ethylene glycol production

InactiveCN100357239CSolve cokingSlow down the speed of cokingHydroxy compound separation/purificationReboilerEvaporation

The invention discloses a method for dewatering treatment in glycol preparation. Wherein, heating the concentrated glycol aqueous solution obtained from multi-effect evaporation system in a preheater to its bubble point or higher; in dewatering tower, taking dewater treatment. This invention solves the problems of reboiler coking, prolongs service lifetime, and can increase the tower load more than 30% by adding a little piece of devices.

Owner:CHINA HUANQIU CONTRACTING & ENG CO LTD

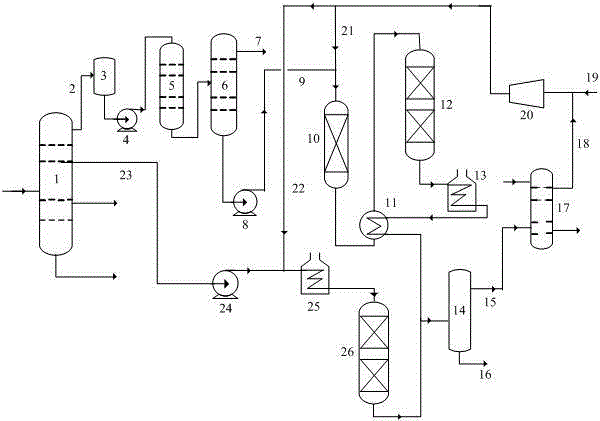

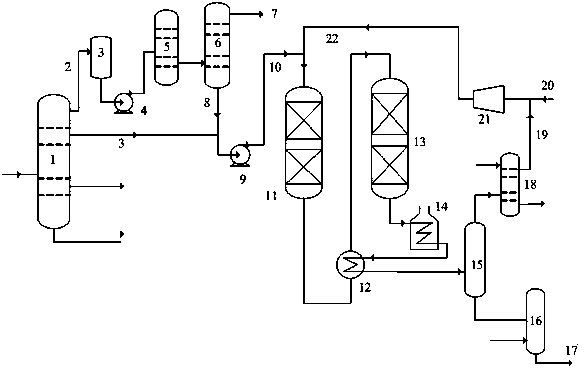

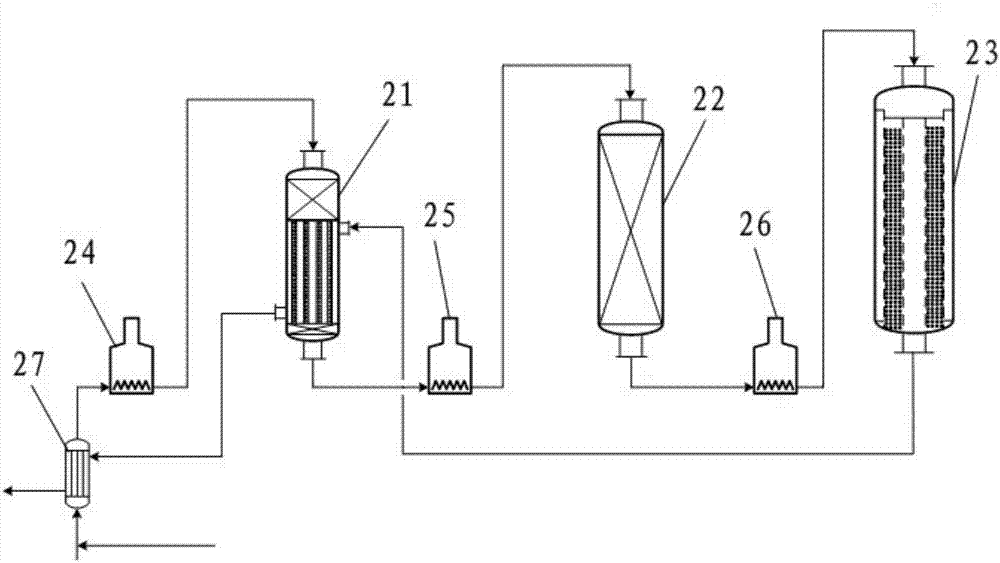

Catalytic cracking and catalytic gasoline hydrogenation combined technological method

ActiveCN103059951BLow investment costLow operating costTreatment with hydrotreatment processesAlkali freeHydrodesulfurization

The invention discloses a catalytic cracking and catalytic gasoline hydrogenation combined technological method. The method comprises: adjusting the operating conditions of a FCC (fluid catalytic cracking) device fractionating tower, conducting cutting pre-separation on FCC gasoline in the fractionating tower so as to obtain light fractions and heavy fractions; subjecting the light fractions to alkali-free deodorization, then letting the deodorized light fractions and thermocatalytic diesel oil enter a hydrogenation prefractionator together, thus obtaining light gasoline at the tower top and medium gasoline at a tower middle lateral line, mixing the medium gasoline with the heavy fractions, then passing the mixture through a hydrogenation protection reactor and a hydrodesulfurization reactor in order, and mixing the obtained refined product with the deodorized refined light gasoline so as to obtain a clean gasoline product. With the method provided in the invention, the equipment energy consumption is significantly reduced, the gasoline octane number loss is small, gasoline product quality can meet the quality requirement of a sulfur content of less than 10 micrograms / g, and the economic benefits of oil refining enterprises are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for producing aromatics and light oil by catalytic conversion of straight-run diesel oil

ActiveCN111718751BImprove conversion rateImprove one-way cycleMolecular sieve catalystsCatalyst activation/preparationCatalytic transformationMolecular sieve

Owner:PETROCHINA CO LTD +1

Catalytic gasoline deep hydrodesulfurization method

ActiveCN103059965BAchieve pre-separationLow investment costTreatment with hydrotreatment processesAlkali freeHydrodesulfurization

The invention discloses a catalytic gasoline deep hydrodesulfurization method. The method comprises: adjusting the operating conditions of a catalytic device fractionating tower, adding a lateral line, adopting an appropriate cutting point to conduct cutting so as to obtain FCC (fluid catalytic cracking) gasoline light fractions at the tower top and FCC heavy fractions at the lateral line; subjecting FCC gasoline light fractions to alkali-free deodorization, and then separating light gasoline and medium gasoline through a hydrogenation prefractionator; and carrying out moderate selective hydrogenation on the medium gasoline, performing deep selective hydrogenation on the heavy gasoline, and mixing the obtained two parts of refined distillate oil with the light gasoline subjected to alkali-free deodorization, thus obtaining a clean gasoline product or a blending component. Compared with the existing catalytic gasoline hydrodesulfurization technologies, the method provided in the invention can significantly reduce equipment energy consumption, the gasoline octane number loss is small, the obtained gasoline product quality can meet the quality requirement for a sulfur content of less than 10 micrograms / g, and the economic benefits of oil refining enterprises are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking and catalytic gasoline hydrogenation combined process

ActiveCN103059958BLow investment costLow operating costTreatment with hydrotreatment processesAlkali freeSulfur

Owner:CHINA PETROLEUM & CHEM CORP +1

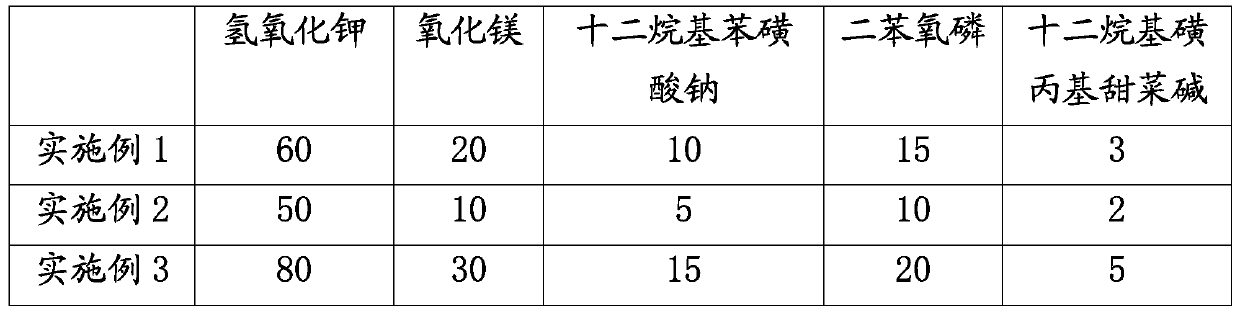

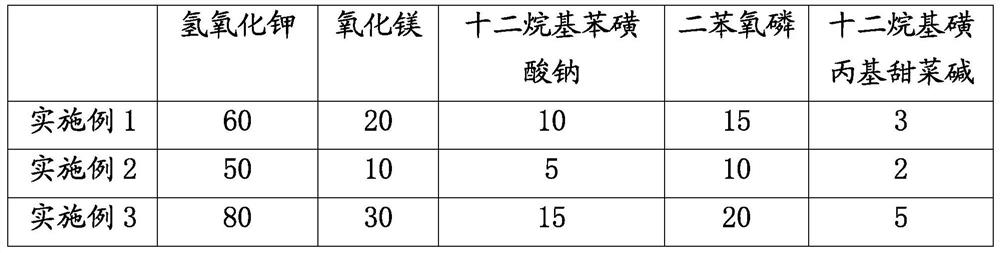

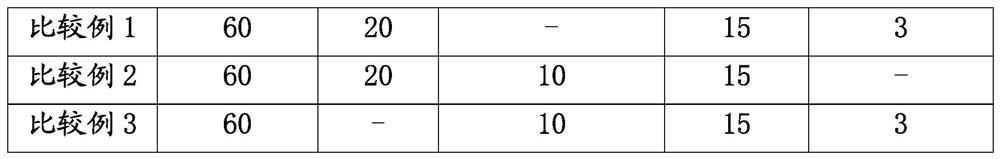

Coking inhibitor

ActiveCN109762601AAvoid condensationInhibition of polymerizationTreatment apparatus corrosion/fouling inhibitionAcid valueAcid corrosion

The invention provides a coking inhibitor capable of retarding the coking of a furnace tube, filler and a heat exchanger in the distillation process of waste oil and effectively prolonging the on-stream time. The coking inhibitor is fully utilized to soften coke blocks, inhibit condensation and polymerization of condensed aromatics, and prevent or reduce the formation of coking materials; after the product is added in the atmospheric and vacuum distillation process, an acid value is effectively reduced and acid corrosion of equipment is controlled; the coking speed is greatly reduced, and theon-stream time is prolonged, i.e., monthly maintenance is prolonged to three-month maintenance once, so that production days are increased, the input of maintenance cost is reduced and direct economicbenefits are brought for a factory.

Owner:湖北大江润业再生资源有限公司

Deep hydrodesulfurization method for catalytic gasoline

ActiveCN103059956BAchieve pre-separationLow investment costTreatment with hydrotreatment processesAlkali freeHydrodesulfurization

The invention discloses a deep hydrodesulfurization method for catalytic gasoline. The method comprises: adjusting the operating conditions of a catalytic device fractionating tower, adding a lateral line, and adopting an appropriate cutting point to perform cutting so as to obtain light fractions at the tower top and heavy fractions at the lateral line; subjecting the light fractions to alkali-free deodorization, then passing the deodorized light fractions through a hydrogenation prefractionator to separate light gasoline and medium gasoline; and subjecting the separated medium gasoline and the heavy fractions to selective hydrogenation, and mixing the refined product with the light gasoline subjected to alkali-free deodorization, thus obtaining a clean gasoline product or a blending component. Compared with the existing catalytic gasoline hydrodesulfurization technologies, the method provided in the invention has the advantages that: the equipment energy consumption is significantly reduced, the gasoline octane number loss is small, the gasoline product quality can meet the quality requirement for a sulfur content of less than 10 micrograms / g, and the economic benefits of oil refining enterprises are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of catalytic gasoline hydrodesulfurization method

ActiveCN103059945BAchieve pre-separationLow investment costTreatment with hydrotreatment processesHydrodesulfurizationGasoline

The invention discloses a catalytic gasoline hydrodesulfurization method. The method comprises: adjusting the operating conditions of a catalytic device fractionating tower, adding a lateral line, and adopting an appropriate cutting point to perform cutting so as to obtain gasoline light fractions at the tower top and gasoline heavy fractions at the lateral line; subjecting the light fractions to alkali extraction, carrying out selective hydrodesulfurization on the heavy fractions, and mixing the obtained refined oil with the light gasoline generated by alkali extraction, thus obtaining a clean gasoline product or a blending component. Compared with the existing catalytic gasoline hydrodesulfurization technologies, the method provided in the invention has the advantages that: the equipment energy consumption is significantly reduced, the gasoline octane number loss is small, the gasoline product quality can meet the quality requirement for a sulfur content of less than 10 micrograms / g, and the economic benefits of oil refining enterprises are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low energy consumption catalytic gasoline hydrodesulfurization method

ActiveCN103059946BAchieve pre-separationLow investment costTreatment with hydrotreatment processesHydrodesulfurizationProcess engineering

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for catalytic gasoline deep hydrodesulfurization

ActiveCN103805269BReduce sulfur contentEliminates the problem of abnormally rapid rise in pressure dropTreatment with hydrotreatment processesAlkali freeHydrodesulfurization

The invention discloses a method used for catalytic gasoline deep hydrodesulfurization. The method comprises following steps: catalytic gasoline is delivered into a prefrationation tower firstly; an appropriate separation point is adopted, light gasoline fraction and middle gasoline fraction are discharged through the top of the prefrationation tower, and heavy gasoline fraction is discharged through the bottom of the prefrationation tower; the light gasoline fraction and the middle gasoline fraction are subjected to alkali-free deodorization, and are delivered into a hydrogenation prefrationation tower so as to separate light gasoline and middle gasoline, wherein catalytic cracking hot diesel oil extracted from a main fractionate tower side line is also delivered into the hydrogenation prefrationation tower; separated middle gasoline and heavy gasoline are mixed, and are subjected to selective hydrogenation, and an obtained distillate is mixed with light gasoline obtained via alkali-free deodorization so as to obtain clean gasoline products. Compared with existing catalytic gasoline hydrodesulfurization method, the method and equipment of the invention is capable of reducing energy consumption greatly, octane value loss of the gasoline products is less, sulfur content of the gasoline products is less than 10<mu>g / g, and economic benefits of oil refining enterprises are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

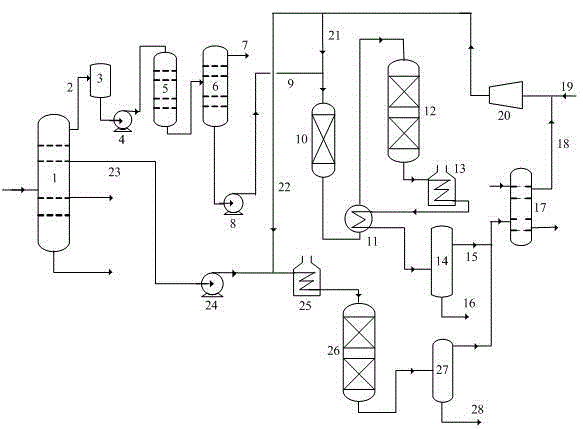

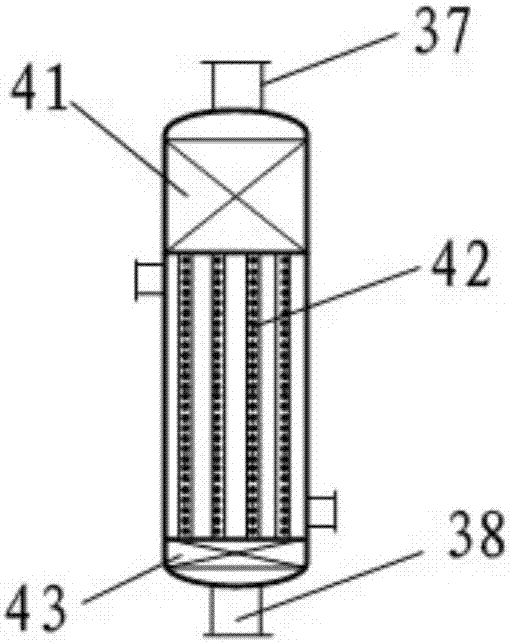

A semi-regenerative catalytic reforming reaction system and method

ActiveCN105623716BIncrease temperatureImprove operational efficiencyCatalytic naphtha reformingHydrocarbon oils treatment productsCatalytic reformingFixed bed

A semi-regeneration catalytic reforming reaction system comprises at least one combined bed reactor and a fixed bed reactor connected with the combined bed reactors in series.Each combined bed reactor is formed by combination of a fixed bed and a tube nest type fixed bed catalyst bed, wherein in the tube nest type fixed bed catalyst bed, the outlet material flow of the follow-up fixed bed reactor makes indirect contact with the reaction material flow of the combined bed reactor and heat is provided.The invention further provides a catalytic reforming method adopting the system.The problem that the operation efficiency of a reforming reaction system is hard to improve due to the limitation of the regeneration period of a catalyst of a final reactor can be well solved, and the reforming reaction system is made to obtain higher operation benefits.

Owner:石玉林

Coke retarder

ActiveCN109762601BAvoid condensationInhibition of polymerizationTreatment apparatus corrosion/fouling inhibitionAcid corrosionCoke

Owner:湖北大江润业再生资源有限公司

A kind of method of catalytic cracking of straight-run diesel oil

ActiveCN111607425BSmall crystalsMany orificesCatalytic crackingMolecular sieve catalystsPtru catalystPhosphate

The invention discloses a method for catalytic cracking of straight-run diesel oil. The method comprises the following steps: step 1, adding acidic substances to straight-run diesel oil to perform pretreatment for removing basic nitrogen compounds; step 2, adding ZSM-5 nanometer molecular sieve The catalyst is put into the reactor for pretreatment; step 3, after the pretreatment is completed, feed straight-run diesel oil and inert diluent gas into the reactor at the same time to carry out catalytic cracking reaction to generate low-carbon olefins; the acidic substance is diphosphoric acid One or two of the group consisting of sodium hydrogen phosphate and potassium dihydrogen phosphate, the amount of acidic substances added is 1%-5% of the mass of straight-run diesel oil; the inert diluent gas is composed of nitrogen, helium and argon One or more of the groups, the molar ratio of the straight-run diesel to the inert diluent gas is 1:0.1-1. The direct-flow diesel catalytic cracking method of the present invention can increase the conversion rate of diesel oil and the yield of low-carbon olefins, and can prolong the one-way cycle of the catalyst.

Owner:PETROCHINA CO LTD

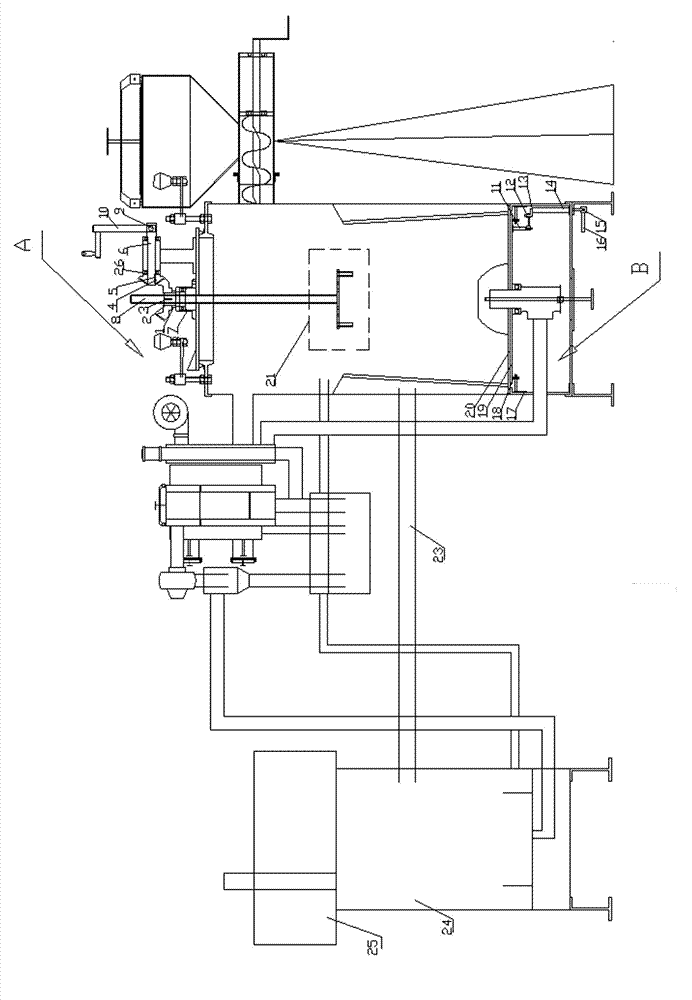

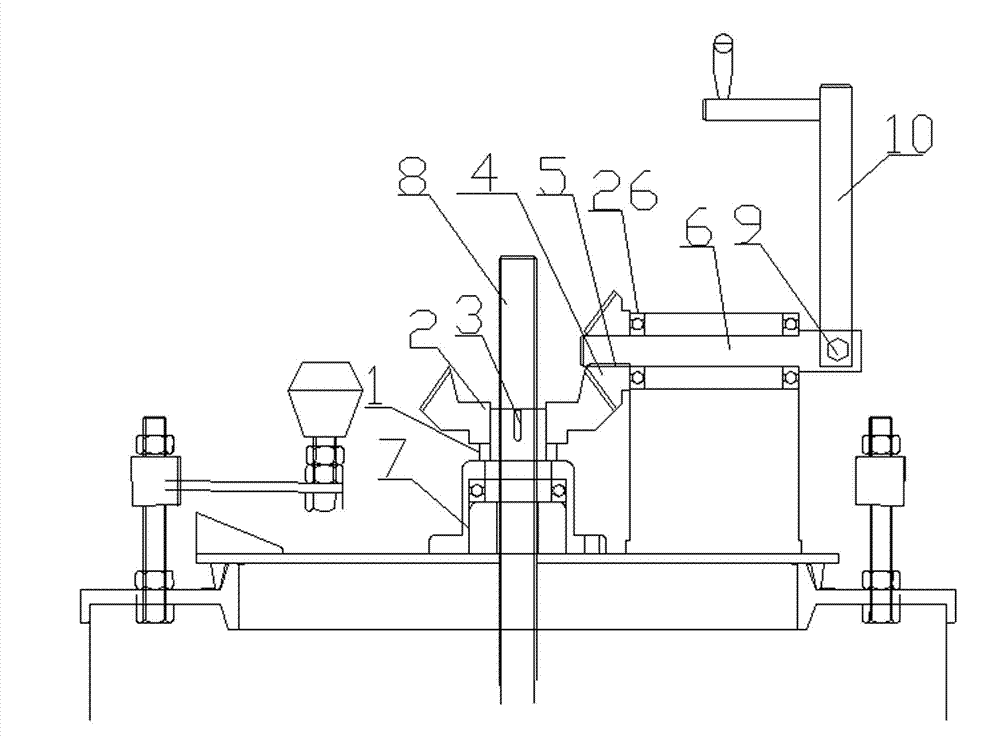

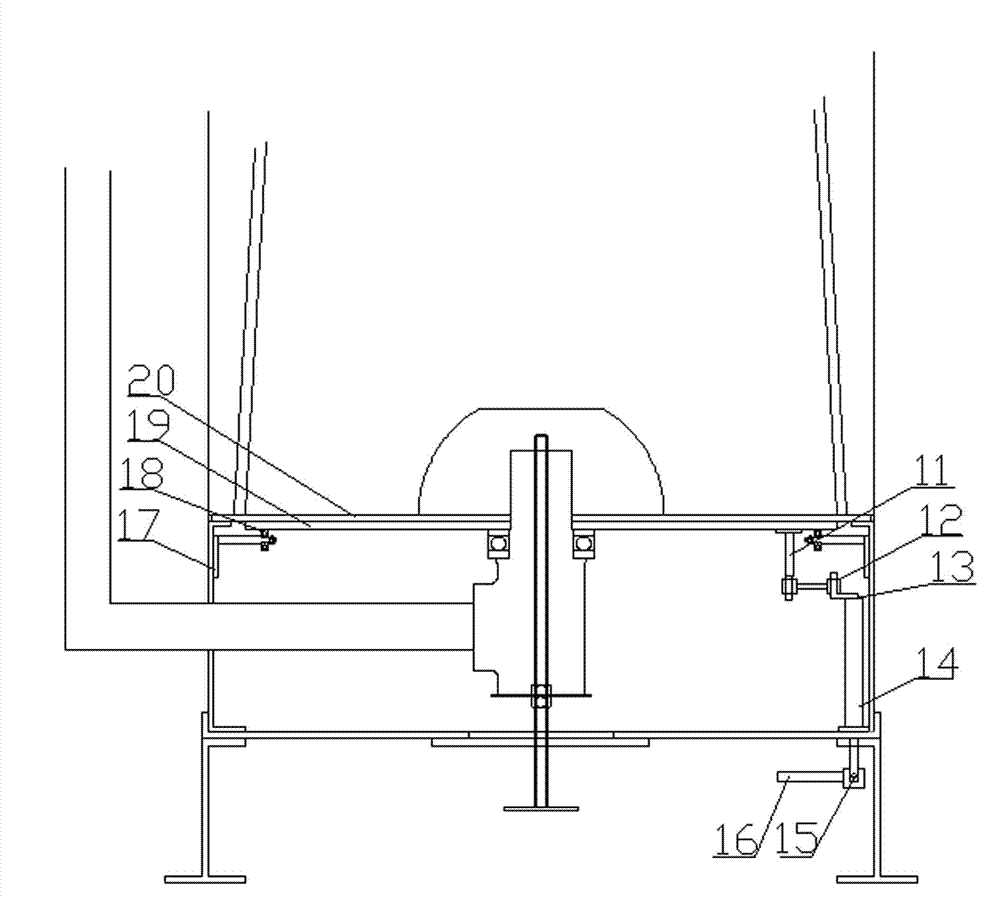

Novel household straw gasification furnace

ActiveCN102374575AIncrease profitSlow down the speed of cokingLighting and heating apparatusCentral heating systemAgricultural engineeringWater circulation

The invention relates to a novel household straw gasification furnace which comprises a pressure device, a flange used for fixing a screw rod, a deashing and decoking block device and a large furnace tooth, a small furnace tooth, a water circulation heating device and a gas-fired boiler of the water circulation heating device, wherein the structure of the pressure device is as follows: a sleeve is sleeved between a first bevel gear and the flange, the first bevel gear and the upper end of the pressure screw rod are fixedly connected, a second bevel gear is fixedly connected with one end of a rocker shaft, and the first bevel gear and the second bevel gear are mutually meshed; and a bearing is arranged behind the second bevel gear on the rocker shaft, the bearing is supported by a bearing base fixed on a furnace top cover, and the other end of the rocker shaft is connected with a rocker. The novel household straw gasification furnace provided by the invention has the advantages that the operation is more simple and convenient through each structure improvement and reconstruction, the using effect is more ideal and stabilized, the thermal efficiency is improved further, thereby also establishing a foundation for realizing automatization.

Owner:程浩德

Catalytic gasoline hydrodesulfurization method

ActiveCN103059950BAchieve pre-separationLow investment costTreatment with hydrotreatment processesHydrodesulfurizationEngineering

The invention discloses a catalytic gasoline hydrodesulfurization method. The method comprises: adjusting the operating conditions of a catalytic device fractionating tower, adding a lateral line, conducting cutting at an appropriate cutting temperature so as to obtain light fractions at the tower top and heavy fractions at the lateral line; subjecting the light fractions to an alkali extraction treatment, and then separating light gasoline and medium gasoline through a hydrogenation prefractionator; and carrying out moderate selective hydrodesulfurization on the medium gasoline, and carrying out deep selective hydrodesulfurization on the heavy gasoline, subjecting the obtained two refined products to gas stripping, and then mixing them with alkali extracted light gasoline, thus obtaining a clean gasoline product. Compared with the existing catalytic gasoline hydrodesulfurization technologies, the method provided in the invention can significantly reduce equipment energy consumption, the gasoline octane number loss is small, the obtained gasoline product quality can meet the quality requirement for a sulfur content of less than 10 micrograms / g, and the economic benefits of oil refining enterprises are substantially improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

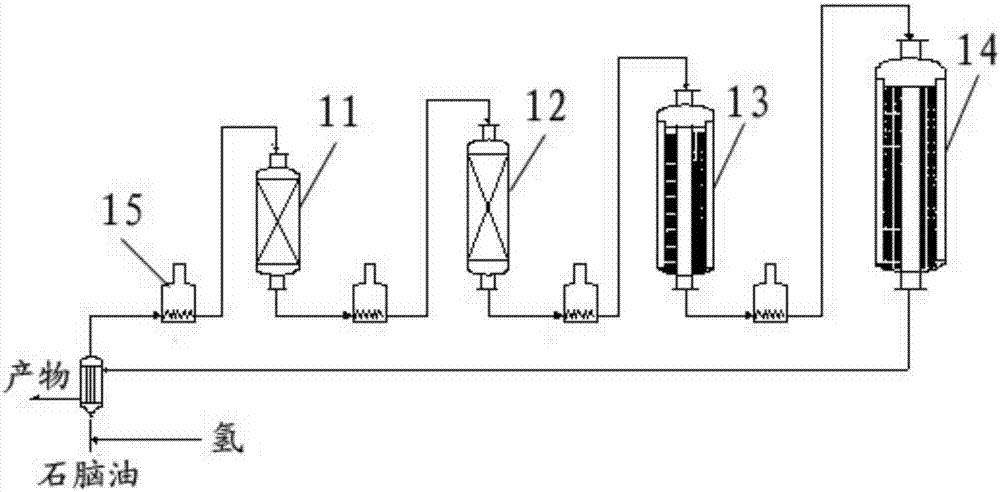

A kind of hydrorefining method of coking gasoline

ActiveCN1990830BThe method flow is simpleEasy and flexible operationRefining to eliminate hetero atomsPresent methodCoke rate

A method for hydrogenation refining of coking gasoline. The raw material oil is mixed with hydrogen and enters the hydrogenation protection reactor to contact with the hydrogenation protection agent. The reaction is carried out under low temperature conditions. The reactor reacts with the hydrorefining catalyst under high temperature conditions, and the reaction product is cooled and separated to obtain hydrogen-rich gas and refined gasoline fraction. The olefin content in the refined gasoline fraction is less than 1% by volume, the sulfur content is less than 300 μg / g, and the nitrogen content is less than 2 μg / g, all of which can meet the feed requirements of reforming prehydrogenation units and steam cracking ethylene units. The method can effectively delay the coking speed of the furnace tube of the heating furnace, greatly reduce the pressure drop generation frequency of the hydrogenation main reactor, and can increase the operating severity of the hydrogenation main reactor.

Owner:CHINA PETROLEUM & CHEM CORP +2

Household straw gasification furnace

ActiveCN102374575BIncrease profitSlow down the speed of cokingLighting and heating apparatusCentral heating systemAgricultural engineeringWater circulation

The invention relates to a novel household straw gasification furnace which comprises a pressure device, a flange used for fixing a screw rod, a deashing and decoking block device and a large furnace tooth, a small furnace tooth, a water circulation heating device and a gas-fired boiler of the water circulation heating device, wherein the structure of the pressure device is as follows: a sleeve is sleeved between a first bevel gear and the flange, the first bevel gear and the upper end of the pressure screw rod are fixedly connected, a second bevel gear is fixedly connected with one end of a rocker shaft, and the first bevel gear and the second bevel gear are mutually meshed; and a bearing is arranged behind the second bevel gear on the rocker shaft, the bearing is supported by a bearing base fixed on a furnace top cover, and the other end of the rocker shaft is connected with a rocker. The novel household straw gasification furnace provided by the invention has the advantages that the operation is more simple and convenient through each structure improvement and reconstruction, the using effect is more ideal and stabilized, the thermal efficiency is improved further, thereby also establishing a foundation for realizing automatization.

Owner:程浩德

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com