Catalytic gasoline hydrodesulfurization method

A technology for catalyzing gasoline and hydrodesulfurization, applied in hydrotreating process, petroleum industry, processing hydrocarbon oil, etc., can solve the problems of poor adaptability of raw material oil, large loss of octane number, etc., to reduce equipment investment and operating costs, The effect of lower energy consumption, lower investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

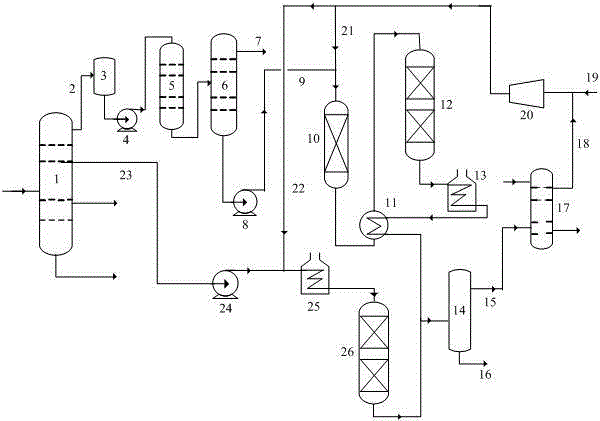

Embodiment 1

[0040] Gasoline is pre-separated in the fractionation tower of the catalytic cracking unit to obtain light fractions and heavy fractions. The division temperature of the light fractions and heavy fractions is 125°C; the light fractions are subjected to alkali extraction, and then enter the hydrogenation pre-fractionation tower for separation. The division temperature of the obtained light gasoline and medium gasoline was 65°C. Among them, the prehydrogenation reaction conditions of the distillate in catalytic gasoline are: hydrogen partial pressure 1.8 MPa, volume space velocity 3.8 h -1 , The reaction temperature is 178°C; the hydrodesulfurization reaction conditions of the distillate in catalytic gasoline are: hydrogen partial pressure 1.6MPa, volume space velocity 3.0h -1 , The reaction temperature is 248°C, the total hydrogen to oil volume ratio is 350:1; the catalytic gasoline heavy fraction hydrodesulfurization reaction conditions are: hydrogen partial pressure 1.7MPa, v...

Embodiment 2

[0043] Gasoline is pre-separated in the fractionation tower of the catalytic cracking unit to obtain light fractions and heavy fractions; the division temperature of the light fractions and heavy fractions is 120°C; the light fractions are subjected to alkali extraction, and then enter the hydrogenation pre-fractionation tower for separation, The division temperature of the obtained light gasoline and medium gasoline is 70°C. Among them, the prehydrogenation reaction conditions of the distillate in catalytic gasoline are: hydrogen partial pressure 2.0MPa, volume space velocity 3.8h -1 , The reaction temperature is 183°C; the hydrodesulfurization reaction conditions of the distillate in catalytic gasoline are: hydrogen partial pressure 1.8MPa, volume space velocity 3.2 h -1 , The reaction temperature is 246°C; the total hydrogen-to-oil volume ratio is 380:1; the catalytic gasoline heavy fraction hydrodesulfurization reaction conditions are: hydrogen partial pressure 1.7MPa, vol...

Embodiment 3

[0046] Gasoline is pre-separated in the fractionation tower of the catalytic cracking unit to obtain light fractions and heavy fractions; the division temperature of the light fractions and heavy fractions is 130°C; the light fractions are subjected to alkali extraction, and then enter the fractions in catalytic gasoline for hydrogenation pre-fractionation The tower is separated, and the cut-off temperature of the obtained light gasoline and medium gasoline is 68°C. Among them, the pre-hydrogenation reaction conditions of the distillate in catalytic gasoline are: hydrogen partial pressure 1.8 MPa, volume space velocity 4.2 h -1 , The reaction temperature is 180°C; the hydrodesulfurization reaction conditions of the distillate in catalytic gasoline are: hydrogen partial pressure 1.6MPa, volume space velocity 3.2 h -1 , The reaction temperature is 252°C; the total hydrogen to oil volume ratio is 320:1; the catalytic gasoline heavy fraction hydrodesulfurization reaction condition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com