Patents

Literature

121results about How to "Evaporate evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

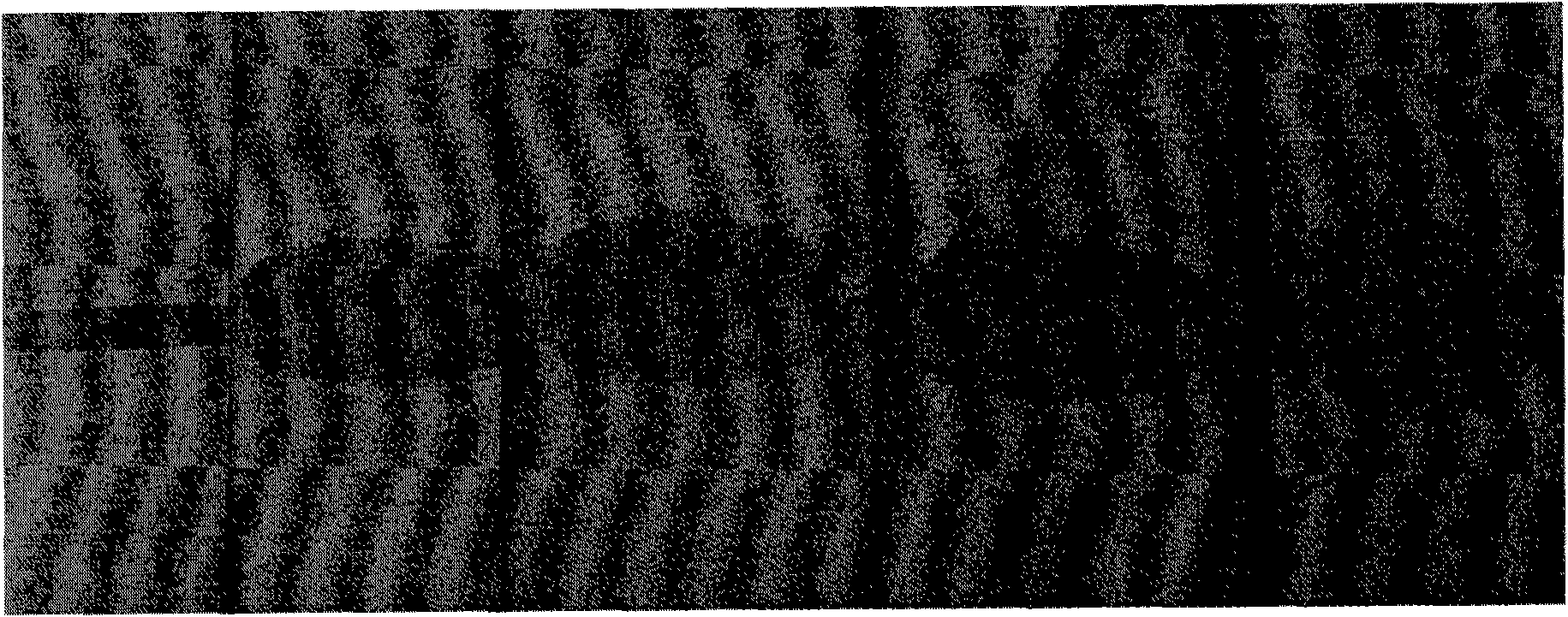

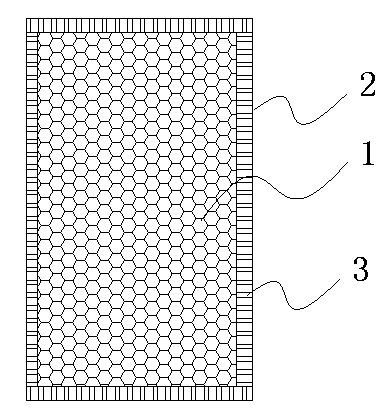

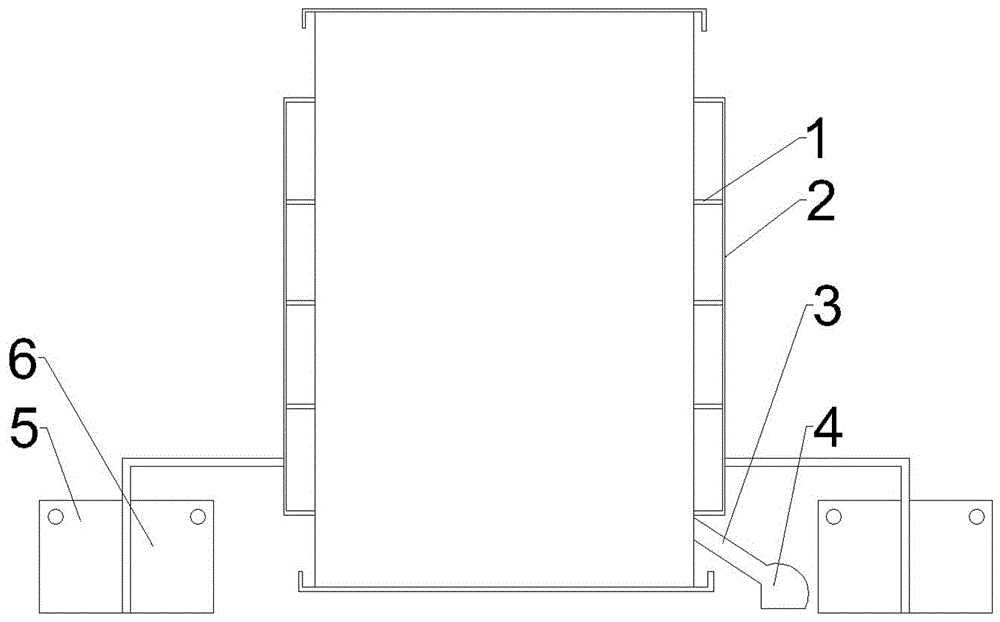

Woven fabric having functions of isomerism on double side, guiding sweat on single direction and rapidly drying and production method thereof

The invention discloses a woven fabric having functions of isomerism on double side, guiding sweat on single direction and rapidly drying and a production method thereof. The front and back sides of the woven fabric of the invention have different hydrophilic and hydrophobic properties; the back side is mainly provided with two or more stranded yarns formed by twisting water-refusing single yarns and hydrophilic single yarns; and the front side is mainly provided with the hydrophilic yarns. The front and back sides of the woven fabric have different hydrophilic and hydrophobic properties so a 'pushing and pulling' effect for water or sweat is generated. The back side of the fabric has hydrophobic property while maintaining a small hydrophilic property, so the water or sweat can be rapidly transmitted to the front side of the fabric and steamed, therefore realizing the function of guiding the sweat on single direction. When user sweats, the fabric is not next to the skin and will dry soon.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

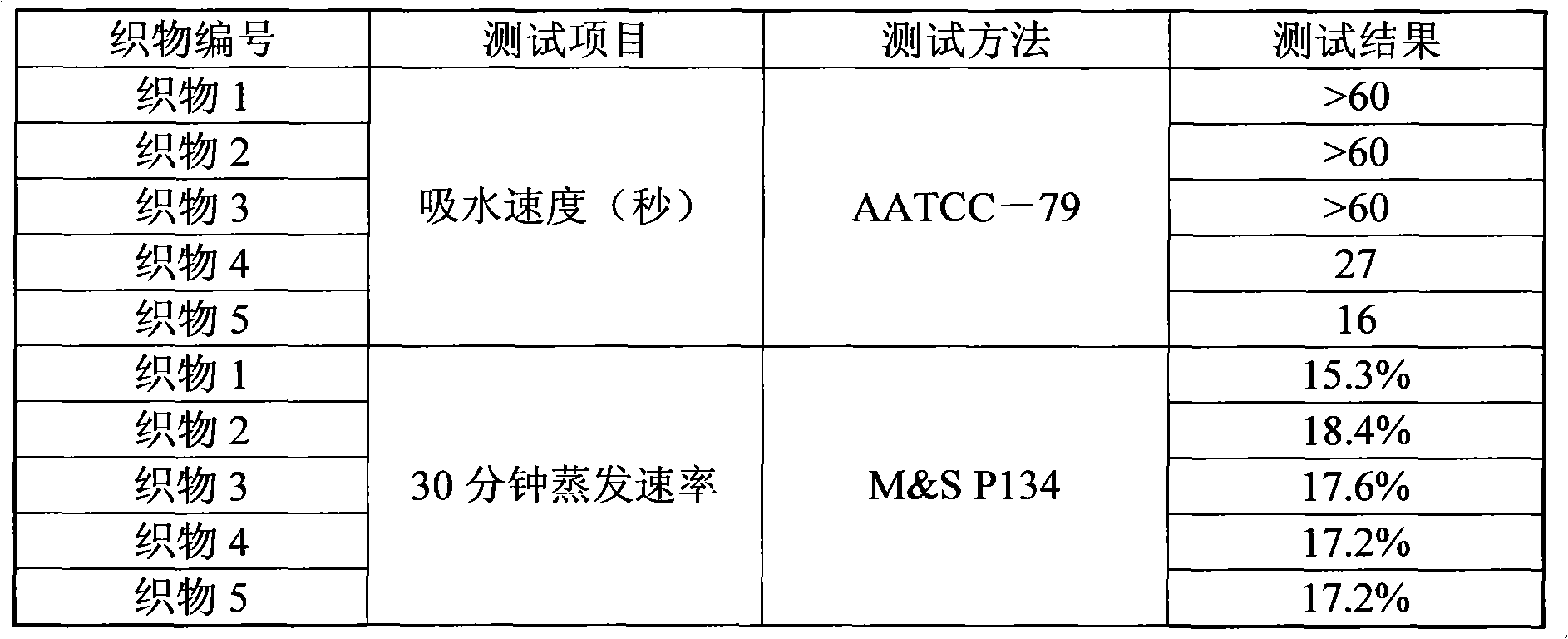

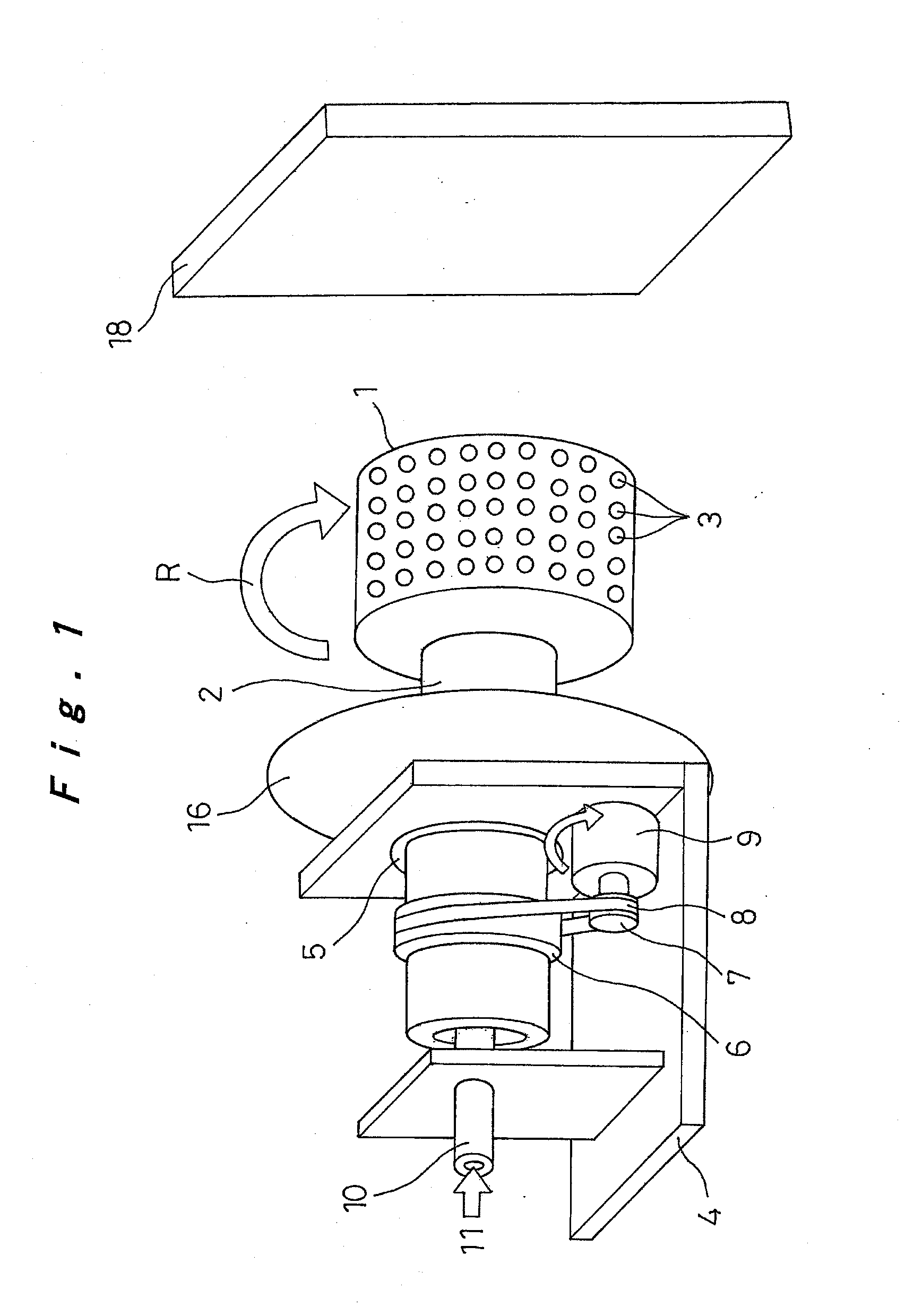

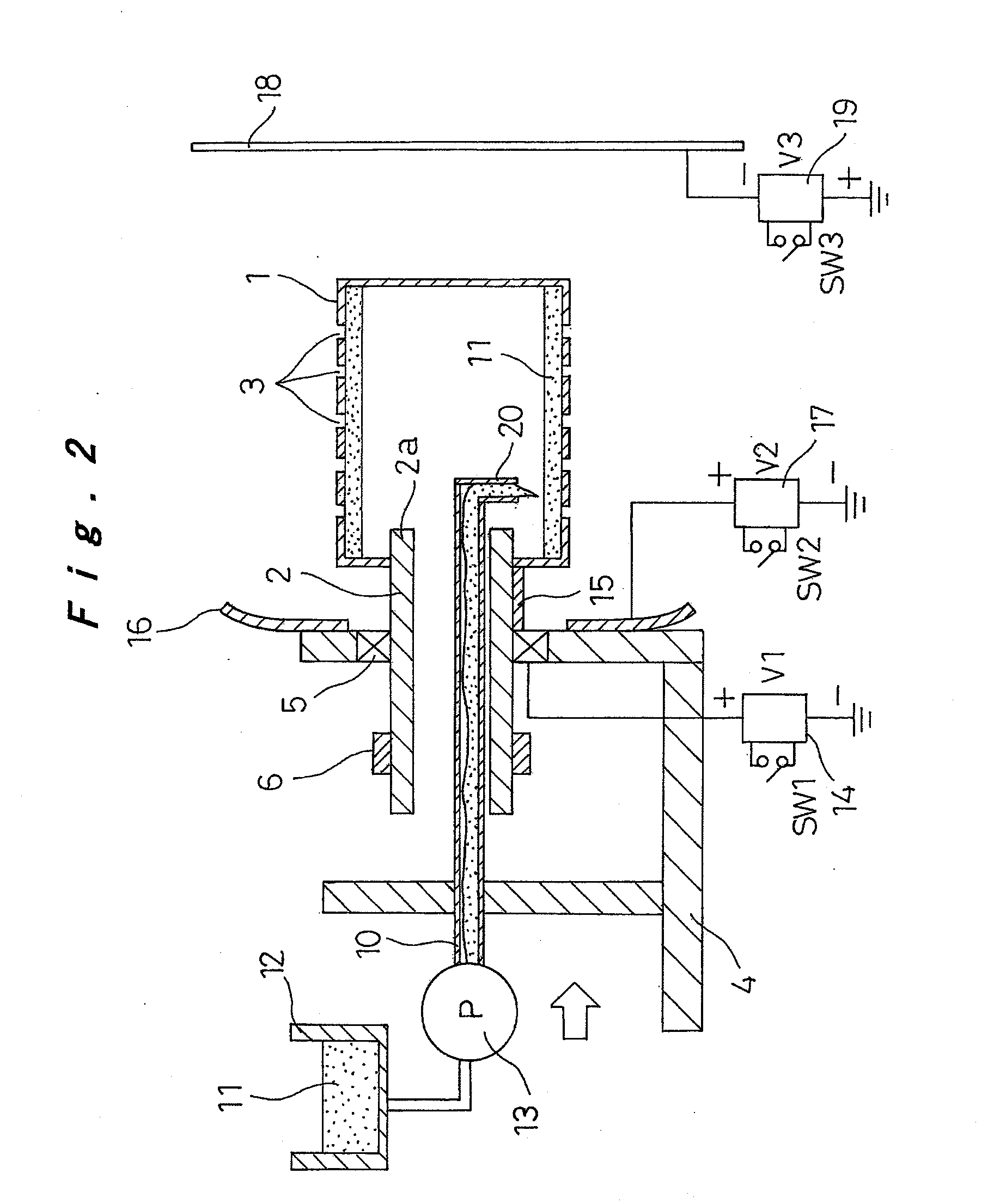

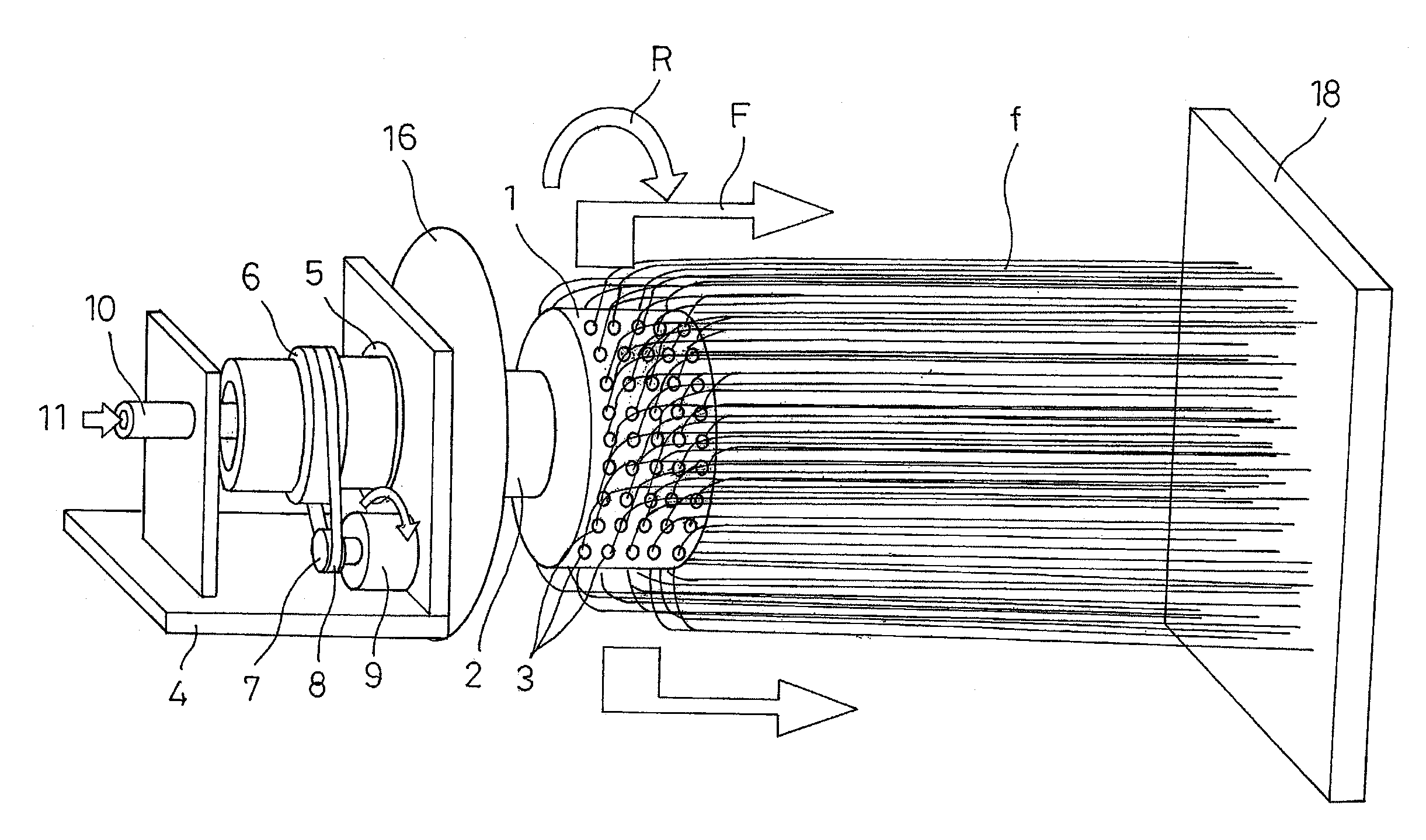

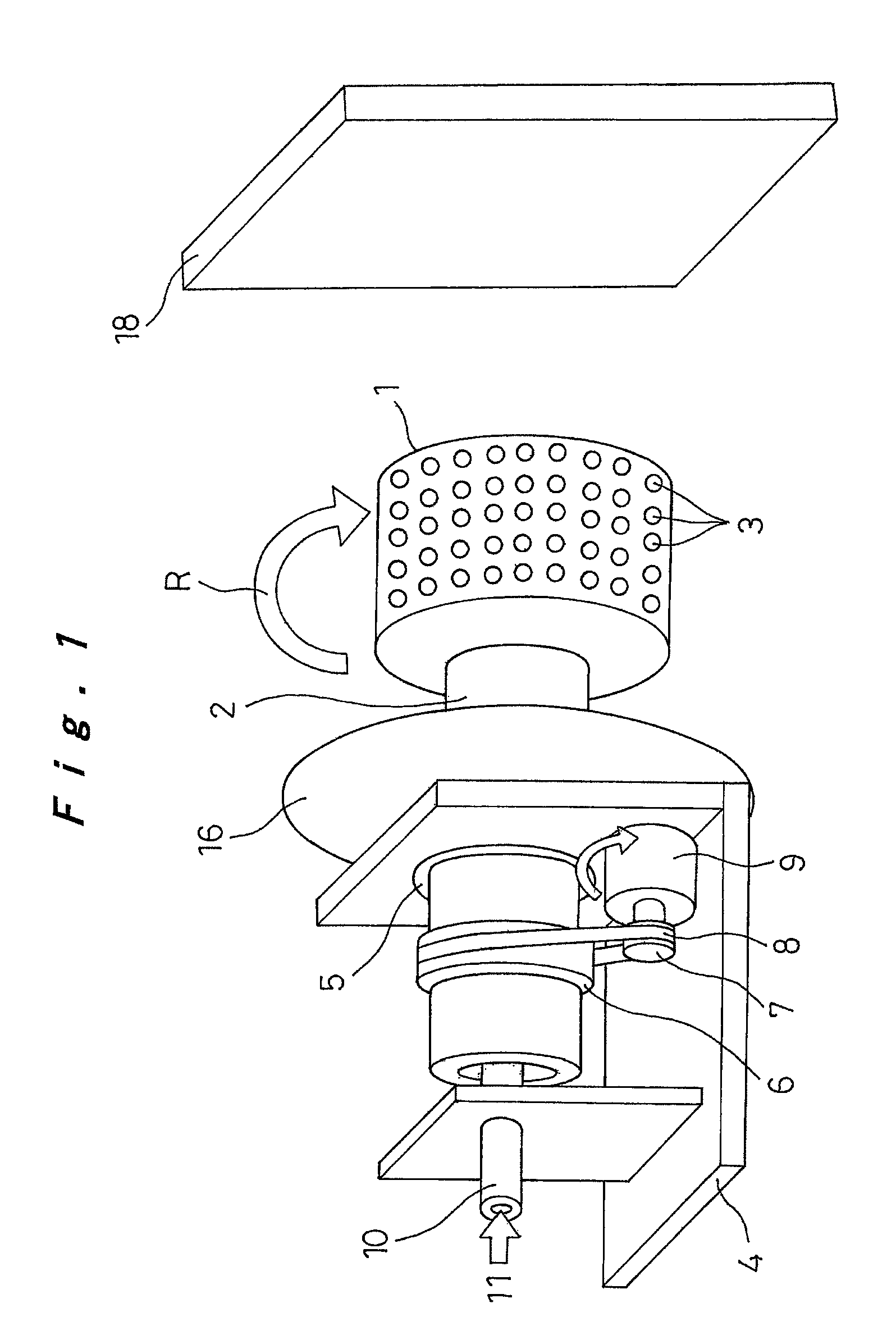

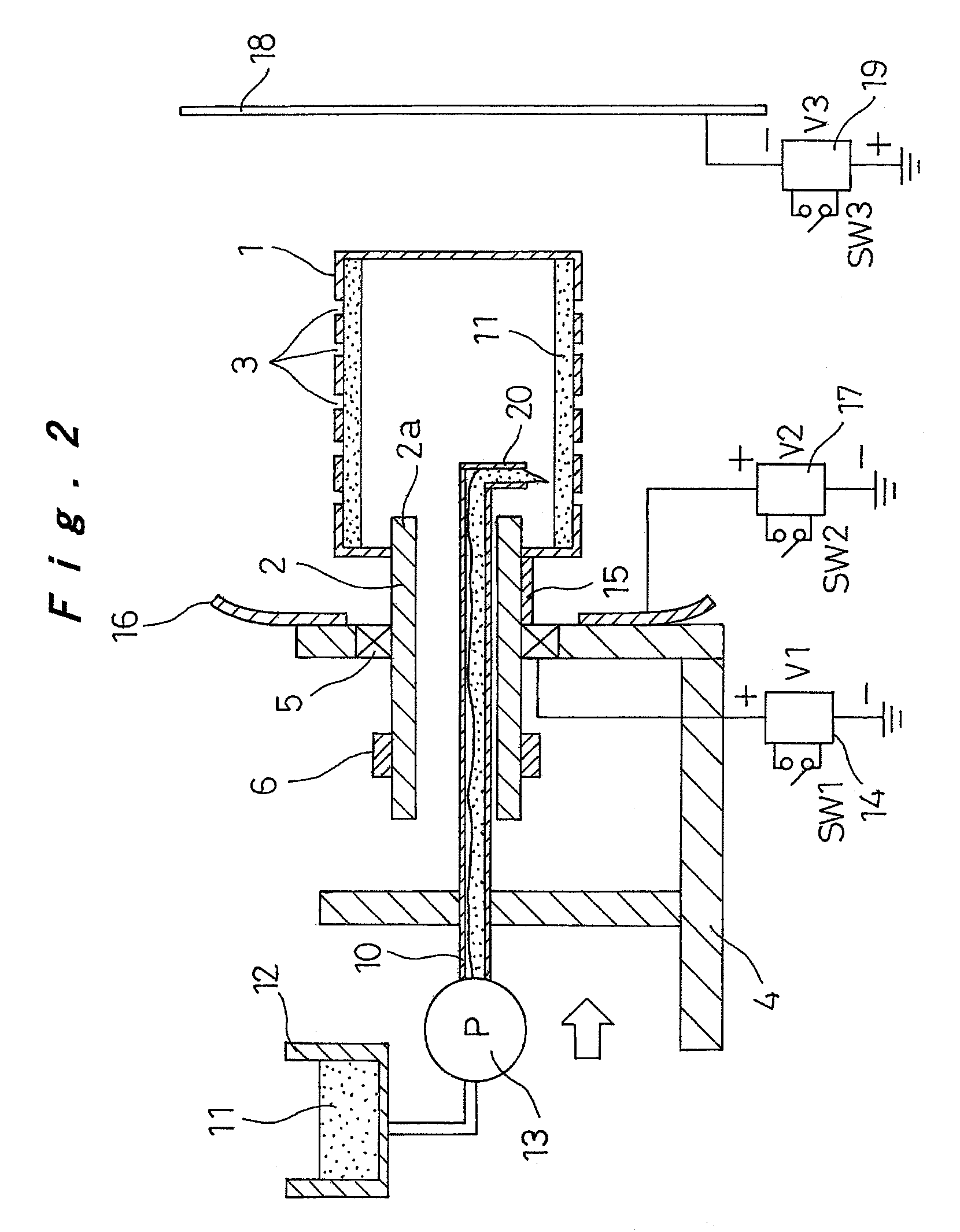

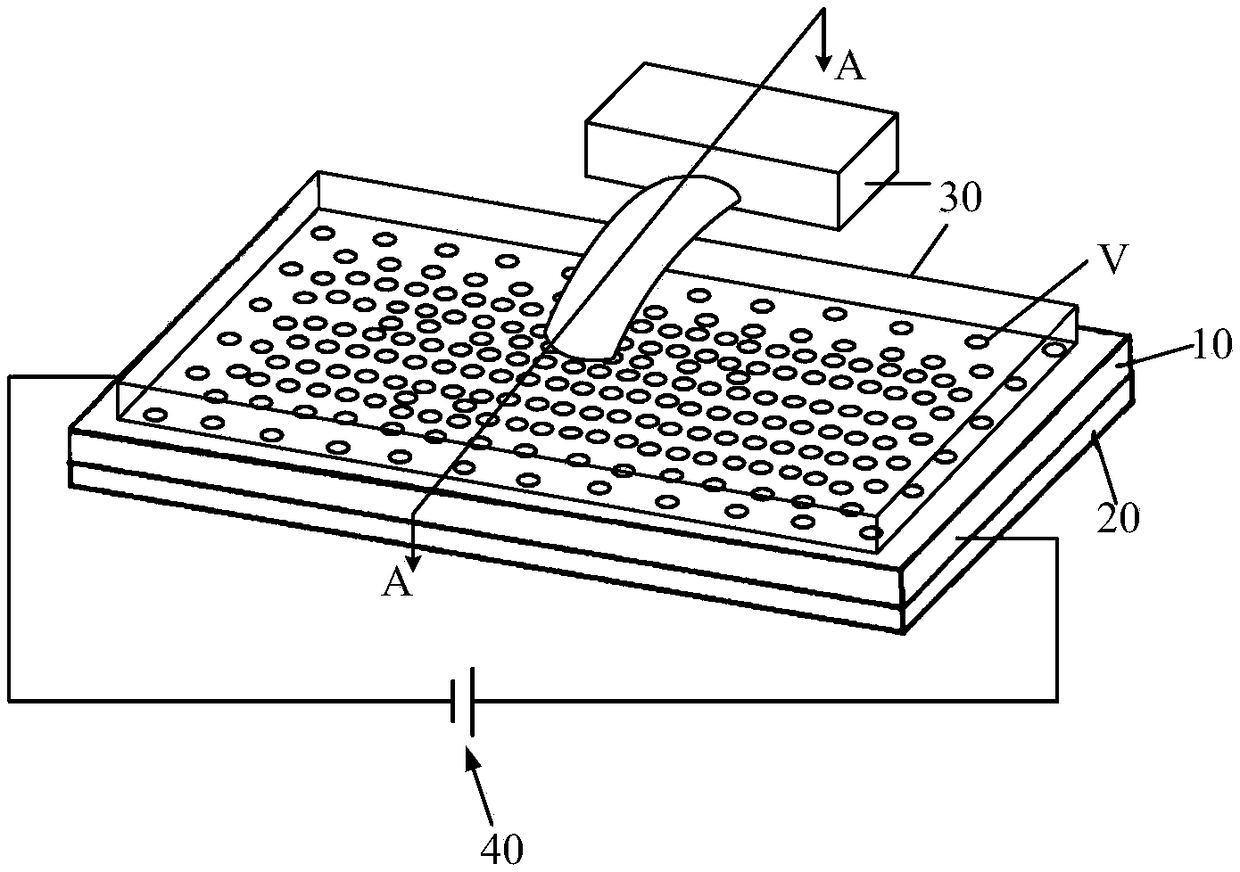

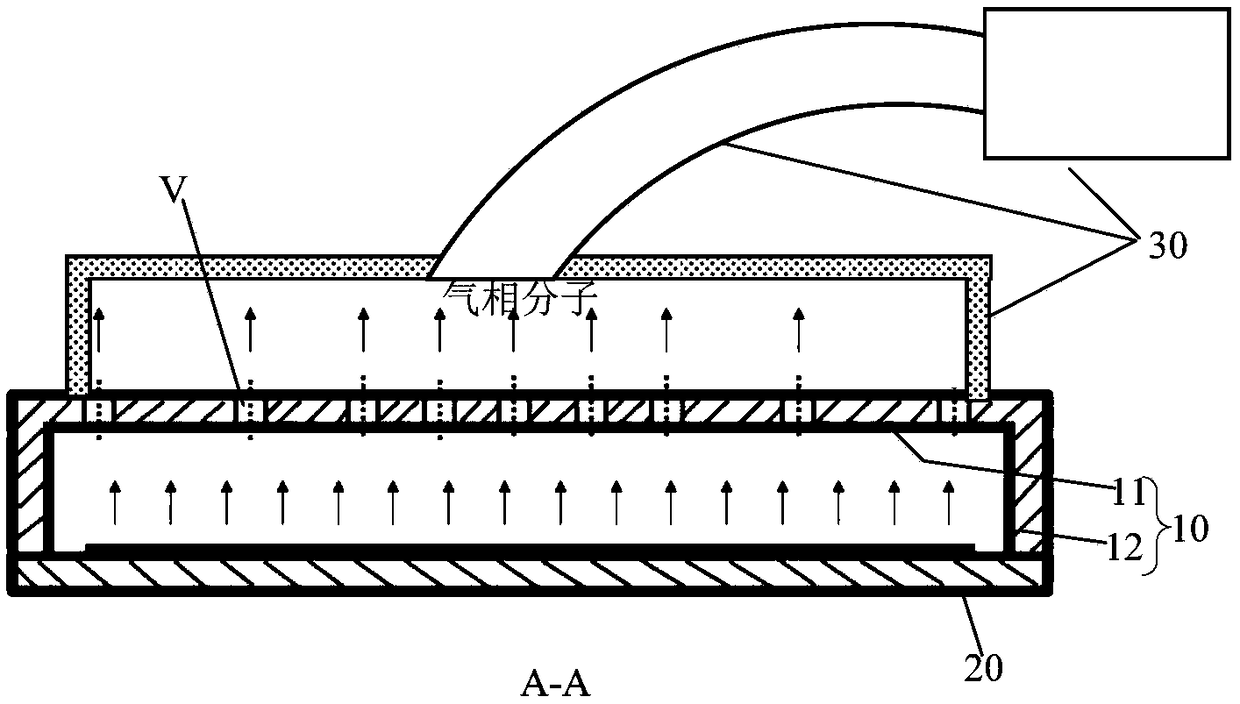

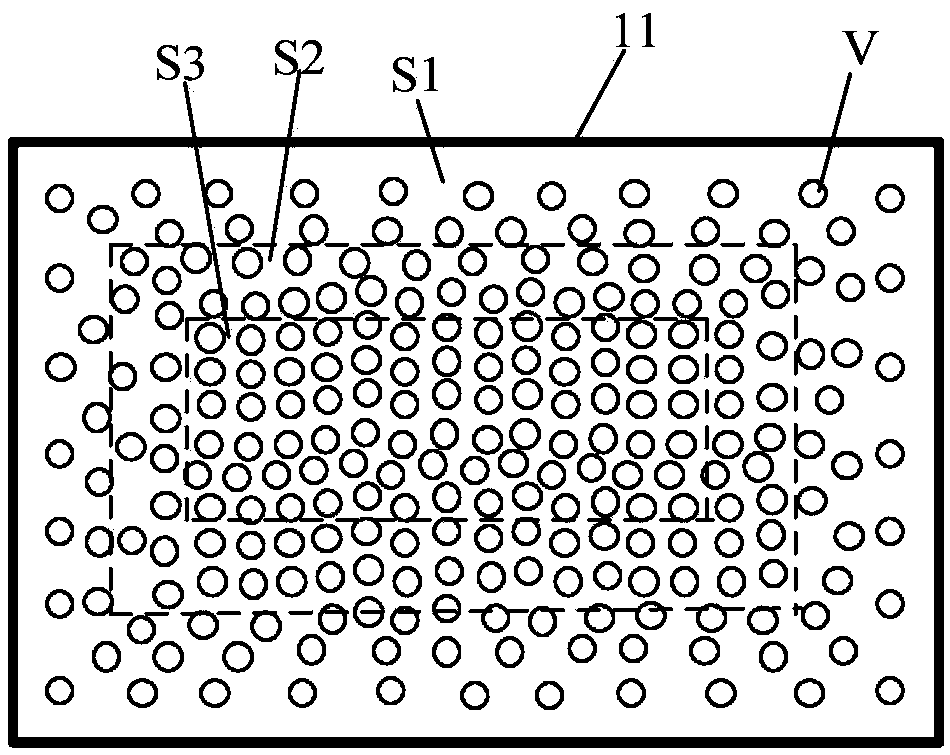

Method and apparatus for producing nanofibers and polymer web

ActiveUS20100072674A1Efficient and stable productionEnsure efficient flowElectric discharge heatingFilament/thread formingProduction rateNanofiber

Nanofibers are formed from a polymer material by rotating a conductive rotating container having a plurality of small holes while supplying a polymer solution formed by dissolving a polymer material in a solvent into the rotating container, charging the polymer solution discharged from the small holes of the rotating container by charging means, and drawing the discharged filamentous polymer solution by centrifugal force and an electrostatic explosion resulting from evaporation of the solvent. The nanofibers from this production step are oriented and made to flow from one side toward the other side in a shaft center direction of the rotating container by a reflecting electrode and / or blowing means, or those nanofibers are deposited, to produce a polymer web. The nanofibers and the polymer web using these nanofibers can be produced uniformly by a simple configuration with good productivity.

Owner:PANASONIC CORP

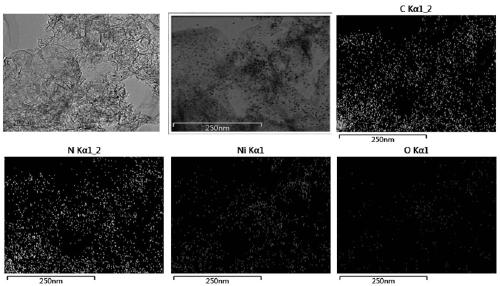

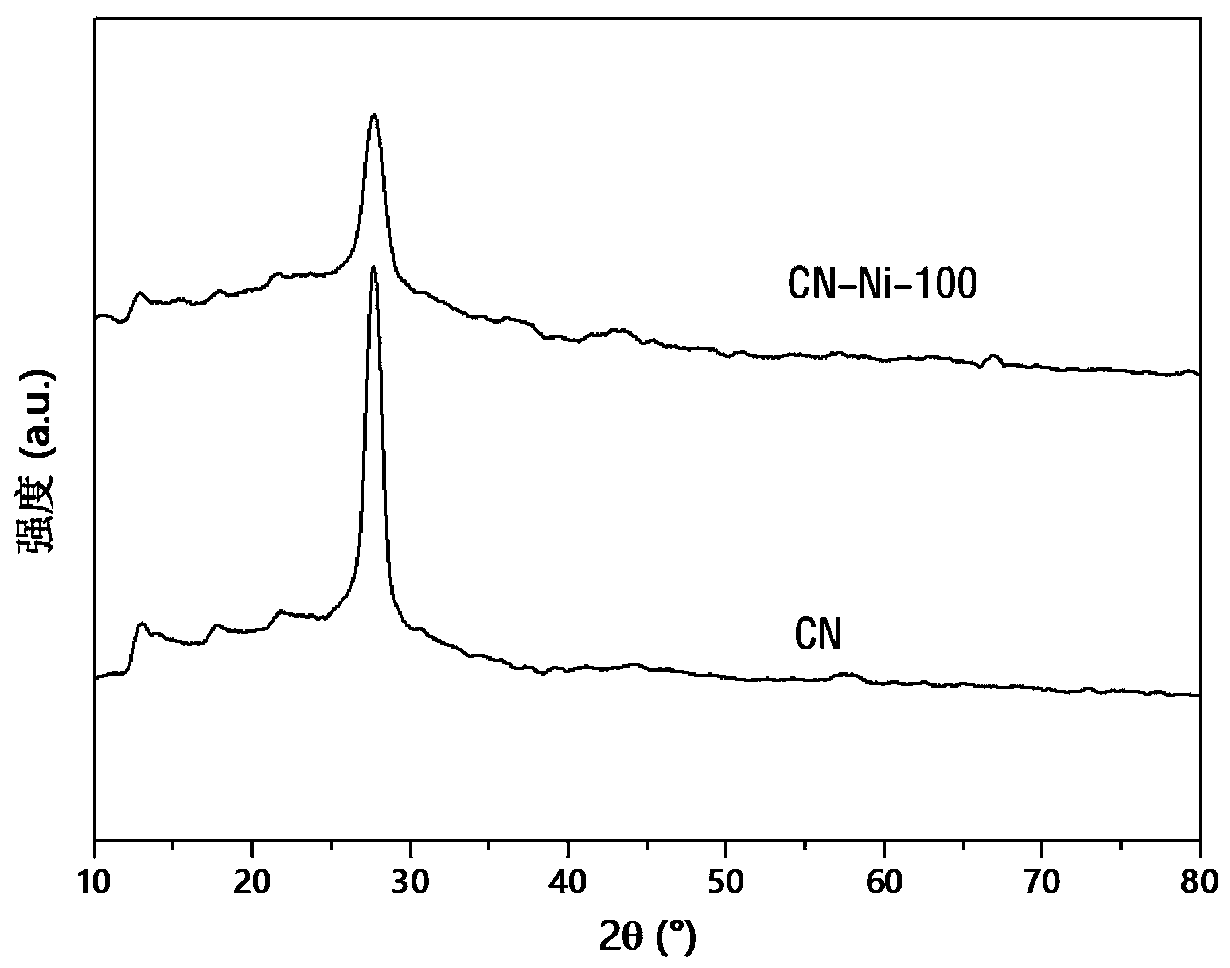

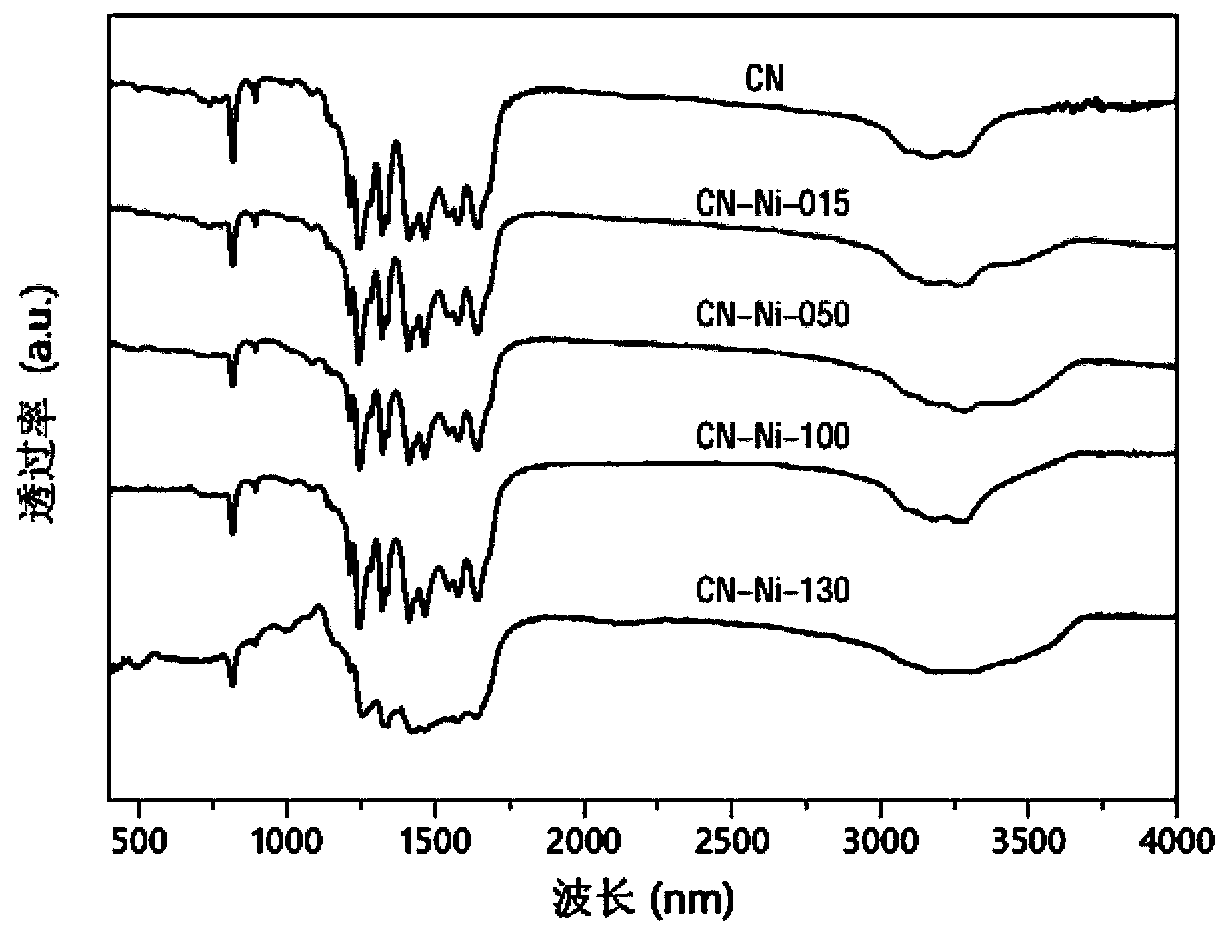

Nickel single-active site graphite-phase carbon nitride-based photocatalytic material as well as preparation method and application thereof

InactiveCN109420514AReduce manufacturing costImproved response to visible lightPhysical/chemical process catalystsHydrogen productionNickelAqueous solution

The invention relates to a Nickel single-active site graphite-phase carbon Nitride-based photocatalytic material as well as a preparation method and application thereof, in the photocatalytic material, Ni is dispersed in a g-C3N4 framework in a single-atom-level degree to form active sites, and the molar content of the Ni is 1-5%. the nickel single-active site graphite-phase carbon nitride-based photocatalytic material has a large specific surface area, is good in dispersion in an aqueous solution, and can effectively inhibit the recombination of photo-generated carriers, the reaction activitysites of the surface of the g-C3N4 are increased, the photocatalytic hydrogen production efficiency can be remarkably improved, and the photocatalytic reaction activity of the g-C3N4 can be improved.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Slow released ClO2 air disinfectant

InactiveCN1887356AImprove the activation effectProlong the evaporation timeDeodrantsDiseaseChlorine dioxide

The present invention is slow released ClO2 air disinfectant, and belongs to the field of hygienic disease controlling and sterilizing technology. The slow released ClO2 air disinfectant consists of ClO2 solution in 1-3 weight portions, silicon gel as the carrier of ClO2 solution in 3 and activator in 0.005-0.1 weight portions. The slow released ClO2 air disinfectant has homogeneous and lasting release to maintain proper ClO2 concentration in the air and reach excellent air disinfecting effect. The used silicon gel may be recovered and reused after treatment.

Owner:陈惠 +1

Method and apparatus for producing nanofibers and polymer web

ActiveUS8110136B2Efficient and stable productionEnsure efficient flowElectric discharge heatingPhysical treatmentProduction rateEvaporation

Nanofibers are formed from a polymer material by rotating a conductive rotating container having a plurality of small holes while supplying a polymer solution formed by dissolving a polymer material in a solvent into the rotating container, charging the polymer solution discharged from the small holes of the rotating container by charging means, and drawing the discharged filamentous polymer solution by centrifugal force and an electrostatic explosion resulting from evaporation of the solvent. The nanofibers from this production step are oriented and made to flow from one side toward the other side in a shaft center direction of the rotating container by a reflecting electrode and / or blowing means, or those nanofibers are deposited, to produce a polymer web. The nanofibers and the polymer web using these nanofibers can be produced uniformly by a simple configuration with good productivity.

Owner:PANASONIC CORP

Cereal-based edible tableware and making method thereof

ActiveCN106954663AIncrease gelatinization temperature and gelatinization viscosityPromote aggregationDough treatmentBakery productsMillet flourRice flour

The invention discloses cereal-based edible tableware and a making method thereof. The cereal-based edible tableware comprises cereal powder and auxiliary materials, wherein the cereal powder comprises the following components in parts by weight of 60-80 parts of whole wheat flour, 5-20 parts of sorghum flour, 5-15 parts of rice flour, 0-10 parts of millet flour and 0-10 parts of purple sweet potato flour; and the auxiliary materials comprise the following components in parts by mass: 30-40 parts of water, 3-5 parts of butter and 0-5 parts of seasonings. The making method comprises the following steps of mixing the cereal powder which is subjected to microwave-assisted treatment and then roasting and precooking treatment or dry heat precooking treatment with the auxiliary materials to make dough; putting the made dough in a mold, performing heat-preservation shaping, conveying the shaped dough into an oven, performing roasting, and in the roasting process, performing pressurization for 1-2 times; and performing roasting until shaped dough is 90% cooked, performing film painting with rice flour dextrinization fluid or starch dextrinization fluid of which the concentration is 2-5%, and continuing roasting for 1-2 min so as to obtain finished products. According to the cereal-based edible tableware and the making method thereof disclosed by the invention, used raw materials are natural cereals, are rich in nutrition and can be directly eaten, so that environmental pollution is avoided; the used technology is simple, industrial production is easy to realize, and the cost is low; and the cereal-based edible tableware is compact in texture and is not deformed.

Owner:QINGDAO AGRI UNIV

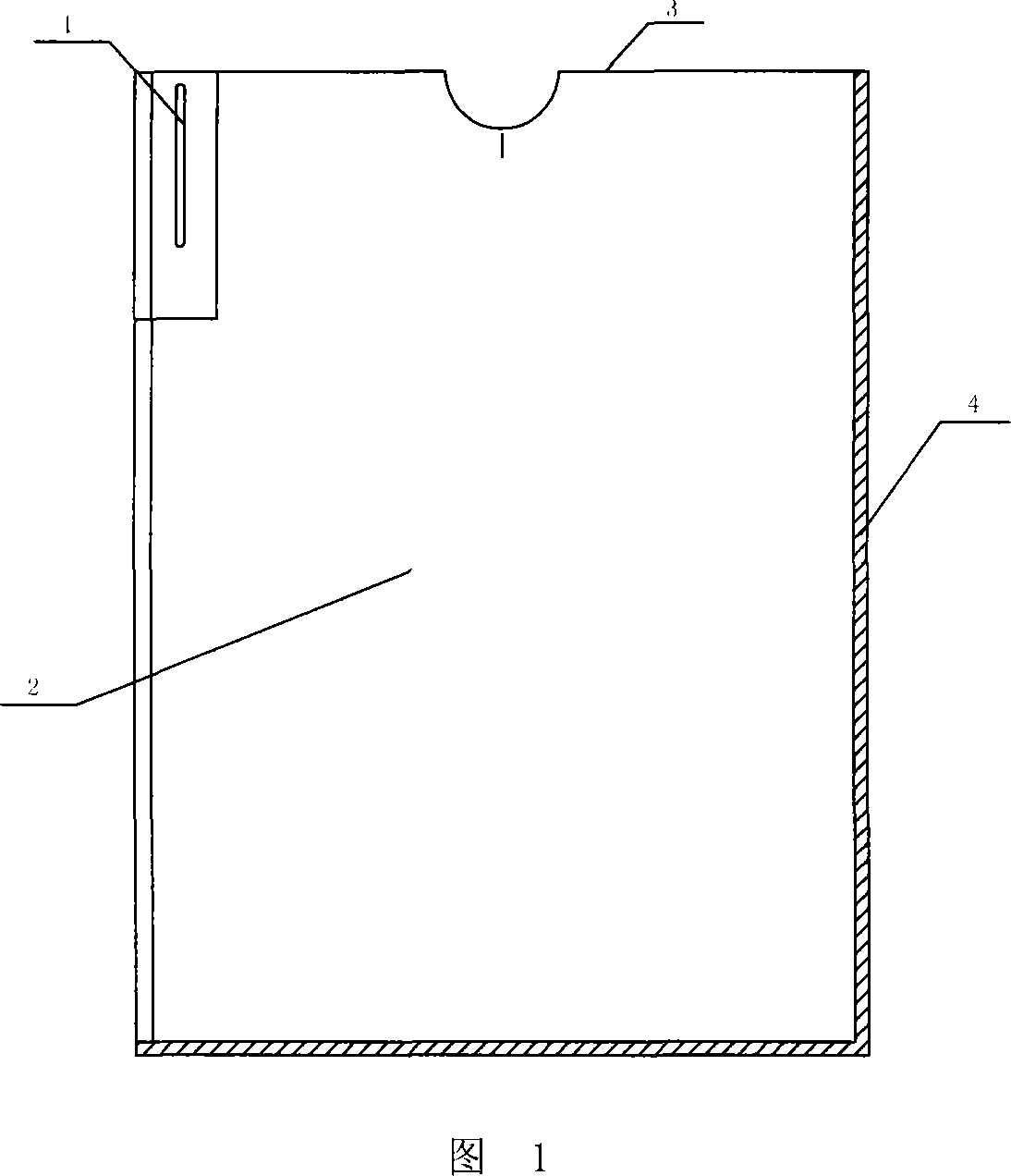

Closed permeating waterproof fruit film bag

InactiveCN101019494ALarge air flowEliminate fruit rustCoatingsPlant protective coveringsPolyolefinCalcium carbonate

The present invention discloses one kind of closed permeating waterproof fruit film bag. The polyolefin film bag is prepared with LDPE polyolefin resin, LLDPE polyolefin resin or PP-polyolefin copolymer resin, calcium carbonate or talcum powder, coupler, modifier and dispersant as materials in a special plastic film bag making machine. It is provided with one tying rope in the mouth.

Owner:徐世慧

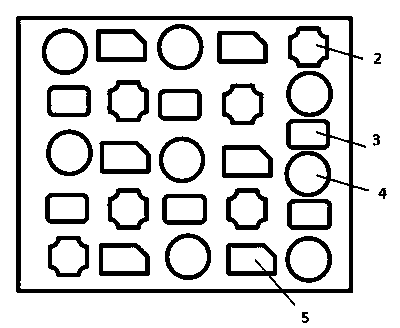

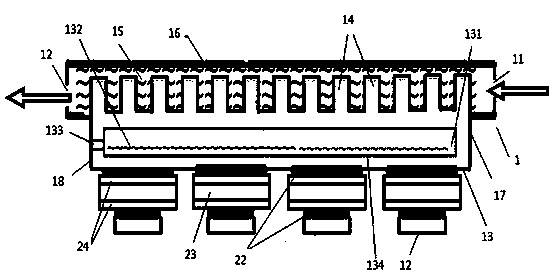

Packaging structure of integrated power control unit

ActiveCN103413790AImprove the stability of useExtended service lifeSemiconductor/solid-state device detailsSolid-state devicesProcess engineeringPower control

The invention provides a packaging structure of an integrated power control unit. Heating elements are not distributed according to a traditional functional module. All the heating elements are distributed in a scattered mode. The problems of the use conditions, power and the like of the heating elements achieving the same function and different functions are comprehensively considered, the heating elements achieving the same function are distributed on a main substrate at intervals, the heating elements achieving the different functions are also distributed on the main substrate at the same time, and therefore under the different use conditions, the heating quantities of different areas on the whole main substrate are even to the great extent. On the one hand, even heating provides the powerful guarantee for even heat dissipation, on the other hand, the simplification of the integrated heat dissipation structure is facilitated, and then the packaging structure is beneficial to meeting the small-size requirement of the control unit. Meanwhile, the even heating is also beneficial to improving the use stability of the main substrate and prolonging the service life of the main substrate.

Owner:SHANDONG INST OF ADVANCED TECH CHINESE ACAD OF SCI CO LTD

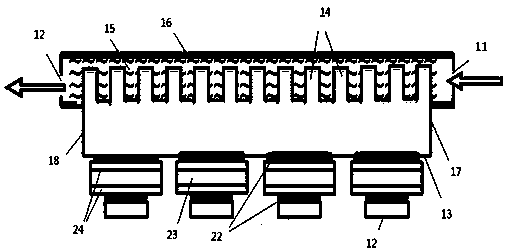

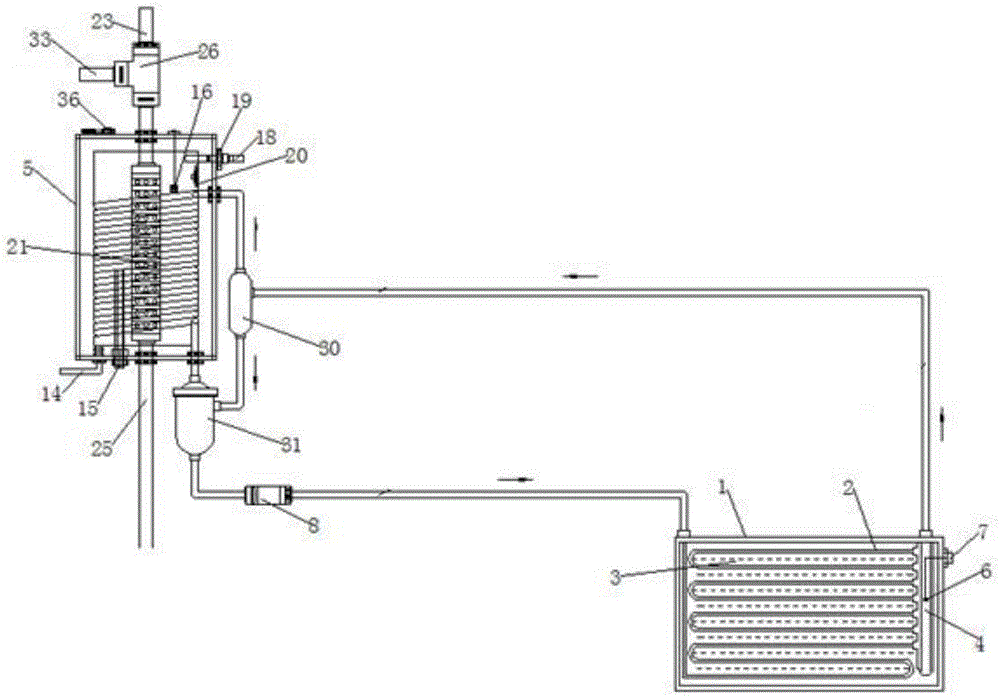

Heating device of solar water heater with discrete-type heat pipes

InactiveCN104595967AHigh energyImprove heat collection effectSolar heating energySolar heat devicesSolar waterEngineering

The invention discloses a heating device of a solar water heater with discrete-type heat pipes. The heating device comprises a solar heat collector and a hot water storage tank, wherein heat of the solar heat collector is transferred into the hot water storage tank for storage; a cold-hot exchanger is arranged in the hot water storage tank; cold air is subjected to heat exchange through the cold-hot exchanger to form hot air, and the hot air is used for indoor heating. Compared with existing solar water heater and domestic heating equipment, the heating device has the advantages of high heating speed, good heating effect, safety and reliability in mounting and using processes, high intelligent level, low power consumption, no pollution and the like. A separate heat pipe technology is adopted, high heat efficiency of a system is guaranteed, and an anti-freezing problem of the solar heat collector and a system pipeline is solved.

Owner:SOUTHEAST UNIV

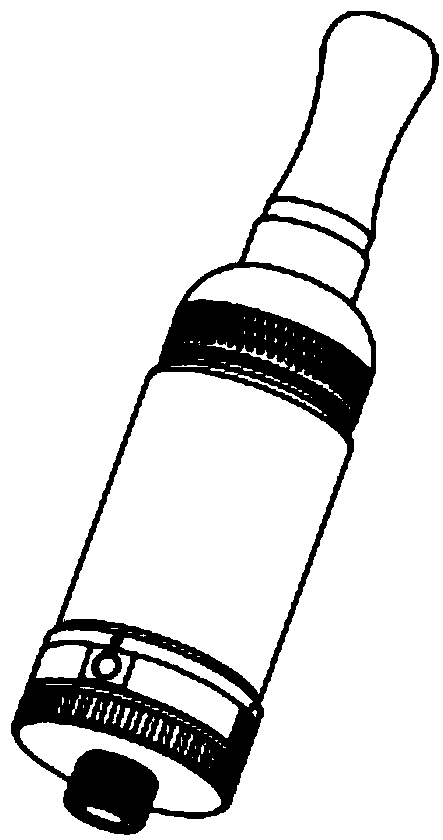

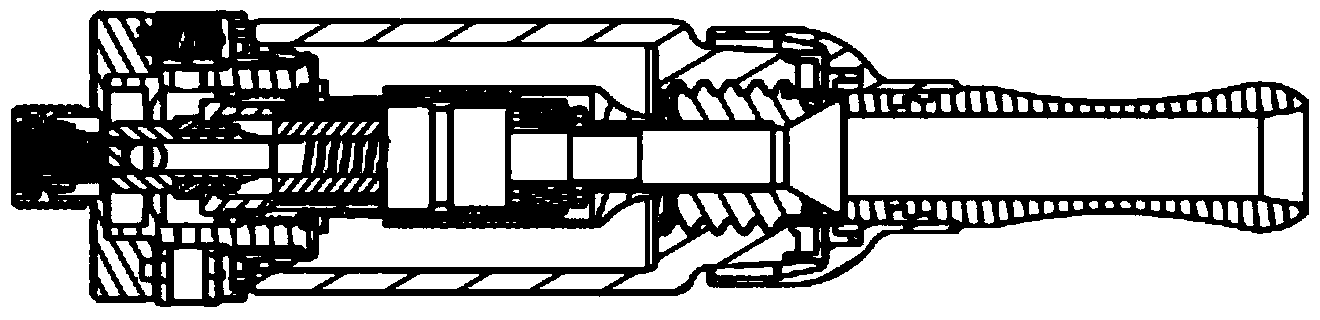

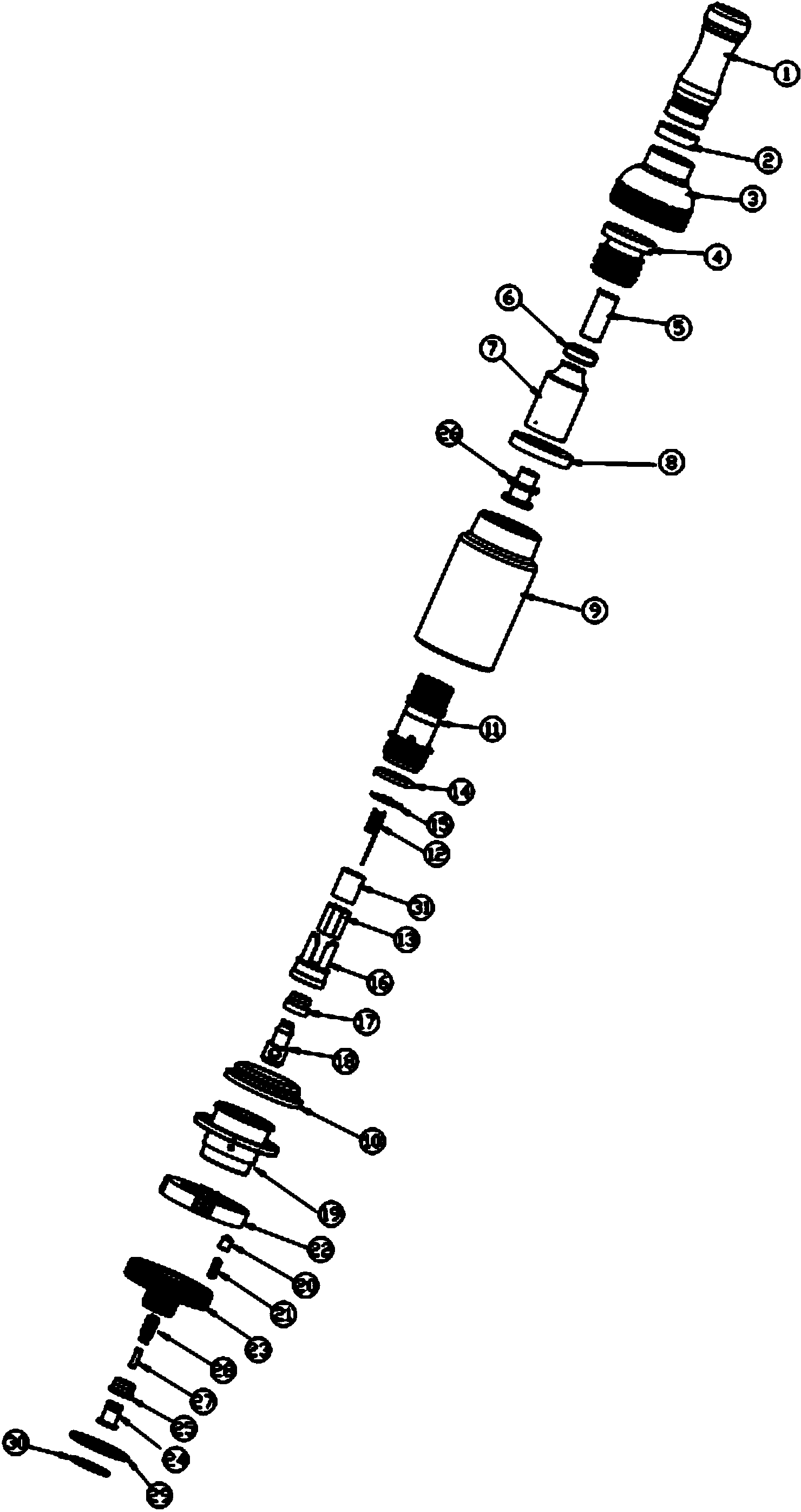

Vertical heating wire atomizer

The invention relates to a vertical heating wire atomizer. The vertical heating wire atomizer comprises an atomization assembly and a glass tube shell. The vertical heating wire atomizer is characterized in that the atomization assembly is located inside the columnar glass tube shell, heating wires are distributed in the atomization assembly, and the heating wires are arranged at intervals and are perpendicular to the cylindrical surface of the glass tube shell; the atomizer further comprises a metal cigarette holder assembly and a glass tube fixing base assembly, the metal cigarette holder assembly is located at the top end of the atomizer, and the metal cigarette holder assembly is in close fit connection with the glass tube fixing base assembly in a pluggable mode and then is in thread connection with the glass tube shell. The heating wires are vertically and evenly distributed inside the tube shell so that even evaporation of inside tobacco liquid can be achieved; besides, due to vertical arrangement, the tobacco liquid in the height direction is heated at the same degree, and coevaporation can be achieved.

Owner:刘团芳

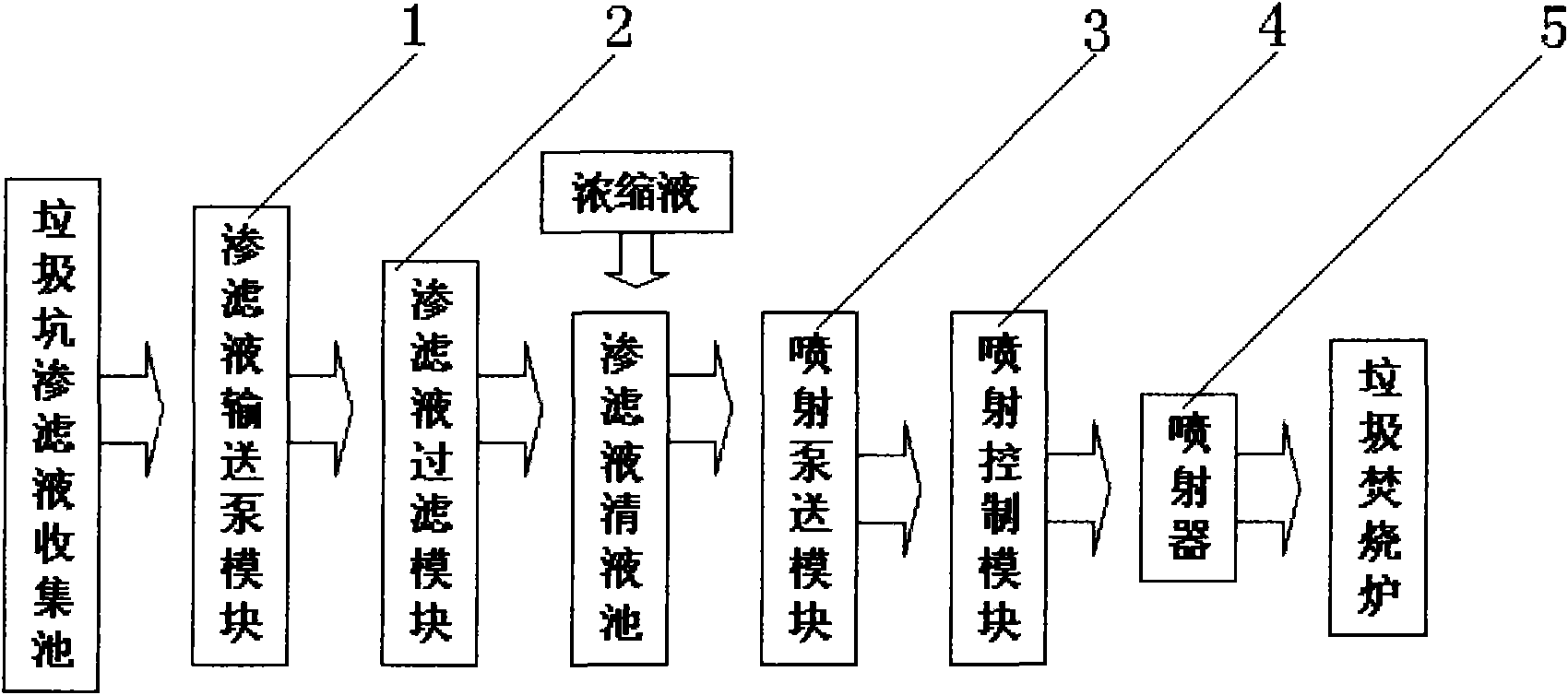

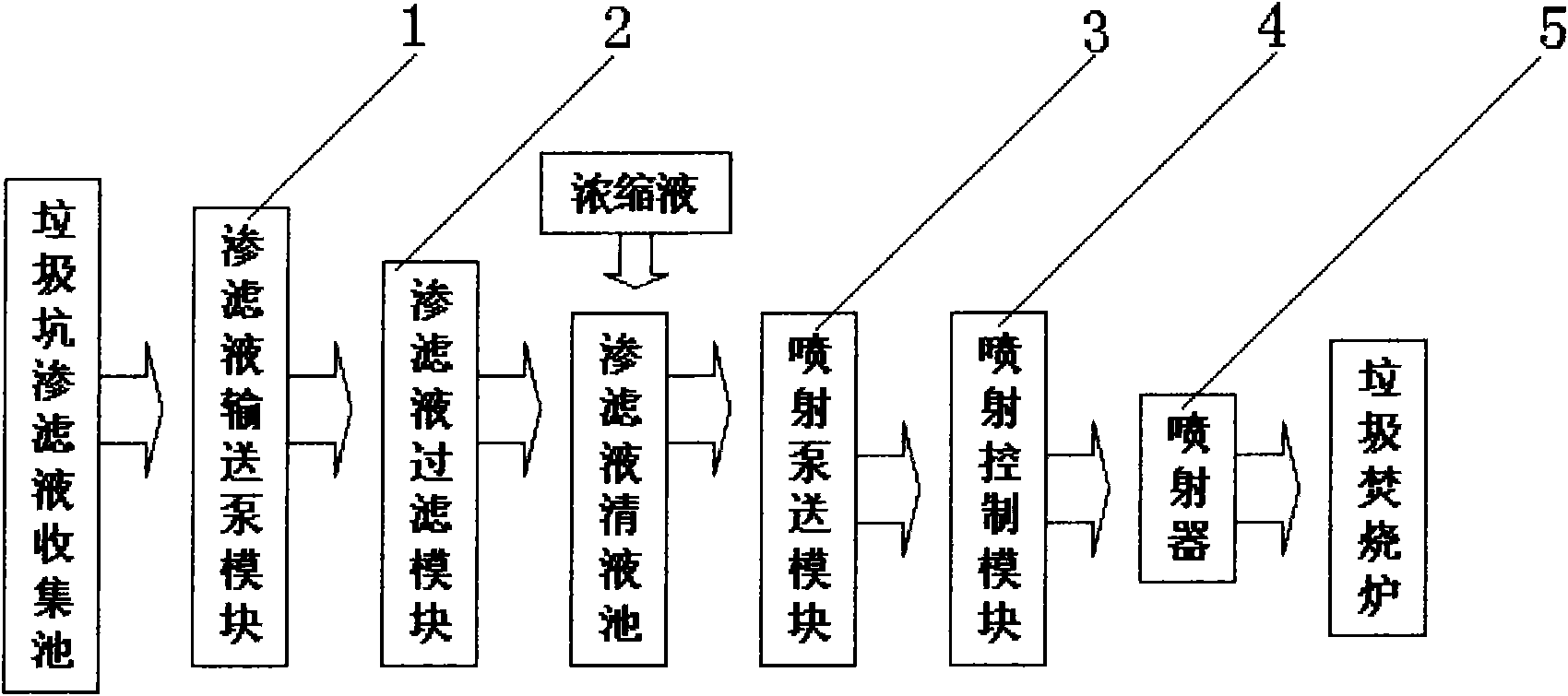

Process for spraying and treating percolate

ActiveCN101979921AExtended operating cycleReduce cokingIncinerator apparatusAutomatic controlBurn treatment

The invention relates to a process for treating garbage percolate, in particular to a process for spraying and treating percolate and aims to provide a reliable and efficient garbage percolate treatment method for spraying the garbage percolate for burning treatment. The garbage percolate can be prevented from polluting the environment and the pollution problem can be solved completely. In order to fulfill the aim, the process for spraying and treating the percolate is provided and comprises the following steps of: collecting the percolate; filtering the percolate; and spraying the percolate. A technical process for spraying, burning and treating the percolate is simple and is convenient to operate. Stock garbage percolate can be decomposed fully or concentrated solution produced in other treatment modes can be treated simultaneously and secondary pollution is avoided; and compared with other treatment modes, the process has low construction, operation and maintenance costs, small floor area and high automatic control degree and is convenient to operate.

Owner:SHANGHAI TECHSPRAY ENG

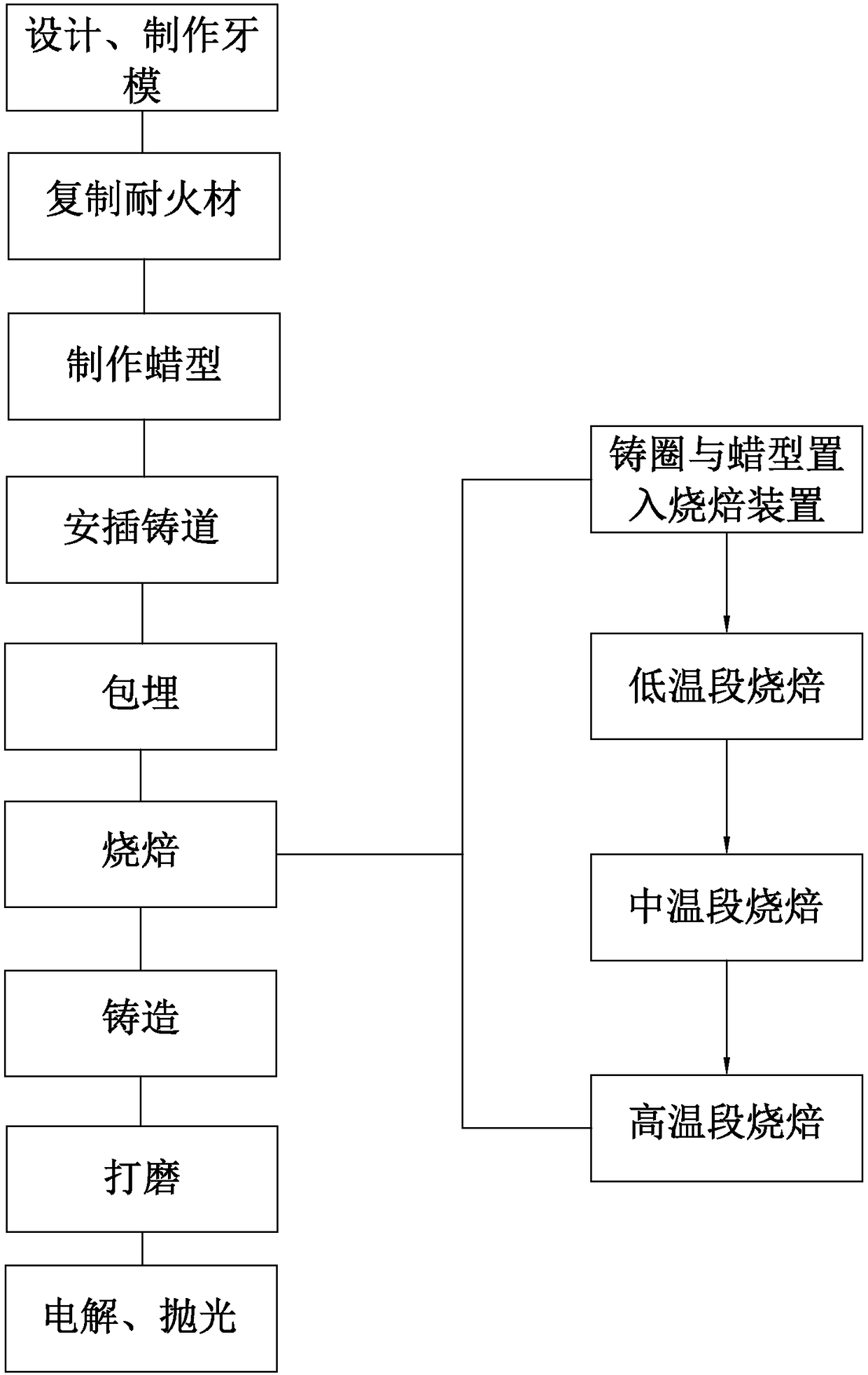

Manufacturing process of denture framework

The invention discloses a manufacturing process of a denture framework. A technical scheme of the process comprises the following steps: a, designing and manufacturing a dental model; b, copying a refractory material model; c, making a wax pattern; d, arranging a sprew on the wax pattern; e, performing embedding treatment; f, roasting a casting ring and the wax pattern in the casting ring, whereinthe step f comprises specific steps as follows: f1, after embedding is completed, the wax pattern and the casting ring are simultaneously put into a roasting device; f2, treatment at low-temperaturesection is performed: the temperature is raised to 280-320 DEG C from room temperature within 30-40 minutes and is kept constant for 30-40 minutes; f3, treatment at medium temperature section is performed: the temperature is gradually increased to 690-710 DEG C within 25-40 minutes and kept constant for 30-40 minutes; f4, treatment at high-temperature section is performed: the temperature is gradually increased to 800-850 DEG C within 10-20 minutes; g, performing casting and taking out the denture framework after completion of casting. The increasing speed of the roasting temperature in the roasting process is controlled, so that the temperature in the roasting process is increased slowly and evenly to the greatest extent, moisture in an embedding material is evaporated, and the success rate of subsequent casting is increased.

Owner:北京圣爱吉友和义齿制作有限公司

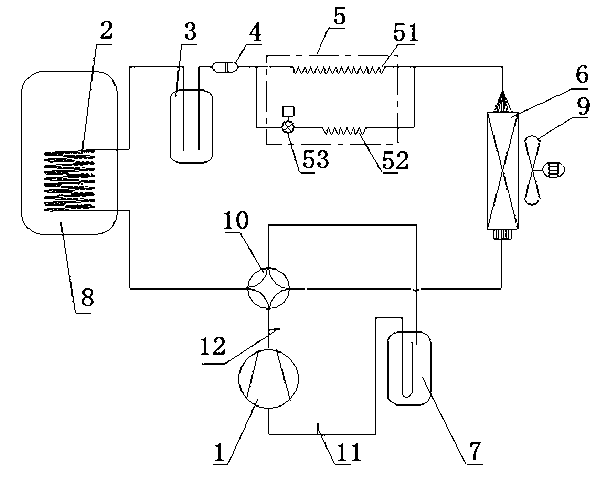

Heat-pump water heater cold shielding system for protecting compressor

InactiveCN103322681ALife expectancyNot adulteratedCompressorFluid heatersVapor–liquid separatorEvaporation

The invention discloses a heat-pump water heater cold shielding system for protecting a compressor. The heat-pump water heater cold shielding system comprises the compressor, a condenser, a throttling device, an evaporator and a gas-liquid separator which are sequentially connected to form a circulation loop, the throttling device comprises a primary capillary tube and a secondary capillary tube which are parallelly connected, and a real-time flow control device is arranged at a liquid inlet end of the secondary capillary tube. Since the real-time flow control device is arranged at the liquid inlet end of the secondary capillary tube, refrigerant flow passing through the secondary capillary tube is adjusted in real time, appropriate amount of refrigerant flows into the evaporator to be evaporated sufficiently, gaseous refrigerant returned into the compressor is guaranteed not to be mixed with liquid, and influence on service life of the compressor from liquid impact is eliminated to the greatest extent. In addition, since the appropriate amount of the refrigerant participates into evaporation in the evaporator, the gaseous refrigerant returned into the compressor is guaranteed to be sufficient, system efficiency is prevented from being affected by the compressor due to insufficient refrigerant, and even affect on normal work of the compressor is avoided.

Owner:ZHEJIANG AMA & HIEN TECH

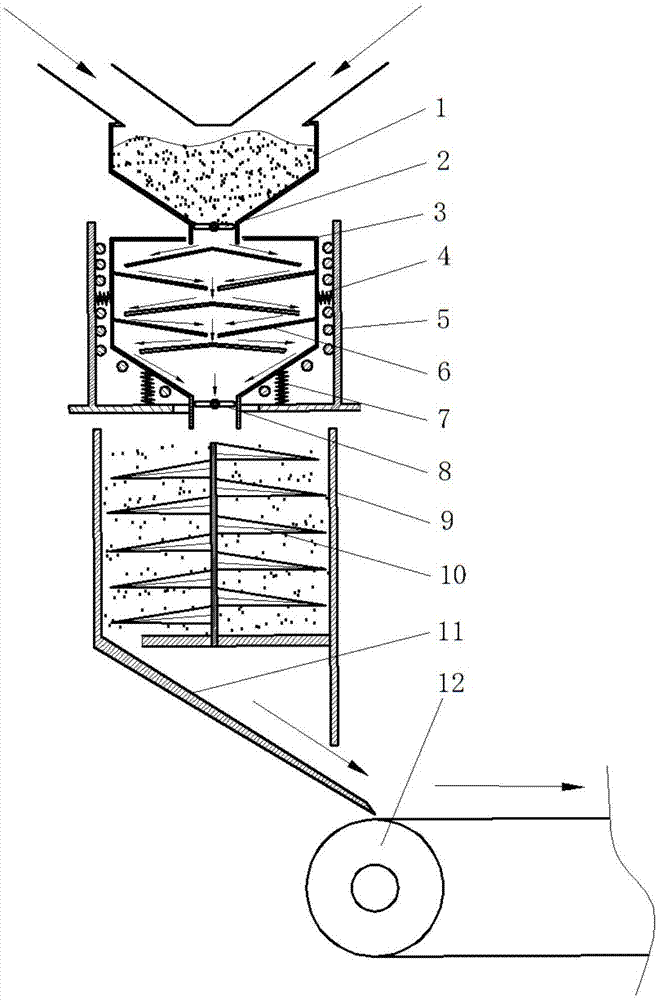

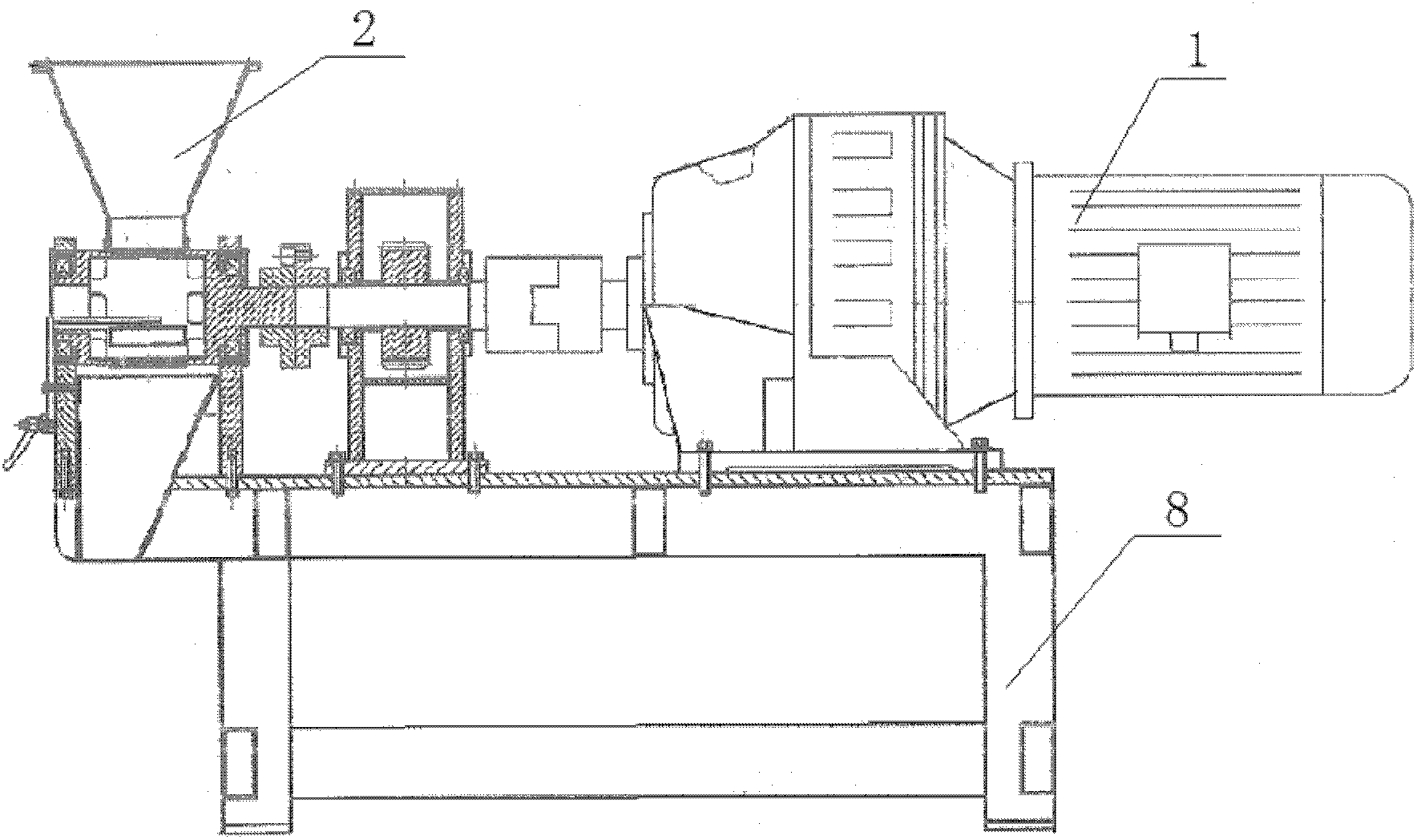

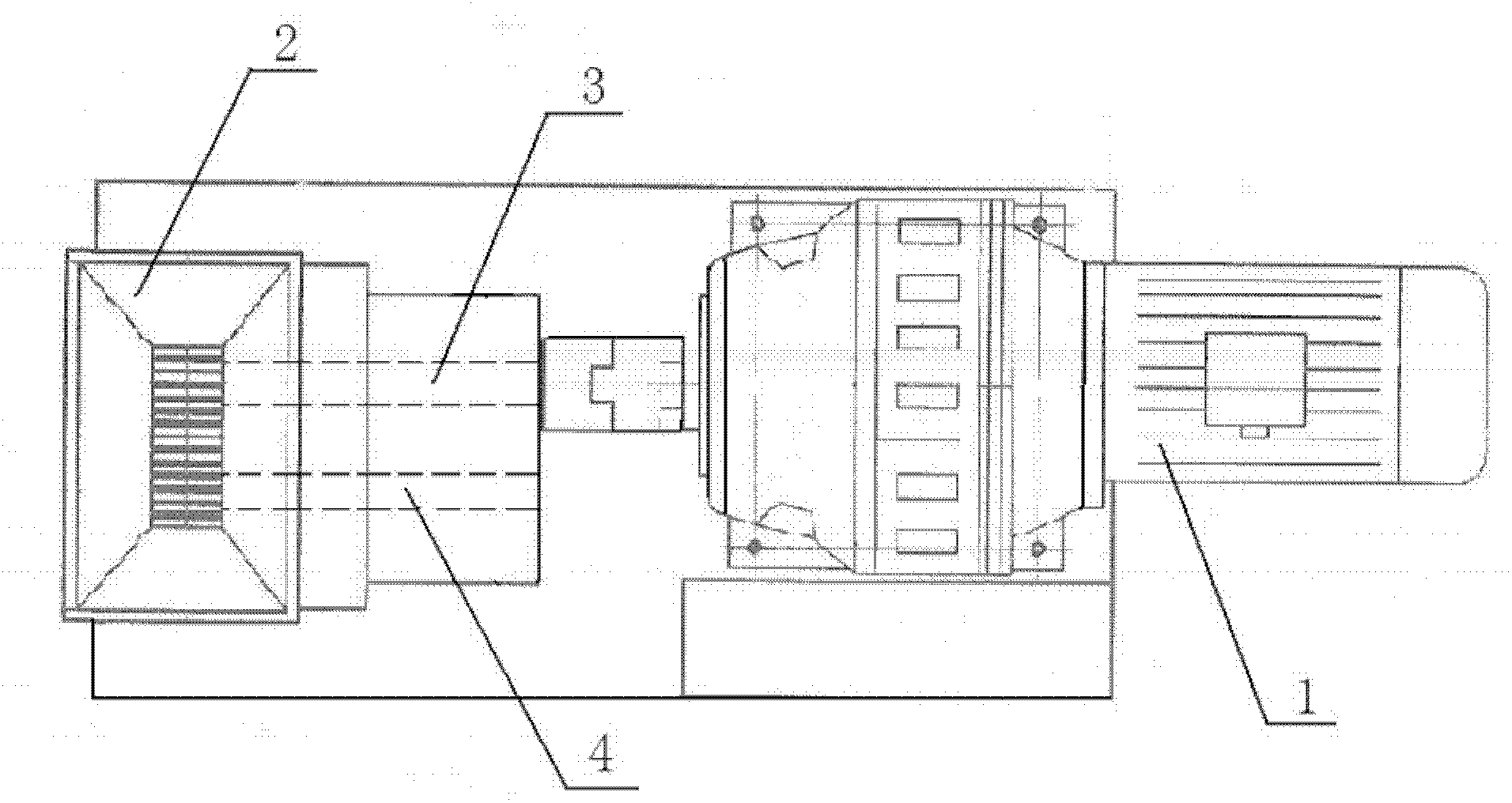

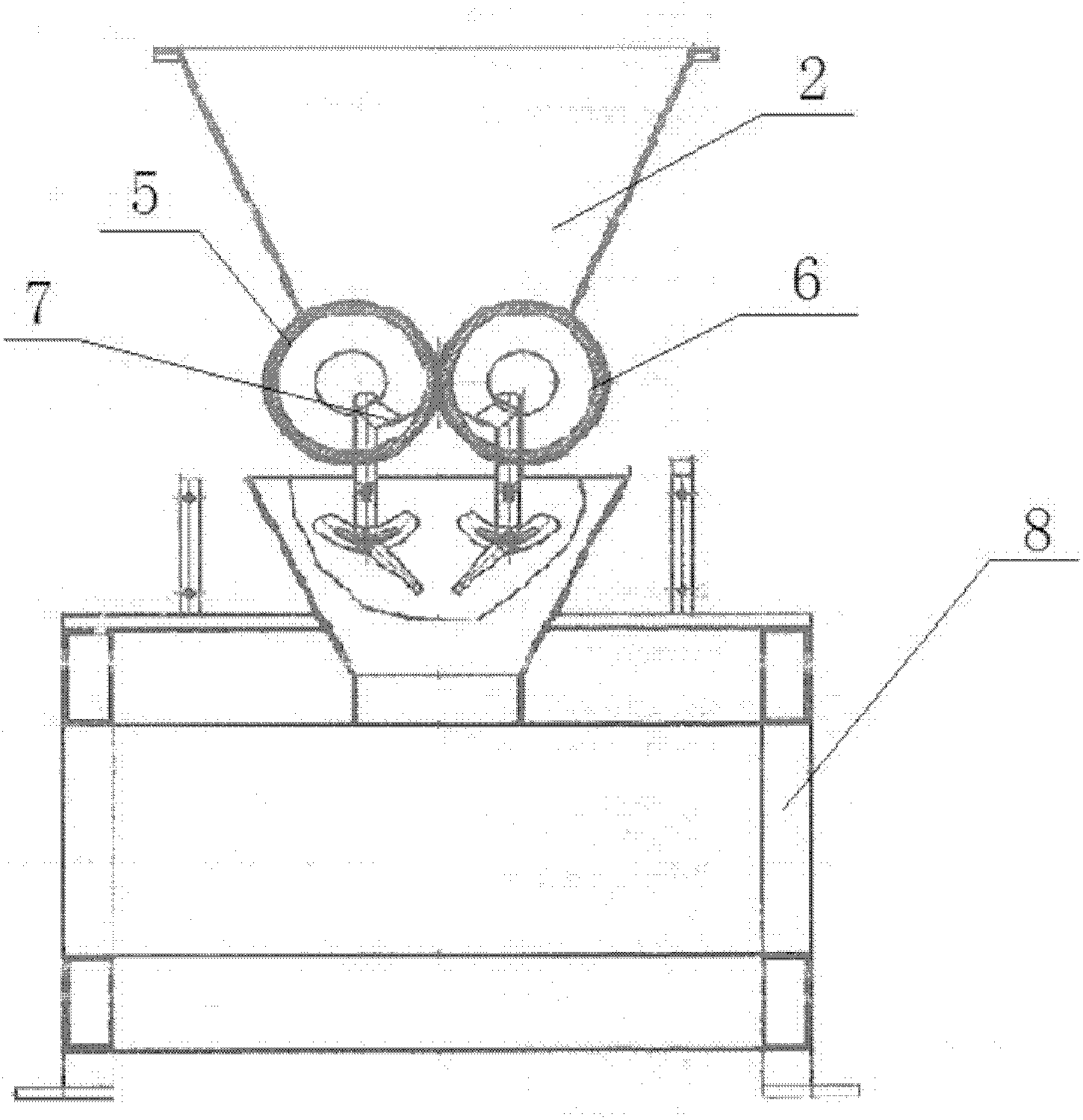

Grain drying device and method

ActiveCN106871622AHeating evenlyAccurate adjustment of heating doseDrying solid materials with heatTransportation and packagingMicrowaveEvaporation

The invention discloses a grain drying device which comprises a premixing container, a premixing container flow control valve, a microwave heating reaction container, a transverse supporting spring, a vibration disc, a longitudinal spring support, a microwave heating reaction container flow control valve, a stirring container, a stirring turbine, an outlet flow guide plate and a grain conveying device. By the adoption of an inverted-V-shaped dividing structure, uniform evaporation is achieved in the whole process, and blocking is avoided. By the adoption of the microwave heating method, grains are evenly heated, and the heating dosage can be accurately adjusted.

Owner:HEXIAN HAIHAO VEGETABLE PLANTATION

Repair method for car paint

The invention provides a repair method for car paint, and relates to the technical field of cars. The repair method for the car paint comprises the following steps of (1) pretreatment of damaged partsof the car paint, (2) spraying of a painting make-up agent, (3) spraying of colored paint, (4) spraying of varnish and (5) grinding and polishing. The repair method for the car paint repairs the damaged parts of the car paint, the whole repair process is simple and easy to realize, the effect is obvious, time for painting make-up is short, the working efficiency is improved, and the time-saving and labor-saving effect is achieved.

Owner:广西速道汽车维修服务有限公司

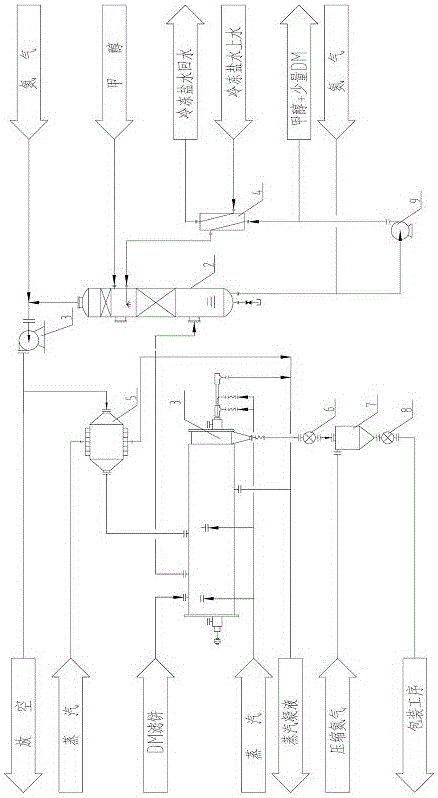

2-benzothiazolethiol nitrogen circulation drying and solvent recovery method

InactiveCN105004145AImprove sealingExtended stayDrying solid materials without heatDispersed particle separationRecovery methodBuffer tank

The invention relates to a 2-benzothiazolethiol nitrogen circulation drying and solvent recovery method. The method comprises the following steps: (1) conveying a 2-mercaptobenzothiazole wet material in a vacuum drying chamber of a vacuum paddle dryer, filling gaps between wedged blades with the 2-mercaptobenzothiazole wet material, meanwhile, introducing steam in a paddle shaft of the vacuum paddle dryer and a jacket of a housing of the vacuum paddle dryer, and thus obtaining the dried material and the evaporated moisture; (2)turning the dried material over an overflow weir to be discharged from a discharging opening, allowing the dried material to enter a seal buffer tank through a rotary discharge valve I, meanwhile, introducing nitrogen in the seal buffer tank for nitrogen sealing, and conveying the dried material to a next process by a rotary discharge valve II at the bottom of the seal buffer tank; (3) carrying the evaporated moisture out by hot nitrogen and allowing hot nitrogen to enter a cooling washing tower to be sprayed so as to obtain washed nitrogen; (4) pressurizing and heating washed nitrogen, enabling the pressurized and heated nitrogen to enter the vacuum paddle dryer to serve as a carrier gas for conveying the evaporated moisture for cyclic utilization. The method has the advantages of being safe, environment-friendly, and low in energy consumption.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

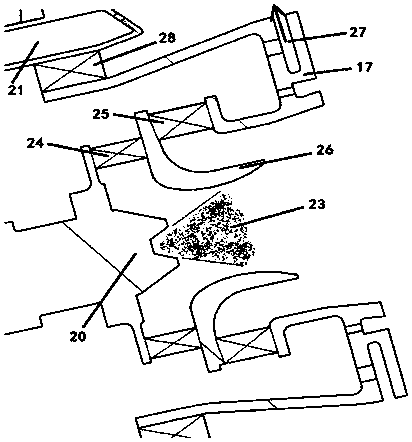

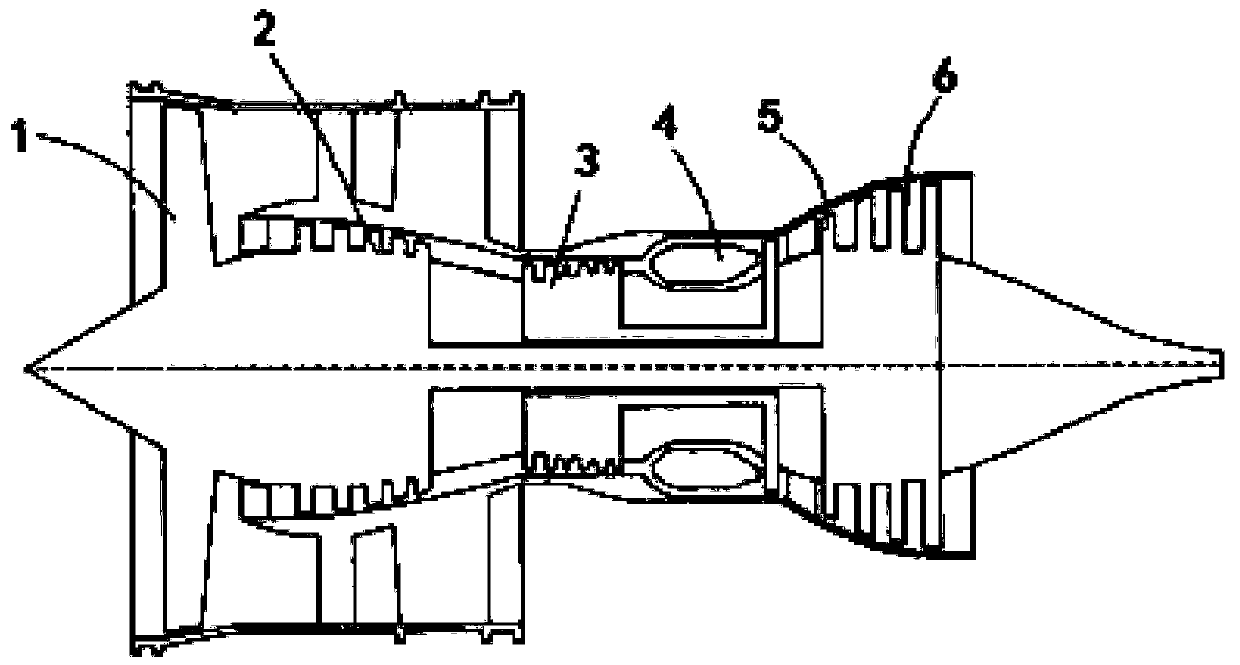

Combustion chamber

ActiveCN110657455AImprove circumferential uniformityImprove the mixing effectContinuous combustion chamberCombustion chamberEngineering

The invention aims to provide a combustion chamber. The combustion chamber adopts a single-ring-cavity flame tube structure, and the pollution emission of a whole LTO cycle of an engine is reduced onthe premise of ensuring the performance of the combustion chamber. In the combustion chamber, the main combustion stage involves an inner swirler, an outer swirler, an oil collecting ring and a premixing pre-evaporation section; the outer swirler adopts a radial swirler, the inner swirler adopts an axial swirler, and the oil collecting ring adopts direct fuel injection holes which are uniformly distributed in the circumferential direction, the fuel oil forms a direct spraying oil mist and forms the main combustion stage pneumatic atomizing oil mist by crushing and atomizing under the shearingaction of an inner swirling flow and an outer swirling flow; and the premixing pre-evaporation section adopts a nozzle structure and has a throat, the direct fuel injection holes are located in the 20%-80% range of the throat height relative to the radial position of the premixing pre-evaporation section of the main combustion stage, and the included angle between the injection direction of the direct fuel injection holes and the axis direction of the main combustion stage is negative 15 degrees to 60 degrees.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

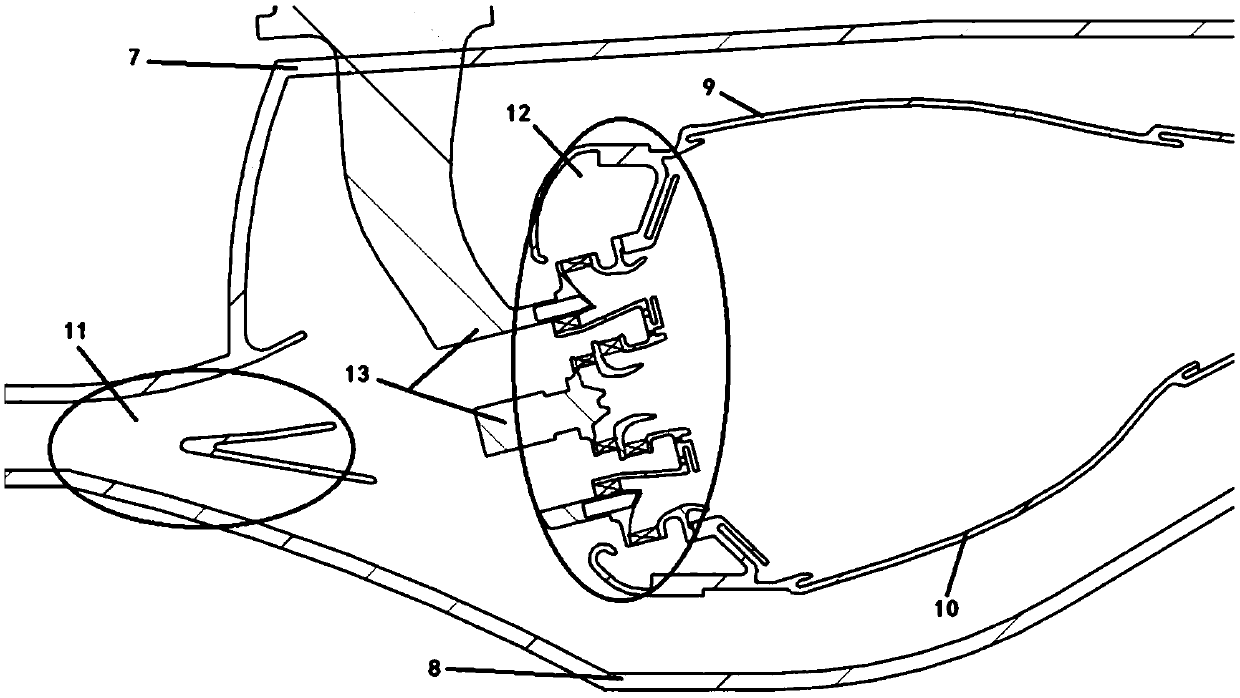

Cut-tobacco dryer with adjustable hot-air directions and method for adjusting same

ActiveCN105361234AEvaporate evenlyReduce volatilityTobacco preparationDrying gas arrangementsEngineeringWind direction

The invention relates to the field of technologies for drying tobacco shreds, and provides a cut-tobacco dryer with adjustable hot-air directions and a method for adjusting the same. The method for adjusting the air directions of the cut-tobacco dryer includes steps of S1, arranging hot-air flow guide devices at hot-air inlet ends of the cut-tobacco dryer; S2, detecting the air speeds of hot-air systems for delivering hot-air into the cut-tobacco dryer; S3, adjusting angles of guide plates of the hot-air flow guide devices according to detection results; S4, butting outlets of the hot-air systems to the hot-air flow guide devices so as to allow the hot-air outputted by the hot-air systems to flow into drums of the cut-tobacco dryer via the hot-air flow guide devices. The cut-tobacco dryer and the method for adjusting the hot-air directions have the advantages that the hot-air flow guide devices are arranged at the inlet ends of the drums of the cut-tobacco dryer, accordingly, the hot-air can uniformly act on tobacco shreds, water in the tobacco shreds can be uniformly evaporated, and the volatility of water at tobacco shred outlets can be reduced.

Owner:CHINA TOBACCO GUIZHOU IND

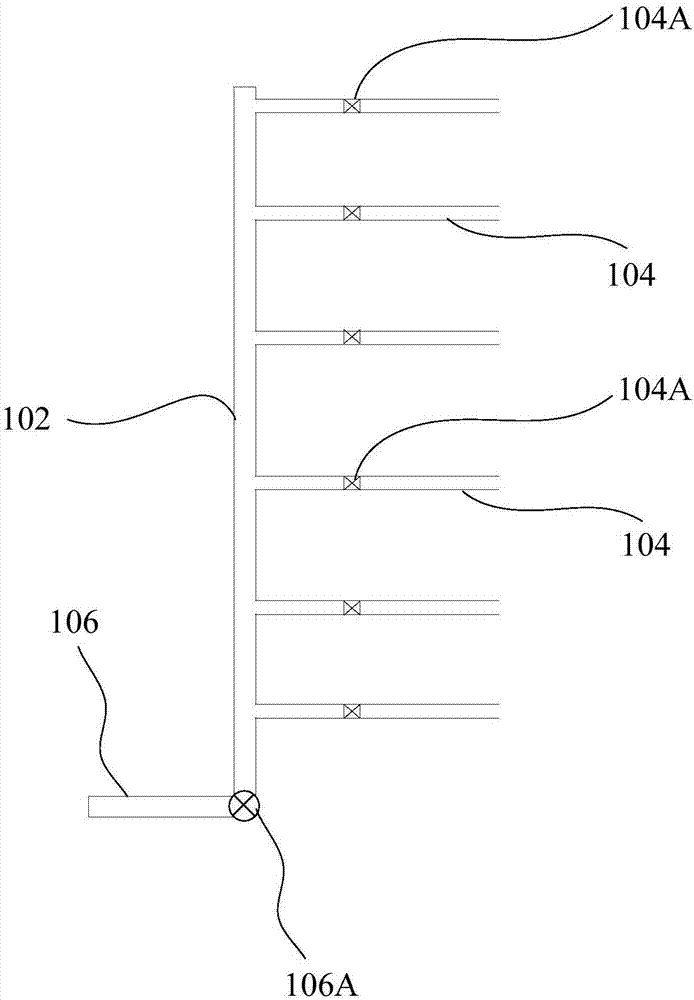

Throttling and flow dividing assembly and air conditioner

PendingCN107543340AImprove stabilityImprove stability and reliabilityFluid circulation arrangementMechanical apparatusWaste management

The invention provides a throttling and flow dividing assembly and an air conditioner. The throttling and flow dividing assembly comprises a main pipe and a plurality of branch pipes; a plurality of flow dividing openings are formed in the side wall of the main pipe; the multiple branch pipes communicate with the multiple flow dividing openings in a one-to-one correspondence mode; and a throttlingdevice is arranged in any branch pipe. Through the technical scheme, liquid in the main pipe can evenly flow towards all the branch pipes through the corresponding flow dividing openings, and thus the good flow dividing effect is achieved; and each branch pipe is provided with the corresponding throttling device, and the liquid flowing into all the branch pipes is subjected to throttling and depressurizing through the throttling devices, so that the stability of the flow dividing and throttling processes of the liquid is improved.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

Perfume volatilizing device

The invention discloses a perfume volatilizing device. The perfume volatilizing device comprises a containing bottle, an air inlet guide pipe and an air outlet guide pipe, wherein the air inlet guide pipe is connected with an air inlet hole; the air outlet guide pipe is connected with an air outlet hole; the containing bottle is of a sealing structure; the interior of the containing bottle is provided with a containing cavity for containing perfume; the air inlet hole and the air outlet hole are formed in the containing bottle. The perfume volatilizing device is characterized in that the interior of the containing bottle is provided with the sealed containing cavity, the perfume raw material is contained into the containing cavity, and the air inlet hole and the air outlet hole are formed in the containing bottle; the air inlet guide pipe is connected with the air inlet hole and is used for conveying air into the containing cavity; the air outlet guide pipe is connected with the air outlet hole and is used for guiding the air out of the containing cavity. The perfume volatilizing device has the advantages that perfume molecules are volatilized into the air in the containing cavity, and the perfume molecules volatilized into the air are guided out of the containing cavity along with the air, so that the purpose of volatilizing the perfume is realized; when the perfume does not need to be volatilized, the conveying of the air into the containing cavity is stopped, so that while the consumption of perfume is greatly decreased, the volatilizing of the perfume is more uniform.

Owner:王铁斌 +1

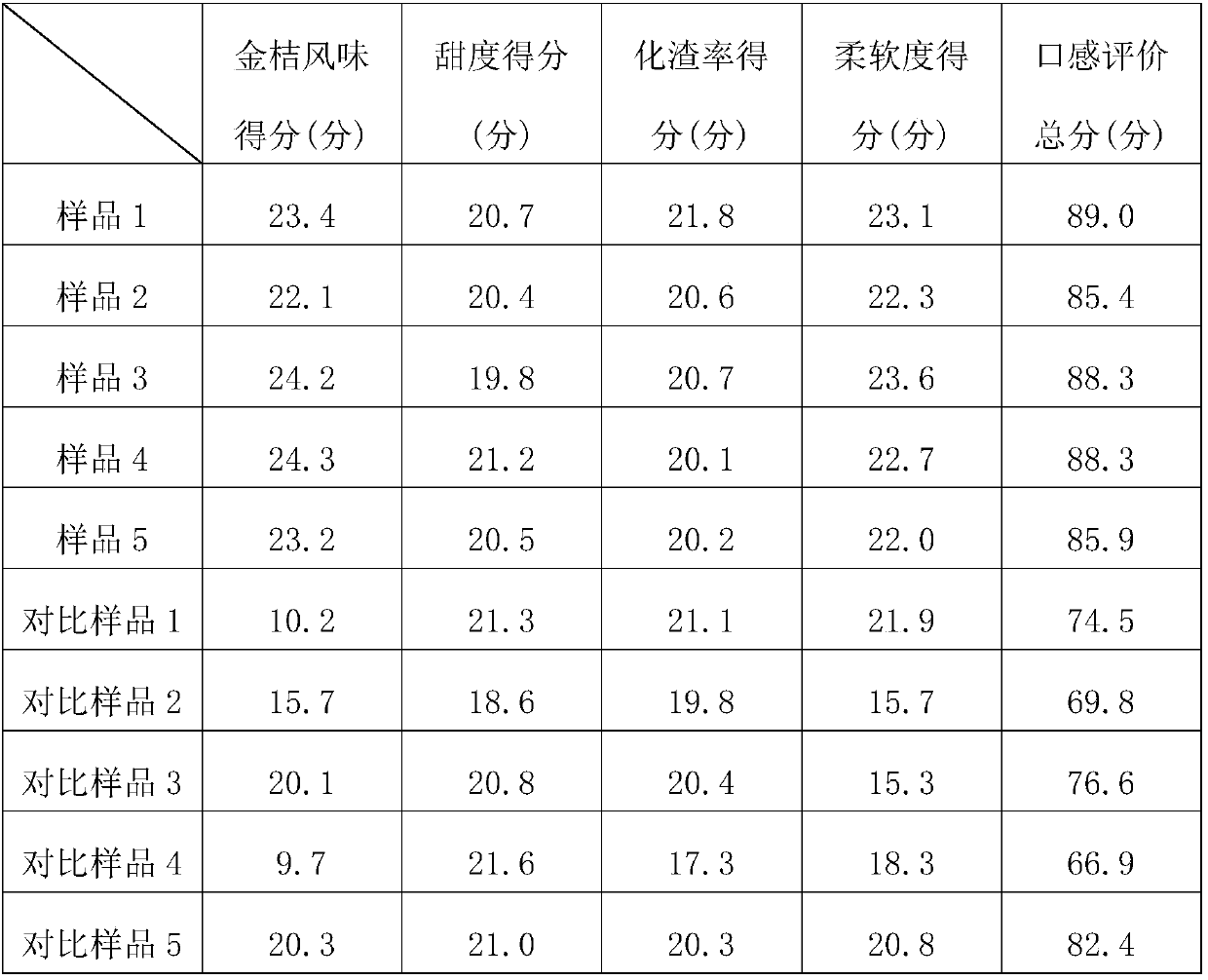

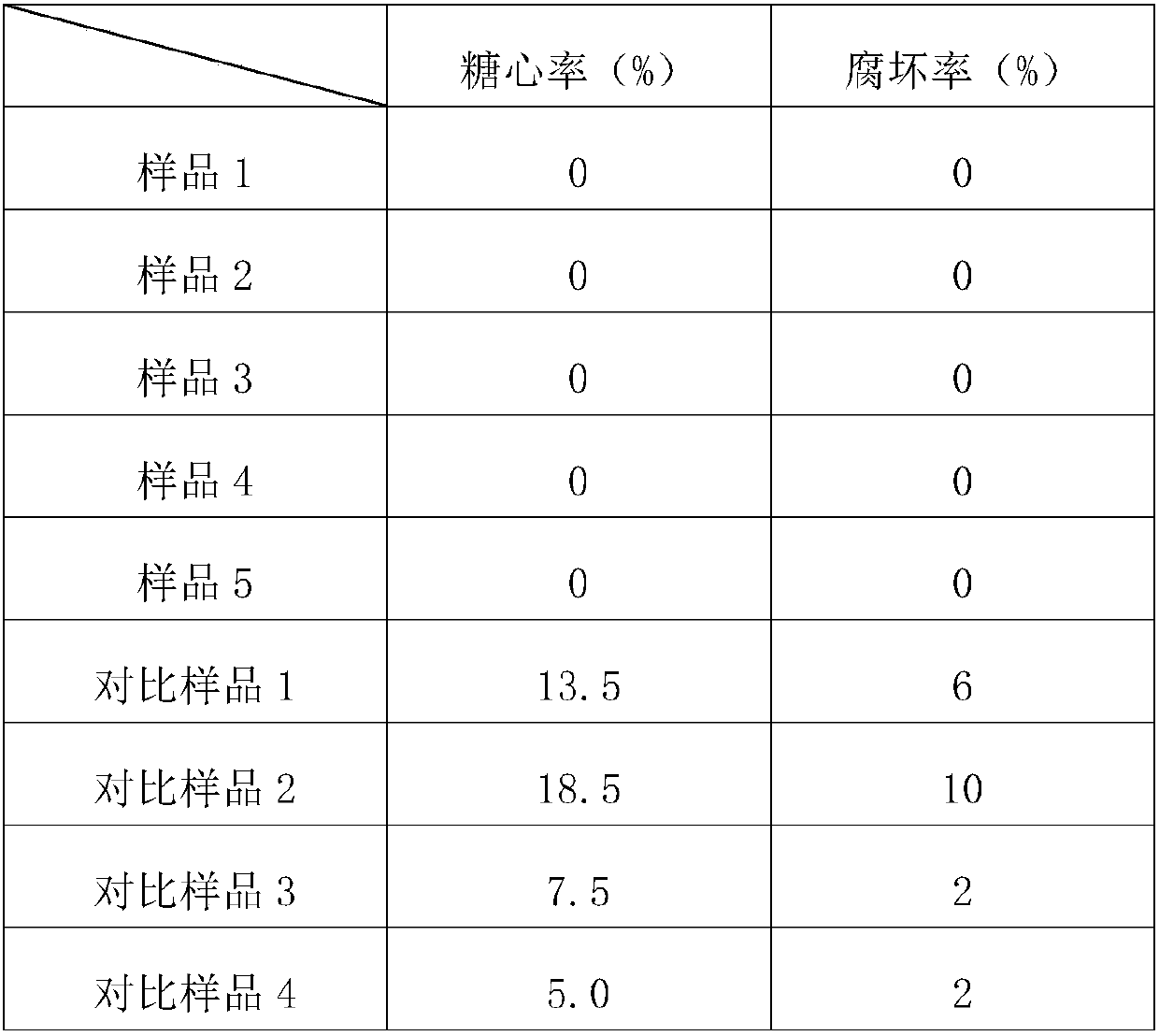

Preparation method of dried fortunella margarita swingle with few seeds

InactiveCN107744117ARich flavorFully soften the peelFruits/vegetable preservation by dehydrationCooking & bakingFlavor

The invention relates to the technical field of fruit processing, in particular to a preparation method of dried fortunella margarita swingle with few seeds. The method comprises the following steps of selecting raw materials, performing cleaning, performing baking in a baking room, and performing airing. According to the method provided by the invention, by adopting fortunella margarita swingle with few seeds and smooth peel as raw materials, firstly, high-temperature high-humidity and low-temperature low-humidity alternative treatment in the baking room is performed, through cooperation of spraying fortunella margarita swingle treatment liquid and reducing pressure intensity of the baking room, volatile oil components in the fortunella margarita swingle peel are protected, the fortunellamargarita swingle peel is softened, besides, moisture in the flesh of the fortunella margarita swingle with few seeds and smooth peel is allowed to uniformly evaporate to achieve the purpose of uniform drying, then the treated fortunella margarita swingle is put in a sunshine room, airing is conducted, supplementary illumination with an infrared heating lamp is performed so that the fortunella margarita swingle flesh is heated, and slow dehydrating is performed so that the flesh of the dried fortunella margarita swingle with few seeds is soft in mouth feel. The dried fortunella margarita swingle with few seeds made by the method has the characteristics of being rich in fortunella margarita swingle flavor, soft in fruit bodies, high in sugariness and free from non-uniformly dried parts.

Owner:融安县金丰农业科技开发有限公司

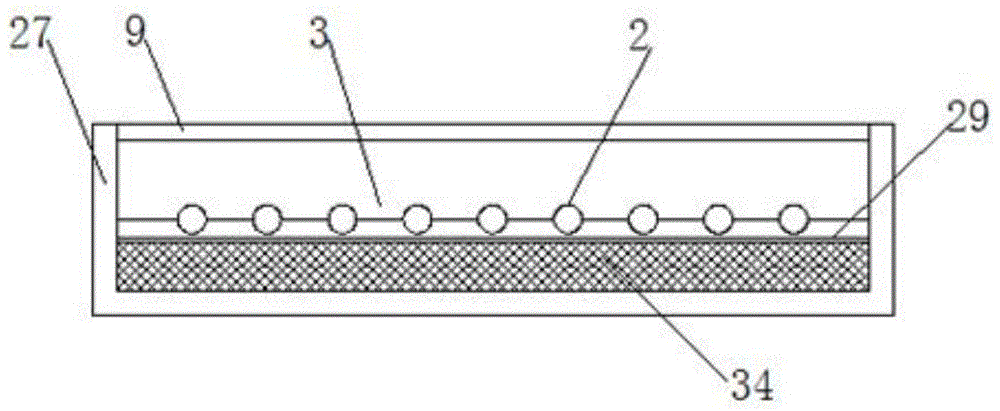

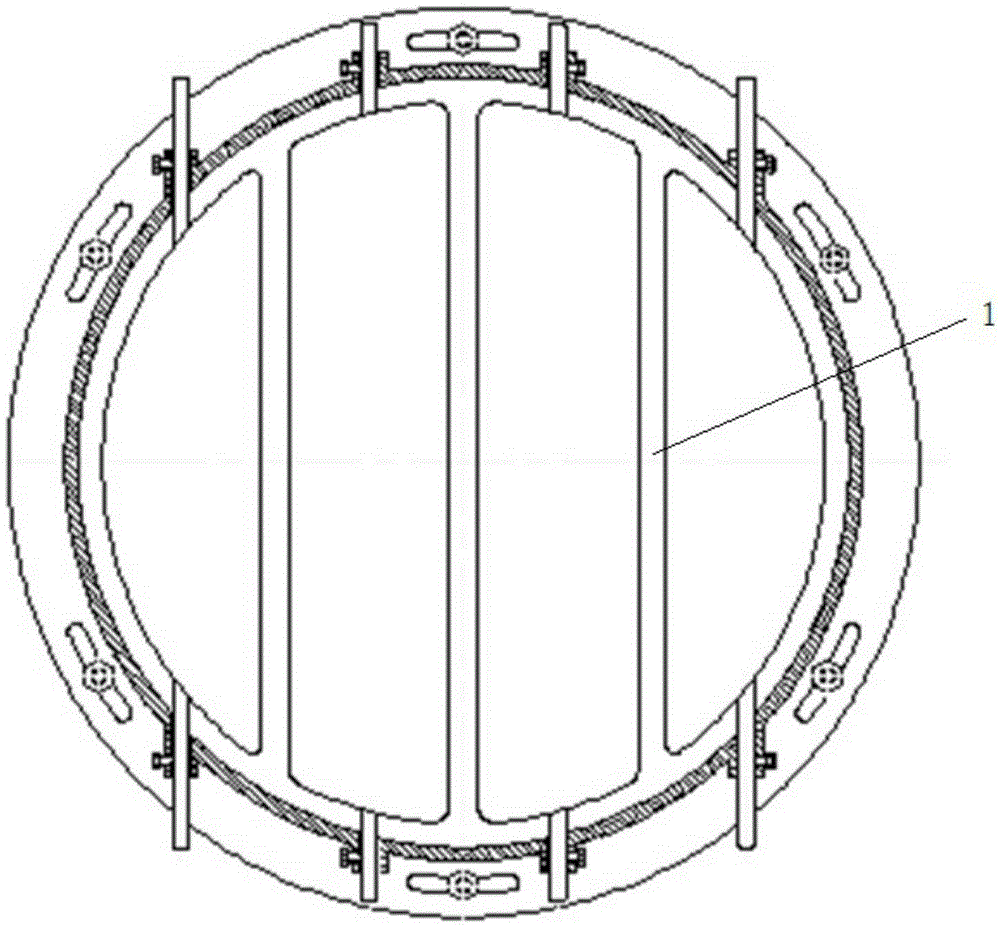

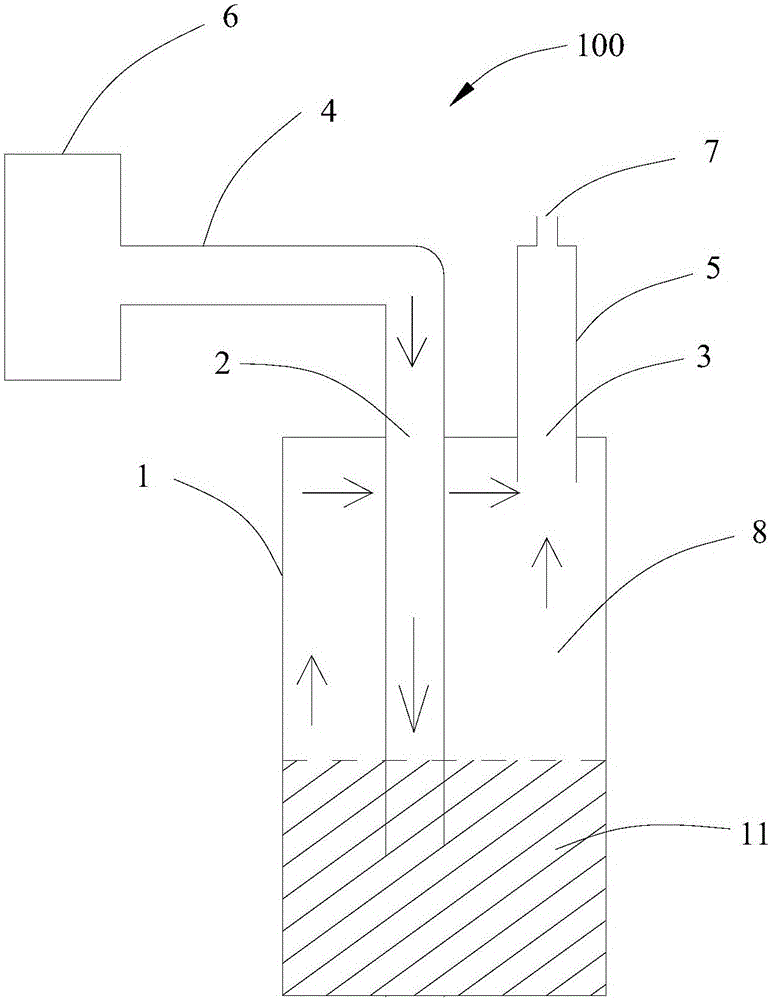

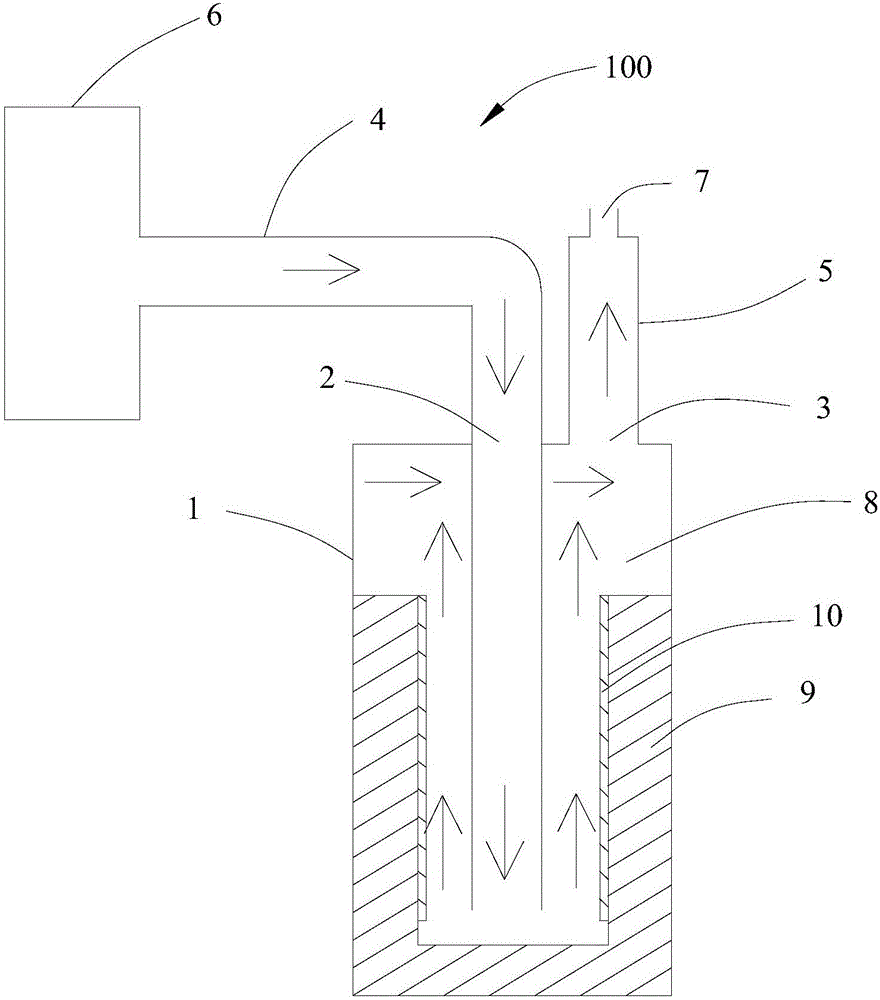

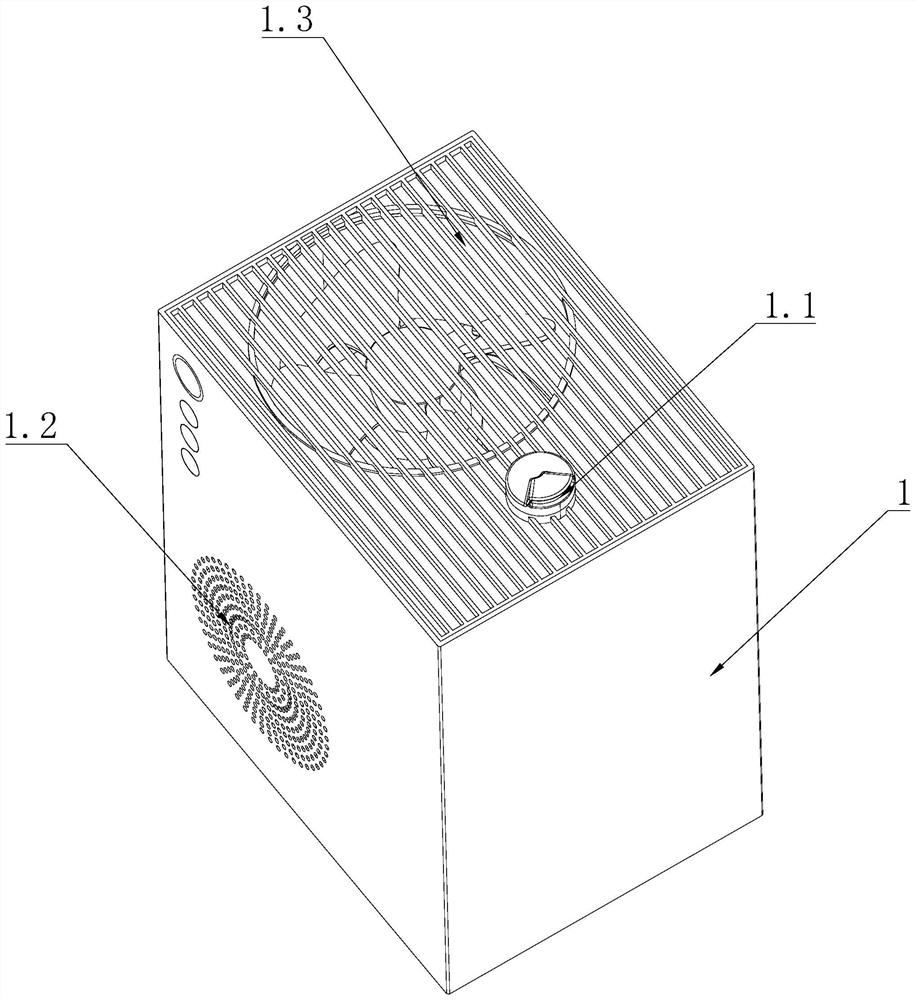

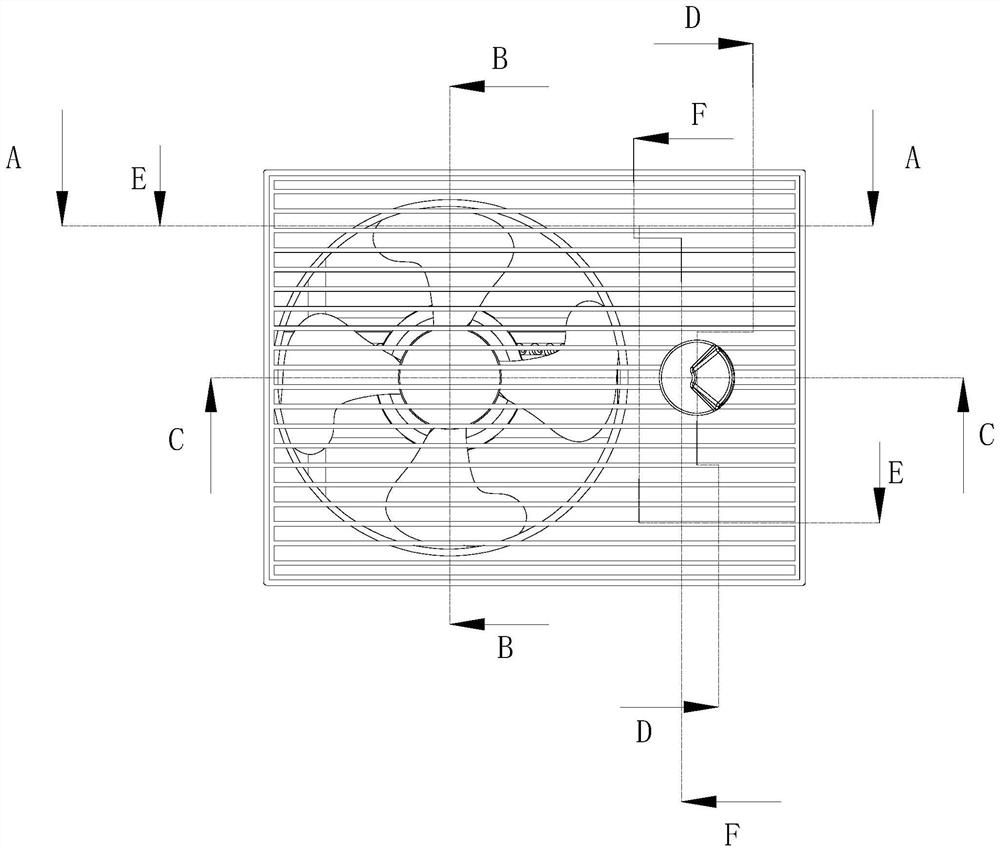

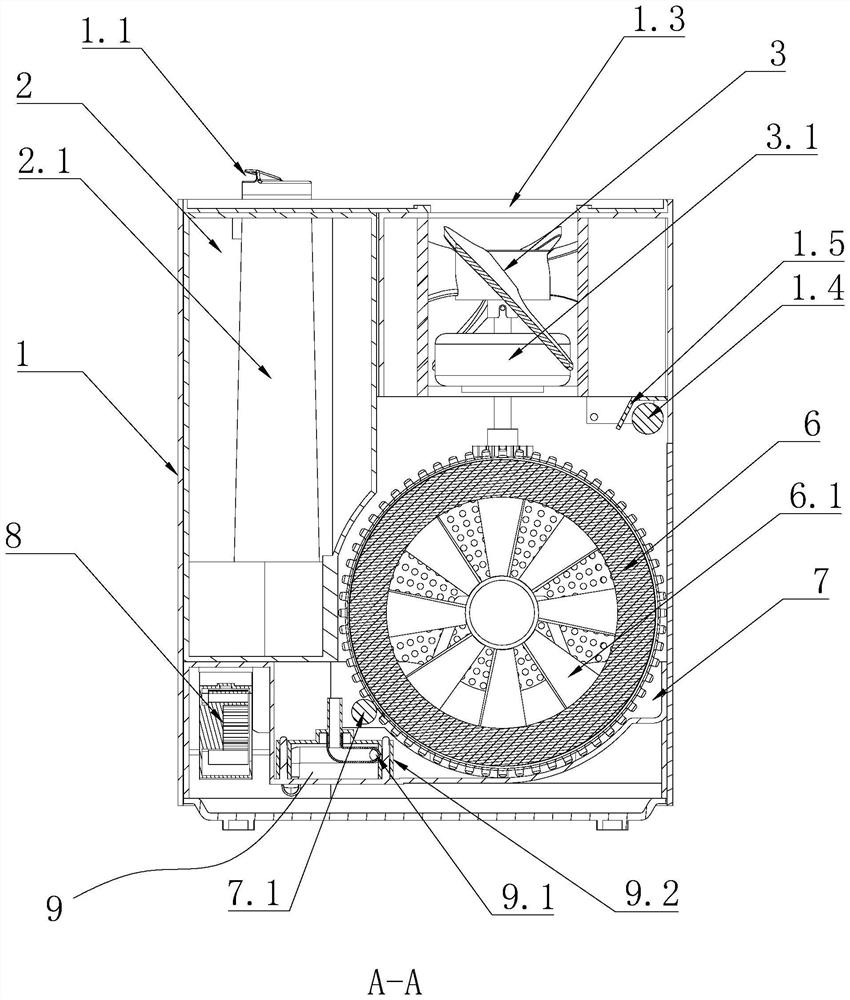

Atomization and evaporation dual-mode humidifier

ActiveCN113983589AImprove evaporation efficiencyEvaporate evenlyMechanical apparatusLighting and heating apparatusThermodynamicsEngineering

The invention discloses an atomization and evaporation dual-mode humidifier which comprises a shell (1), and a mist outlet (1.1) is formed in the shell (1); an ultrasonic atomization water tank (4) communicated with the mist outlet (1.1) is arranged in the shell (1); an ultrasonic atomization humidification assembly (5) is arranged in the ultrasonic atomization water tank (4); a rotatable evaporation filter element (6) and an evaporation humidification water tank (7) for supplying water to the evaporation filter element (6) are arranged in the shell (1); the evaporation filter element (6) is provided with a guide vane (6.1) which plays a role in guiding airflow during rotation; the atomization and evaporation dual-mode humidifier is high in evaporation efficiency, uniform in evaporation of the evaporation filter element, large in effective evaporation area and large in air flow flux penetrating through the evaporation filter element at the same air flow velocity, and has the mute and energy-saving effects.

Owner:宁波小乎科技有限公司

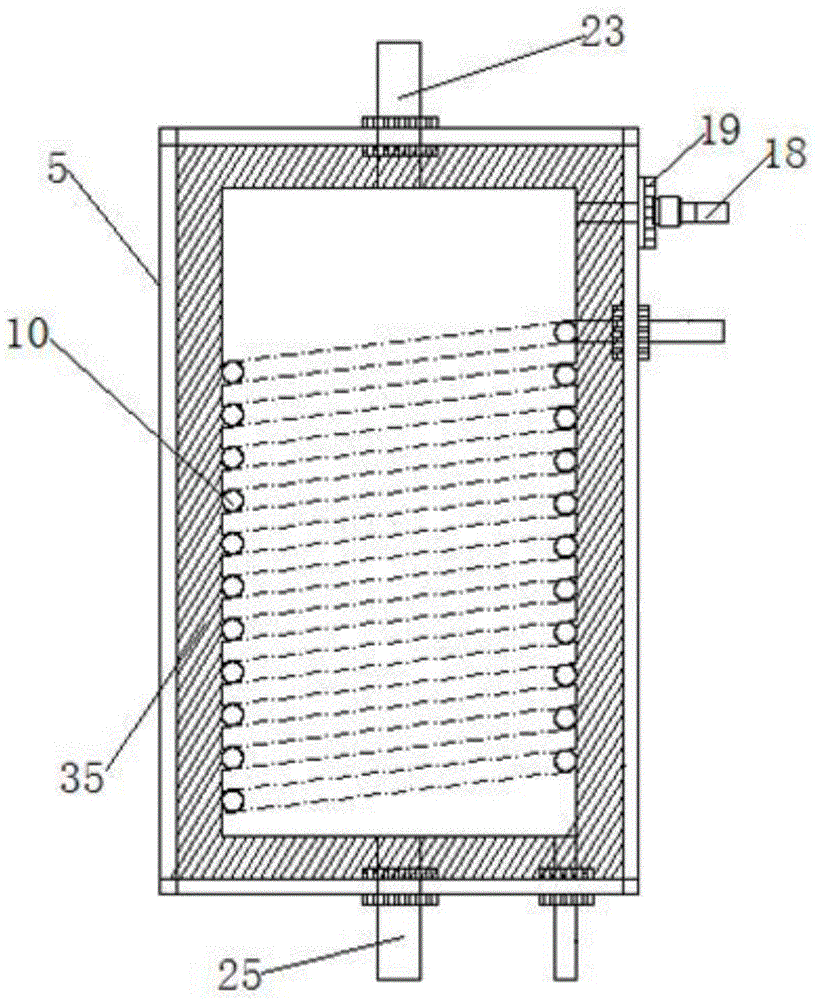

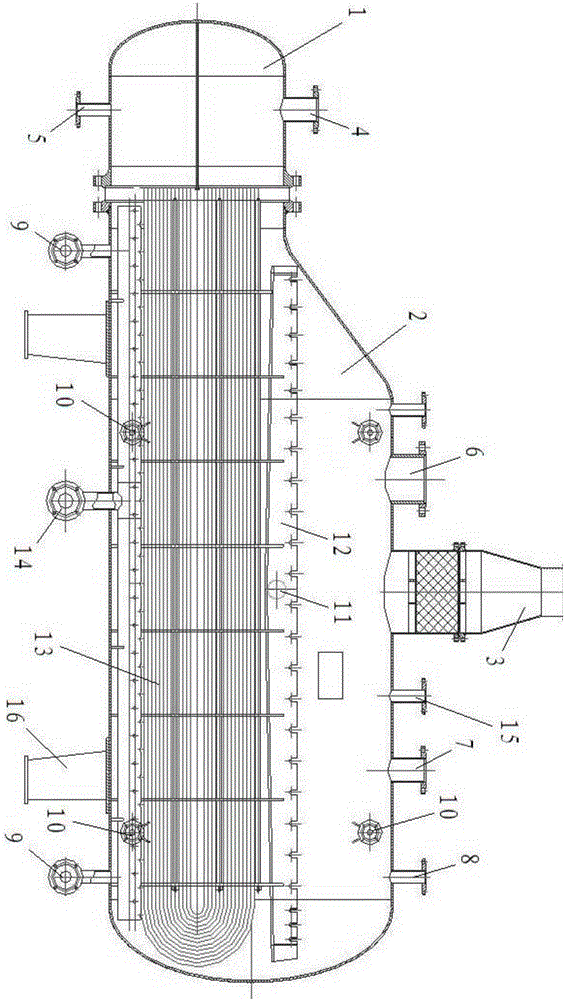

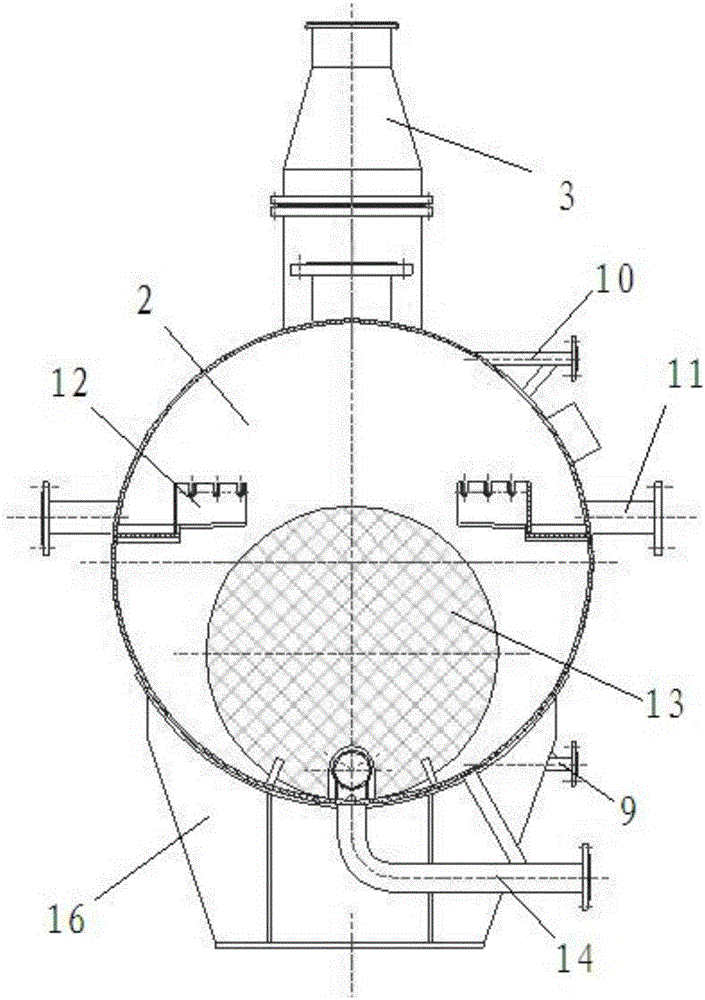

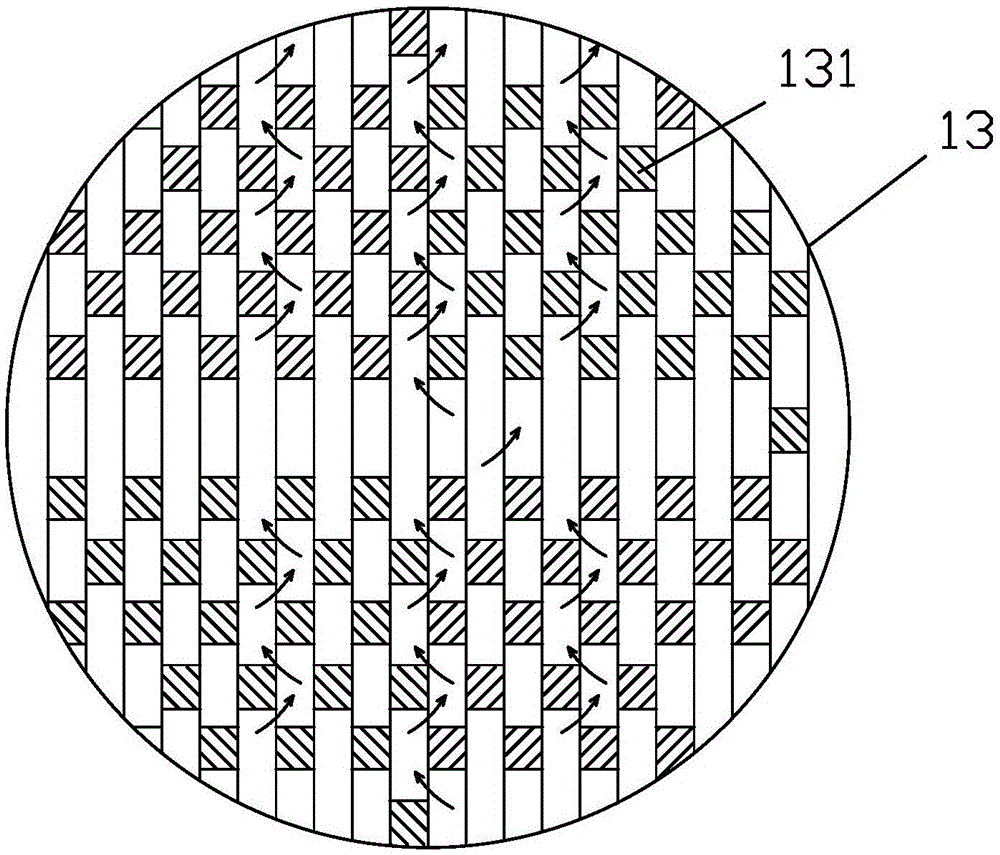

Sulfuric acid evaporator for refined acid producing apparatus

InactiveCN106166395AEasy on-site inspectionApplicable concentration is wideSulfur compoundsEvaporator regulation/controlWeld seamCondensed water

The invention discloses a sulfuric acid evaporator for a refined acid producing apparatus. The sulfuric acid evaporator is provided with a nicotinic acid tank and a water vapor tank, wherein the bottom portion of the nicotinic acid tank is provided with a nicotinic acid inlet, the top portion of the nicotinic acid tank is provided with a SO3 gas outlet, both side walls on the middle portion of the nicotinic acid tank are respectively provided with a nicotinic acid outlet, the top portion of the water vapor tank is provided with a steam inlet, the bottom portion of the water vapor tank is provided with a condensed water outlet, a U-shaped tube bundle is arranged inside the nicotinic acid tank, the inlet of the U-shaped tube bundle is positioned inside the water vapor tank and is communicated to the steam inlet, the outlet of the U-shaped tube bundle is positioned inside the water vapor tank and is communicated to the condensed water outlet, both sides on the middle portion inside the nicotinic acid tank are respectively provided with an overflow groove, and the bottom portion of the overflow groove is communicated to the nicotinic acid outlet. According to the present invention, the sulfuric acid evaporator is changed into the horizontal evaporator, the U-shaped tube bundle is used, the medium inside the tube bundle is the steam, the nicotinic acid is arranged outside the tube bundle, the actual pressure component of the equipment is reduced, the tube bundle welding seam on the tube nest contacts the steam, no corrosion is generated, and the acid inflow structure and the acid outflow structure of the evaporator consider the uniform flowing so as to ensure the uniform evaporation.

Owner:上海京藤化工有限公司

Incense core and preparation method thereof

ActiveCN104001203AReduce evaporation rateEvaporate evenlyGaseous substancesHydrophilic coatingChemistry

The invention aims to provide an incense core and a preparation method thereof so as to satisfy the demand that the incense core used by the user is great in perfume adsorption and long in service life. The incense core provided by the invention comprises an incense core matrix which adsorbs oily perfume. The key point is that an oil-dispelling hydrophilic coating film with ventilating holes is wrapped on the surface of the incense core matrix. The oil-dispelling hydrophilic coating film can effectively prevent oily perfume from permeation on the surface of the incense core and makes the oily perfume adsorbed by the incense core be diffused from the ventilating holes of the coating film, so that the diffusing speed is alleviated and the perfume can be used for a relative long time. The incense core is wrapped by the coating film where perfume cannot permeate, so that the volatilization speed of the perfume is delayed, the volatilization speed of the perfume is more uniform, the service life of the perfume is effectively prolonged, the concentration of the perfume in a vehicle can be maintained over a certain numerical value within the whole service cycle of the perfume, and the using experience of passengers is improved.

Owner:深圳市灵珞车品有限公司

Uniform and fast tea withering machine

ActiveCN106417713AWither evenlyEvaporate evenlyPre-extraction tea treatmentClimate change adaptationAgricultural engineeringAir blower

The invention discloses a uniform and fast tea withering machine. A barrel body comprises a top cover, a bottom cover and a barrel wall, wherein the top cover and the bottom cover are buckled at the two ends of the barrel wall. The uniform and fast tea withering machine comprises a plurality of withering devices, each of the withering devices comprises shaft rods and withering troughs, each of the withering troughs is connected with the corresponding shaft rod through a buckle, the adjacent shaft rods are in detachable connection with each other, and a baffle with the same size as a bottom plate of the withering trough is connected to each of the withering troughs; slide rails are arranged on the barrel wall, a pulley in sliding fit with the corresponding slide rail is arranged on each of the withering troughs, resistance sheets are arranged on each of the slide rails and are connected through a resistance plate, air cylinders are connected to the resistance plate, and a hot air blower is connected to the barrel wall. The uniform and fast tea withering machine disclosed by the invention has the benefits that tea leaves are put in the withering troughs of each of the withering devices, each of the withering troughs is connected with the corresponding shaft rod, and hot air is used for withering the tea leaves to accelerate the tea leaf withering speed; withering is performed in the barrel body, so that the floor area is reduced; the resistance plate is connected with the extension air cylinder and the contraction air cylinder, and the two air cylinders alternately run; each of the withering devices gradually moves downwards, so that the temperature is higher and higher, and the tea leaves are gradually withered.

Owner:汉中云峰茶业发展有限公司

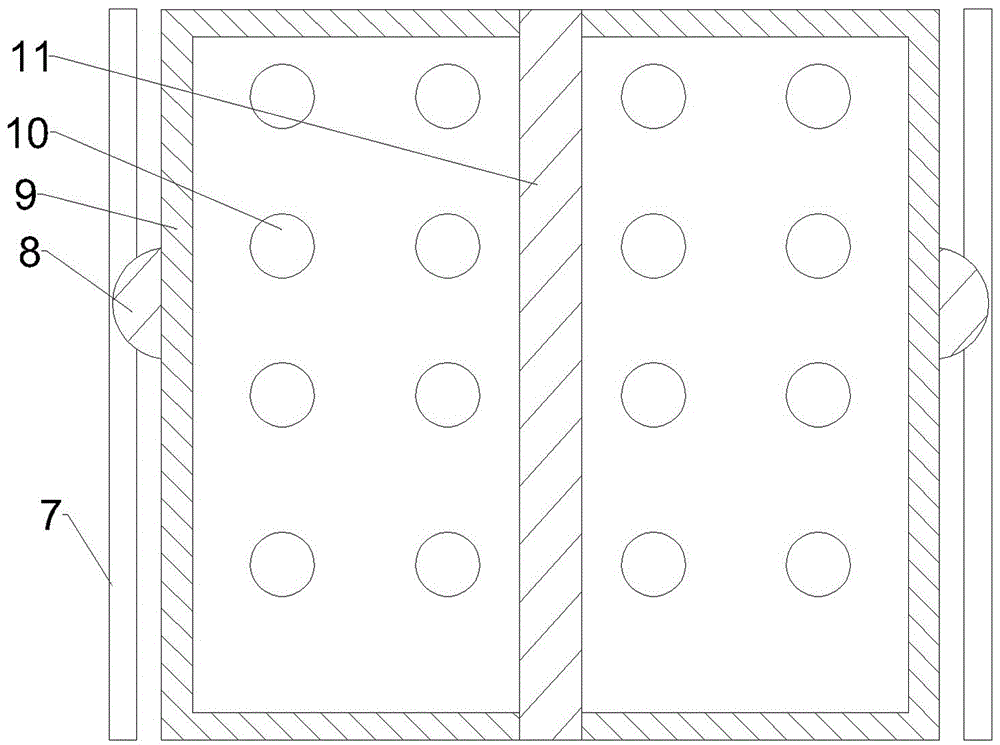

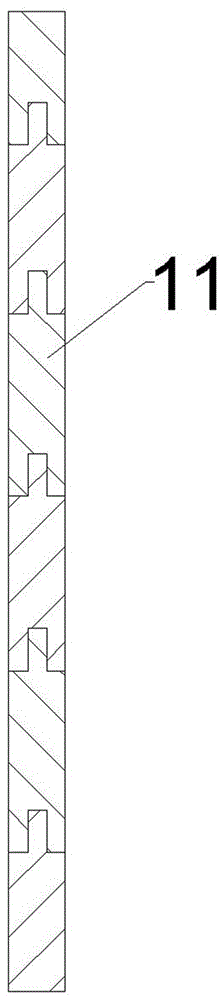

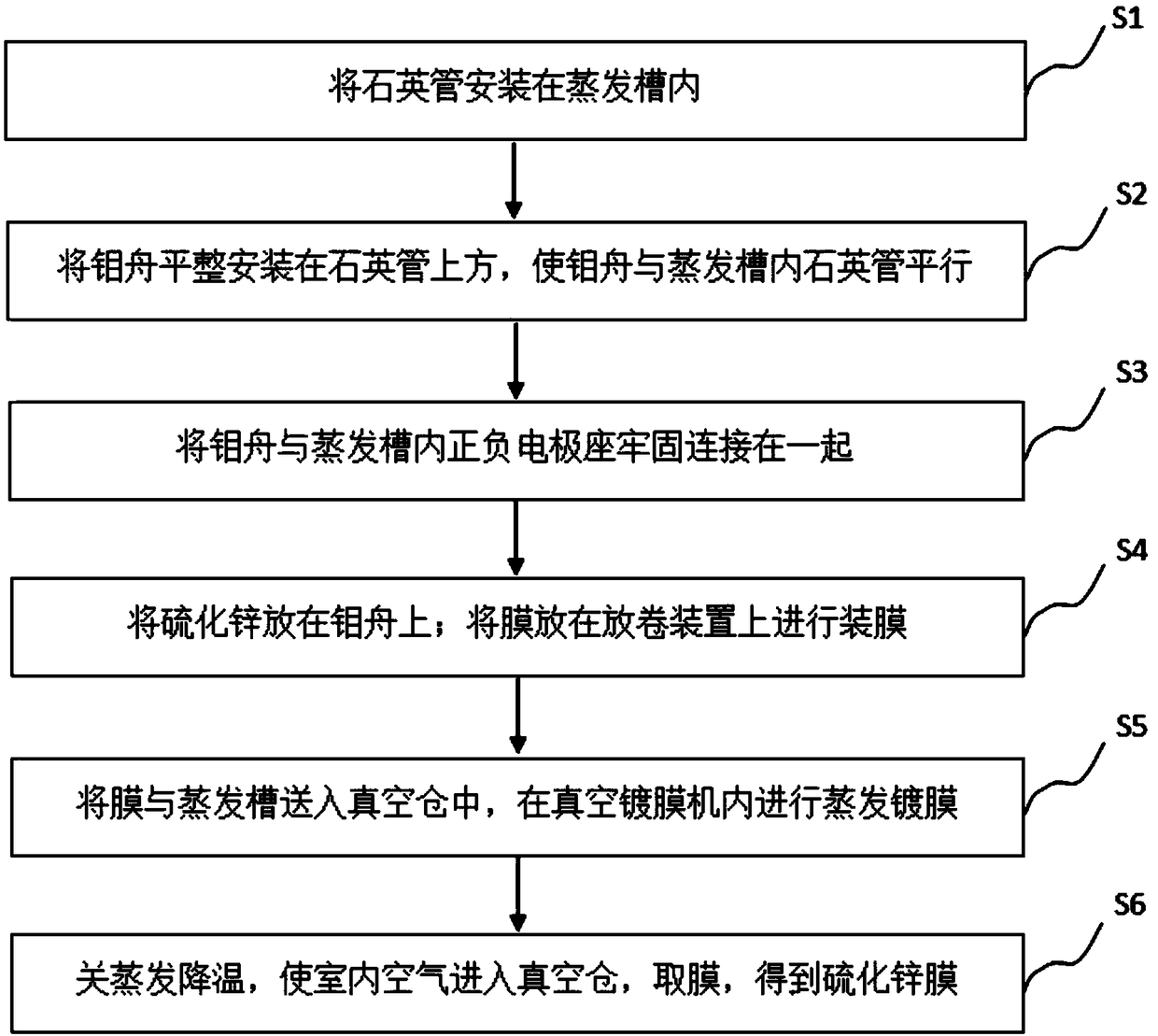

Method for preparing zinc sulfide film

InactiveCN108330444AEvaporate evenlyUniformityVacuum evaporation coatingSputtering coatingEvaporationZinc sulfide

The invention relates to a method for preparing a zinc sulfide film. The method comprises the following steps that a quartz tube is installed in an evaporation groove; a molybdenum boat is flatly installed above the quartz tube so that the molybdenum boat can be parallel to the quartz tube in the evaporation groove; the molybdenum boat is firmly connected with a positive and negative electrode seat in the evaporation groove; zinc sulfide is put on the molybdenum boat; a film is put on an unwinding device to carry out film loading; the film and the evaporation groove are sent into a vacuum bin,and evaporation coating is carried out in a vacuum coating machine; and evaporation is stopped to carry out cooling, indoor air enters the vacuum bin, and the film is taken to obtain the zinc sulfidefilm. According to the method for preparing the zinc sulfide film, the quartz tube is additionally arranged in the evaporation groove, the molybdenum boat is flatly installed above the quartz tube, and a quartz tube pad plays a role in radiating and supporting and leveling the molybdenum boat at the bottom of the molybdenum boat; and the molybdenum boat is flatly placed so that the zinc sulfide can be uniformly evaporated in the vacuum bin. According to the zinc sulfide film prepared by the method, the arrangement mode of the zinc sulfide is changed, the prepared zinc sulfide film is good inuniformity and orderly in arrangement, and the production efficiency of zinc sulfide film prepaeation is remarkably improved.

Owner:CHANGDE JINDE NEW MATERIAL TECH CO LTD

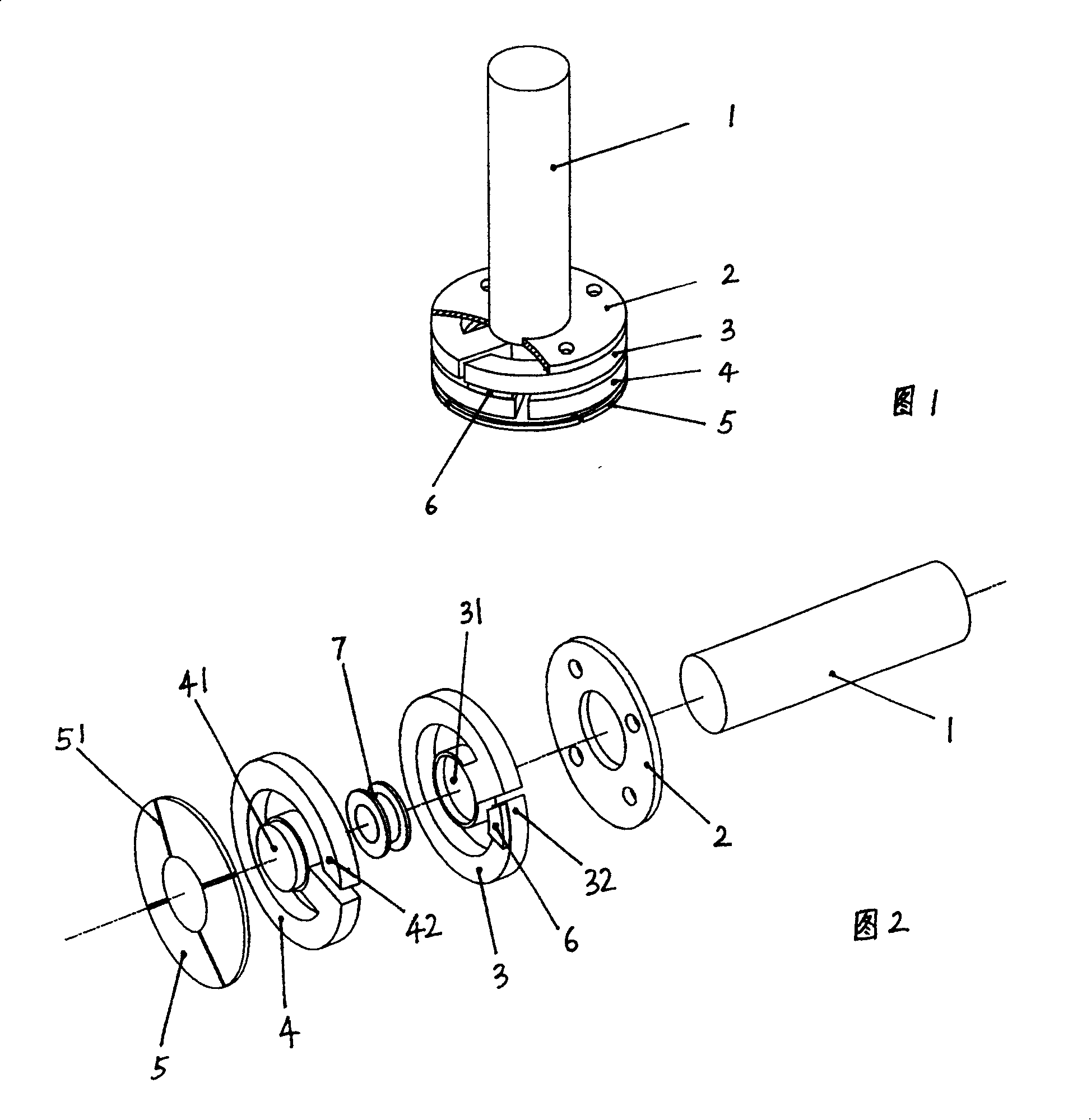

Double turn type longitudinal magnetic field contact for vacuum arc extinguishing chamber

InactiveCN100397538CImprove stabilityExtended service lifeHigh-tension/heavy-dress switchesAir-break switchesEngineeringVacuum arc

This invention relates to a vacuum arc-suppressing chamber contactor, a double turn longitudinal magnetic field contactor including a conducting bar, a current coil, a contactor plate, among which, the contactor coil is set between the conducting bar and the contactor plate, the conducting bar, the current coil and the contactor are serial orderly, the current coil is a dual turn coil, both ends of which are set at the shaft core to form two coaxial connecting ends, the front end is fixedly connected with the center of the contactor plate, the back end is fixedly connected with the conducting bar. Since the invention applies double-turn coil, it generates strong magnetic field density to increase stability of arc and prolong the lifetime of the contactor plate.

Owner:ZHEJIANG ZIGUANG ELECTRIC APPLIANCE

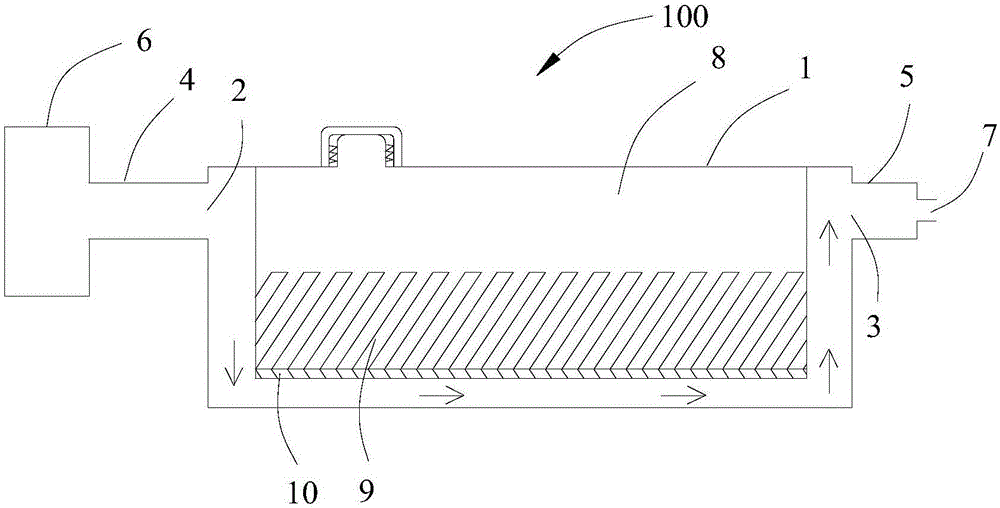

Evaporation auxiliary device and drying equipment

PendingCN108759360AEvaporate evenlyUniform thicknessDrying solid materialsDrying machines with local agitationSolventEngineering

The invention provides an evaporation auxiliary device which is used for the film layer drying technology and comprises a shield plate, wherein the shield plate comprises a top wall and side walls connected with the top wall; the top wall is used for being arranged opposite to the to-be-dried area of a to-be-dried base plate; the side walls are used for supporting the to-be-dried base plate and surrounding the to-be-dried area; a plurality of vent holes are formed in the top plate; the top wall of the shield plate is divided into a plurality of ventilation areas distributed from the middle ofthe top wall to the edge of the top wall; and from the middle of the top wall to the edge of the top wall, the the ratio of the sum of the opening areas of the vent holes in the ventilation areas to the areas of the ventilation areas is gradually reduced. Correspondingly, the invention further provides drying equipment. According to the evaporation auxiliary device, the volatilization speed of solvent in the entire to-be-dried area can be balanced, so that the thicknesses of film layers formed after drying different positions of the to-be-dried area are more uniform.

Owner:BOE TECH GRP CO LTD +1

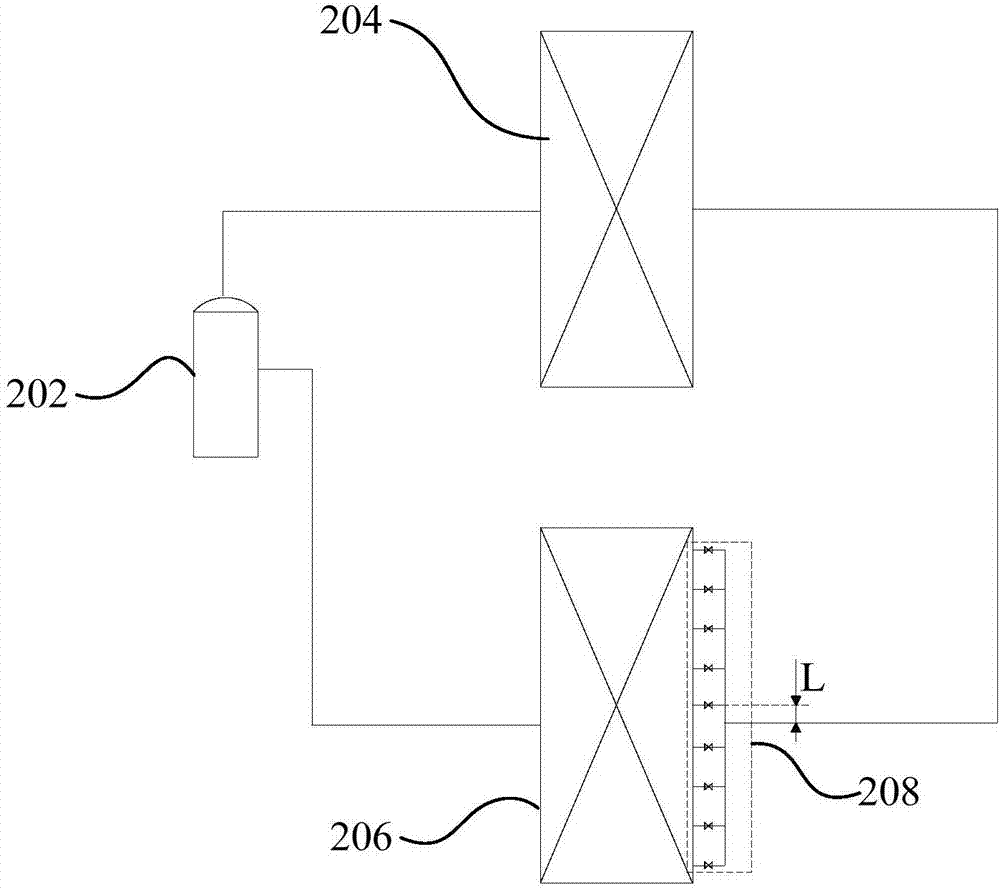

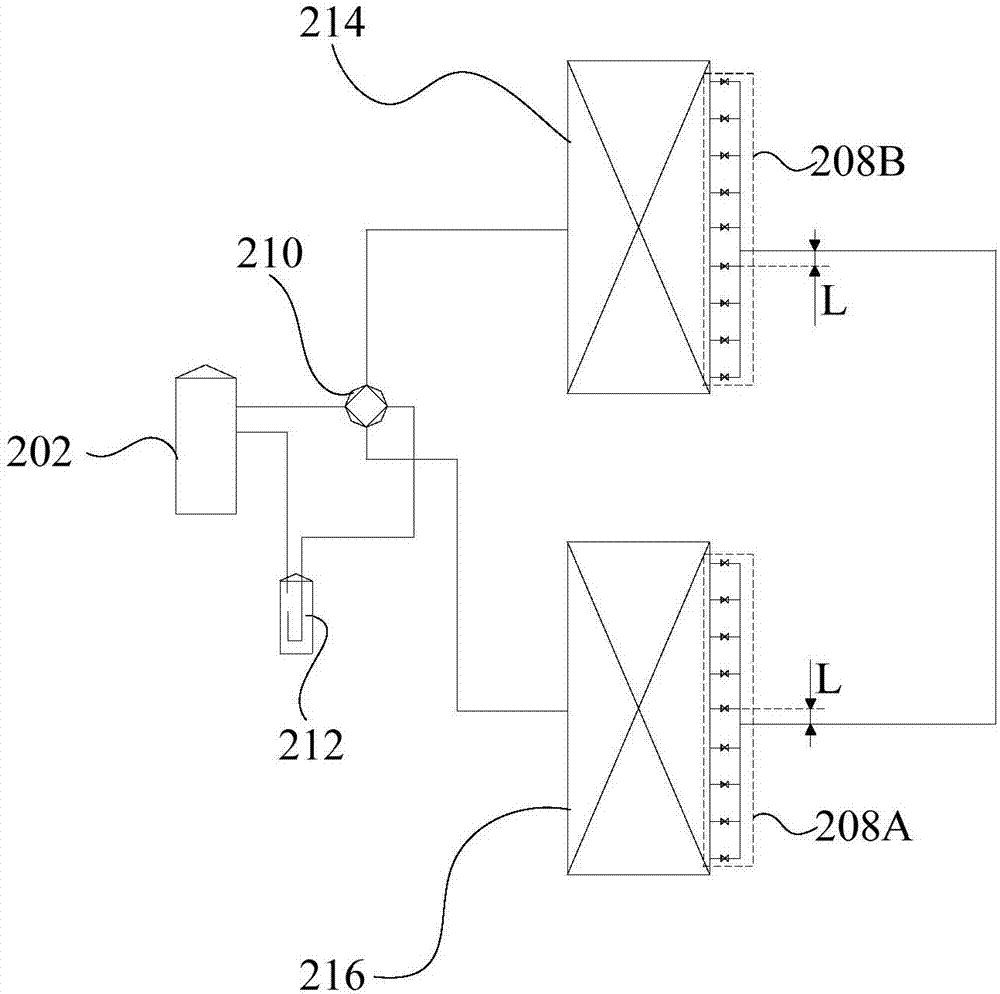

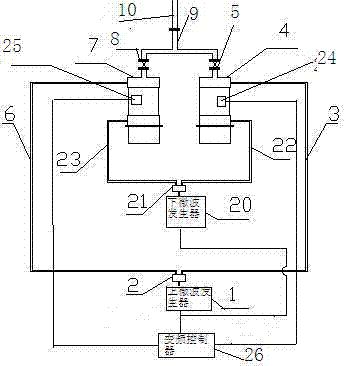

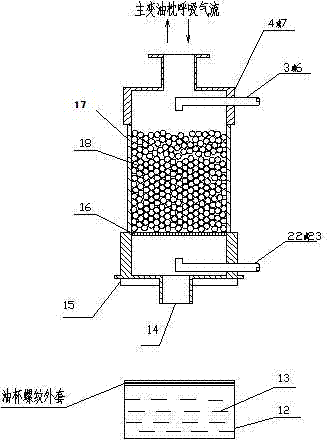

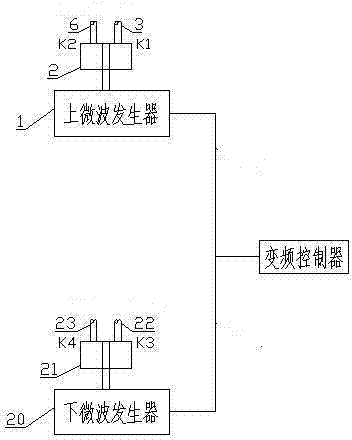

Main transformer regeneration breather with frequency conversion control and bidirectional microwave heating functions and use method of breather

ActiveCN104517706ASolve security risks and other issuesReduce frequencyTransformers/inductances coolingDispersed particle filtrationTransformerFrequency conversion

The invention provides a main transformer regeneration breather with frequency conversion control and bidirectional microwave heating functions and a use method of the breather. The breather comprises a frequency converter controller, an upper frequency conversion microwave heating device, a lower frequency conversion microwave heating device, a first moisture absorption tank, a second moisture absorption tank, a three-way pipe, a first humidity sensor and a second humidity sensor. According to the breather provided by the invention, the problems of manual replacement during moisture absorption saturation failure of a moisture absorption agent, major potential safety hazards due to exiting of a main transformer heavy gas protection device in a replacement process and the like for a conventional large-sized main transformer breathing device are solved by a bidirectional microwave heating drying regeneration technology; due to the use of the frequency converter controller, the microwave emission frequency of a microwave generator can be controlled according to the moisture absorption degree of the moisture absorption agent, so that the moisture absorption agent in the breather can be uniformly heated and dried; the breather has the huge advantages of being high in efficiency and safe to use.

Owner:STATE GRID CORP OF CHINA +5

Granulator for soda lime and calcium lime and preparing method of granulator

InactiveCN102553492AReduce moisture contentReduce consumptionGranulation by material expressionCalcium/strontium/barium oxides/hydroxidesDrive shaftChemical products

The invention relates to the preparation of chemical products, and particularly discloses a granulator for soda lime and calcium lime and a preparation method of the granulator. Compared with the prior art, the granulator and the preparation method has the advantages that the resource and the energy source are effectively saved, the rigidity of obtained grain is high, and the water content of a finished product can be better controlled. The technical scheme disclosed by the invention is that the granulator for the soda lime and the calcium lime comprises an electric motor, a drive shaft, a die and a raw material groove, wherein the drive shaft comprises a main drive shaft and an auxiliary drive shaft, and the die comprises a main die and an auxiliary die. The preparation method of the granulator comprises the following steps of preparation of raw materials, preparation of a semi-finished product and preparation of the finished product.

Owner:SHANGHAI 54 CHEM REAGENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com