Granulator for soda lime and calcium lime and preparing method of granulator

The technology of calcium lime and soda lime is applied in the field of preparation of chemical products, which can solve the problems of waste of resources and energy, blockage of extruders, low hardness of soda lime and soda lime particles, save resources and energy, reduce water content, The effect of low moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0027] 1) The structure of the granulator:

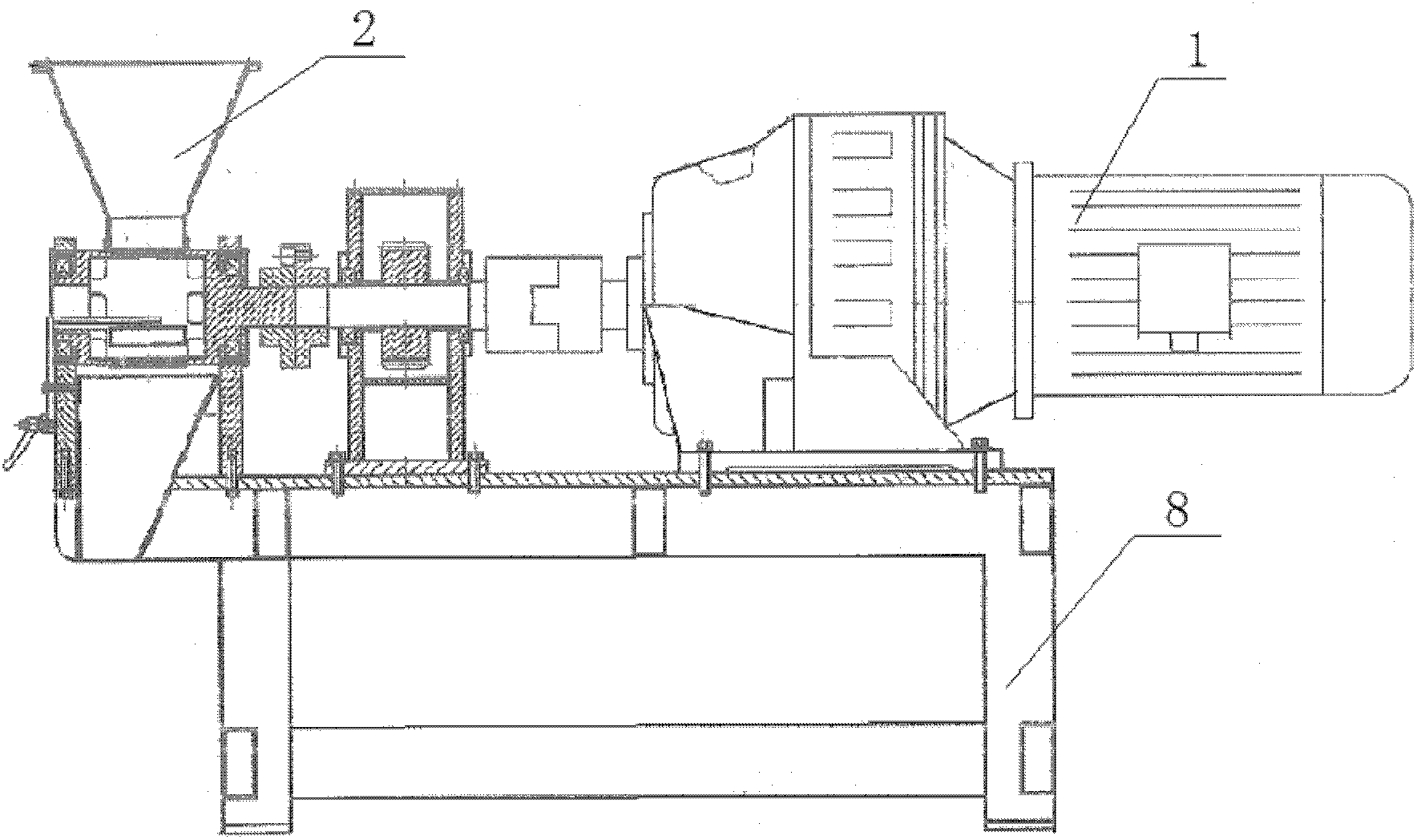

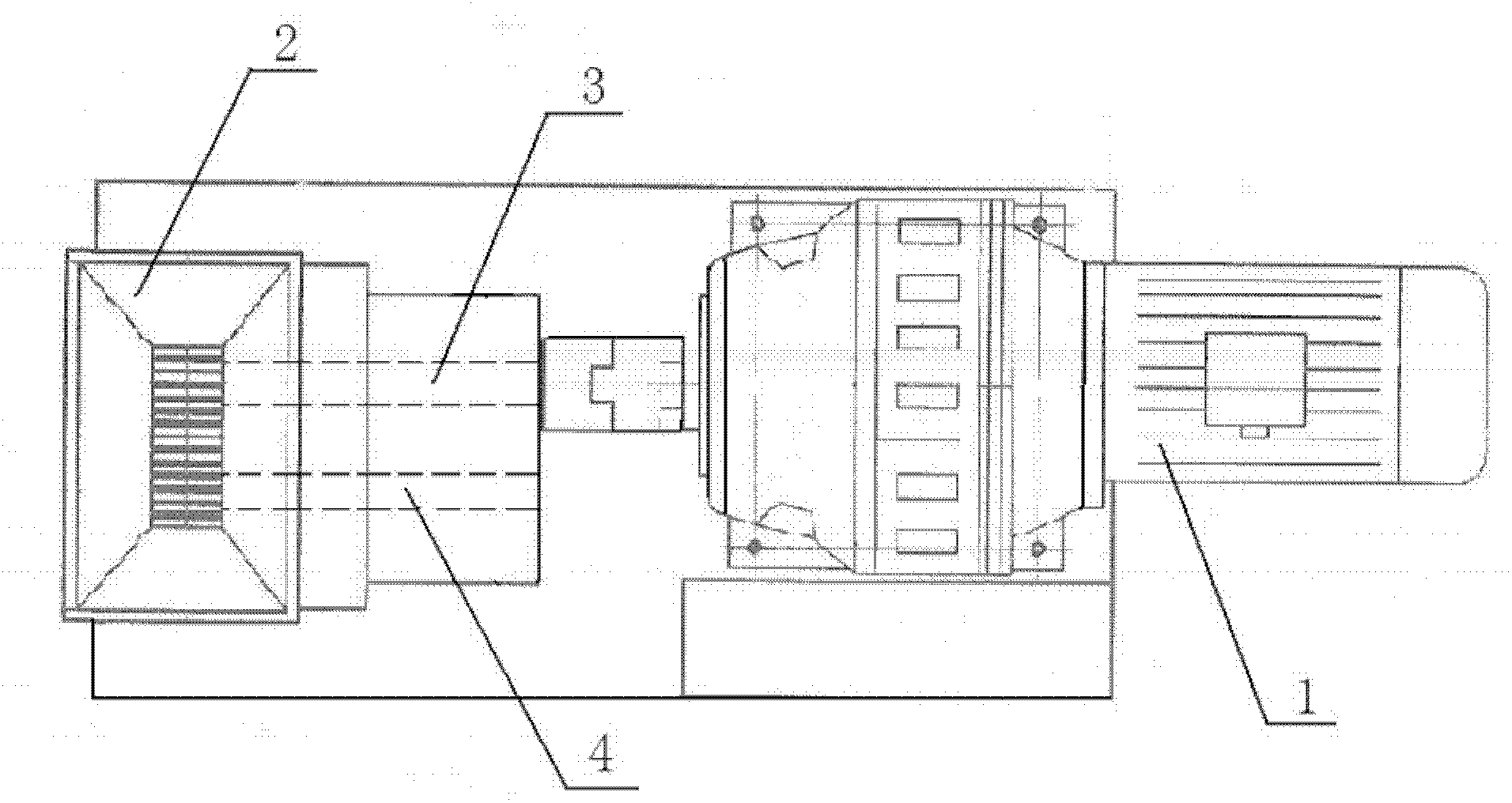

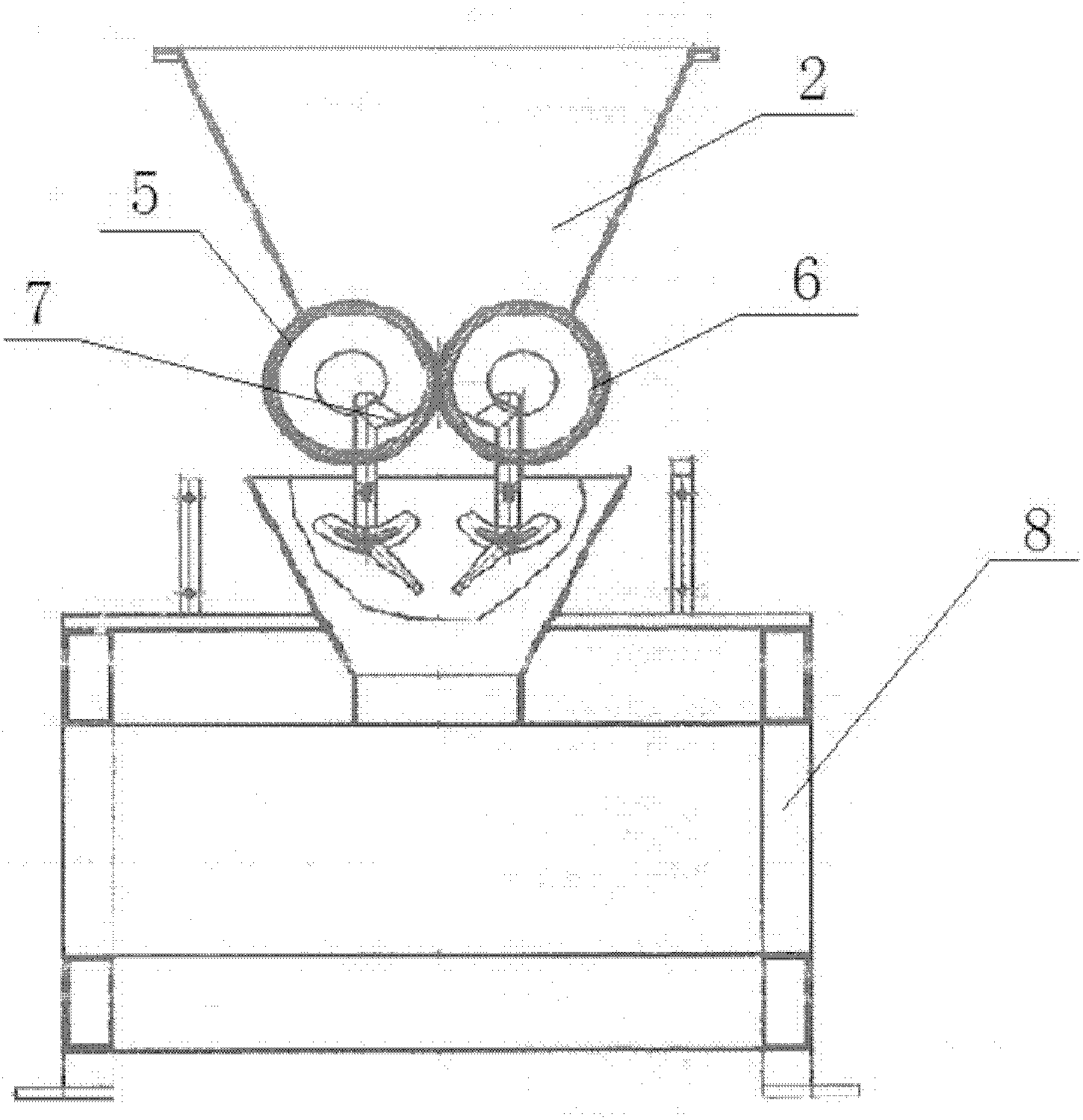

[0028] Such as figure 1 , figure 2 and image 3 , the soda lime and calcium lime granulator in the figure includes a motor 1, a transmission shaft, a mold and a raw material tank 2, the transmission shaft includes a main transmission shaft 3 and an auxiliary transmission shaft 4, and the mold includes a main mold 5 and a secondary mold 6, The motor 1 drives the main transmission shaft 3 to connect with the main mold 5, and one-half of the main transmission shaft 3 is connected to the auxiliary transmission shaft 4 in a gear-driven manner, and the auxiliary transmission shaft 4 is connected to the auxiliary mold 6, and the motor 1 is turned on to drive the main transmission shaft 3 , and then the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com