Woven fabric having functions of isomerism on double side, guiding sweat on single direction and rapidly drying and production method thereof

A double-sided anisotropic, woven fabric technology, applied in the direction of fabrics, textiles, textiles and papermaking, can solve the problems of not being able to disperse sweat evenly, not being able to obtain a comfortable appearance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

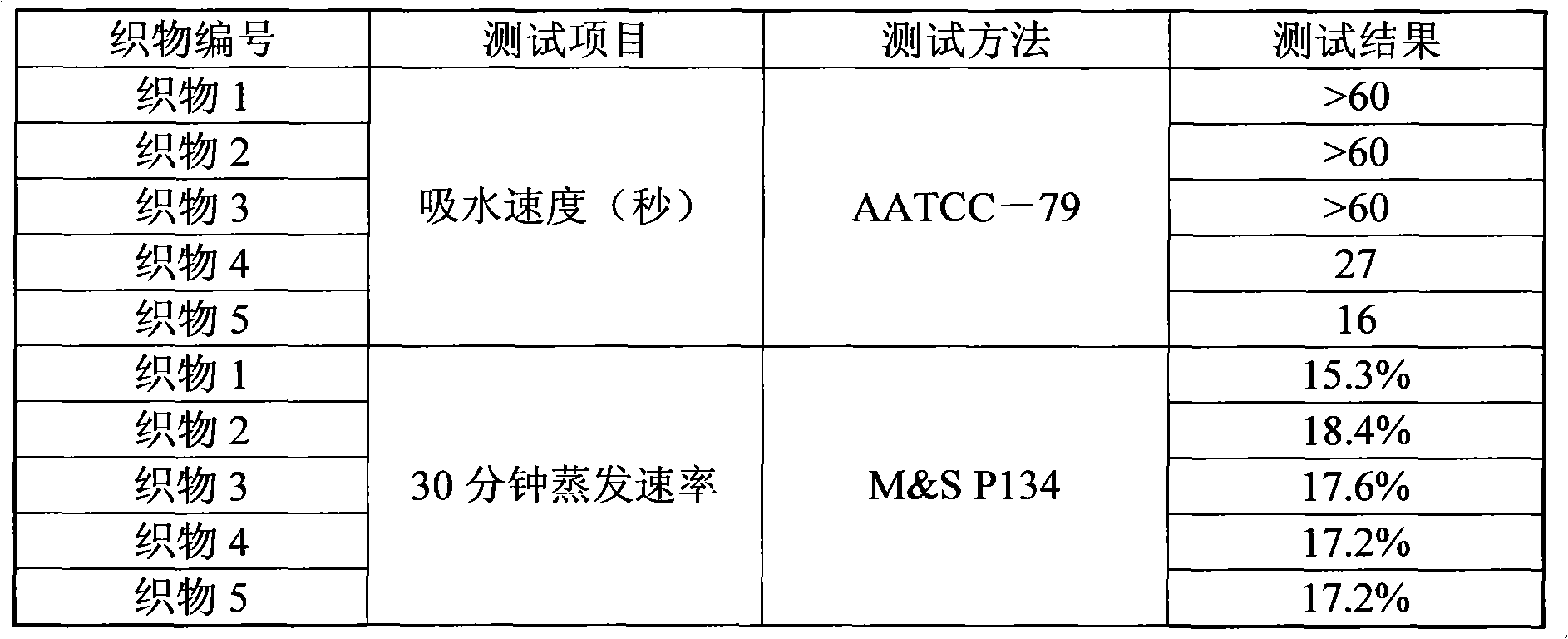

Embodiment 1

[0041] The warp yarn of the fabric is 40s cotton yarn, and the weft yarn is 80s / 2 cotton yarn. 2 / 1 right twill weave.

[0042] Warp preparation:

[0043] Scouring→bleaching→dyeing→soaping, color fixing→overhydrophilic soft oil→drying

[0044] Add the 40s cotton yarn that has been scoured, bleached, dyed, soaped and color-fixed according to the conventional process into the aqueous solution of hydrophilic soft oil Magnasoft HWS (GE company) with a concentration of 4g / l, and treat it at 40°C for 30 minutes, and the weight Calculated, the ratio (bath ratio) of cotton yarn to hydrophilic soft oil aqueous solution is 1:10. The treated yarn is dried by high frequency at 100°C.

[0045] Preparation of weft yarn:

[0046] The 80s / 1 pure cotton single yarn is subjected to scouring, bleaching, dyeing, soaping and color fixing according to the conventional process, and then divided into vats. Half of the yarns were treated with hydrophilic soft oil to obtain hydrophilic single yarns...

Embodiment 2

[0052] The warp yarn of the fabric adopts 80s / 2 cotton yarn, and the weft yarn adopts 80s / 2 cotton yarn. 3 / 1 herringbone twill weave.

[0053] Warp preparation:

[0054] 80s / 2 cotton yarn scouring→bleaching→dyeing→soaping, color fixing→hydrophilic soft oil→drying

[0055] Wherein scouring, bleaching, dyeing, soaping, and color fixing are carried out according to conventional processes. After color fixing is completed, the cotton yarn is added with a concentration of 4g / l hydrophilic soft oil Ultraphil DCW (Huntsman company) in the aqueous solution, and treated at 40 ° C for 30 minutes, the liquor ratio is 1:10. The treated yarn is dried by high frequency at 100°C.

[0056] Preparation of weft yarn:

[0057] 80s single yarn (single yarn 1) scouring→bleaching→dyeing→soaping, color fixing→hydrophilic softening oil→drying

[0058] 80s single yarn (single yarn 2) scouring→bleaching→dyeing→soaping, color fixing→water-repellent softening oil→drying

[0059] Above-mentioned sing...

Embodiment 3

[0065] The warp yarn of the fabric is 40s single cotton yarn, and the weft yarn is 80s / 3 cotton yarn. 3 / 1 left twill weave.

[0066] Warp preparation:

[0067] Scouring→bleaching→dyeing→soaping, color fixing→overhydrophilic soft oil→drying

[0068] Among them, scouring, bleaching, dyeing, soaping, and color fixing are carried out according to the conventional process. After the color fixing is completed, add a concentration of 3g / l hydrophilic soft oil NT-H550 (Nanotex company) in the aqueous solution, and treat it at 40 ° C for 20 minutes , the bath ratio is 1:8. The treated yarn is dried by high frequency at 100°C.

[0069] Preparation of weft yarn:

[0070] 80s single cotton yarn (single yarn 1) scouring→bleaching→dyeing→soaping, color fixing→hydrophilic soft oiling→drying

[0071] 80s single cotton yarn (single yarn 2) scouring→bleaching→dyeing→soaping, color fixing→water-repellent softening oil→drying

[0072] The above-mentioned single yarn 1 and single yarn 2 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com