Incense core and preparation method thereof

A fragrance core and perfume technology, which is applied in the direction of vaporized substances, can solve the problems of less perfume adsorption, less perfume adsorption, and weak perfume adsorption, so as to achieve the effect of delaying volatilization speed, uniform volatilization speed and improving user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

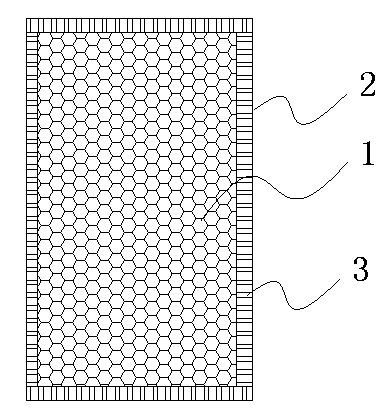

[0016] Such as figure 1 As shown, the fragrance core of this embodiment includes a fragrance core substrate 1 that absorbs oily perfume. The key point is that the surface of the fragrance core substrate is covered with a layer of oil-repellent and hydrophilic coating film 2 with air holes 3 .

[0017] Specifically, the coating film is formed by mixing and drying a film-forming material, a solvent, and a plasticizer. The weight percentages of each component are as follows: film-forming material: 1%, solvent: 91%, plasticizer Agent: 8%. Wherein the film-forming material is seaweed gel, the solvent is water, and the plasticizer is glycerin.

[0018] The incense core base is made by mixing absorbent, wetting agent, binder and lubricant, and the weight percentage of each component is as follows: absorbent: 35%, wetting agent: 50%, binder: 5%, lubricant : 10%; the absorbent is calcium silicate; the wetting agent is water; the binder is carboxymethyl cellulose; the lubricant is tal...

Embodiment 2

[0027] Different from Example 1, in this embodiment, the coating film is formed by mixing and drying film-forming material, solvent, plasticizer, and the weight percentage of each component is as follows: film-forming material: 3%, solvent : 92%, plasticizer: 5%. Wherein the film-forming material is hydroxypropyl cellulose; the solvent is water; and the plasticizer is polyethylene glycol.

[0028] In this embodiment, the scent core base is made by mixing absorbent, wetting agent, binder and lubricant, and the weight percentage of each component is as follows: absorbent: 28%, wetting agent: 55%, binder : 6%, lubricant: 11%; the absorbent is fumed silica; the wetting agent is water; the binder is gum arabic; the lubricant is polyethylene glycol.

[0029]

Embodiment 3

[0031] Different from Example 1, in this embodiment, the coating film is formed by mixing and drying film-forming materials, solvents, and plasticizers, and the weight percentages of each component are as follows: film-forming materials: 5% , Solvent: 93%, Plasticizer: 2%. The film-forming material is the mixture of hydroxypropyl cellulose and acrylic resin polymer; the solvent is water; the plasticizer is propylene glycol.

[0032] In this embodiment, the scent core base is made by mixing absorbent, wetting agent, binder and lubricant, and the weight percentage of each component is as follows: absorbent: 30%, wetting agent: 52%, binder : 5%, lubricant: 13%; the absorbent is microcrystalline cellulose; the wetting agent is water; the binder is a mixture of povidone and pure gum; the lubricant is magnesium lauryl sulfate and magnesium stearate mixture.

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com