Coal dust inhibitor and preparation method thereof

A technology of coal dust inhibitor and penetrant, applied in chemical instruments and methods, cleaning methods, other chemical processes, etc., can solve the problems of short duration of effect, high labor intensity of workers, unfavorable and widespread use, etc. Harsh, less production equipment, suitable for mechanical strength and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、1

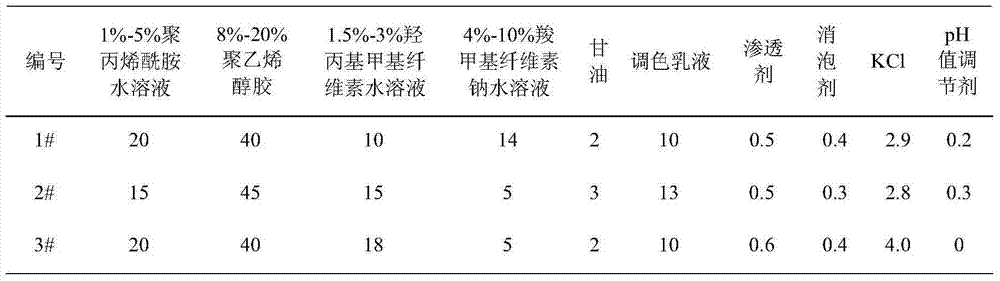

[0053] Example 1, Preparation and application of 1# coal dust inhibitor

[0054] According to the above-mentioned raw material mass percentage and preparation method, 1# coal dust inhibitor was prepared, in which the mass percentage of the polyacrylamide aqueous solution was 2%, the mass percentage of polyvinyl alcohol glue was 8%, and the hydroxypropyl methyl The mass percentage of the base cellulose aqueous solution is 3%, and the mass percentage of the sodium carboxymethyl cellulose aqueous solution is 8%. The toner emulsion is ZC-1026 anti-alkali sealant emulsion; the penetrant is water glass; the defoamer is NXZ defoamer; the pH adjuster is a 32wt% sodium hydroxide aqueous solution.

[0055] In the 1# coal dust inhibitor prepared in this example, the quality ratio of each component is as follows:

[0056] Polyacrylamide: Polyvinyl Alcohol: Hydroxypropyl Methyl Cellulose: Sodium Carboxymethyl Cellulose: Glycerin: Toning Emulsion: Penetrant: Defoamer: KCl: pH Adjuster: Water = 0....

Embodiment 2

[0059] Example 2, Preparation and application of 2# coal dust inhibitor

[0060] According to the above-mentioned raw material mass percentage and preparation method, 2# coal dust inhibitor was prepared, wherein the mass percentage of the polyacrylamide aqueous solution was 3%, the mass percentage of the polyvinyl alcohol gum was 10%, and the hydroxypropyl methyl The mass percentage of the base cellulose aqueous solution is 2%, and the mass percentage of the sodium carboxymethyl cellulose aqueous solution is 8%. The toner emulsion is ZC-1026 anti-alkali sealing emulsion; the penetrant is water glass; the defoaming agent is NXZ defoaming agent; the pH adjusting agent is a 32wt% sodium hydroxide aqueous solution.

[0061] In the 2# coal dust inhibitor prepared in this example, the quality ratio of each component is as follows:

[0062] Polyacrylamide: Polyvinyl Alcohol: Hydroxypropyl Methyl Cellulose: Sodium Carboxymethyl Cellulose: Glycerin: Toning Emulsion: Penetrant: Defoamer: KCl:...

Embodiment 3

[0065] Example 3, Preparation and application of 3# coal dust inhibitor

[0066] According to the above-mentioned raw material mass percentage and preparation method, 3 coal dust inhibitors were prepared, wherein the mass percentage of polyacrylamide aqueous solution was 4%, the mass percentage of polyvinyl alcohol gum was 15%, and the hydroxypropyl methyl The mass percentage of the cellulose aqueous solution is 2%, and the mass percentage of the sodium carboxymethyl cellulose aqueous solution is 6%. Toning emulsion is ZC-1026 anti-alkali sealing emulsion; penetrant is water glass; defoamer is NXZ defoamer.

[0067] In the 3# coal dust inhibitor prepared in this example, the quality ratio of each component is as follows:

[0068] Polyacrylamide: Polyvinyl Alcohol: Hydroxypropyl Methyl Cellulose: Sodium Carboxymethyl Cellulose: Glycerin: Toning Emulsion: Penetrant: Defoamer: KCl: Water = 0.8: 6: 0.36: 0.3: 2: 10: 0.6: 0.4: 4: 75.54.

[0069] The technical indicators of the 3# coal du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com