2-benzothiazolethiol nitrogen circulation drying and solvent recovery method

A benzothiazole nitrogen, circulating drying technology, applied in separation methods, drying solid materials, chemical instruments and methods, etc., can solve the problems of methanol solvent waste, endangering personal safety, irritation and toxicity, etc., and achieves long residence time, Improve product quality and prevent material denaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

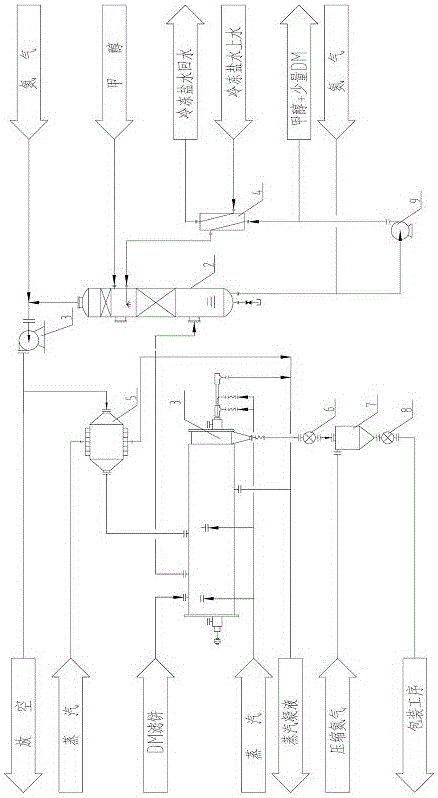

[0022] Such as figure 1 Shown, a kind of 2-thiol benzothiazole nitrogen circulation drying and solvent recovery method may further comprise the steps:

[0023] (1) Transport the 2-mercaptobenzothiazole wet material to the vacuum drying chamber of the vacuum paddle dryer 1, and fill the gap between the wedge-shaped blades, and at the same time, the steam at a temperature of 110~120°C is passed into the vacuum paddle dryer 1 In the jacket of the paddle shaft and the shell; under the rotation of the paddle shaft, the 2-mercaptobenzothiazole wet material is indirectly heated by the steam while moving forward, and the drying temperature is 90~100℃ respectively. After the material and evaporated moisture.

[0024] (2) The dried material is discharged from the outlet through the overflow weir, and enters the sealed buffer tank 7 through the rotary unloading valve I6, and nitrogen gas is input into the sealed buffer tank 7 for nitrogen sealing, and the dried material passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com