Vertical heating wire atomizer

A technology of heating wire and atomizer, which is applied in application, tobacco, smoker's supplies, etc. It can solve the problems of harmful substances, poor contact, and unable to adjust the amount of smoke, etc., and achieve the effect of adjustable airflow and uniform evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

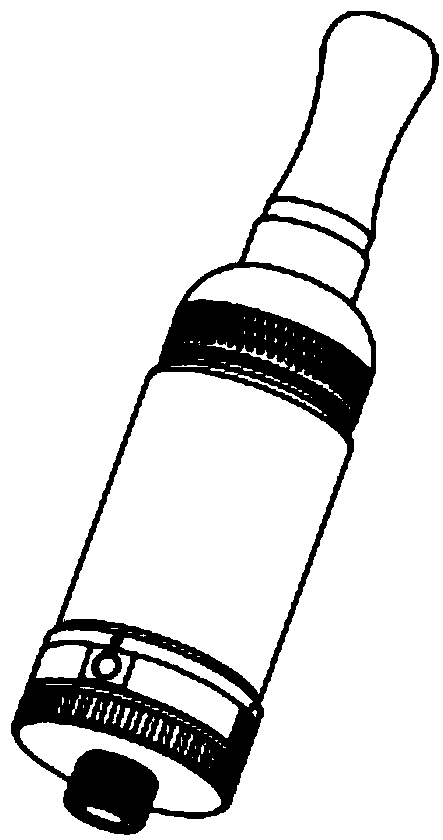

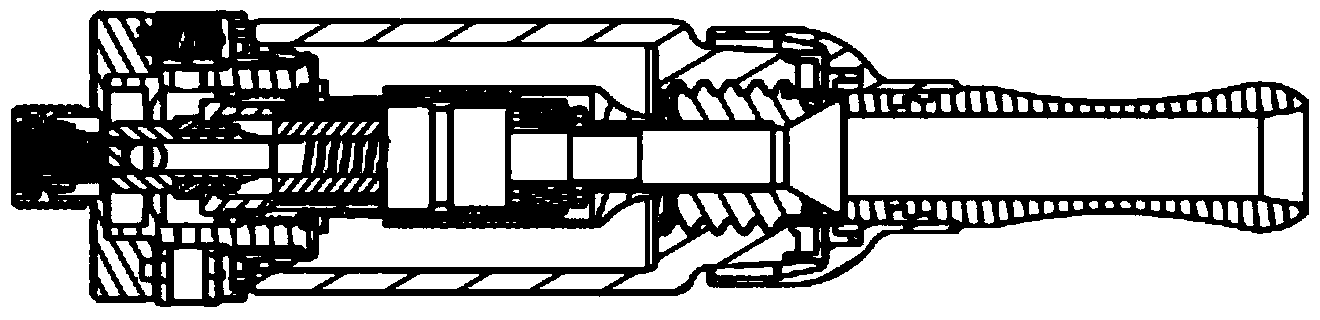

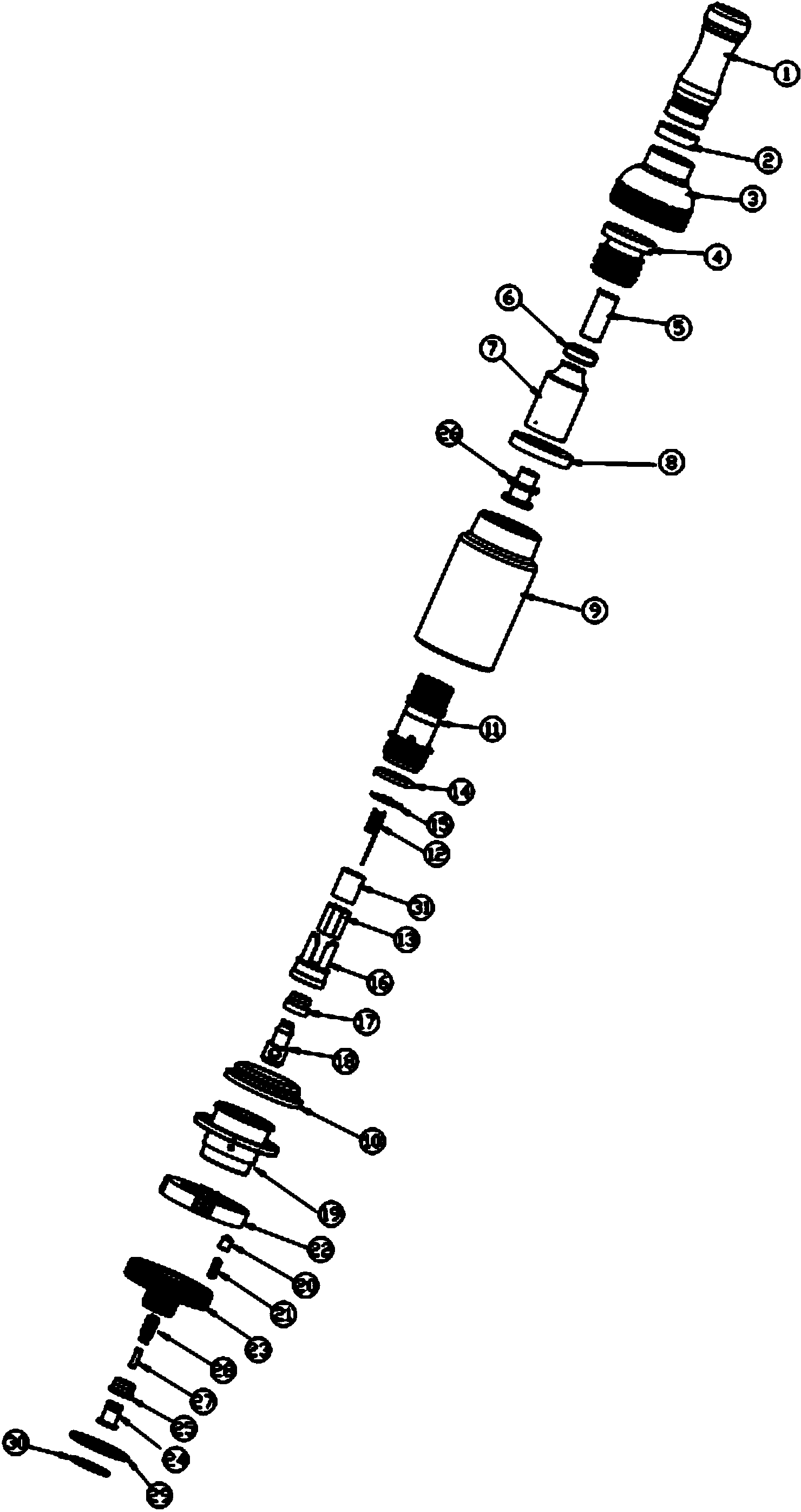

[0019] image 3 As shown, the electronic cigarette atomizer of the invention includes a metal mouthpiece assembly A, a glass tube holder assembly B, a glass tube body 9, an atomization assembly D, an airflow control valve assembly E, a metal mouthpiece assembly A and a glass tube holder assembly B adopts plug-in tight fit connection, and then connects with glass tube shell body 9 by thread; atomization component D and air flow control valve component E are assembled by thread, and finally is assembled with glass tube fixing seat component B as a whole.

[0020] Among them, the metal mouthpiece assembly includes a metal mouthpiece 1 at the top, a mouthpiece holder 3 in the middle, and a mouthpiece rod 5 inserted from the bottom. A mouthpiece sealing ring 2 is placed between the metal mouthpiece 1 and the mouthpiece holder 3. It is fixedly connected by the cigarette holder fixing screw 4, and the inside of the fixing screw includes a sealing gasket 8 on the glass bottle; in addi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com