Evaporation auxiliary device and drying equipment

An auxiliary device and drying technology, which is applied in the direction of lighting and heating equipment, heating devices, drying solid materials, etc., can solve the problems of uneven film thickness and affecting the display effect of organic electroluminescent display devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

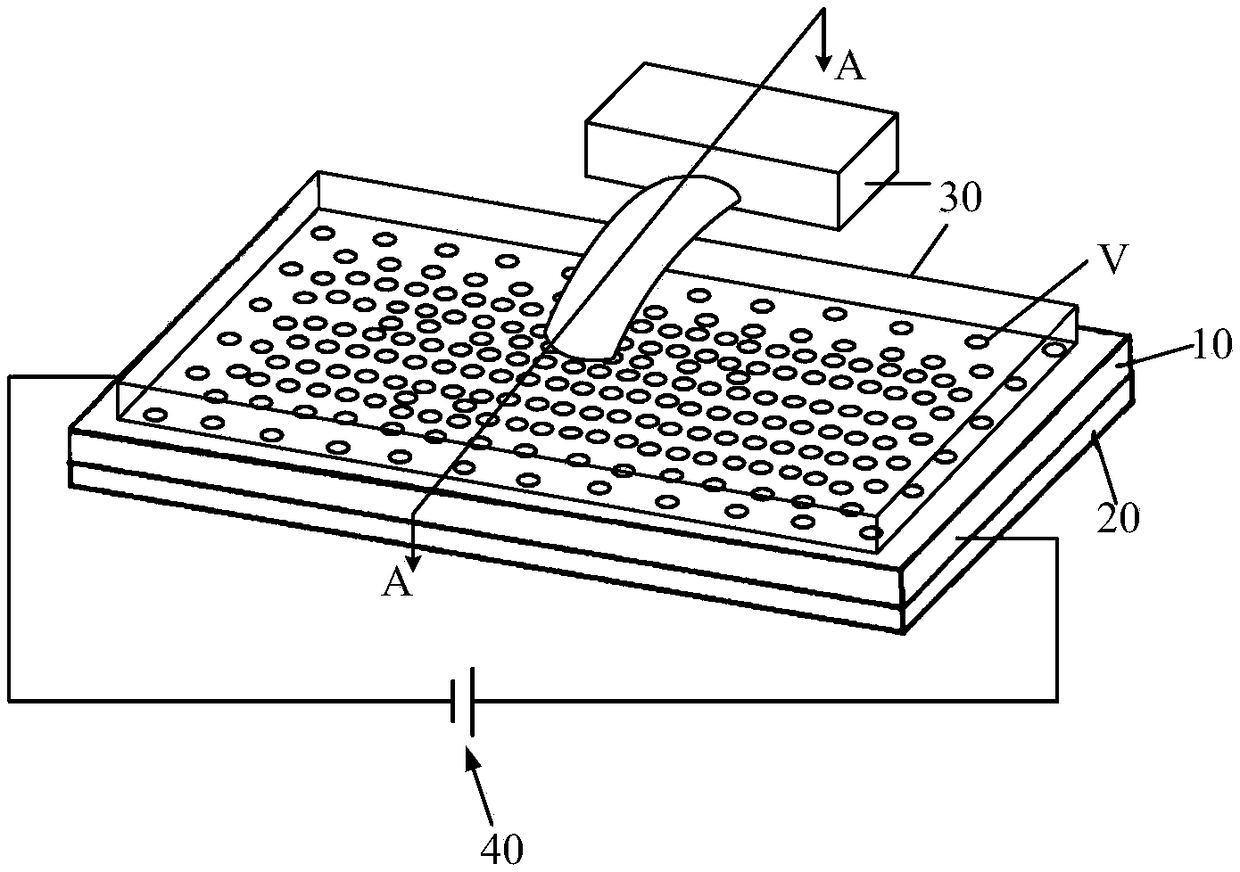

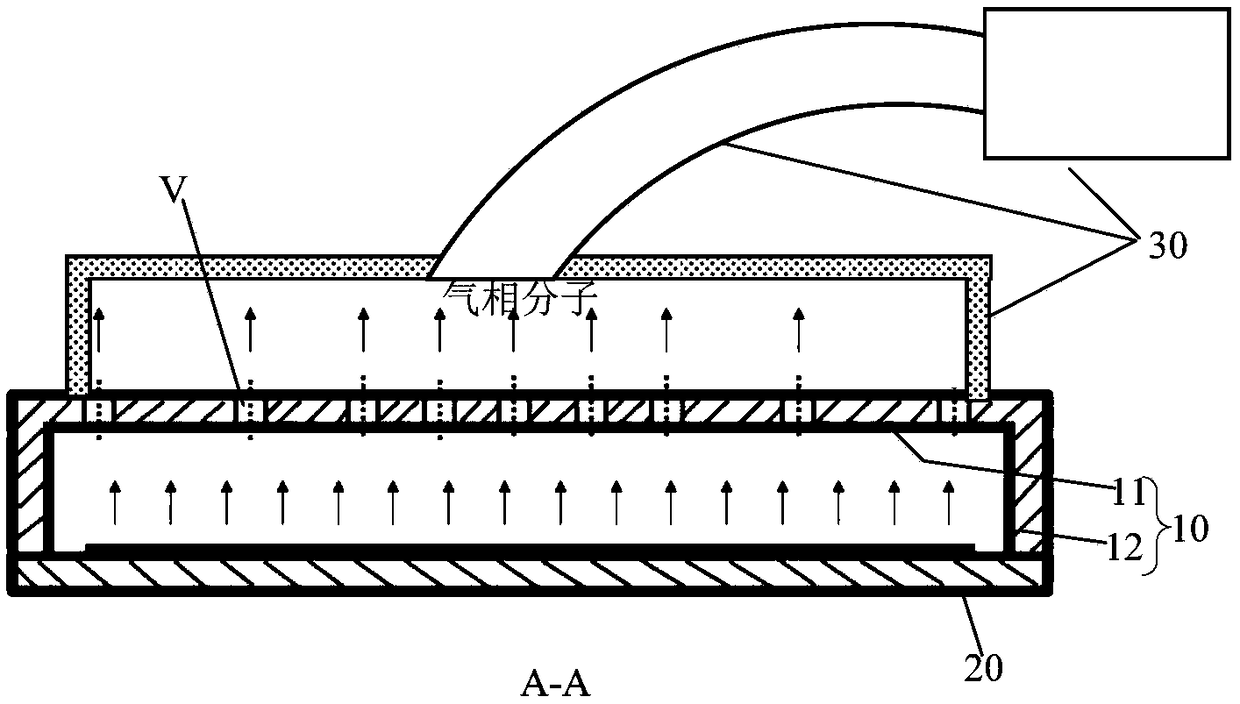

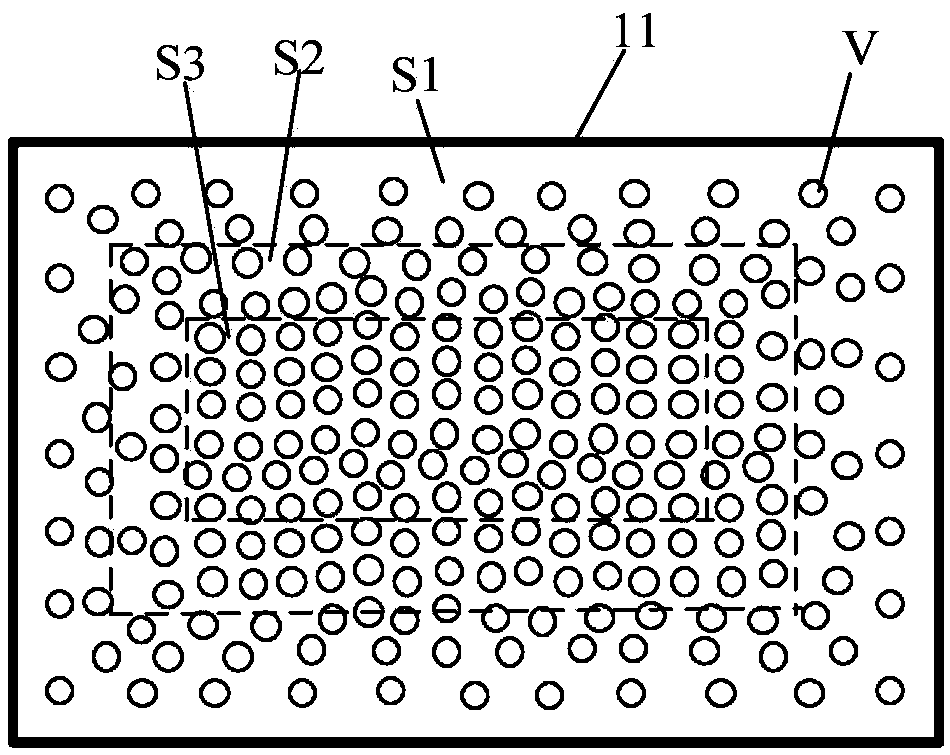

[0026] figure 1 It is a schematic diagram of the application of the evaporation auxiliary device provided in Embodiment 1 of the present invention, figure 2 is along figure 1 Sectional view of line AA in the middle, image 3 It is one of the top views of the cover plate in the evaporation auxiliary device provided by Embodiment 1 of the present invention, Figure 4 It is the second top view of the cover plate in the evaporation auxiliary device provided by the first embodiment of the present invention. The evaporation auxiliary device is used in a film layer drying process, and the film layer drying process is a process of drying the ink to form a film layer after printing the ink on the substrate. combine Figure 1 to Figure 4 As shown, the evaporation auxiliary device includes a cover plate 10, the cover plate 10 includes a top wall 11 and a side wall 12 connected to the top wall 11, the top wall 11 is used to be arranged opposite to the area to be dried of the substrat...

Embodiment 2

[0038]The evaporative auxiliary device of this embodiment is similar in structure to the evaporative auxiliary device of Embodiment 1, the only difference lies in the distribution of the ventilation holes V. Figure 5 It is a schematic diagram of the distribution of ventilation holes on the cover plate of the evaporation auxiliary device in the second embodiment of the present invention, as shown in Figure 5 As shown, the distribution density of the ventilation holes V in each ventilation area S1-S3 is the same; from the middle of the top wall 11 to the edge of the top wall 11, the opening size of the ventilation holes V in the ventilation areas gradually decreases. Wherein, in the same ventilation zone, the opening sizes of the ventilation holes V can be the same, or can be set according to the rule that the farther away from the center of the top wall 11 the smaller the openings are. use Figure 5 The method can also make the ratio of the sum of the opening areas of the ve...

Embodiment 3

[0042] Embodiment 3 provides a drying device, which includes a carrier table and the evaporation auxiliary device described in Embodiment 1 or Embodiment 2 above, and the carrier table is used to carry a substrate to be dried. The carrier table can also heat the substrate to be dried, so as to speed up the volatilization of the solvent on the substrate to be dried.

[0043] Since the above-mentioned evaporation auxiliary device is used in the film layer drying process, it can balance the volatilization rate of the solvent in the entire area to be dried of the substrate to be dried. Therefore, the drying equipment using the evaporation auxiliary device can dry different positions in the area to be dried. The thickness of the formed film layer is more uniform, so that when the substrate to be dried is used in a display device, the display effect is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com