Uniform and fast tea withering machine

A technology of withering machine and tea leaves, which is applied in tea processing before extraction, etc., which can solve the problems of uneven withering, large floor space, and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

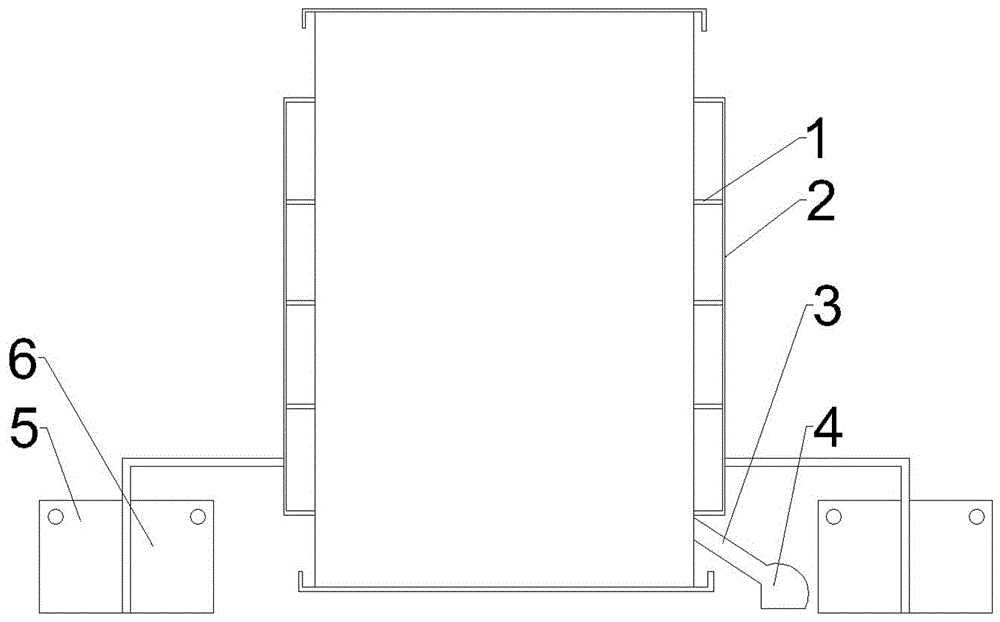

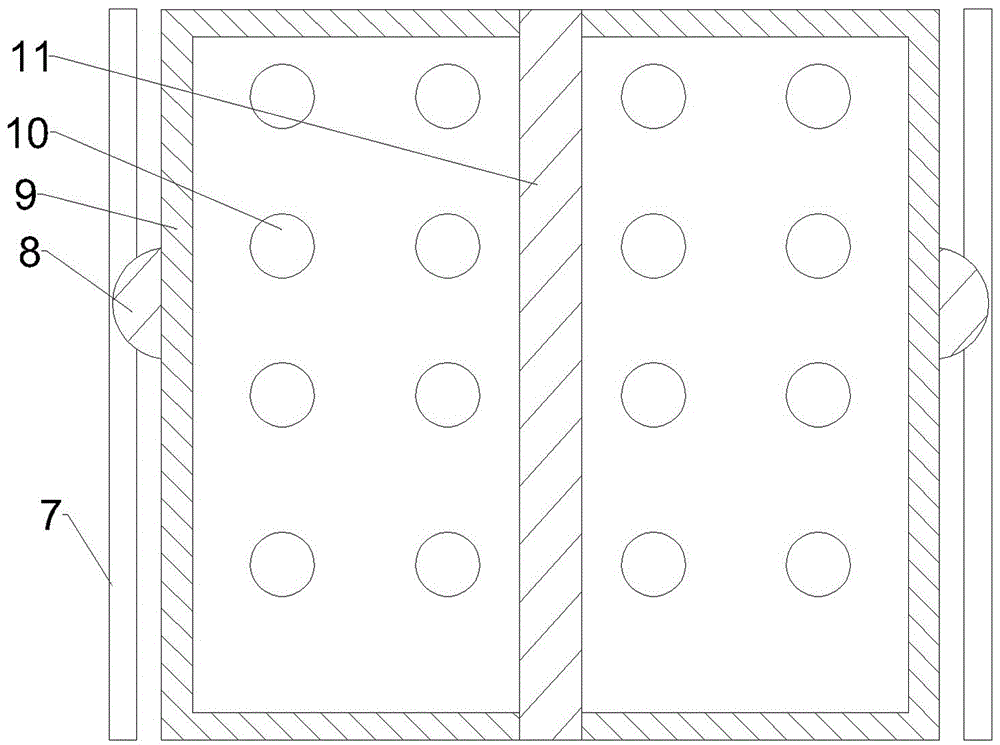

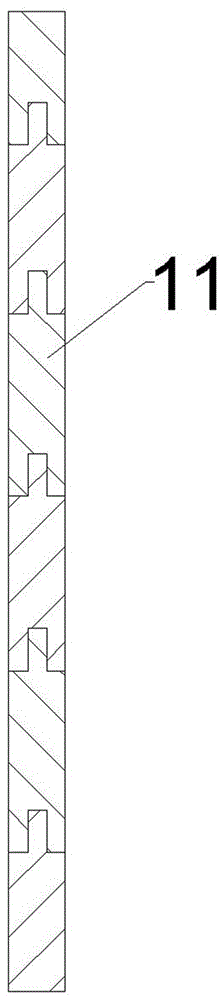

[0018] The reference signs in the drawings of the description include: blocking plate 1, blocking plate 2, ventilation pipe 3, hot air blower 4, deep-in cylinder 5, retracting cylinder 6, slide rail 7, pulley 8, withering groove 9, ventilation hole 10, Shaft 11.

[0019] The embodiment is basically as attached figure 1 —Shown in 3: a uniform and rapid tea withering machine, including a cylinder body, the cylinder body includes a top cover, a bottom cover and a high temperature resistant glass cylinder wall, the top cover and the bottom cover are fastened to the two ends of the cylinder wall, and also includes several A withering device, the withering device includes a shaft 11 and a withering groove 9, a number of ventilation holes 10 are opened on the withering groove 9, the withering groove 9 and the shaft 11 are connected by buckles, and the adjacent shafts 11 are det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com