Atomization and evaporation dual-mode humidifier

An atomization evaporation, dual-mode technology, applied in the air humidification system, heating mode, lighting and heating equipment, etc., can solve the problems of uneven water distribution, reduced evaporation efficiency, poor air permeability, etc., and achieve large effective evaporation area, evaporation The effect of high efficiency and large air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

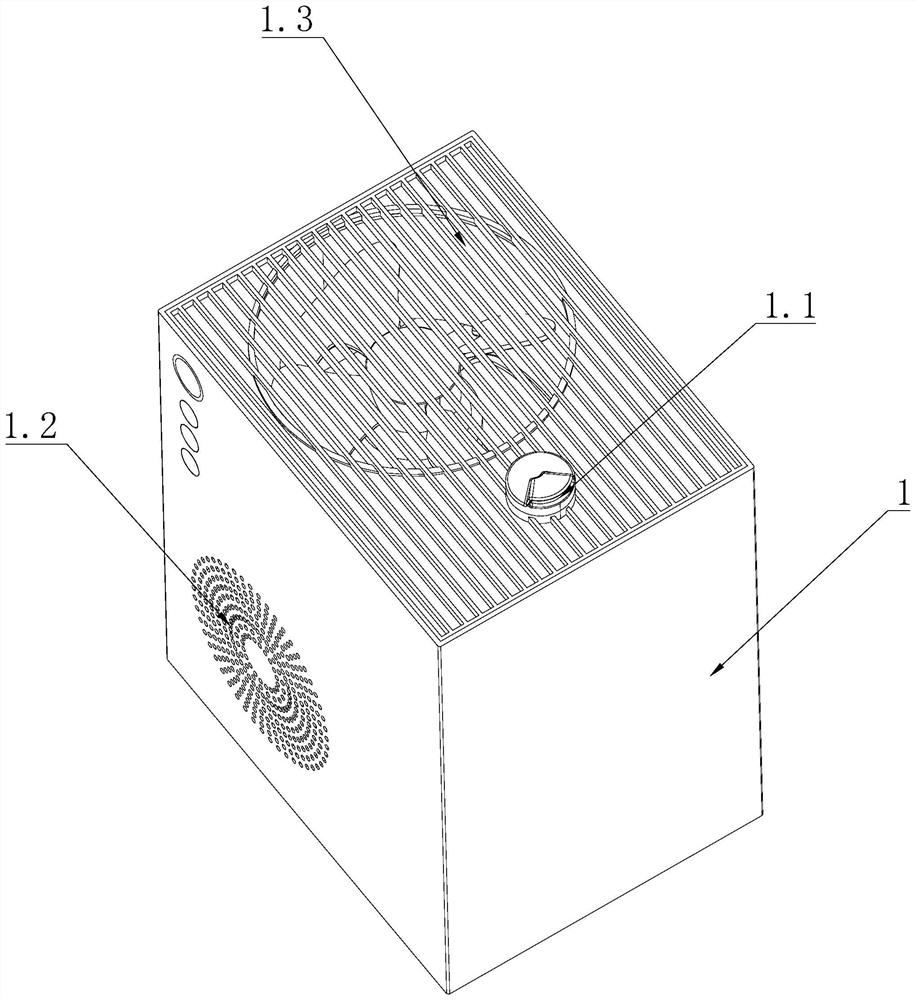

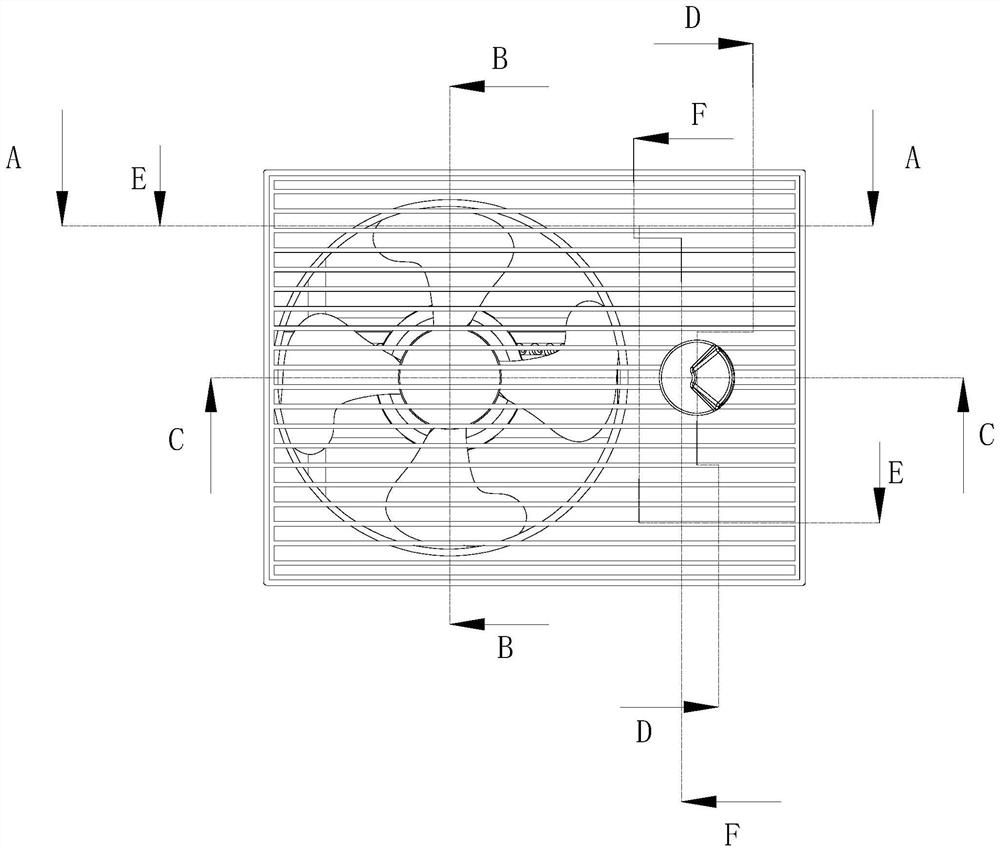

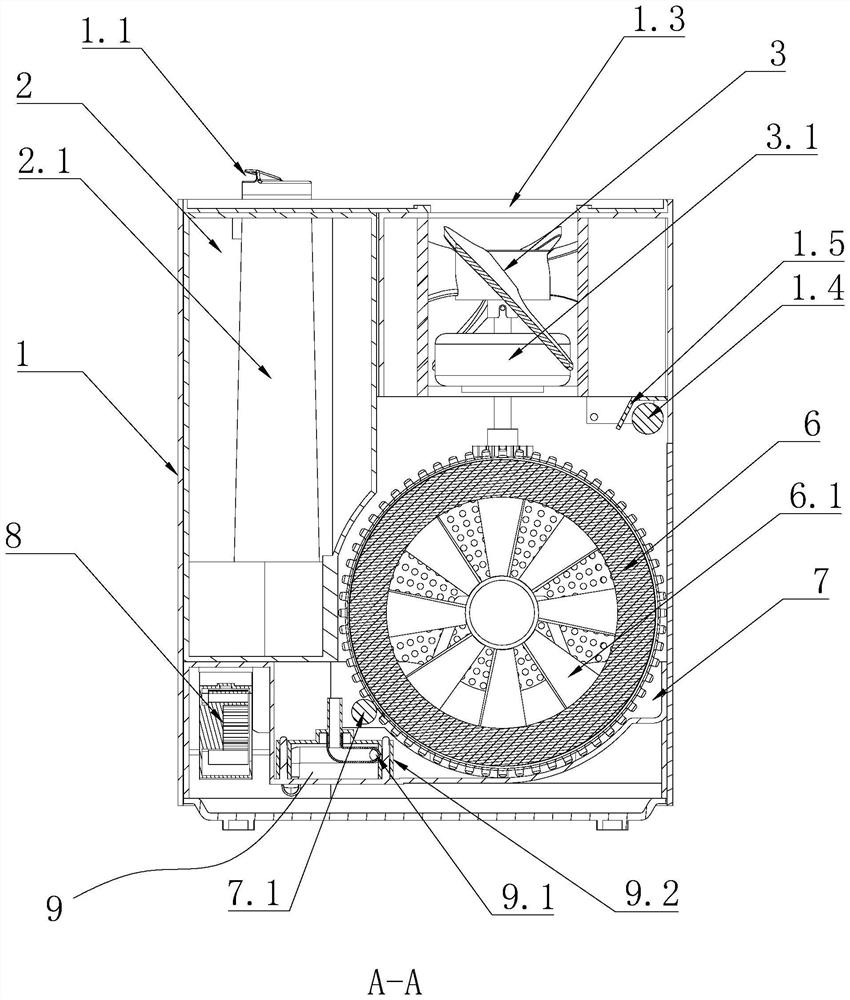

[0040] Such as Figure 1-11 As shown in the figure, an atomization and evaporation dual-mode humidifier includes a housing 1, and the housing 1 is provided with a mist outlet 1.1, an air inlet 1.2, and an air outlet 1.3; the housing 1 is also provided with a water tank 2 and an air outlet fan 3 that cooperates with the air outlet 1.3; the housing 1 is provided with an ultrasonic atomization tank 4 connected to the mist outlet 1.1; the ultrasonic atomization tank 4 is provided with an ultrasonic atomizer Humidification assembly 5; the housing 1 is provided with a rotatable evaporation filter element 6 and an evaporative humidification water tank 7 for supplying water to the evaporation filter element 6; the evaporation filter element 6 is provided with guide vanes 6.1 that guide the airflow when rotating .

[0041] The evaporation and humidification water tank 7 is provided with bearings supporting the evaporation filter element 6; the evaporation filter element 6 is in the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com