Heat-pump water heater cold shielding system for protecting compressor

A heat pump water heater and compressor technology, applied in compressors, fluid heaters, refrigerators, etc., can solve the problems of damage to the compressor, less evaporation, and insufficient suction of the compressor, so as to reduce the fluctuation of liquid supply and improve the Heat exchange efficiency, the effect of increasing the heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

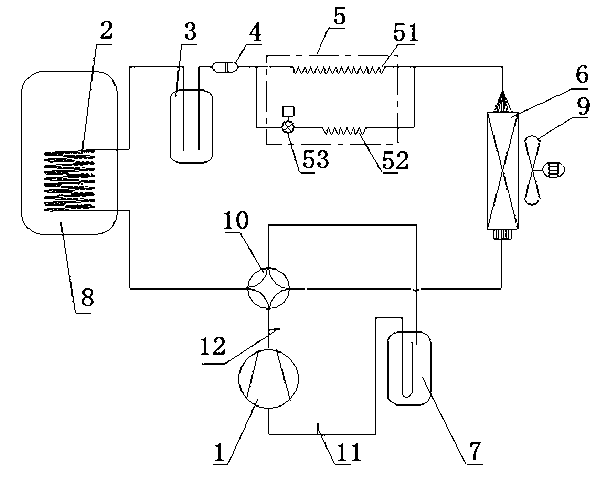

[0029] see figure 1 , a heat pump water heater cooling shield system for protecting compressors, including a compressor 1, a condenser 2, a throttling device 5, an evaporator 6, and a gas-liquid separator 7 connected in sequence to form a circulation loop; the throttling device 5 It includes a main capillary 51 and an auxiliary capillary 52 arranged in parallel, and the liquid inlet end of the auxiliary capillary 52 is provided with a real-time flow control device. The real-time flow control device includes a solenoid valve 53, a controller electrically connected to the solenoid valve 53, and a temperature sensor electrically connected to the controller. The refrigerant flow rate of the solenoid valve 53. The controller has a PWM switch, and after receiving the internal and external temperature feedback of the system, the controller controls the flow of refrigerant flowing through the solenoid valve 53 in real time through the output of the PWM switch.

[0030] This embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com