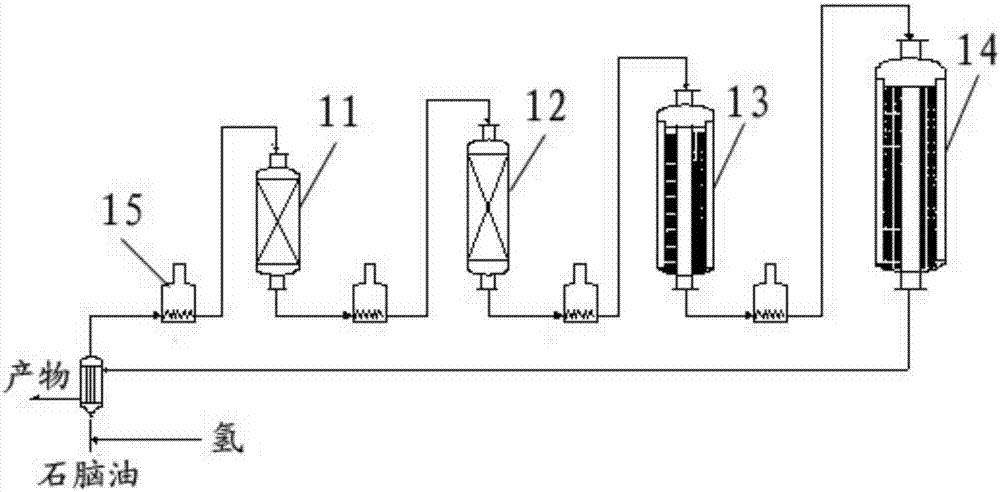

A semi-regenerative catalytic reforming reaction system and method

A catalytic reforming and reaction system technology, applied in the fields of naphtha catalytic reforming, petroleum industry, hydrocarbon oil treatment products, etc. The effect of reducing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

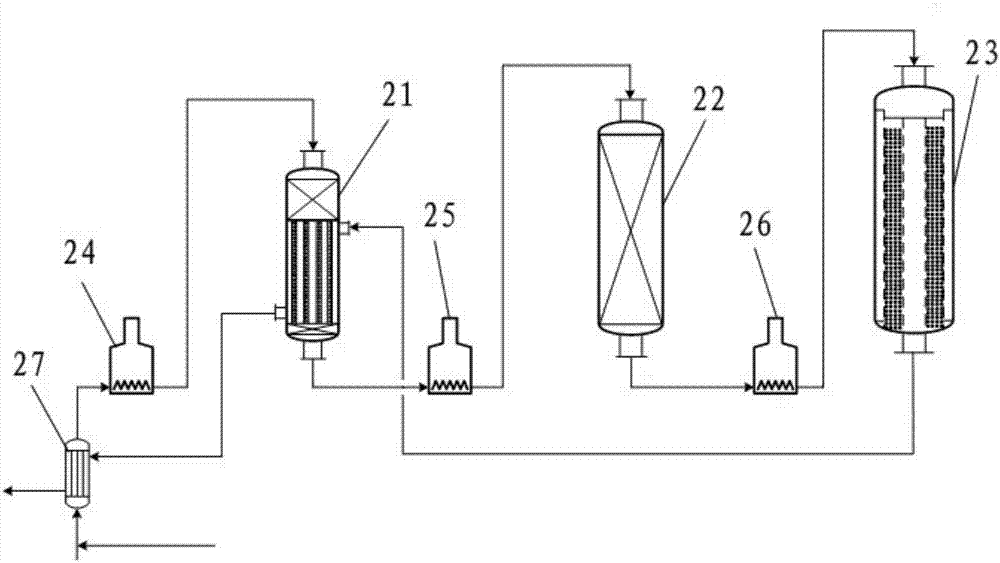

[0070] use as figure 2 The shown reaction system provided by the present invention carries out catalytic reforming reaction of naphtha. Wherein, the properties of the catalytic reforming feedstock oil are the same as those of Comparative Example 1.

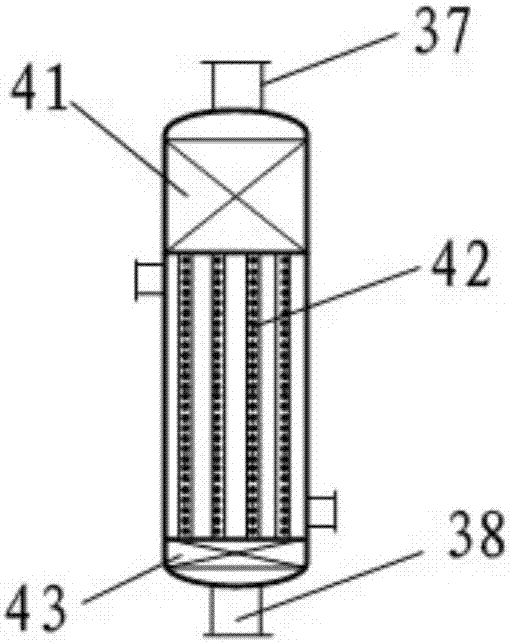

[0071] Such as figure 2 As shown, the reaction system adopted in this embodiment is provided with three reactors connected in series, one of which is the combined bed reactor provided by the present invention, the catalyst type and loading are the same as those of Comparative Example 1, and the second and third reactors The reactor structure, catalyst loading type and volume remained the same as in Comparative Example 1. Among them, the ratio of the catalyst loading volume in the fixed bed section, the column tube section and the fixed bed section in the first reactor is 33:67:0. The inlet temperature of each reactor was optimized according to the characteristics of the present invention, and the specific process conditions a...

Embodiment 2

[0085] use as Figure 6 The reaction system shown carries out the catalytic reforming reaction of naphtha, wherein the properties of the catalytic reforming feed oil are the same as those of Comparative Example 1, and the product quality indicators are the same as those of Comparative Example 2. The specific process conditions are shown in Table 8. In Example 2, the temperature of the reforming feed is 80°C. After heat exchange by the heat exchanger, the temperature of the reforming feed at the entrance of the first heating furnace is 430°C, and the reactant flow of the three reverses enters the first reverse tube section The inlet temperature is 475°C. After providing heat, the temperature leaving the first-stage pipe section is 465°C. After being heated by the fourth heating furnace, it enters the fourth stage to continue the catalytic reforming reaction; the reaction outlet stream of the four-stage reaction enters the second stage pipe section. The inlet temperature of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com