Catalytic cracking and catalytic gasoline hydrogenation combined technological method

A catalytic cracking and catalytic gasoline technology, applied in hydrotreating process, petroleum industry, treatment of hydrocarbon oil, etc., can solve the problems of different process flow, poor adaptability of raw materials, etc., to reduce energy consumption, mature and reliable technical solutions, reduce The effect of retrofit investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

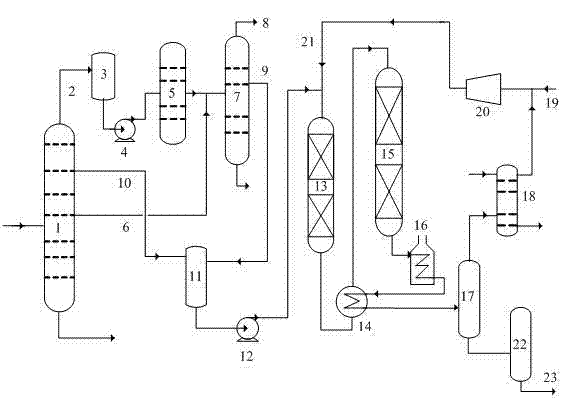

Image

Examples

Embodiment 1

[0044] The catalytic gasoline 1 is pre-separated in the fractionation tower of the catalytic cracking unit to obtain light fractions and heavy fractions. The division temperature of the light fractions and heavy fractions is 73°C; The thermocatalytic diesel oil enters the hydrogenation pre-fractionation tower together for fractionation. The separation temperature of the obtained light gasoline and medium gasoline is 65°C, and the dry point of medium gasoline is 78°C. The prehydrogenation reaction conditions are: hydrogen partial pressure 1.8MPa, volume space velocity 3.8 h -1 , The reaction temperature is 178°C; the hydrodesulfurization reaction conditions are: hydrogen partial pressure 1.6MPa, volume space velocity 2.8h -1 , The reaction temperature is 282°C; the total hydrogen-to-oil volume ratio is 350.

[0045] The alkali-free deodorization conditions are: the operating pressure of the reactor is 0.6MPa, the reaction temperature is 35°C, and the feed space velocity is 0.9...

Embodiment 2

[0048] The catalytic gasoline 2 is pre-separated in the fractionation tower of the catalytic cracking unit to obtain light fractions and heavy fractions; the division temperature of the light fractions and heavy fractions is 76°C; The thermocatalytic diesel oil enters the hydrogenation pre-fractionation tower together for separation. The separation temperature of the obtained light gasoline and medium gasoline is 62°C, and the dry point of medium gasoline is 76°C. The prehydrogenation reaction conditions are: hydrogen partial pressure 2.0 MPa, volume space velocity 3.5 h -1 , The reaction temperature is 183°C; the hydrodesulfurization reaction conditions are: hydrogen partial pressure 1.8MPa, volume space velocity 3.0 h -1 , The reaction temperature is 288°C; the total hydrogen-to-oil volume ratio is 380.

[0049] The alkali-free deodorization conditions are: the operating pressure of the reactor is 0.5MPa, the reaction temperature is 45°C, and the feed space velocity is 0.8h...

Embodiment 3

[0052] The catalytic gasoline 3 is pre-separated in the fractionation tower of the catalytic cracking unit to obtain light fractions and heavy fractions; the division temperature of the light fractions and heavy fractions is 80°C; The thermocatalytic diesel oil enters the hydrogenation pre-fractionation tower together for separation. The separation temperature of the obtained light gasoline and medium gasoline is 67°C, and the dry point of medium gasoline is 83°C. The prehydrogenation reaction conditions are: hydrogen partial pressure 1.8MPa, volume space velocity 4.2 h -1 , Reaction temperature 180℃; hydrodesulfurization reaction conditions: hydrogen partial pressure 1.6MPa, volume space velocity 3.2 h-1 , The reaction temperature is 277°C; the total hydrogen-to-oil volume ratio is 320.

[0053] The conditions for alkali-free deodorization are: reaction pressure 0.5MPa, reaction temperature 40°C, feed space velocity 1.1h -1 , with an air / feed volume ratio of 1.0. The operat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dry point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com