Low-energy consumption catalytic gasoline hydrodesulfurization method

A catalytic gasoline and hydrodesulfurization technology, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment, can solve the problems of different process flow and poor adaptability of feedstock oil, and reduce investment and operating costs, as well as equipment investment and operating costs, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

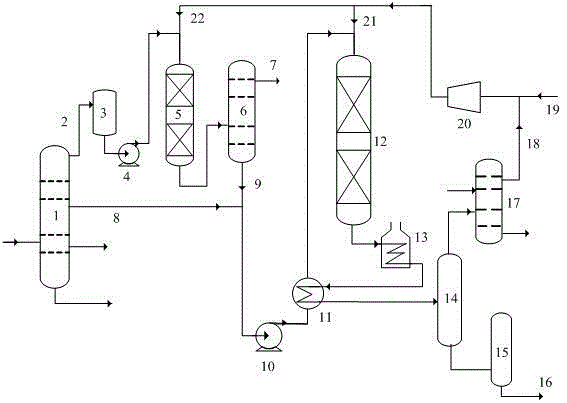

Image

Examples

Embodiment 1

[0037] The gasoline raw material 1 is pre-separated in the fractionation tower of the catalytic cracking unit to obtain light fractions and heavy fractions. The cut point temperature of the light fractions and heavy fractions is 80°C; Separation is carried out in a fractionating tower, and the cut point temperature of the obtained light gasoline and medium gasoline is 65°C. Among them, the conversion reaction conditions of hydrogen mercaptans are: hydrogen partial pressure 2.0 MPa, volume space velocity 4.8 h -1 , The reaction temperature is 148°C, the volume ratio of hydrogen to oil is 12; the hydrodesulfurization reaction conditions are: hydrogen partial pressure 1.6MPa, volume space velocity 2.8h -1 , The reaction temperature is 282°C; the total hydrogen-to-oil volume ratio is 350.

[0038] The operating conditions and test results are listed in Table 2 and Table 3, respectively.

[0039] It can be seen from Table 3 that using this technology can reduce the sulfur content...

Embodiment 2

[0041] The gasoline raw material 2 is pre-separated in the fractionation tower of the catalytic cracking unit to obtain light fractions and heavy fractions; the cut point temperature of the light fractions and heavy fractions is 78°C; the light fractions undergo hydromercaptan conversion and then enter hydrogenation pre-fractionation The tower is separated, and the cut point temperature of the obtained light gasoline and medium gasoline is 63°C. The reaction conditions for the conversion of hydrogen mercaptans are: hydrogen partial pressure 2.2 MPa, volume space velocity 5.4 h -1 , the reaction temperature is 157°C, the volume ratio of hydrogen to oil is 18; the hydrodesulfurization reaction conditions are: hydrogen partial pressure 1.8MPa, volume space velocity 3.0 h -1 , The reaction temperature is 288°C; the total hydrogen-to-oil volume ratio is 380.

[0042] The operating conditions and test results are listed in Table 2 and Table 3, respectively.

[0043] It can be seen...

Embodiment 3

[0045] The gasoline raw material 3 is pre-separated in the fractionation tower of the catalytic cracking unit to obtain light fractions and heavy fractions; the cut point temperature of the light fractions and heavy fractions is 85°C; the light fractions undergo hydromercaptan conversion, and then enter the hydrogenation pre- Separation is carried out in a fractionating tower, and the cut point temperature of the obtained light gasoline and medium gasoline is 68°C. Among them, the conversion reaction conditions of hydrogen mercaptans are: hydrogen partial pressure 1.8 MPa, volume space velocity 4.5 h -1 , the reaction temperature is 152°C, the volume ratio of hydrogen to oil is 26; the hydrodesulfurization reaction conditions are: hydrogen partial pressure 1.6MPa, volume space velocity 3.2 h -1 , The reaction temperature is 277°C; the total hydrogen-to-oil volume ratio is 320.

[0046] The operating conditions and test results are listed in Table 2 and Table 3, respectively. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com