Coking inhibitor

A coking inhibitor and chemical technology, applied in the petroleum industry, processing equipment corrosion/scaling inhibition, hydrocarbon oil treatment, etc., can solve problems such as blocked pipelines, hidden dangers of device safety, high cost, etc., to reduce the speed of coking and increase production The effect of the number of days and extending the start-up cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

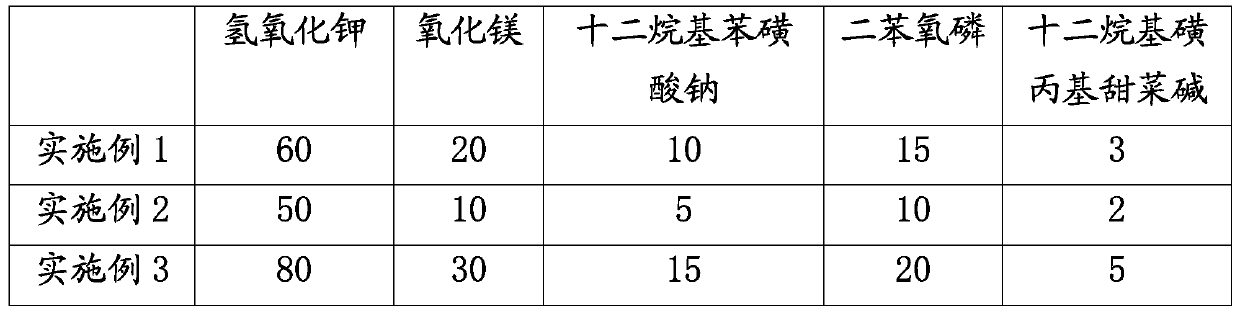

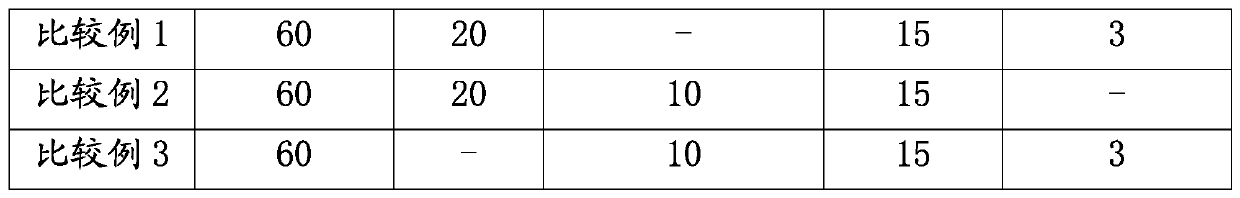

preparation example Construction

[0018] The preparation method of the above-mentioned scorch retarder provided by the present invention is to mix the components together in proportion.

[0019] In view of the fact that the acid value of domestic waste oil is around 2, the amount of coke inhibitor used is 2-3 kg per ton of waste oil (clean oil), and the specific dosage is determined by the acid value obtained from the sampling test of the oil tank in the factory laboratory.

[0020] The present invention also provides a method for using the above-mentioned scorch retarder, which includes adding 3-4 times the amount of water to the scorch retarder, fully stirring it into a suspension, pumping it to the oil tank and stirring evenly, and the waste oil in the tank can enter the distillation At this time, the acid value has been completely neutralized, and the microcosmic coke particles produced by the heating furnace in the distillation process are difficult to gather on the surface of the furnace tube in the prese...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com