Horizontal water boiler with ash holes

A technology for ash falling and boiler application in the direction of water tube steam boilers, steam boilers, steam boiler accessories, etc., which can solve problems such as deformation bulging, high temperature creep at the bottom of the boiler shell, and inconvenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

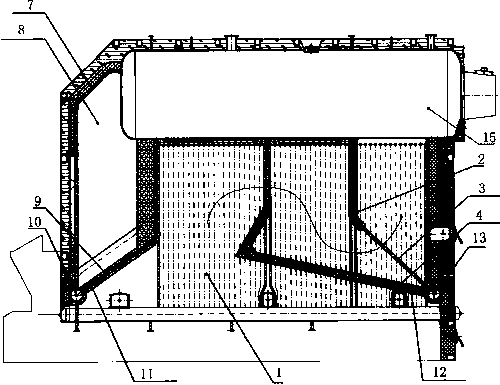

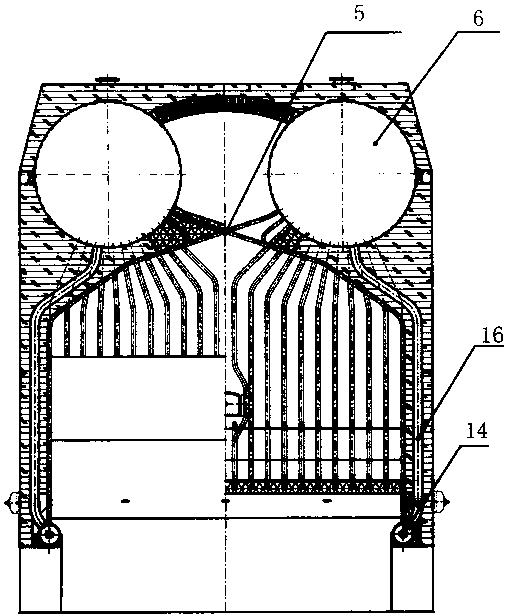

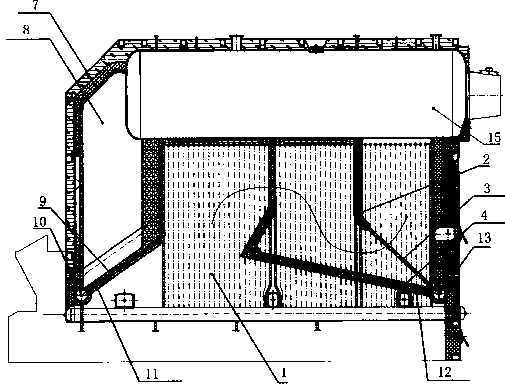

[0008] Such as figure 1 The present invention shown is a horizontal water-fire tube shell boiler with ash holes in the front arch, the upper part is the pot shell 6, the pot shell 6 is connected to the downcomer, and the downcomer is respectively connected to the front header 10, the rear header 13, The side header 14, the front header 10 is connected with the front arch 9 and the front shed pipe 7, and enters the pot shell 6; the rear header 13 is connected with the rear arch, and enters the pot shell; figure 2 As shown, the side header 14 is connected with the side water-cooled wall, and the side water-cooled wall pipe 5 intersects into the pot shell 6; the pot shell is placed outside the furnace 1, and the front arch 9 has refractory cement wrapped water pipes to form a refractory board. Ash falling hole is divided into preceding ash falling hole 11 and rear ash falling hole 12.

[0009] Such as figure 1 Shown, the pot shell front part is formed built-in smoke chamber 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com