Process and equipment for continuously preparing nano carbon ball

A process method and technology of nano-carbon spheres, applied in the field of continuous production of nano-carbon spheres and devices, to achieve uniform particle size, rich raw material sources, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

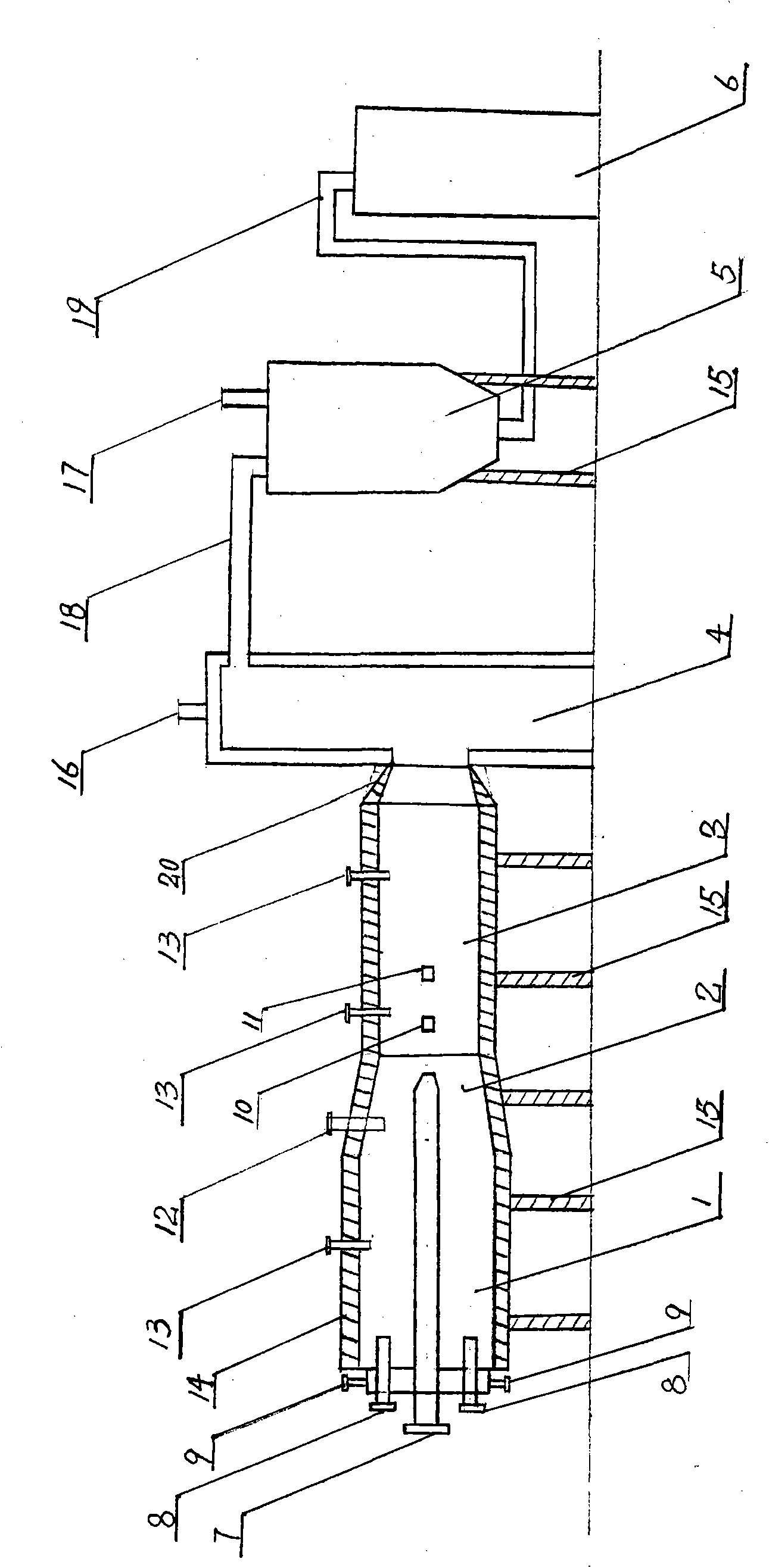

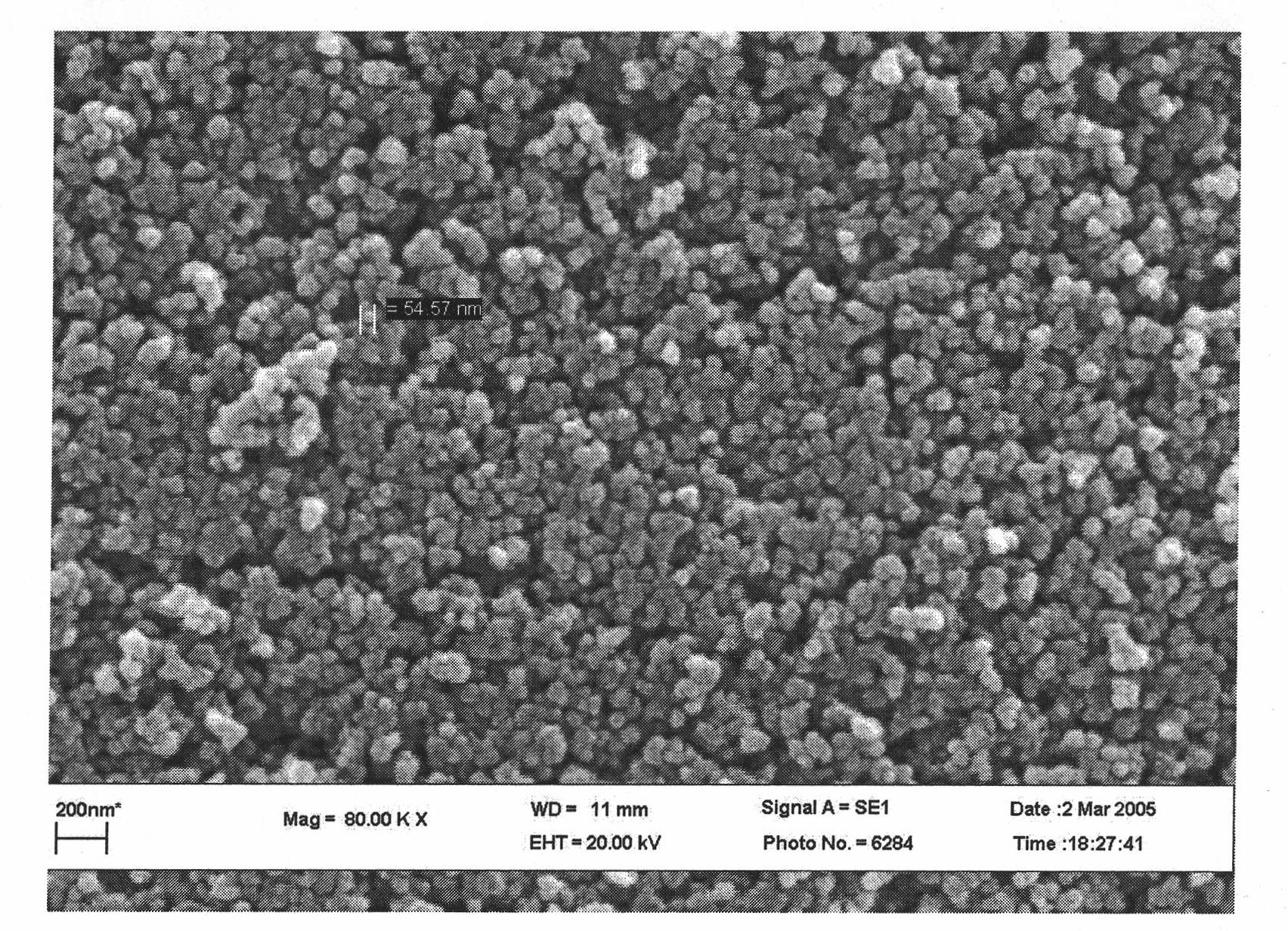

[0027] Embodiment 1: take coal tar as the embodiment of the nano-carbon spheres of raw material production,

[0028] like figure 1 In the shown device, the inner diameter of heating furnace 1 is 40cm, the outer diameter is 100cm, and the length is 100cm; the middle connecting pipe is 2cm, the inner diameter is 20cm, the outer diameter is 60cm, and the length is 100cm. 40cm, with an outer diameter of 100cm and a length of 300cm. The catalyst inlet 10 is located on the horizontal axis furnace wall of the cracking reactor, 5 cm away from the front end of the cracking reactor. Auxiliary agent inlet 11 is located on the horizontal axis furnace wall of the cracking reactor, 45cm away from the front end of the cracking reactor. The protective gas inlet 12 is located at the top of the intermediate pinch tube 2, 20 cm away from the front end of the intermediate pinch tube. There are three thermometers 13, which are respectively located at the top of the heating furnace and the top o...

Embodiment 2

[0030] Embodiment 2: take heavy aromatics as the embodiment of the carbon nanospheres that raw material produces,

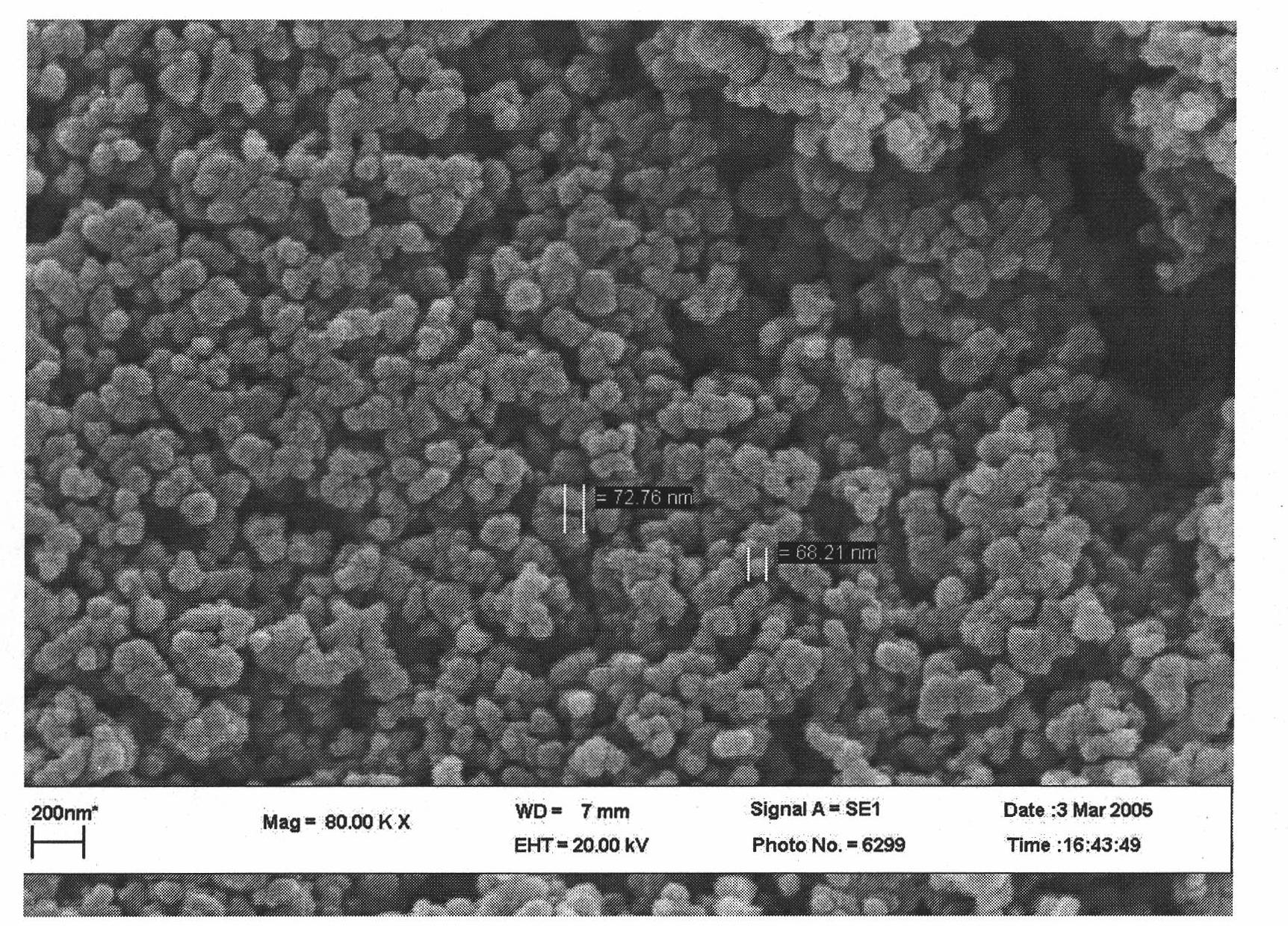

[0031] With the device of embodiment 1, take natural gas as fuel and inject into heating furnace together with air, heavy aromatic hydrocarbon is carbon raw material with 2300m 3 h -1 The flow rate is sprayed into the heated cracking reaction furnace under the pressure of 1.2MPa, and the catalyst and auxiliary agent are sprayed into the cracking furnace at the same time. The catalyst injection pressure is 2.8MPa, and the flow rate is 2.0kg·h -1 , the auxiliary agent has a pressure of 2.3Mpa and a flow rate of 2200ml·h -1 , the raw materials in the cracking reaction furnace are separated and diluted with natural gas and nitrogen, and cracked at a reaction temperature of 1180-1190°C. The gas-solid separation is carried out by the separator, and the parameters of the electron microscope photo of the obtained nano-carbon sphere products are shown in image 3 .

Embodiment 3

[0032] Embodiment 3: use the device of embodiment 1, take mixed benzene as raw material to produce nano-carbon spheres, how flow control is 2100m 3 h -1

[0033] With the device of embodiment 1, take natural gas as fuel and inject into heating furnace together with air, mixed benzene is carbon raw material with 3000m 3 h -1 The flow rate is sprayed into the heated cracking reaction furnace under the pressure of 3.5MPa, and the catalyst and additives are sprayed into the cracking furnace at the same time. The catalyst injection pressure is 3.5MPa, and the flow rate is 10kg h -1 , the auxiliary agent has a pressure of 3.0Mpa and a flow rate of 3000ml·h -1 , in the pyrolysis reaction furnace, the raw materials are cracked at the reaction temperature of 1040-1080°C under the isolation and dilution conditions of natural gas and nitrogen, and the materials after the cracking reaction are sent to the heat exchanger for heat exchange and cooling to 200-300°C, and then introduced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com