Lithium ion battery negative electrode material and preparation method thereof

A technology for lithium ion batteries and negative electrode materials, which can be applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., and can solve problems such as harming the ecological environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

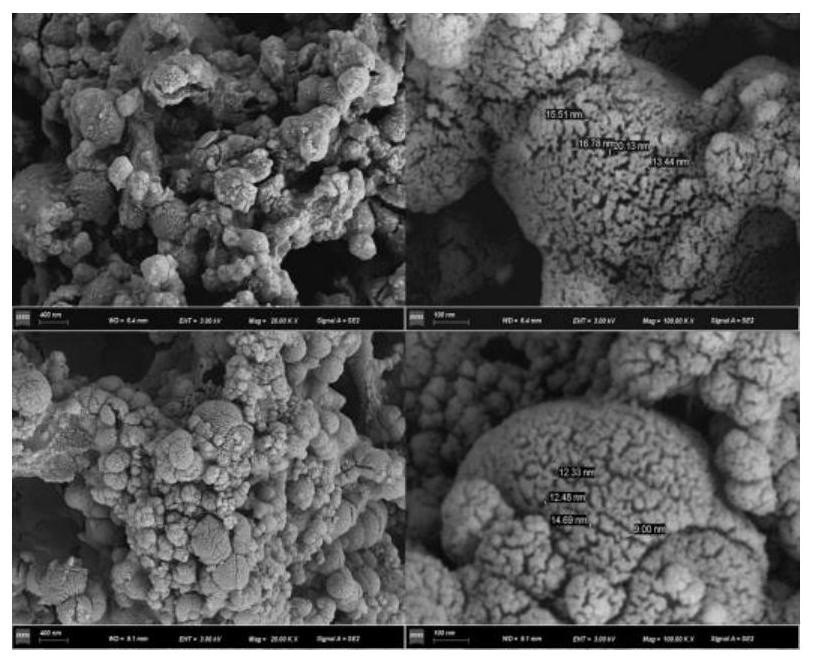

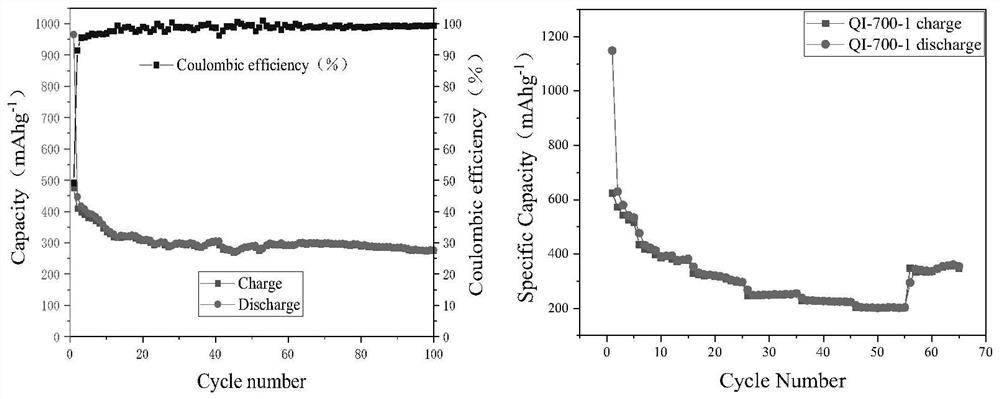

Embodiment 1

[0054] a) Add 25g of coal tar pitch and 50g of washing oil kerosene mixed solvent (solvent ratio: 2:1) into the reaction kettle, pressurize to 1.0MPa after nitrogen purging, heat up to 130°C, and then mechanically Stir for 1h, maintain the temperature and pressure and let it settle for 4h, then take out the residue at the bottom of the reaction kettle to obtain coal tar pitch quinoline insoluble matter;

[0055] b) Add coal tar pitch quinoline insolubles in quinoline solution, utilize quinoline solution to disperse ultrasonically under heating conditions, after fully washing, place in a 50ml centrifuge tube, centrifuge at 4000R / min for 30min, collect the centrifuge tube solid;

[0056] c) The collected solid was washed four times with quinoline solution and toluene solution while hot, and placed in an oven at 120°C to remove residual solvent;

[0057] d) Grind the washed solid and KOH uniformly at a ratio of 1:1, place it in a tube furnace, and activate it at 700°C under a ni...

Embodiment 2

[0062] a) Add 25g of coal tar pitch and 50g of washing oil kerosene mixed solvent with a ratio of 0.4 to aromatic resin (solvent ratio is 2:1) into the reaction kettle, pressurize to 1.0Mpa after purging with nitrogen, heat up to 130°C and then mechanically Stir for 1h, maintain the temperature and pressure and let it settle for 4h, then take out the residue at the bottom of the reaction kettle to obtain coal tar pitch quinoline insoluble matter;

[0063] b) Add coal tar pitch quinoline insolubles in quinoline solution, utilize quinoline solution to disperse ultrasonically under heating conditions, after fully washing, place in a 50ml centrifuge tube, centrifuge at 4000R / min for 30min, collect the centrifuge tube solid;

[0064] c) The collected solid was washed four times with quinoline solution and toluene solution while hot, and placed in an oven at 120°C to remove residual solvent;

[0065] d) Grind the washed solid and KOH uniformly at a ratio of 1:3, place it in a tube ...

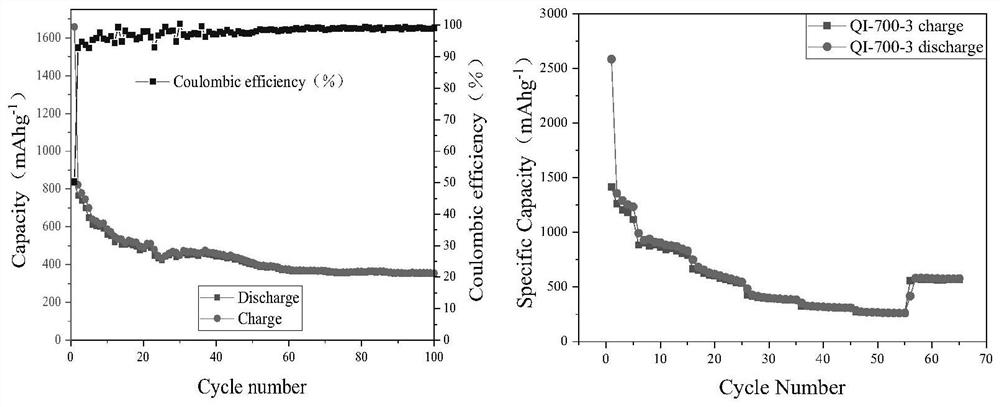

Embodiment 3

[0070] a) Add 25g of coal tar pitch and 50g of washing oil kerosene mixed solvent with a ratio of 0.4 to aromatic resin (solvent ratio is 2:1) into the reaction kettle, pressurize to 1.0Mpa after purging with nitrogen, heat up to 130°C and then mechanically Stir for 1h, maintain the temperature and pressure and let it settle for 4h, then take out the residue at the bottom of the reaction kettle to obtain coal tar pitch quinoline insoluble matter;

[0071] b) Add coal tar pitch quinoline insolubles in quinoline solution, utilize quinoline solution to disperse ultrasonically under heating conditions, after fully washing, place in a 50ml centrifuge tube, centrifuge at 4000R / min for 30min, collect the centrifuge tube solid;

[0072] c) The collected solid was washed four times with quinoline solution and toluene solution while hot, and placed in an oven at 120°C to remove residual solvent;

[0073] d) Grind the washed solid and KOH uniformly at a ratio of 1:3, place it in a tube ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com