Processing method of coal tar

A processing method and technology for coal tar, applied in the field of coal chemical industry, can solve the problems of single coal tar processing method, large pollution in the working environment, and unstable quality, so as to prevent the environment from pollution by flue gas, the processing technology is simple and reasonable, and the quality of the product is stable. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0024] A kind of processing method of coal tar is characterized in that comprising the following steps:

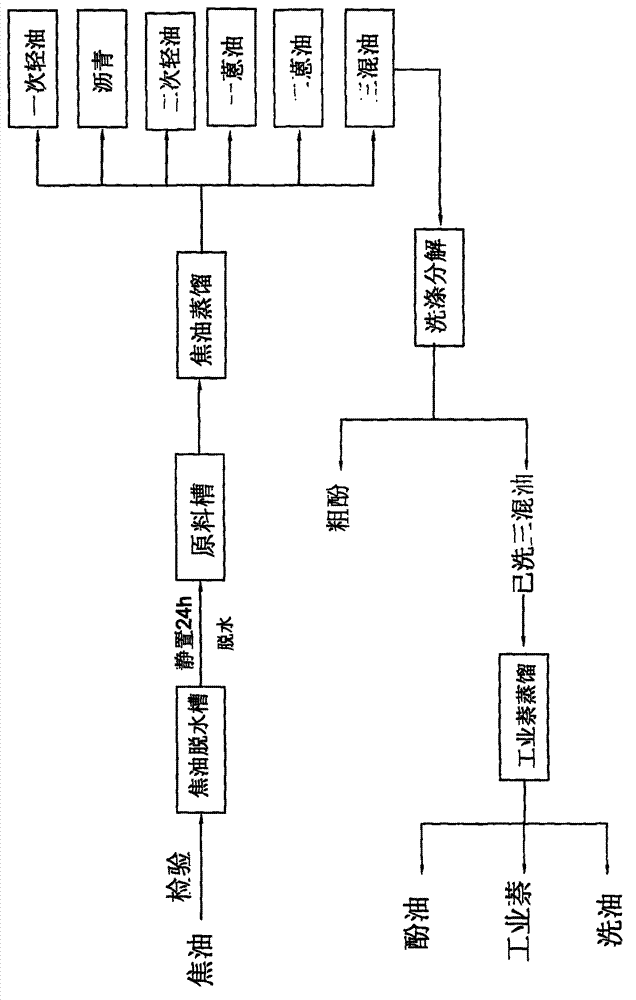

[0025] 1) Dehydration of tar: tar must remove water before distillation. Dehydrated tar can reduce heat consumption in the distillation process, increase equipment production capacity, and reduce system resistance of continuous distillation heating. After the general tar is evenly finished, part of the water is mixed in the tar, and it needs to be heated and left for 24 hours to separate the oil and water, and then dehydrated to meet the production requirements.

[0026] Process route: incoming inspection of raw materials—put into the underground unloading tank—send to the tar dehydration tank—send to the raw material tank for production.

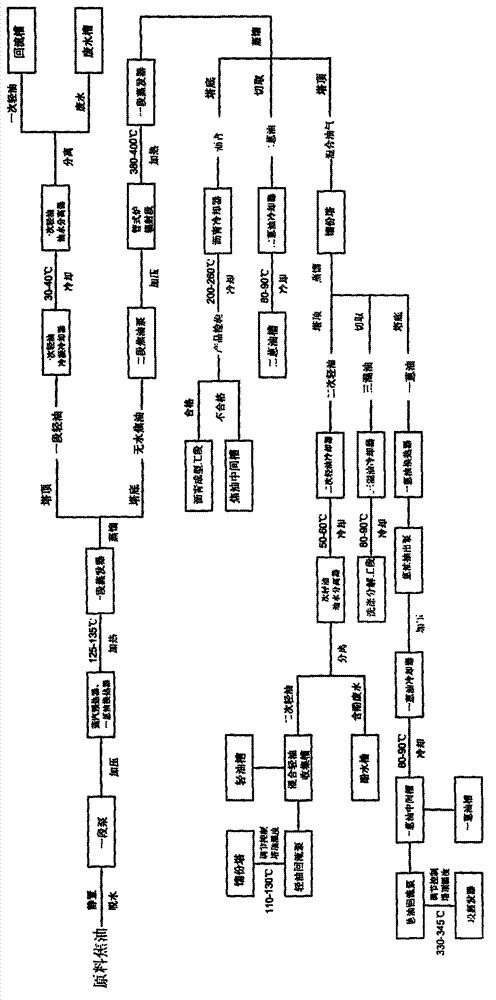

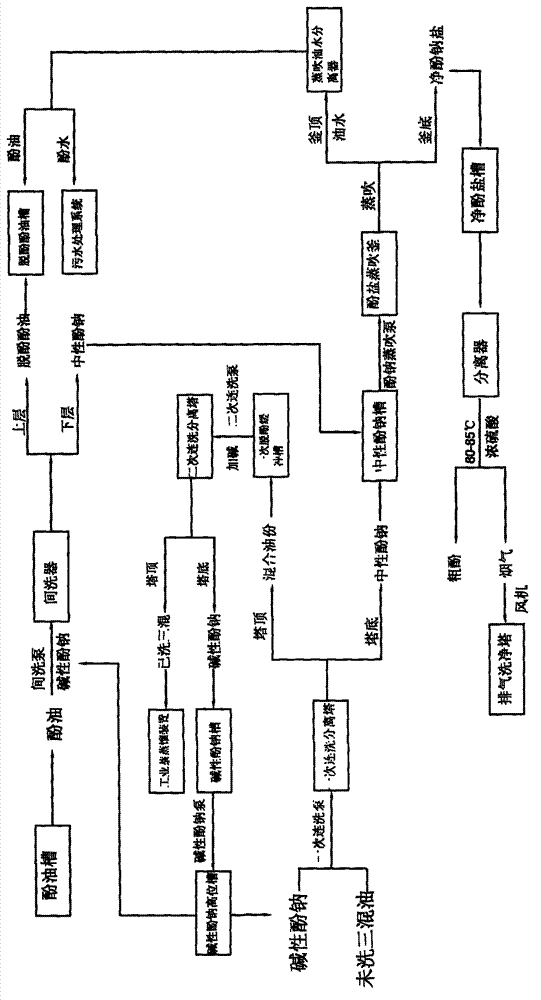

[0027]2) Tar distillation: using a continuous distillation device, after the raw tar is left to sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com