Pumping liquid asphalt loading system and process

A liquid asphalt and bitumen technology, applied in liquid distribution, transportation or transfer devices, packaging, distribution devices, etc., can solve the problems of wasting electric energy, occupation, wear, etc., achieve simple and convenient process operation procedures, overcome technical barriers, and facilitate popularization applied effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

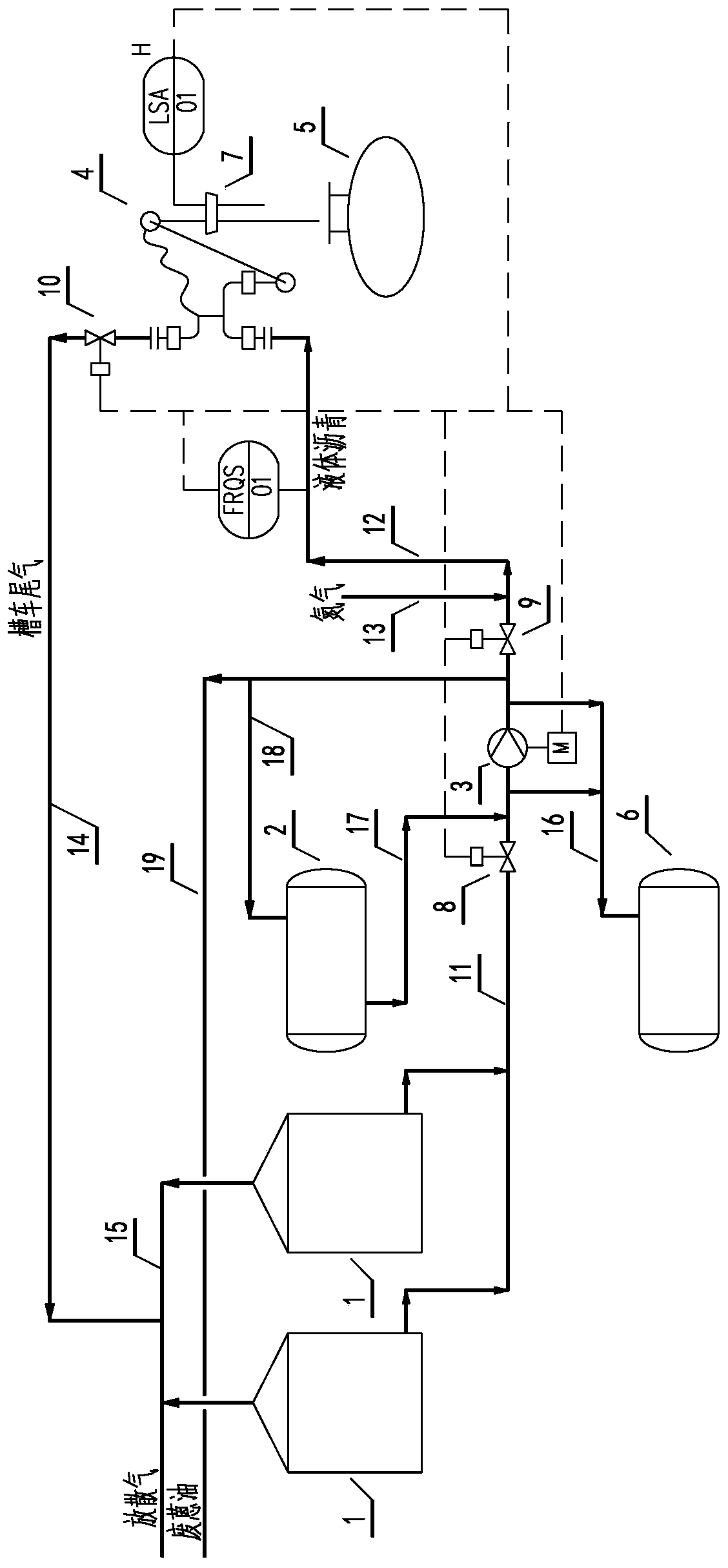

[0027] Such as figure 1 As shown, a pumping liquid asphalt loading system of the present invention includes a loading system and a maintenance and cleaning system; the loading system includes an asphalt storage tank 1, an asphalt loading pump 3, an automobile charging arm 4 and an automobile Tank car 5; the bottom of the asphalt storage tank 1 is provided with an asphalt outlet, which is connected to the car tanker 5 through the asphalt discharge pipeline 11, the asphalt loading pipeline 12 and the vehicle loading arm 4 in turn, and the discharge electromagnetic is set on the asphalt discharge pipeline 11. The valve 8, the asphalt loading pipeline 12 are provided with an asphalt loading pump 3 and a loading solenoid valve 9 in sequence along the asphalt conveying direction; the vehicle loading arm 4 is provided with an exhaust pipe, and the exhaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com