Production method of pigment carbon black applied to leather color paste

A technology of pigment carbon black and production method, which is applied in the direction of fibrous filler, etc., can solve the problems of high impurity content of pigment carbon black, unstable dispersion of pigment carbon black, and reduction of non-carbon impurity content, etc., to achieve Improve the light transmittance, reduce the oil film on the particle surface, and facilitate large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

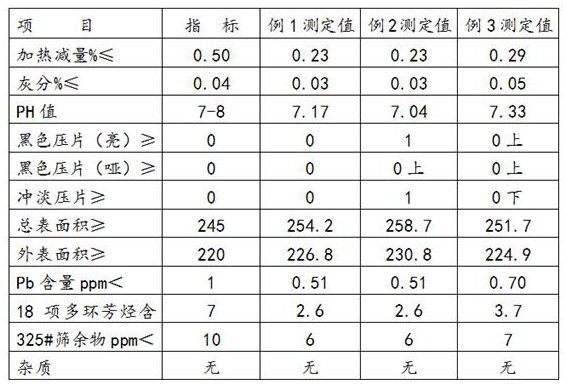

Examples

Embodiment 1

[0030]The weight ratio of the amount of raw material oil to the amount of additive potassium hydroxide is 1200:0.02, the moisture content of the raw material oil is ≤1.0%, the density is 1.125g / cm³, the viscosity is 1.3, and the initial boiling point temperature is 218°C. The oil distillation rate is 96%.

[0031] Pigment carbon black product of the present invention adopts furnace process new process pigment carbon black production technology to be specific as follows:

[0032] 1) After the natural gas with a flow rate of 500Nm³ / h and a pressure of 65kpa is axially sent into the combustion chamber, the air is filtered and compressed to a pressure of 0.16Mpa by a Roots blower, and the flow rate after being heated to 580°C by a 650°C high-temperature air preheater is The hot air A of 5500Nm³ / h is mixed and fully combusted, the temperature of the combustion chamber is controlled at 1700°C, and the hot flue gas after combustion flows through the throat section of the reactor at h...

Embodiment 2

[0041] The weight ratio of the amount of raw material oil to the amount of additives is 1300:0.04, the moisture content of the raw material oil is ≤1%, the density is 1.128g / cm³, the viscosity is 1.3, and the initial boiling point temperature is 220°C. The raw material oil distillation rate 98%.

[0042] Pigment carbon black product of the present invention adopts furnace process new process pigment carbon black production technology to be specific as follows:

[0043] 1) After the natural gas with a flow rate of 545Nm³ / h and a pressure of 65kpa is axially sent into the combustion chamber, the air is filtered (the filter mesh diameter is less than 2 microns) and compressed by a Roots blower to a pressure of 0.17Mpa, and preheated by 650°C high-temperature air After the reactor is heated to 590°C, hot air A with a flow rate of 6000Nm³ / h is mixed and fully combusted. The temperature of the combustion chamber is controlled at 1730°C, and the hot flue gas after combustion flows th...

Embodiment 3

[0052] The weight ratio of the amount of raw material oil to the amount of additives is 1300:0.03, the moisture content of the raw material oil is ≤1%, the density is 1.130g / cm³, the viscosity is 1.3, and the initial boiling point temperature is 222°C. The raw material oil distillation rate 98%.

[0053] Pigment carbon black product of the present invention adopts furnace process new process pigment carbon black production technology to be specific as follows:

[0054] 1) After the natural gas with a flow rate of 564Nm³ / h and a pressure of 65kpa is axially sent into the combustion chamber, the air is filtered (the filter mesh diameter is less than 1 micron) and compressed by a Roots blower to a pressure of 0.17Mpa, and preheated by 650°C high-temperature air After the reactor is heated to 600°C, the source hot air with a flow rate of 6200Nm³ / h is mixed and fully combusted. The temperature of the combustion chamber is controlled at 1750°C, and the hot flue gas after combustion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com