Patents

Literature

109 results about "Hydroxide potassium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potassium hydroxide (KOH), commonly called caustic potash, is used in products that clean and disinfect surfaces, in drain cleaners, cuticle removal products and leather tanning chemicals.

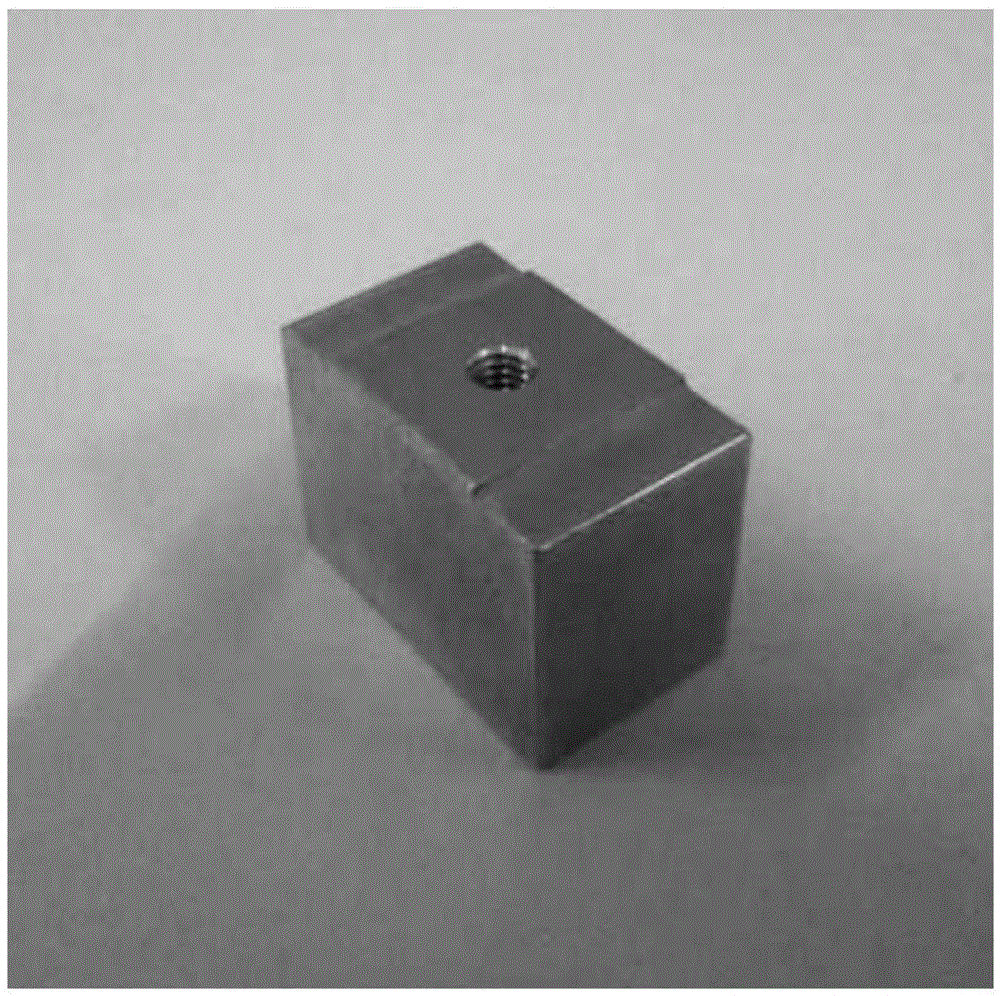

Preparation method for quick in-situ growth of ultrathin wear-resisting coating on surface of aluminum alloy irregular part

ActiveCN103526255AIncrease frictionImprove corrosion resistanceAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a preparation method for quick in-situ growth of an ultrathin wear-resisting coating on the surface of an aluminum alloy irregular part, relates to a preparation method of an aluminum alloy surface coating, and aims to solve the technical problem that the film obtained when parts of an LY12 aluminum alloy irregular part are treated by a micro-arc oxidation technology is easy to wear. The method comprises the following steps: I, surface pretreatment of the LY12 aluminum alloy irregular part; II, preparation of an electrolyte, wherein the electrolyte is prepared from a main film-forming agent, an auxiliary film-forming agent, potassium hydroxide, glycerol, polyethylene glycol 1000 and distilled water; III, micro-arc oxidation, wherein the ultrathin wear-resisting coating is quickly obtained on the surface of the LY12 aluminum alloy irregular part. The thickness of the film of the ceramic film is 5-15 mu m, the average friction coefficient of the film is 0.12-0.20, and the bonding strength of the film is 14-30MPa. The preparation method can be applied to structural connectors of spacecrafts.

Owner:HARBIN INST OF TECH

Uncolored bamboo fiber with high antibacterial activity and processing method thereof

ActiveCN104141256AProduction to preventEmission reductionPaper material treatmentFiberHydroxide potassium

The invention discloses an uncolored bamboo fiber with high antibacterial activity. The beating degree of the fiber is 16-25 0SR, the fracture length ranges from 4 km to 6 km, the folding number ranges from 65 to 80, the whiteness is 22-25% ISO, the value of potassium permanganate ranges from 80 to 100, and the antibacterial rate is greater than or equal to 90%. A processing method of the uncolored bamboo fiber includes the steps that 1, materials are prepared, wherein bamboo plant raw materials are processed to be bamboo chips in a wet method; 2, cooking is carried out, wherein the bamboo chips are added into a potassium hydroxide solution and are heated to be at the temperature of 110-125 DEG C through steam, then the temperature is kept for 50-60 minutes, and a bamboo fiber material is obtained; 3, antibacterial treatment is carried out, wherein high molecular chitosan is added after the cooked bamboo fiber material is grinded into thick liquid. The uncolored bamboo fiber has the large fiber length, high flexibility and good water absorbing and water-retaining properties, and is soft in texture, fluffy and high in antibacterial property, the natural color of the bamboo fiber is kept, and the quality of down-stream products is improved remarkably. The processing method has the characteristics that operation is easy, production is convenient, the cost is low, and environmental protection is achieved.

Owner:SICHUAN HUANLONG NEW MATERIAL

Dewatering demulsifier for triple composite driven extract and its production

ActiveCN101029253AExcellent demulsification and dehydration effectHydrocarbon oil dewatering/demulsificationDemulsifierEpoxy

A triple composite-driven extract dewatering demulsifier and its production are disclosed. The demulsifier consists of drier 45-65wt%, water 30-45wt% and methanol 5-10wt%; drier consists of AE surface activator 15-30wt%, SP surface activator 10-40wt%, AT surface activator 15-35wt%, epoxy chloropropane 5-8wt%, which are synthesized by caustic potash, epoxypropane, triethenoid tetrammine, epoxyethane and acetic acid. The additive amount is between 80-100mg / 1 and water content is<0.2%, oil content is<500mg / 1. It has better demusifying effect.

Owner:PETROCHINA CO LTD

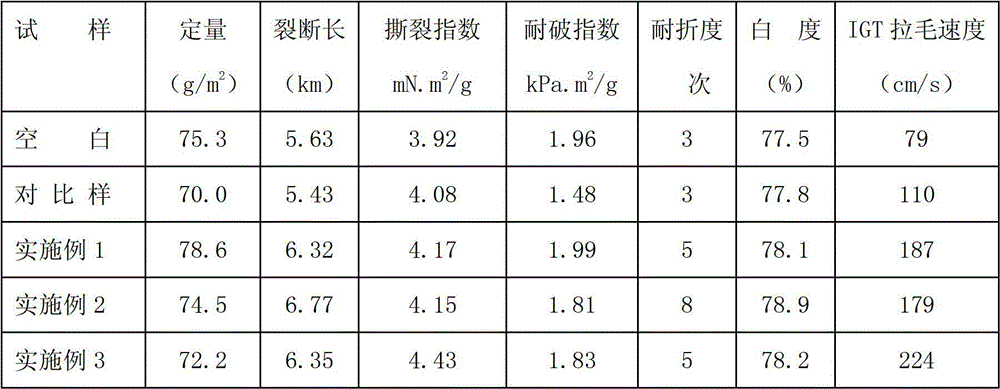

Preparation method and application of oxidized starch

InactiveCN102718878AComply with clean and environmentally friendly production requirementsImprove smoothnessWater-repelling agents additionPaper coatingBursting strengthFiber

The invention provides oxidized starch, a preparation method thereof and application. The preparation method of the oxidized starch includes the steps: (1) under the condition of mixing, spraying catalyst solution into the starch, spraying oxidants and increasing the temperature to reach 30-50 DEG C; (2) after mixing the starch every 15 minutes within an hour, spraying residual oxidants to react for 4-8 hours; and (3) cooling the starch, adding neutralizers until the pH (potential of hydrogen) of a system is 6-8, crushing the starch, and screening the starch by a screen with 90-120 meshes to obtain the oxidized starch. The weight of the sprayed oxidants accounts for 30-60wt% of the overall weight of oxidants, catalysts are sodium hydroxide or potassium hydroxide, and the oxidants are hydrogen peroxide. The oxidized starch can be used for gluing the surface of paper, continuous and uniform films are formed on the surface of a paper sheet, oil resistance and scratch resistance of the paper sheet can be improved, and smoothness and glossiness of the paper sheet are improved. When the oxidized starch is used for internal sizing, paste can be uniformly and adsorbed on fibers, and the bursting strength and the folding resistance of the paper are improved.

Owner:新乡市东升新材料有限公司 +1

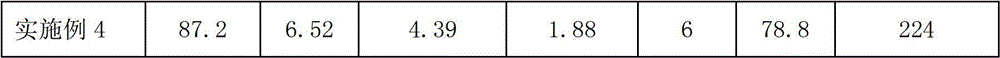

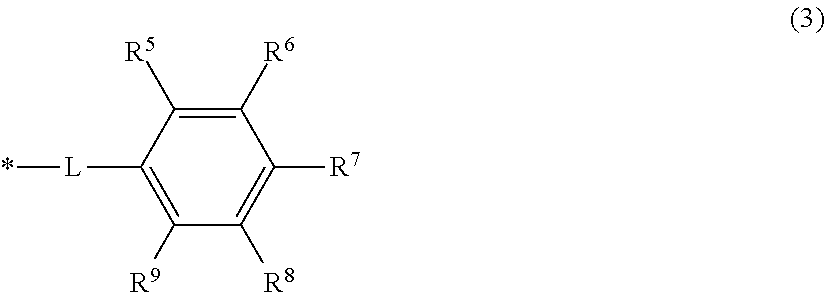

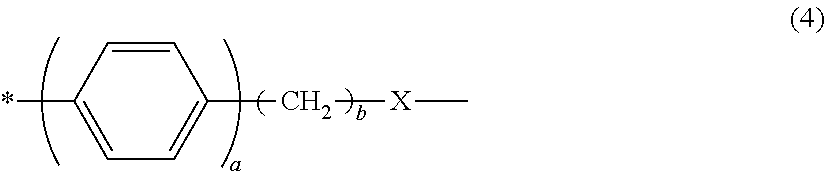

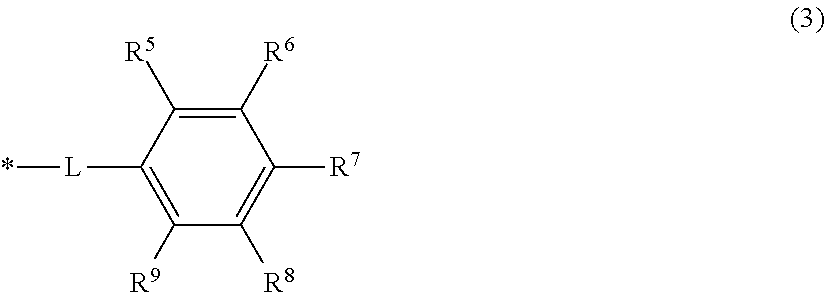

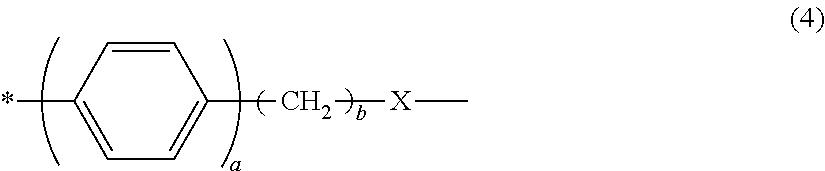

Toner and toner manufacturing method

ActiveUS10295922B2Excellent tinting strength and transferabilityDevelopersHydroxide potassiumPigment dispersion

A toner containing a toner particle including a binder resin, a resin A having a pKa of 6.0-9.0, and a pigment having a pKb of 4.0-7.0, wherein the pKa is an acid dissociation constant measured by preparing a resin solution in which 1.0 part by mass of the resin A, 70.0 parts by mass of toluene and 30.0 parts by mass of ethanol are mixed, and carrying out neutralization titration with a potassium hydroxide ethanol solution of 0.1 mol / L, and the pKb is a basic dissociation constant measured by preparing a pigment dispersion in which 10.0 parts by mass of the pigment, 140.0 parts by mass of toluene and 60.0 parts by mass of ethanol are mixed, and carrying out neutralization titration with a hydrochloric acid ethanol solution of 0.1 mol / L.

Owner:CANON KK

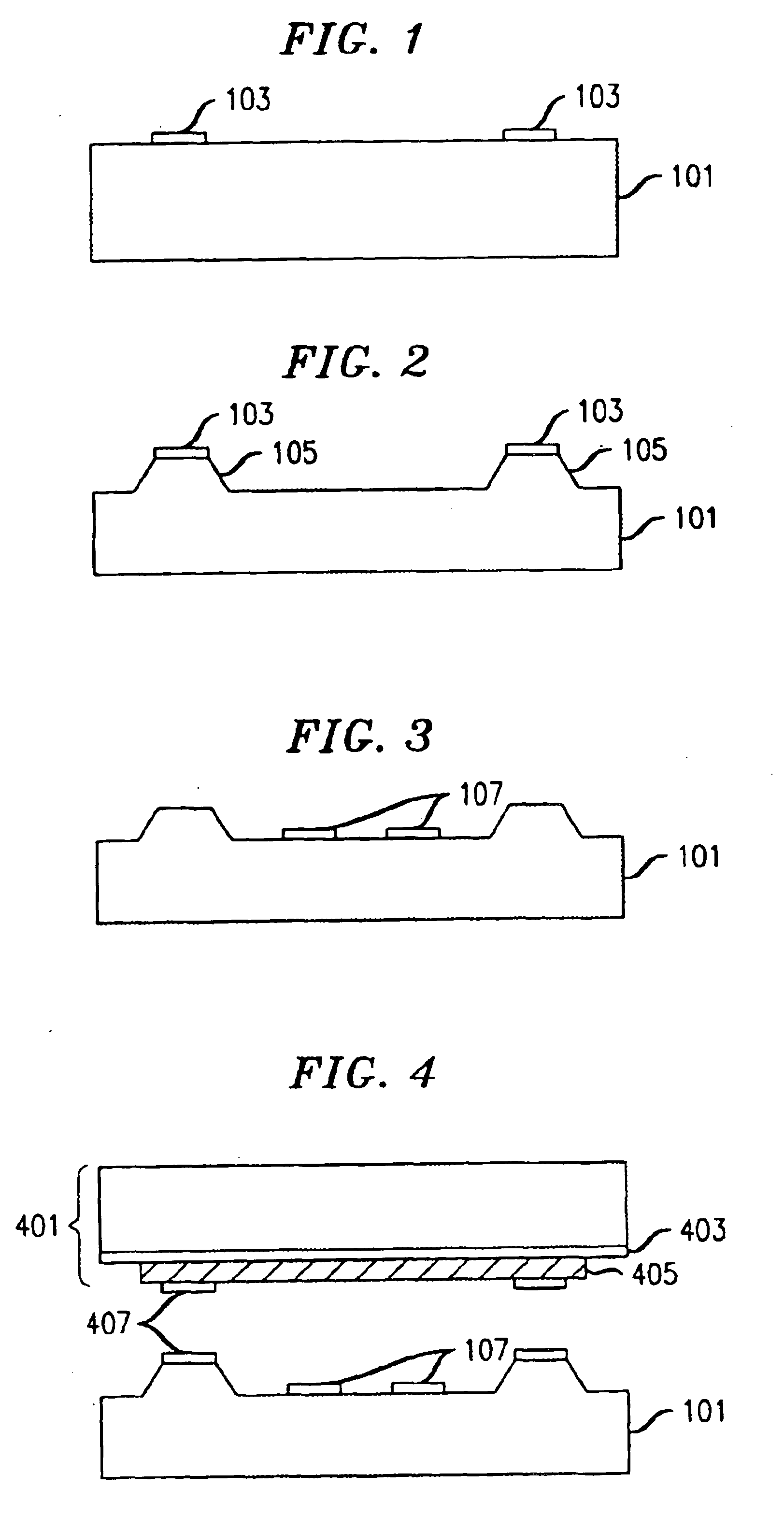

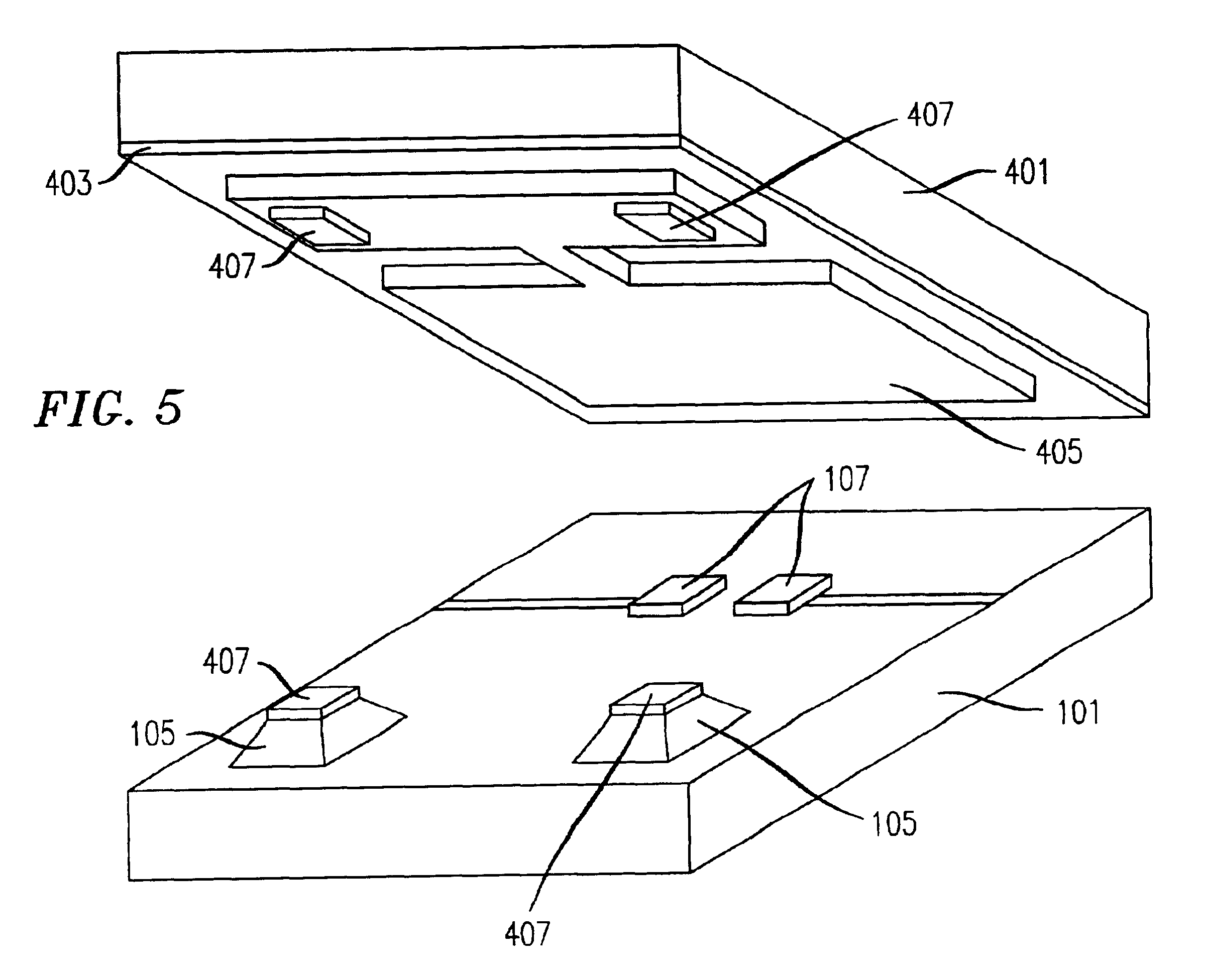

Optical micro-electromechanical systems (MEMS) devices and methods of making same

InactiveUS6912081B2Easy to achieveImprove relationshipDecorative surface effectsPhotomechanical apparatusAmmonium hydroxidePotassium hydroxide

Owner:WSOU INVESTMENTS LLC +1

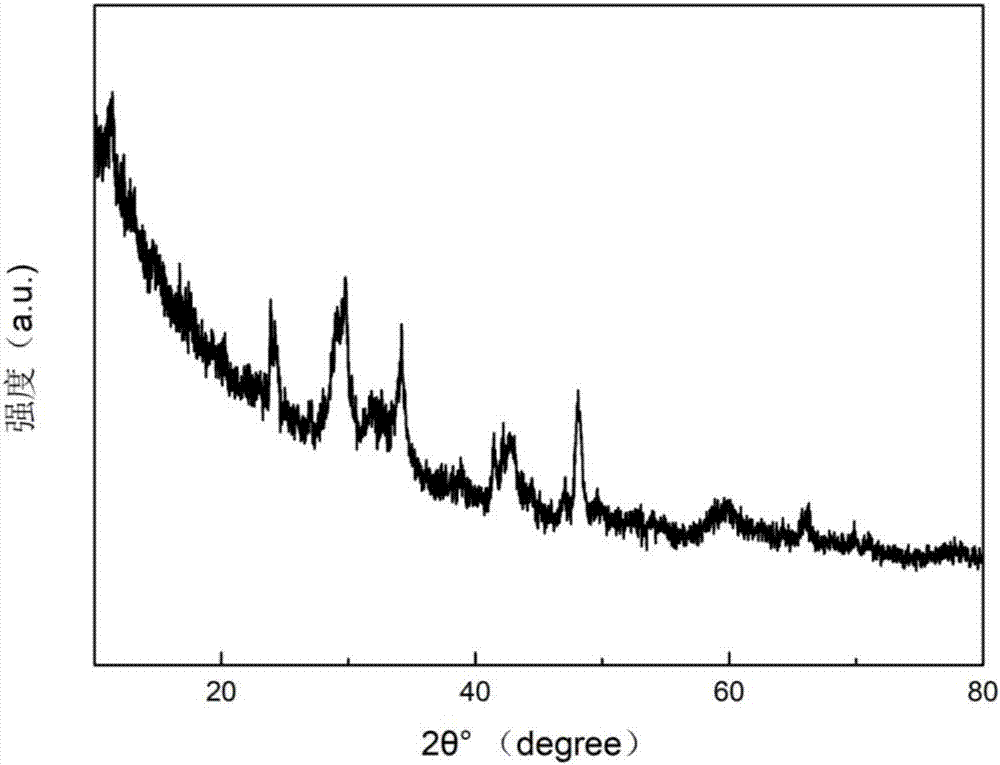

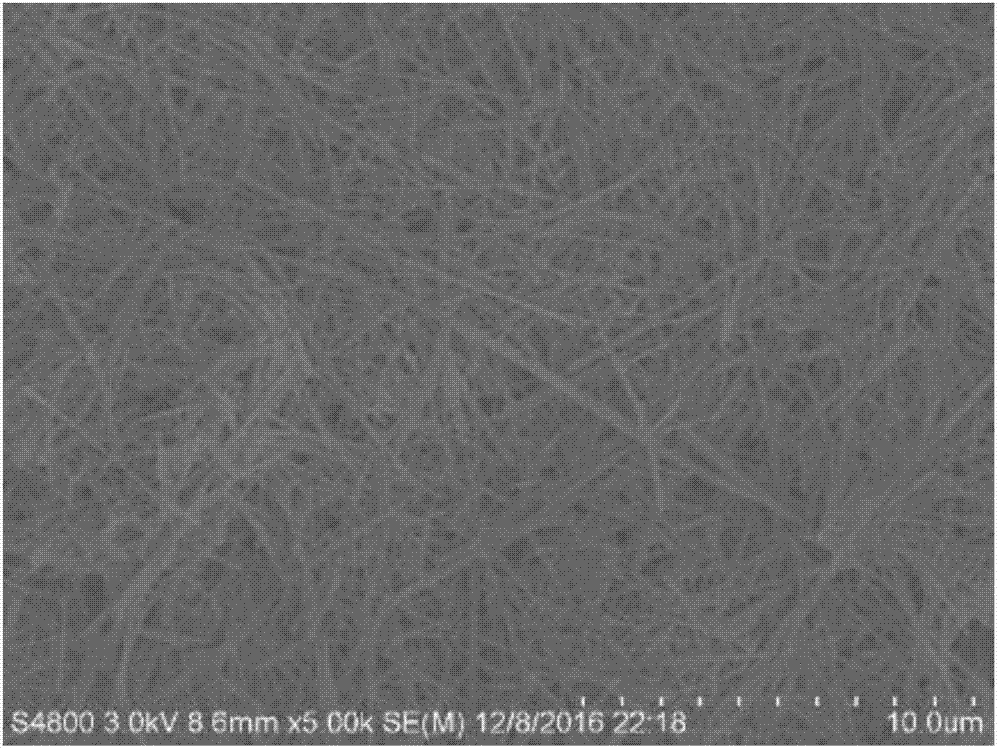

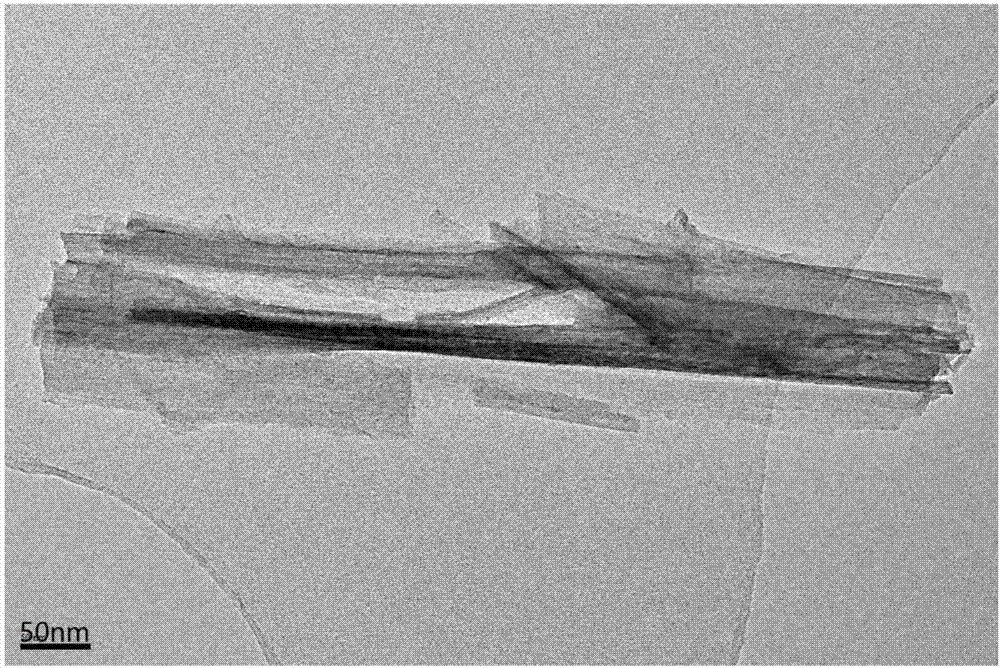

Preparation method of mixed-crystal-form titanium dioxide fiber and product

InactiveCN107227511ANo pollution in the processSimple processPhysical/chemical process catalystsInorganic material artificial filamentsHydrogenPolyvinyl alcohol

The invention relates to a preparation method of mixed-crystal-form titanium dioxide fiber. The preparation method comprises the following steps: 1) adding a potassium hydroxide solution into a tetrabutyl titanate solution, mixing, performing a hydrothermal reaction, and filtering and cleaning a product to obtain potassium titanate fiber; 2) dispersing the potassium titanate fiber in a nitric acid solution which is 1 to 1.5M in concentration, adding a polyvinyl alcohol solution, mixing, performing a hydrothermal reaction, cleaning and filtering the product to obtain the titanium dioxide fiber. The invention further relates to a product prepared by the preparation method. The obtained titanium dioxide fiber can be of an anatase type and a rutile type, and can keep the appearance of a precursor; a large quantity of gaps exist in a fiber structure, and high photocatalytic hydrogen generation performance is achieved.

Owner:ZHEJIANG UNIV

Aqueous anti-rust lacquer prepared from nano slurry

InactiveCN101475769AImprove rust resistanceReasonable priceAnti-corrosive paintsEmulsion paintsWater basedAcrylic resin

The invention relates to a water-based antirust paint prepared from nanometer slurry. The water-based antirust paint consists of the following compositions in percentage by weight: 3 to 8 percent of water-based nanometer slurry, 0.3 to 0.8 percent of a surfactant, 0.5 to 1 percent of a dispersant, 0.2 to 0.6 percent of a defoaming agent, 0.5 to 1 percent of an anti flash-rust additive, 0.08 to 0.2 percent of a chloric ketone disinfector, 1.0 to 1.6 percent of propanediol, 10 to 15 percent of compound ferrotitanium powder, 10 to 15 percent of iron oxide red powder, 1 to 3 percent of magnesium hydroxide potassium titanate whiskers , 2 to 6 percent of mica powder, 5 to 10 percent of talcum powder, 12 to 20 percent of polyacrylic emulsion, 12 to 20 percent of water-based acrylic resin, and the like, and the balance being deionized water. The water-based antirust paint has the advantages that the paint has innocuity, harmlessness, safety, and environmental protection; the excellent antirust performance of the paint exceeds that of alcohol acid red lead rust-proof paint; through detection of an authoritative institution, the capacity for brine resistant of the water-based antirust paint reaches over 500 hours; and the price of the water-based antirust paint is relatively reasonable.

Owner:湖北中科博策新材料科技有限公司

High-yield high-performance bamboo fiber material prepared from bamboo used as raw material and preparation method thereof

ActiveCN104131483AHigh yieldReduce manufacturing costCellulose material pulpingFiberChemical solution

The invention discloses a high-yield high-performance bamboo fiber material prepared from bamboo used as a raw material. K value of the material is 80-100. A preparation method of the material comprises the following steps: S1, a potassium hydroxide solution which accounts for 8-10% of consumption of the absolute dry raw material is added into the bamboo plant raw material, and the solid-liquid ratio is 1:3-4; and S2, stream is blown in and heating is carried out, and thermal insulation is carried out for 50-60 min when temperature is rising to 110-125 by heating. The invention has the following beneficial effects: a bamboo plant is used as a raw material to prepare the high-performance fiber material by a method except a method of pulping with an organic solvent; and during the preparation process, dosage of a cooking liquor is reduced and cooking time is shortened to prepare the high-performance bamboo fiber material. By reducing the dosage of a chemical solution and shortening the cooking time, production cost of an enterprise will be decreased. Thus, the high-yield high-performance bamboo fiber material is obtained.

Owner:SICHUAN HUANLONG NEW MATERIAL

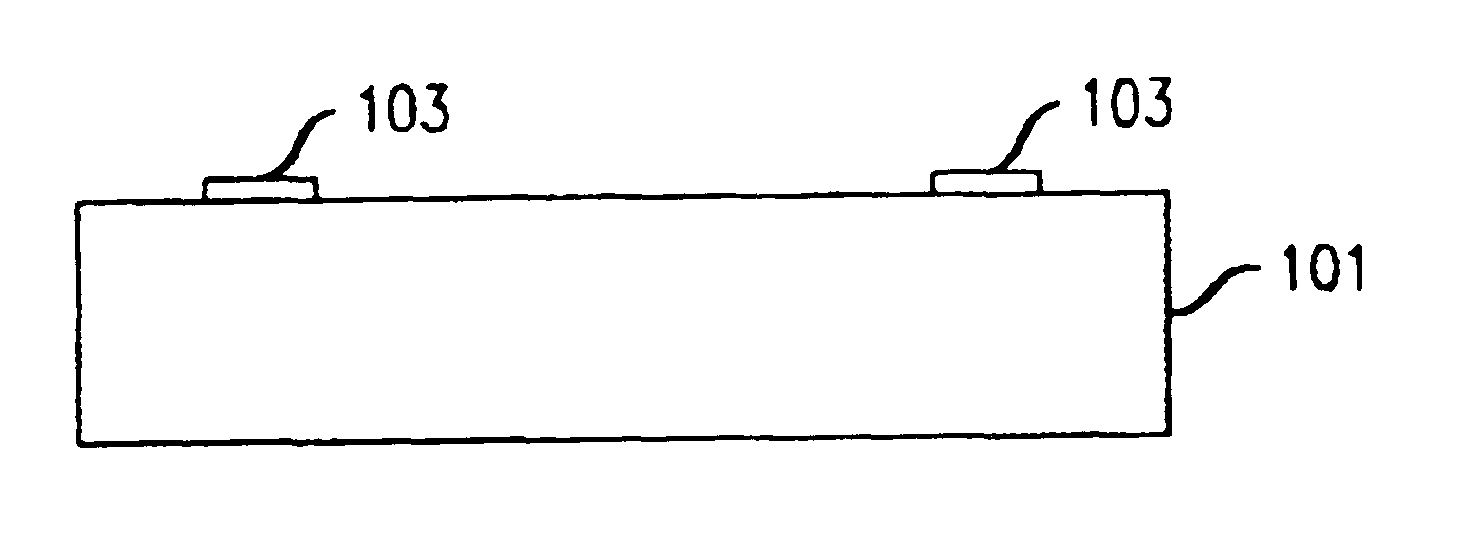

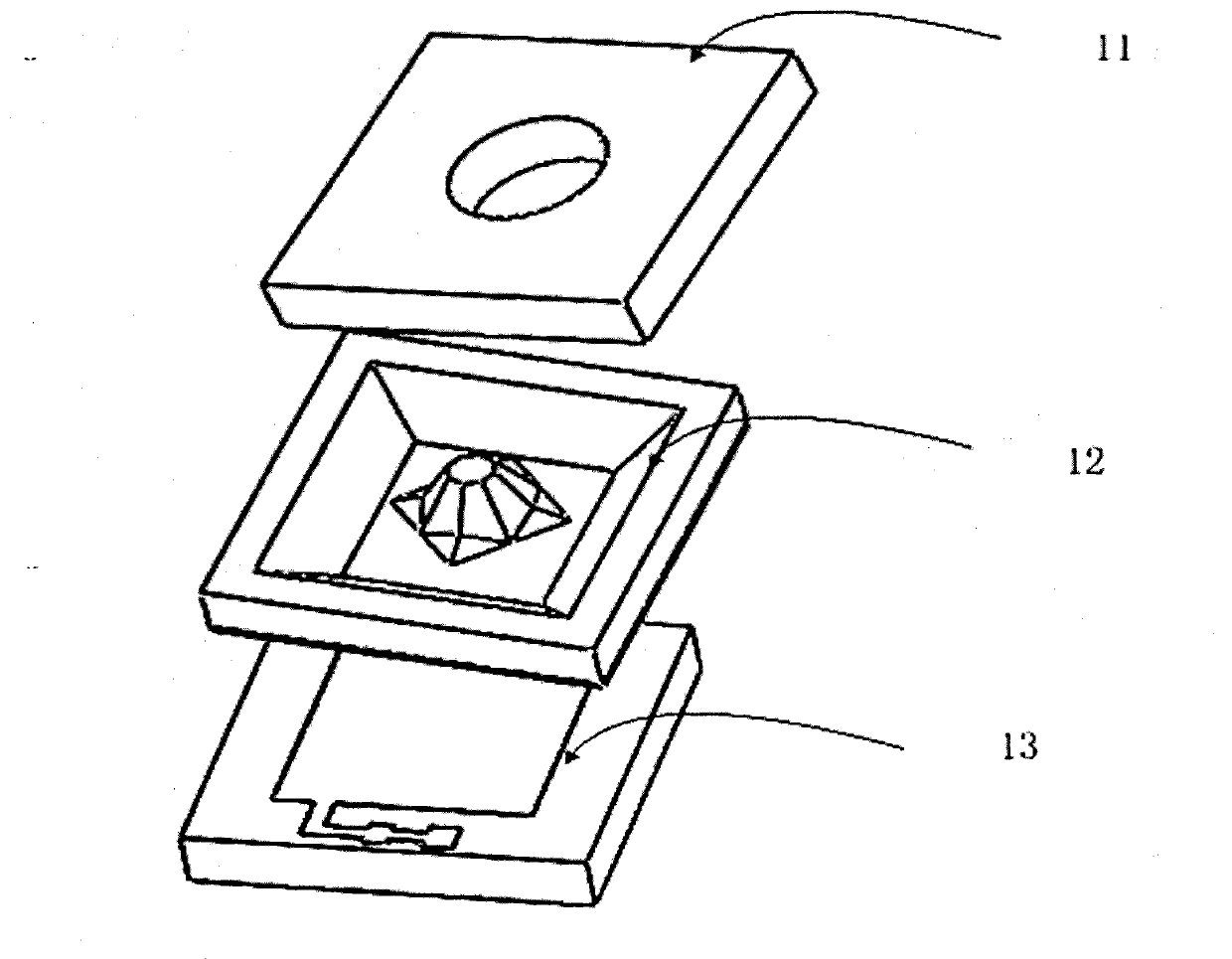

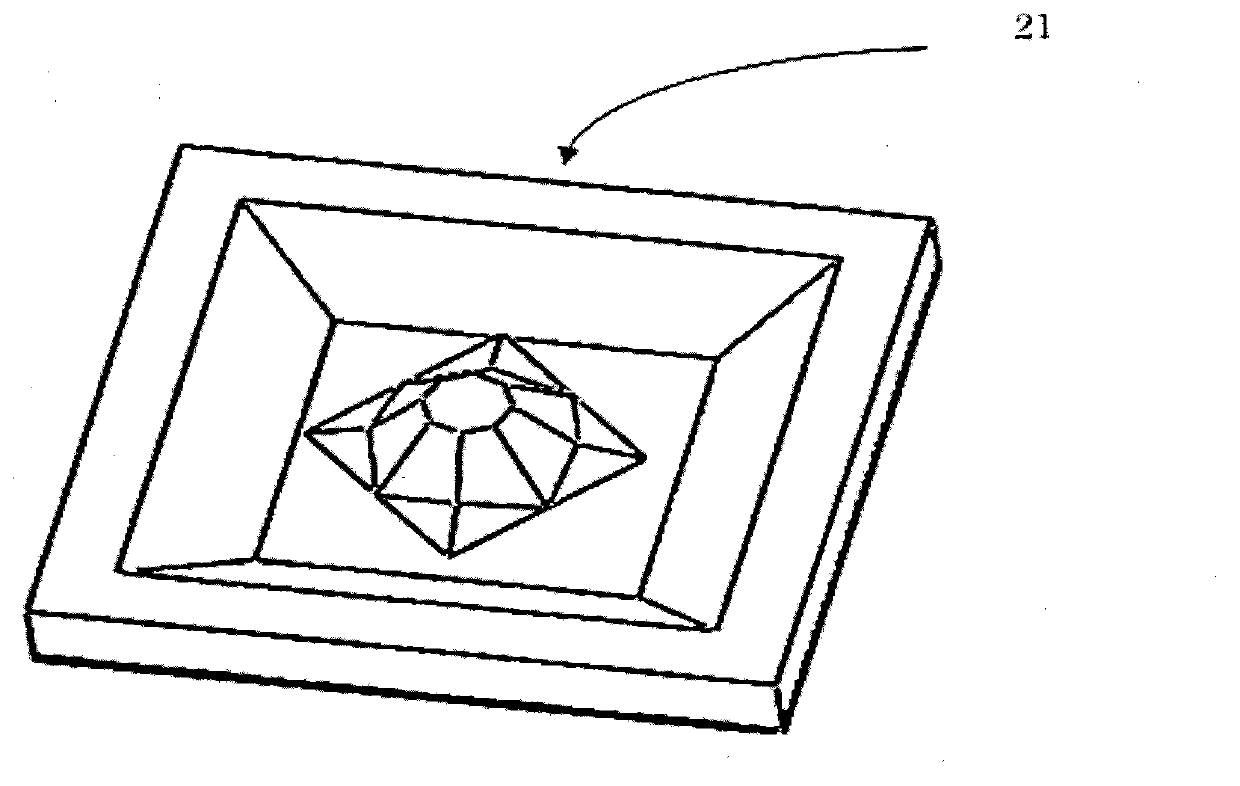

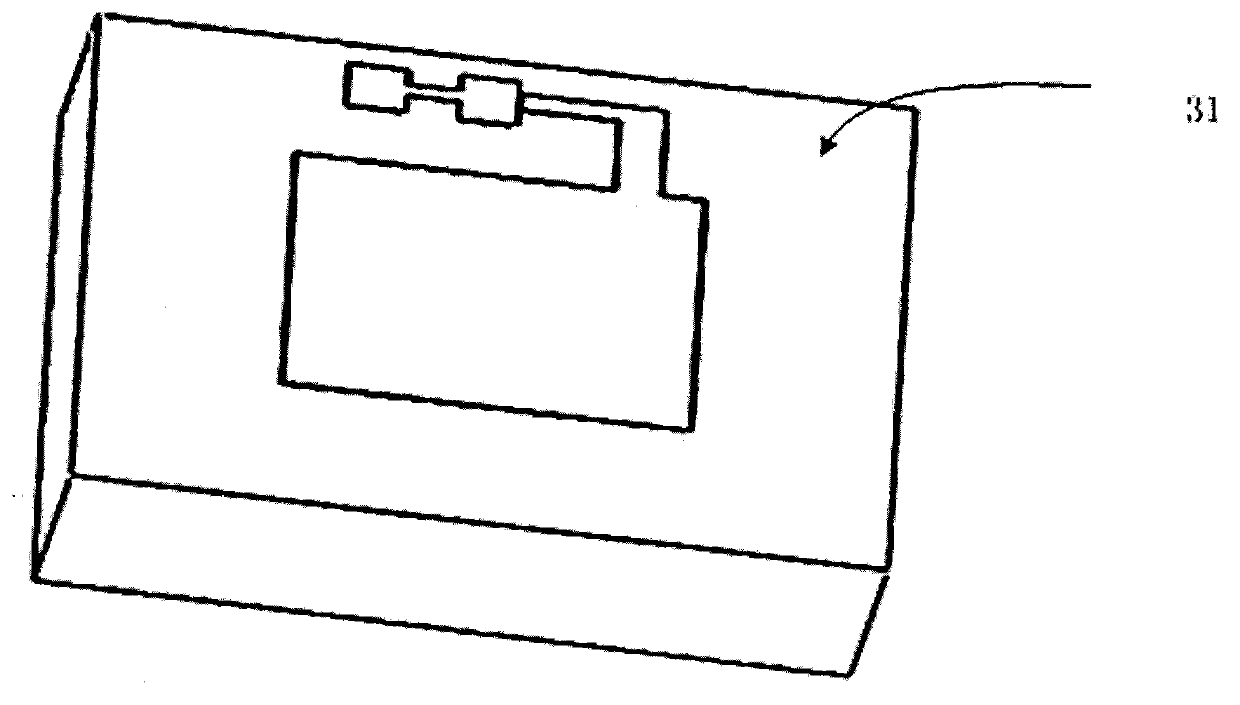

Method for preparing capacitive pressure transducer

InactiveCN103964370ASimple processEasy to implementDecorative surface effectsChemical vapor deposition coatingTetramethylammonium hydroxideCapacitance

The invention relates to a method for preparing a capacitive pressure transducer and aims to manufacture a device which has a simple structure and good reliability and repeatability through a relatively simple method. The specific processing method comprises the steps of processing a sensitive diaphragm, processing a capacitive gap, processing an electrode and leading out the electrode, bonding silica glass and so on. The processing of the sensitive diaphragm comprises the steps of etching the capacitive gap by using a tetramethylammonium hydroxide (TMAH) solution, and etching a silica island by using a potassium hydroxide (KOH) solution. The invention is characterized by the etching of the silica island and aims at providing a variable cross-section (octangle) diaphragm. The variable cross-section diaphragm has good linearity and low stress concentration; the capacitive gap has a width of 2-4um, and the etching accuracy of the capacitive gap is easy to control by using the TMAH solution; a Cr / Au electrode is deposited and then is bonded with a glass electrode; after the glass side is protected by glue, photoetching is carried out on the front and the silicon island is etched; and as for bonding, the problems in electrostatic bonding and the water-tightness of the cavity are taken into account, and corresponding designs are made.

Owner:PEKING UNIV

High-temperature-resistant ceramic coating and preparation method thereof

ActiveCN110951287AImprove high temperature resistanceImprove thermal conductivityFireproof paintsPolyurea/polyurethane coatingsImideCeramic coating

The invention discloses a high-temperature-resistant ceramic coating, and belongs to the field of paints. The high-temperature-resistant ceramic coating comprises a component A and a component B at amass ratio of 1: 1, wherein the component A is prepared from the following raw materials in parts by weight: 25 to 30 parts of modified silane, 1 to 1.5 parts of a leveling agent, 0.3 to 0.5 part of formic acid and 0.1 to 0.2 part of potassium hydroxide; the component B is prepared from the following raw materials in parts by weight: 50 to 60 parts of silica sol, 5 to 10 parts of mica powder; 15 to 20 parts of silica powder; and 10-15 parts of water. The modified silane is used as a main film-forming substance and is closely related to the heat resistance of the coating. Gamma-aminopropylmethyldimethoxysilane is used as a modified silane based body and has good bonding performance with inorganic materials, and imide rings with excellent thermal stability are introduced into modified molecular chains, so that the high-temperature resistance of film layers is greatly improved.

Owner:浙江裕辉新材料科技有限公司

Environment-friendly high-efficiency laundry detergent and preparation method thereof

ActiveCN103146501AGood decontamination effectThe synthesis process is green, environmentally friendly and safeInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsActive agentHydroxide potassium

The invention relates to an environment-friendly high-efficiency laundry detergent and a preparation method thereof. At present, the dirt-removing power of the laundry detergent is improved generally by increase the content of surfactant in components, but the emission amount of active substances in the discharge process of the laundry detergent can be increased to cause environment burden. The environment-friendly high-efficiency laundry detergent comprises the following components in percentage by weight: 2-8% of fatty alcohol-polyoxyethylene ether sulfate, 2-6% of fatty alcohol-polyoxyethylene ether, 1-3% of anion dimeric surfactant, 0.5-3% of organic amine, 0.5-4% of potassium hydroxide, 0.5-2% of sodium citrate, 0,05-0.5% of essence and the balance of water. The laundry detergent adopts a green and natural anion bimeric surfactant' compared with the traditional surfactant, the green and natural anion bimeric surfactant has the advantages that synthetic raw materials are natural regenerable resources, the the synthetic process is green, environment-friendly and safe, biodegradability is good, and performances are excellent, the dirt-removing power of the laundry detergent can be obviously improved after a small amount of anion bimeric surfactant is added.

Owner:上海开米科技有限公司

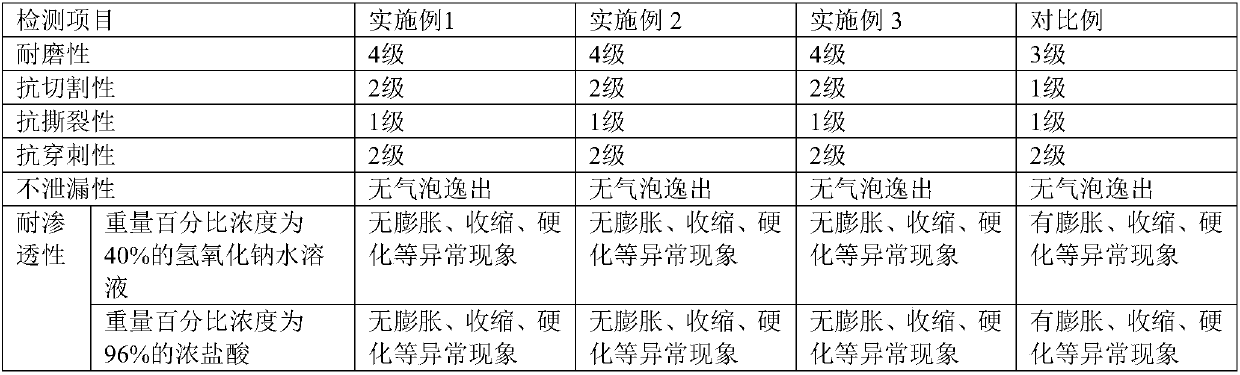

Acid and alkali resistant latex glove and preparation process thereof

ActiveCN109627517AImprove wear resistanceImprove cut resistanceGlovesDomestic articlesLatex glovePotassium hydroxide

The invention relates to a preparation process of acid and alkali resistant latex glove, which comprises the following steps of: immersing a pretreated hand mold into latex at a temperature of 25-27 DEG C, shaping the soaked hand mold at a temperature of 50-65 DEG C to form an adhesive film, leaching the hand mold with the adhesive film by using ammonia water with a temperature of 23-25 DEG C anda pH value of 9-10, and then drying at a temperature of 55-70 DEG C; vulcanizing at 75-90 DEG C, sequentially soaking the hand mold in cold water at a temperature not higher than 35 DEG C, chlorine water at a temperature not higher than 45 DEG C, and a potassium hydroxide aqueous solution at a temperature not higher than 45 DEG C and a pH value of 8-10, and demoulding to obtain the acid and alkaliresistant latex glove. The invention also relates to an acid and alkali resistant latex glove which is prepared by the preparation process of the acid and alkali resistant latex glove. The acid and alkali resistant latex glove has good compactness and still has excellent permeability resistance after being soaked in strong acid and strong alkali.

Owner:BEIJING REAGENT LATEX PRODS

Preparation method of cobalt coated alpha-nickel hydroxide composite material for alkaline secondary battery

InactiveCN108075126AHigh specific capacityExtended service lifeCell electrodesNitrateNickel oxide hydroxide

The invention discloses a preparation method of a cobalt coated alpha-nickel hydroxide composite material for an alkaline secondary battery. The preparation method comprises the following steps: (1) dissolving nickel chloride, ferrous nitrate and yttrium nitrate into glycol, adding deionized water, adding dilute ammonia water into the mixed solution to perform reaction, washing and drying to obtain an iron-yttrium doped alpha-nickel hydroxide precursor; and (2) mixing the iron-yttrium doped alpha-nickel hydroxide precursor and a cobalt sulfate solution, dispersing uniformly, adding a potassiumhydroxide solution dropwise, washing, filtering and drying to obtain the iron and yttrium doped cobalt coated alpha-nickel hydroxide composite material. The alpha-nickel hydroxide composite materialfor the alkaline secondary battery prepared by the method the electrical conductivity and the cycling stability of spherical nickel hydroxide are improved while the energy density of the material is increased; and when the alpha-nickel hydroxide composite material is applied to the alkaline secondary battery, the battery has high specific capacity and long service life.

Owner:宁波高新区锦众信息科技有限公司

Improved wood floor adhesive

InactiveCN104403586AQuality improvementShort curing timeNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveAdhesive cementEthylene diamine tetra acetic

The invention discloses an improved wood floor adhesive which is characterized by being prepared by the following raw materials in part by weight: 5-10 parts of sodium silicate, 2-4.7 parts of borax, 1.7-4.5 parts of vinyl versatate, 1.2-2.7 parts of polyurethane, 1.4-2.6 parts of ethyl acrylate, 0.5-1.2 parts of potassium hydroxide, 2.5-5 parts of milled wood lignin and 0.5-1.6 parts of dipotassium ethylene diamine tetraacetate. Compared with the conventional product, the improved wood floor adhesive has the advantages that the storage time is long, and the construction efficiency is effectively improved; the full-curing time required by the adhesive at the room temperature is short; as the raw materials used by the adhesive are safe and pollution-free and can release negative oxygen ions beneficial for the human body, so that the improved wood floor adhesive is environment-friendly, and can purify air and improve the air quality.

Owner:QINGDAO LAOXIANG TEA PROD

Production process of medical spunlace non-woven fabric

InactiveCN111235876ARealize the sterilization functionMaintain soft propertiesCarbon fibresDyeing processYarnActivated carbon

The invention discloses a production process of medical spunlace non-woven fabric. High-density cotton yarn, activated carbon fiber and nano-silver modified slurry are adopted as raw materials, and the medical spunlace non-woven fabric is obtained through raw material opening, carding web forming, spunlace reinforcing, dipping modification, fruit dyeing treatment, drying and reeling processing. The nano-silver modified slurry is composed of nano-silver powder, modified starch, polyvinyl alcohol, 2-naphthol, potassium hydroxide and deionized water. The cotton yarn is blended and modified by adopting the activated carbon fiber and the nano-silver modified slurry, the sterilization function of the medical non-woven fabric is achieved, meanwhile, steam does not need to be consumed in the dyeing process, no chemical additive or chemical dye is needed, a fruit dyed product has the characteristics of being purely natural, healthy and comfortable, a layer of natural active pectin can be formedon a dyed cloth cover, unique soft luster is generated, the moisture absorption and air permeability are improved, and good skin friendliness is achieved.

Owner:SHANDONG DERUN NEW MATERIAL TECH

Disposable glove processing technology

PendingCN112480502AComfortable to wearExcellent chemical resistanceGarment special featuresGlovesLatex gloveHydroxide potassium

The invention discloses a disposable glove processing technology, wherein the disposable gloves comprise: 70-80 parts of butyronitrile latex, 10-20 parts of potassium hydroxide aqueous solution, 5-10parts of sulfur dispersion liquid, 10-15 parts of zinc oxide dispersion liquid, 3-5 parts of accelerant dispersion liquid, 3-8 parts of anti-aging agent dispersion liquid, 15-20 parts of titanium dioxide dispersion liquid, 4-6 parts of defoaming agent, 8-16 parts of stabilizer, 5-15 parts of surface treating agent, 20-30 parts of chlorine water and 10-20 parts of viscosity reducer. According to the invention, disposable butyronitrile gloves are prepared by taking butyronitrile latex as a main raw material, the disposable butyronitrile gloves not only have the characteristics of latex gloves, but also are improved aiming at the defects of the latex gloves. In addition, the disposable butyronitrile gloves can tolerate the corrosion of animal fat and are free of cause allergy.

Owner:仙桃市松青塑料制品有限公司

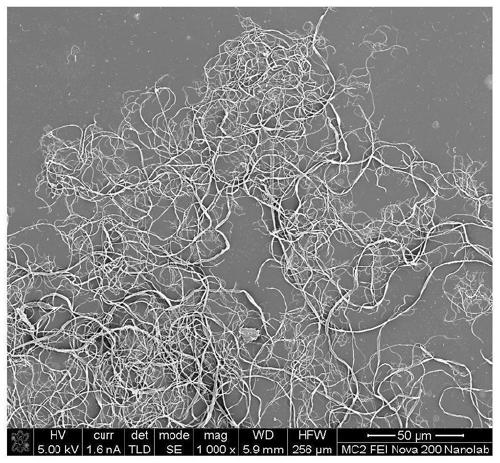

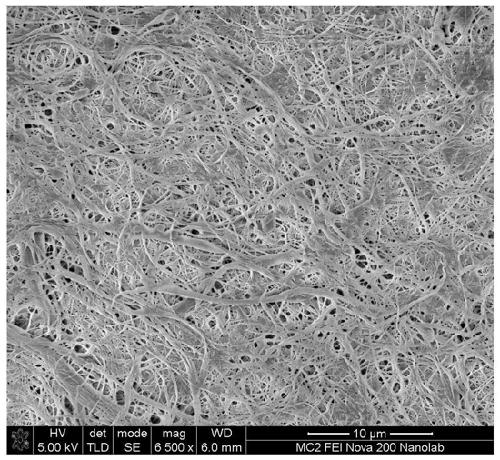

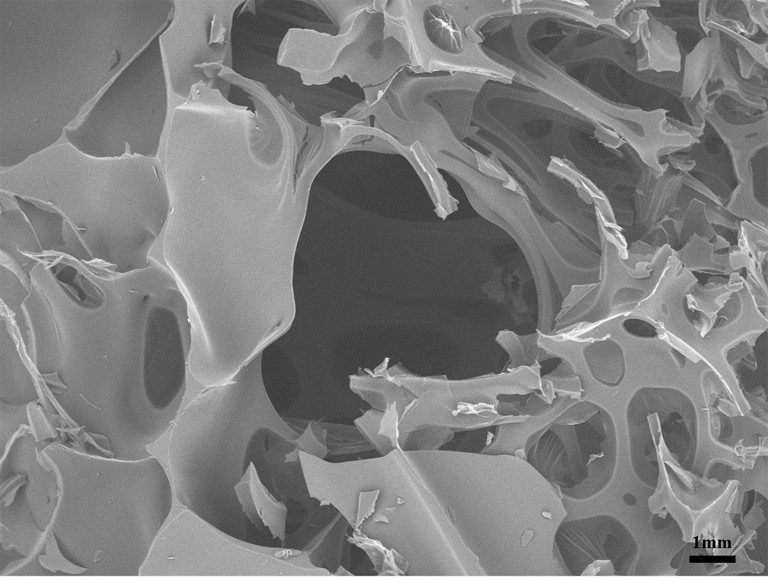

Preparation method and application of large-scale porous aramid fiber microfiber diaphragm

InactiveCN111211276AWeakened hydrogen bondsWeaken π-π conjugationFibre typesSecondary cellsHydroxide potassiumLithium-ion battery

The invention discloses a preparation method and an application of a large-scale porous aramid fiber microfiber diaphragm, and belongs to the technical field of diaphragm preparation. The invention aims to solve problems of insufficient strength, a low heat-resistant temperature and poor wettability of anexisting lithium ion battery diaphragm. The method comprises the following steps of adding aramid fiber chopped fibers into a dimethyl sulfoxide reaction container containing potassium hydroxide for soaking; cleaning with pure dimethyl sulfoxide, removing redundant potassium hydroxide, dispersing the pre-oxidized aramid fiber chopped fibers into dimethyl sulfoxide, and mechanically separating; and carrying out suction filtration to prepare a diaphragm by adopting a vacuum suction filtration mode, after dimethyl sulfoxide is completely pumped, cleaning, removing redundant dimethyl sulfoxide, taking down the diaphragm, and compacting. Excellent mechanical properties of aramid fiber microfibers can inhibit growth of lithium dendrites in acycle process, prevent ashort circuit phenomenon caused by piercing the diaphragm and fulfill aims of prolonging aservice life of a battery and improving safety of the battery.

Owner:HARBIN INST OF TECH

Graphene hydrogel modified latex and preparation method of graphene modified hydrogel rubber gloves

The invention relates to graphene hydrogel modified latex, which comprises the following components in parts by weight: 100 parts of carboxylic butadiene-acrylonitrile rubber, 1-2 parts of potassium hydroxide, 1-1.5 parts of sulfur, 1.5-3 parts of zinc oxide, 0.5-1.2 parts of an accelerant, 0.01-0.03 part of a dispersing agent and 5-50 parts of graphene hydrogel. The preparation method of the graphene modified hydrogel rubber glove comprises the following steps: preparing graphene hydrogel modified latex, controlling the viscosity to be 3000-5000 mps, and performing standing treatment; preheating the glove core; dipping the glove core in a coagulator; dipping the glove core in graphene hydrogel modified latex; uniformly spreading salt on the glue surface for shaping the glove core; and pre-vulcanizing, soaking and washing, and vulcanizing the product. Compared with a traditional glove, the manufactured high-performance protective glove is more resistant to abrasion, tearing, electricity conduction and corrosion.

Owner:恒劢安全防护用品(南通)有限公司

Application of low-ammonia or ammonia-free latex in domestic rubber gloves

ActiveCN110054813AExtended storage timeGood performance such as stabilityGlovesProtective garmentPolymer scienceActive agent

The invention relates to the field of rubber products, in particular to application of low-ammonia or ammonia-free latex in domestic rubber gloves. The invention also provides a domestic rubber glove.The domestic rubber glove is prepared by, by weight, 100 parts of natural raw latex, 0.1-1.0 part of casein, 0-1.5 parts of potassium hydroxide, 1-7 parts of mixed dispersion, 0.1-0.4 part of surfactant, 1-10 parts of filler and 0-3 parts of auxiliaries. The domestic rubber glove has the advantages that the domestic rubber glove is quite good in mechanical performance such as tensile strength, elongation at break, tear strength and stress at definite elongation and quite good in aging resistance, and the mechanical performance and aging resistance of the domestic rubber glove are much higherthan common natural rubber products; the main raw material of the domestic rubber glove is a natural rubber component which has performance such as oil resistance and heat resistance, migration of small-molecule compounds in the domestic glove materials during use can be avoided by the synergistic effect of various components, problems such as aging and blooming are avoided, and service life prolonging is achieved.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

Glue-permeation-free plant protein sucrose-based environment-friendly adhesive for plywood as well as preparation method and application of glue-permeation-free plant protein sucrose-based environment-friendly adhesive

PendingCN113861936AModerate viscosityImprove glue penetration defectNon-macromolecular adhesive additivesProtein adhesivesCelluloseSucrose

The invention discloses a glue-permeation-free plant protein sucrose-based environment-friendly adhesive for plywood. The adhesive comprises the following components in parts by weight: 100 parts of sucrose; 20-40 parts of ammonium dihydrogen phosphate; 3-4 parts of sodium pyrosulfite; 2-4 parts of sodium carboxymethyl cellulose; 0.03-1 part of sodium dodecyl benzene sulfonate; 4-5 parts of boric acid; 3-5 parts of potassium hydroxide; 0.5-2 parts of citric acid; 10-25 parts of defatted soybean protein; 10-25 parts of dephenolized cottonseed protein and 27-55 parts of water. The invention further discloses a preparation method of the glue-permeation-free plant protein sucrose-based environment-friendly adhesive for the plywood and an application of the glue-permeation-free plant protein sucrose-based environment-friendly adhesive to preparation of the plywood. According to the glue-permeation-free plant protein sucrose-based environment-friendly adhesive for the plywood as well as the preparation method and the application of the glue-permeation-free plant protein sucrose-based environment-friendly adhesive, the glue permeation defect occurring when a traditional sucrose-based adhesive is used for preparing the plywood is overcome, and the problem of glue permeation on the surface of the plywood is obviously solved.

Owner:NANJING FORESTRY UNIV

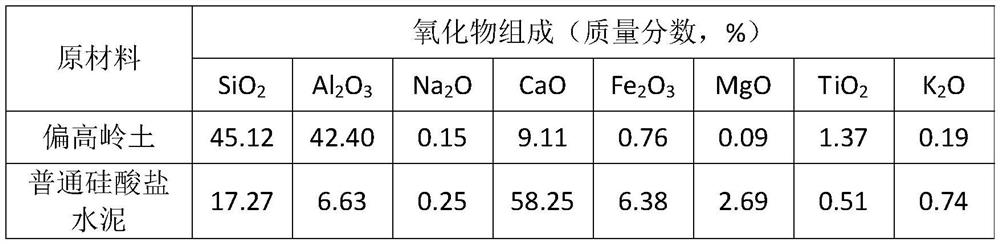

Geopolymer coating material for rust prevention and corrosion prevention of steel bars and manufacturing and using method thereof

InactiveCN111675511AIncreased durabilityDoes not affect collaborative workCement productionHydroxide potassiumKaolin clay

The invention relates to a geopolymer coating material for rust prevention and corrosion prevention of steel bars and a manufacturing and using method thereof. The coating material is composed of thefollowing materials: 90 parts of meta-kaolin, 10 parts of ordinary Portland cement, 10 parts of potassium hydroxide, 70 parts of potash water glass, 65-105 parts of water, 160-200 parts of natural fine sand, a high-performance polycarboxylate water reducer, which accounts for 1.2% of the total weight of meta-kaolin and ordinary Portland cement, and polypropylene fibers, which account for 0.25% ofthe total weight of meta-kaolin and ordinary Portland cement in unit volume. The beneficial effects of the invention are that: the material has mechanical properties for protecting the protective coating of steel bars, chloride ion permeability resistance, resistivity and bonding strength, is suitable for an anticorrosive protective layer of internal reinforcement of cast-in-place concrete or precast concrete members, can improve the durability of a concrete structure and effectively prolong the service life of the concrete structure, and does not influence the cooperative work of concrete andsteel bars.

Owner:ZHEJIANG COLLEGE OF CONSTR

Negative pole additive of low-gas-evolution alkaline zinc-manganese battery and preparation method thereof

InactiveCN102938464AImprove storage performanceReduce manufacturing costCell electrodesPhysical chemistryManganese

The invention provides a negative pole additive of a low-gas-evolution alkaline zinc-manganese battery and a preparation method thereof. The negative pole additive is prepared from the following raw materials in percentage by weight: 56-74% of zinc powder, 15-30% of deionized water, 5-20% of potassium hydroxide, 1-2% of zinc oxide, 0.1-1% of bonding agent and 0.01-0.1% of silicate. According to the negative pole additive of a low-gas-evolution alkaline zinc-manganese battery and the preparation method thereof, the silicate is used instead of indium oxide as a negative pole corrosion inhibitor in the active component composition of the negative pole; and the negative pole corrosion inhibitor can effectively reduce the gas evolution of the battery and obviously improve the storage performance of the battery, and can greatly lower the production cost of the battery, thereby being beneficial to improving the market competitiveness.

Owner:浙江特源电池有限公司 +1

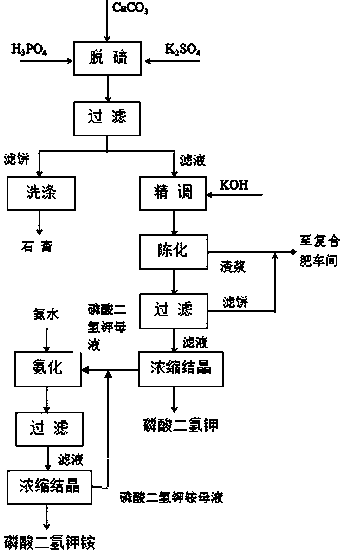

Method for preparing monopotassium phosphate with co-production of potassium-ammonium dihydrogen phosphate

InactiveCN108117054AStrong cost advantageReduce processingAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPotassiumPhosphoric acid

The invention discloses a method for preparing monopotassium phosphate with co-production of potassium-ammonium dihydrogen phosphate. The method comprises the following steps: (1) mixing and dissolving wet-method phosphoric acid and potassium sulfate according to a ratio, adding calcium carbonate to react completely, and filtering; (2) adjusting the pH value of filtrate with a potassium hydroxidesolution, sufficiently aging, filtering, concentrating and crystallizing filtrate so as to obtain a monopotassium phosphate product; and (3) neutralizing crystallized mother liquor with ammonia water,enabling the components to react sufficiently, filtering, and concentrating and crystallizing filtrate, thereby obtaining potassium-ammonium dihydrogen phosphate. As the wet-method phosphoric acid and the potassium sulfate are adopted as raw materials directly, the production cost is low; and as the ammonia water is introduced to convert the crystallized mother liquor into potassium-ammonium dihydrogen phosphate, tedious mother liquor decontamination procedures are avoided, and very good economic benefits can be achieved.

Owner:HUBEI SANNING CHEM

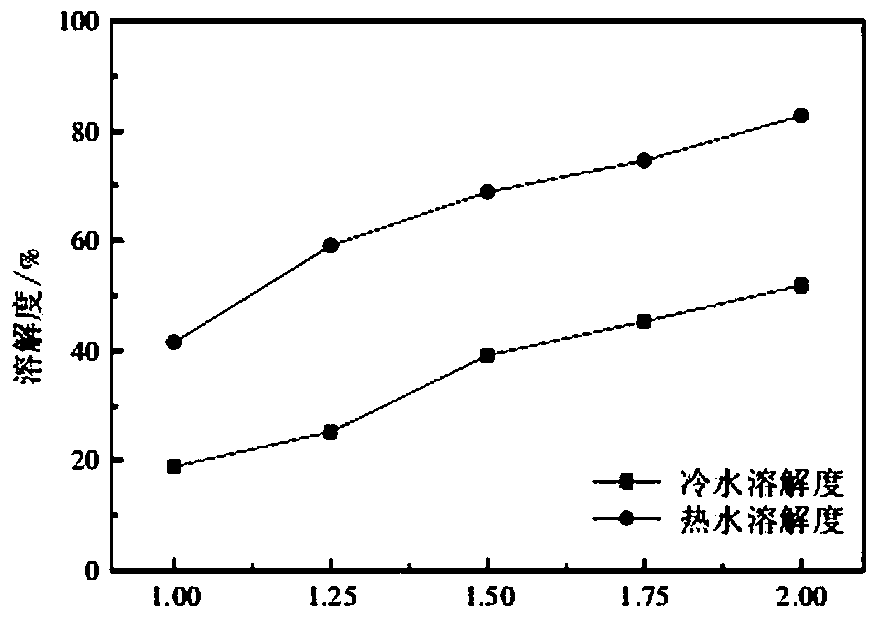

Preparation and testing technologies of boron-containing high molecular slow-release fertilizer

InactiveCN109810234AReduce fixed amountEnsure nutritional needsComponent separationUrea compound fertilisersWater bathsHydrogen

The invention provides preparation and testing technologies of boron-containing high molecular slow-release fertilizer and belongs to the technical field of fertilizer preparation. The preparation technology comprises the following steps: (1) adding 2.06g of boric aid and 1.87g of potassium hydroxide into a round bottomed flask; reacting at 90 DEG C for 3h to obtain a product A; cooling a system for later use; (2) adding a certain ratio of urea and formaldehyde into a three-necked flask and adjusting the pH (Potential of Hydrogen) of the system to be 8 through a 5 percent KOH water solution; stirring at the temperature T1 and reacting for 80min (through carrying out addition reaction); adjusting the temperature of a water-bath pot to be 60 DEG C and continually reacting for 40min (throughcarrying out condensation polymerization reaction); adding a product into the system of step (1) and adjusting the temperature to be T3 (gelation temperature); reacting under stirring until the systembecomes sticky, and stopping reaction; after granulating, drying at the temperature T4. The slow-release fertilizer prepared by the preparation method is more reliable.

Owner:曾勇

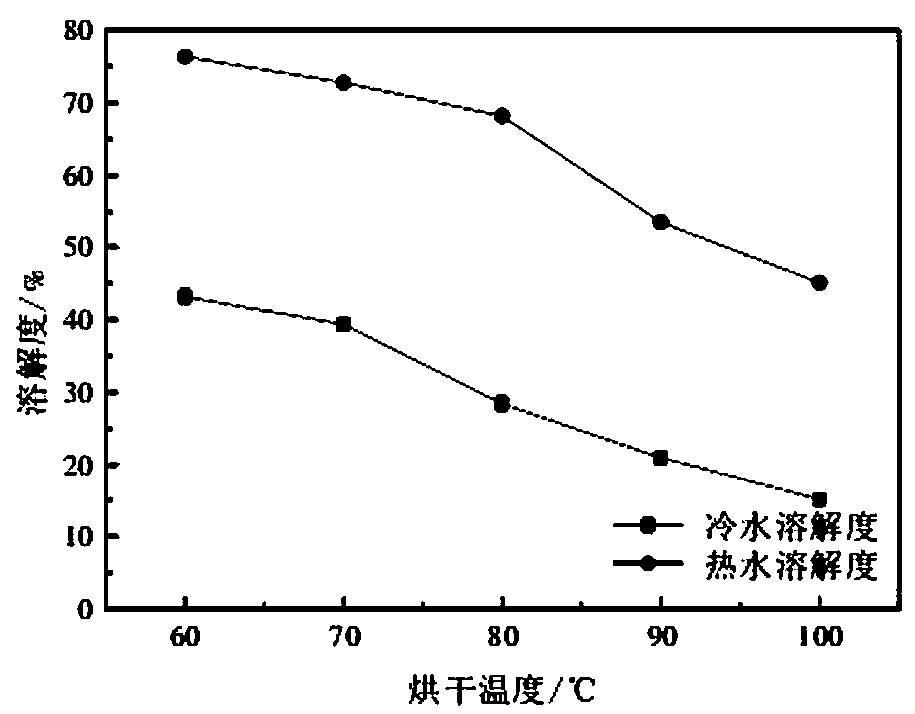

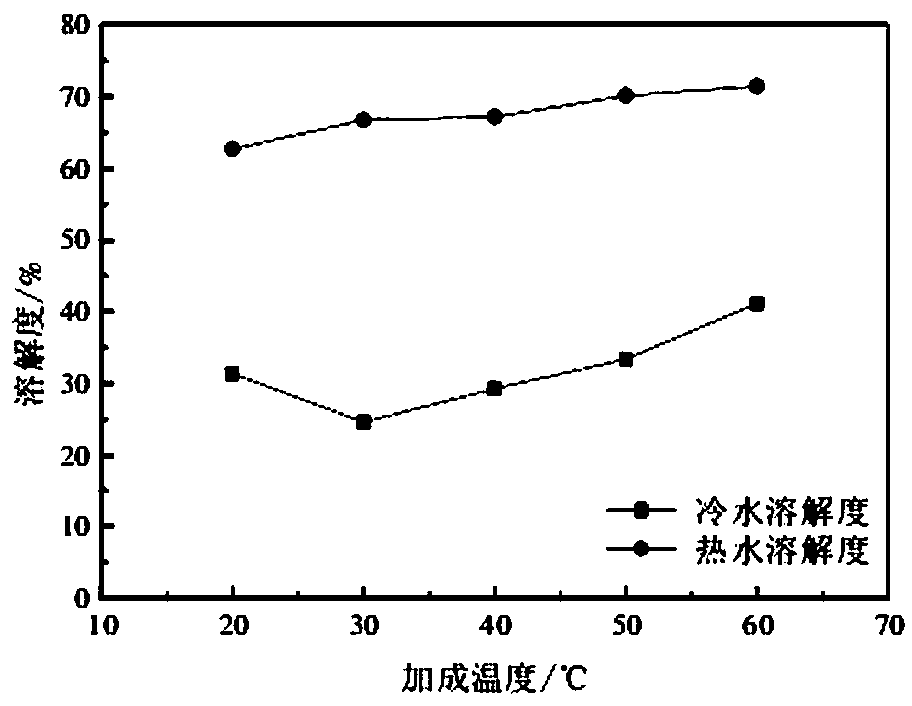

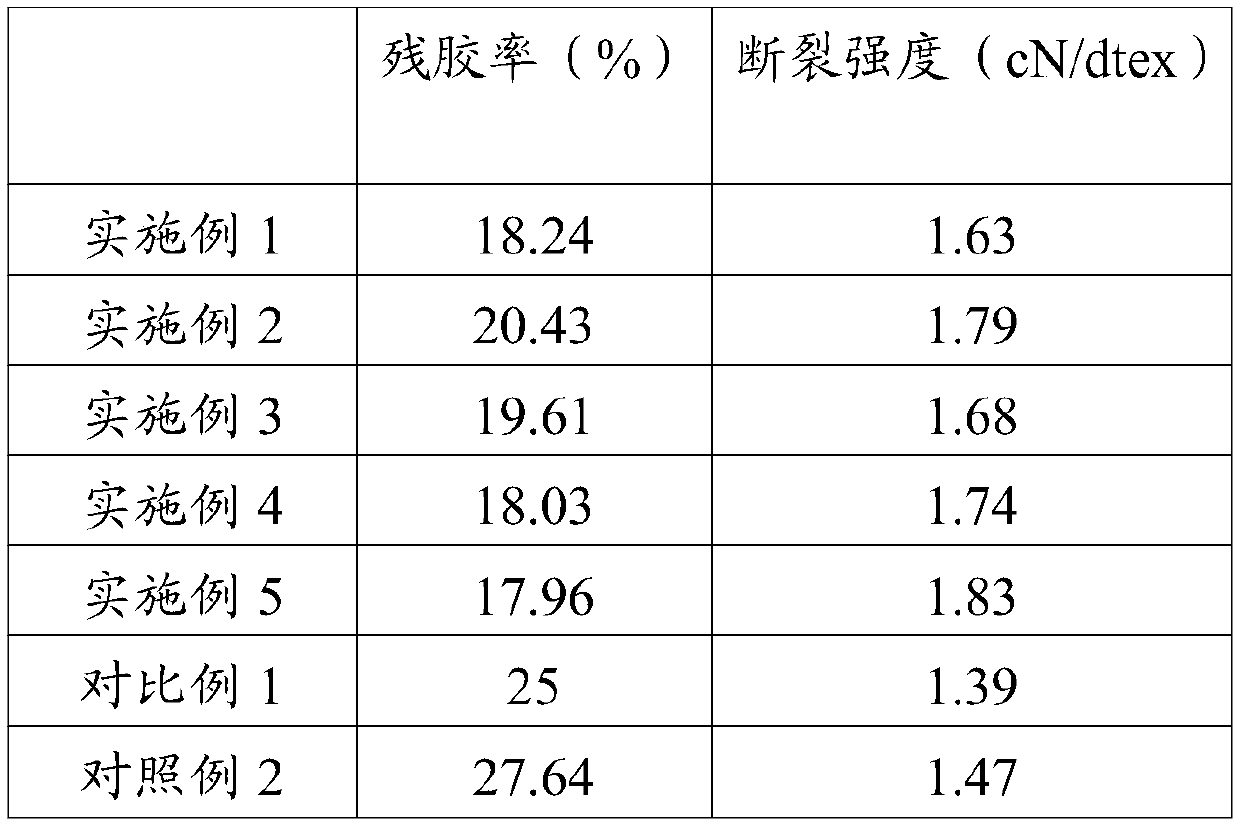

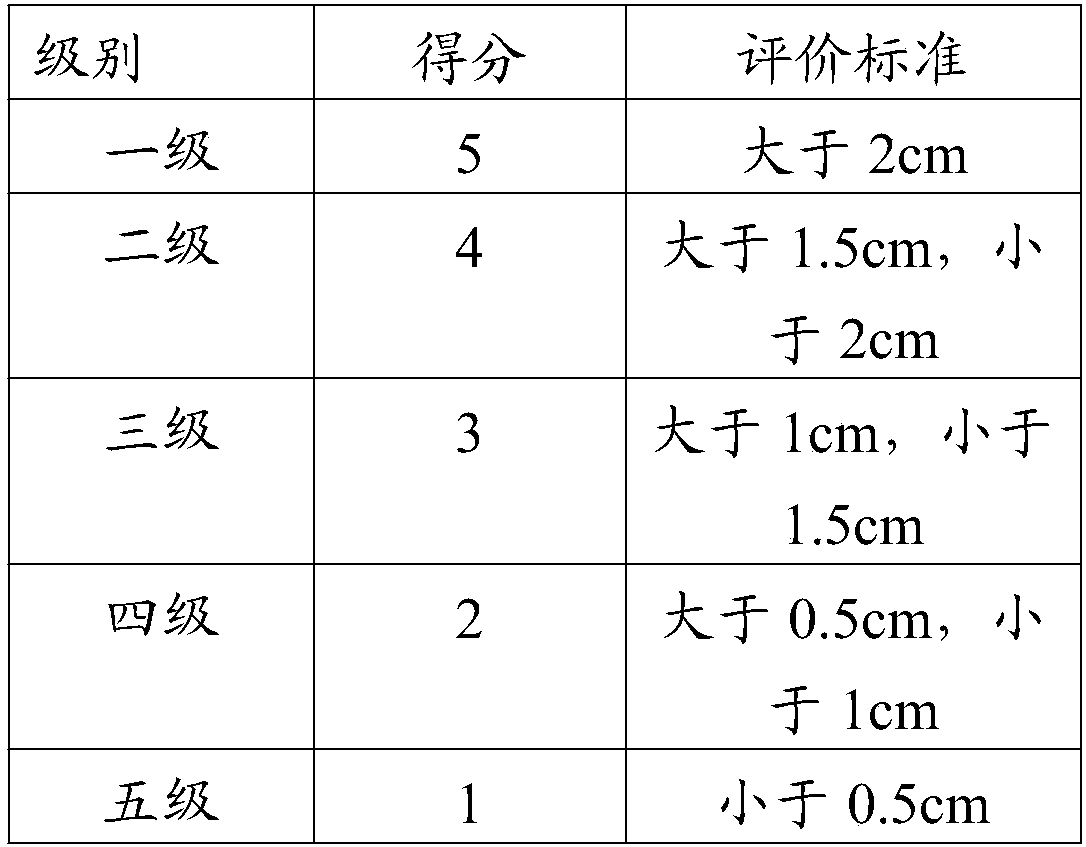

Method for bacterially degumming corn bran fibers

ActiveCN107740194AAvoid damageVegetable materialBacteriological rettingHydroxide potassiumPulp and paper industry

The invention provides a method for bacterially degumming corn bran fibers, belonging to the technical field of renewable resource utilization. The method comprises the following steps: (1) selectingcorn brans without mildew, cleaning dust and foreign substances on the corn brans; (2) performing soak pretreatment on corn bran fibers; (3) fermenting with Aspergillus niger HYA4 solids to prepare acorn bran fiber bacterial degumming solution; (4) bacterially degumming the corn bran fibers; (5) soaking with a potassium hydroxide solution; and (6) washing and drying to obtain the corn bran fibers. The degumming method has small damage on corn bran fibers, and the prepared corn bran fibers have relatively low residual gum content, relatively high strength and flexible fibers; and the effects of no pollution to the environment, and environmental protection can be realized.

Owner:QIQIHAR UNIVERSITY

Toner and toner manufacturing method

ActiveUS20170269495A1High tinting strengthGood transferabilityDevelopersHydroxide potassiumPigment dispersion

A toner containing a toner particle including a binder resin, a resin A having a pKa of 6.0-9.0, and a pigment having a pKb of 4.0-7.0, wherein the pKa is an acid dissociation constant measured by preparing a resin solution in which 1.0 part by mass of the resin A, 70.0 parts by mass of toluene and 30.0 parts by mass of ethanol are mixed, and carrying out neutralization titration with a potassium hydroxide ethanol solution of 0.1 mol / L, and the pKb is a basic dissociation constant measured by preparing a pigment dispersion in which 10.0 parts by mass of the pigment, 140.0 parts by mass of toluene and 60.0 parts by mass of ethanol are mixed, and carrying out neutralization titration with a hydrochloric acid ethanol solution of 0.1 mol / L.

Owner:CANON KK

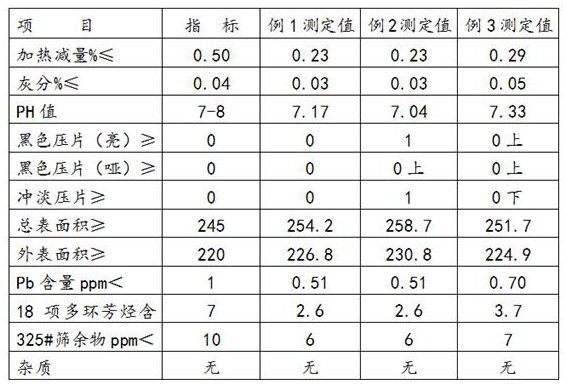

Production method of pigment carbon black applied to leather color paste

ActiveCN113527915AHigh purityHigh light transmittancePigmenting treatmentAir preheaterCombustion chamber

The invention relates to the technical field of pigment carbon black, and discloses a production method of pigment carbon black applied to leather color paste. Natural gas serves as fuel, anthracene oil serves as a raw material, potassium hydroxide serves as an additive, the natural gas and hot air heated through a high-temperature air preheater are completely combusted in a combustion chamber to generate high-temperature combustion residual gas, and the additive and raw oil are fully mixed in a mixer and then sprayed into the high-temperature combustion residual gas through a raw oil gun. Under the action of thermal kinetic energy provided by high-temperature combustion residual gas, raw oil is cracked to generate carbon black, demineralized water is sprayed into high-temperature flue gas in a horizontal quenching section (vaporization) for direct cooling to terminate a carbon black generation reaction (main reaction), medium-pressure steam is sprayed in a vertical quenching section to perform an activation reaction (side reaction) on carbon black particles, and the carbon black obtained by the method disclosed by the invention has the characteristics of high purity, good blackness, strong covering power, easiness in dispersion compared with products of the same series, and the like.

Owner:WUHAI BLACK CAT CARBON BLACK

Preparation method of rapid in-situ growth ultra-thin wear-resistant coating on the surface of aluminum alloy special-shaped parts

ActiveCN103526255BIncrease frictionImprove corrosion resistanceAnodisationPlasma electrolytic oxidationMicro arc oxidation

The invention discloses a preparation method for quick in-situ growth of an ultrathin wear-resisting coating on the surface of an aluminum alloy irregular part, relates to a preparation method of an aluminum alloy surface coating, and aims to solve the technical problem that the film obtained when parts of an LY12 aluminum alloy irregular part are treated by a micro-arc oxidation technology is easy to wear. The method comprises the following steps: I, surface pretreatment of the LY12 aluminum alloy irregular part; II, preparation of an electrolyte, wherein the electrolyte is prepared from a main film-forming agent, an auxiliary film-forming agent, potassium hydroxide, glycerol, polyethylene glycol 1000 and distilled water; III, micro-arc oxidation, wherein the ultrathin wear-resisting coating is quickly obtained on the surface of the LY12 aluminum alloy irregular part. The thickness of the film of the ceramic film is 5-15 mu m, the average friction coefficient of the film is 0.12-0.20, and the bonding strength of the film is 14-30MPa. The preparation method can be applied to structural connectors of spacecrafts.

Owner:HARBIN INST OF TECH

Apocynum venetum peel degumming method

PendingCN112981551AEasy accessLoose textureBacteriological rettingFibre treatment to obtain bast fibreFiberApocynum venetum

The invention relates to an apocynum venetum peel degumming method. The method is mainly realized through the following technical processes of performing alkali soaking: soaking apocynum venetum peel in a potassium hydroxide soaking solution for 40-90 minutes; performing alkali boiling: performing boiling at the temperature of 103-108 DEG C under the pressure of 0.15-0.3 MPa for 40-90 minutes; and performing fermentation: inoculating a degumming strain and performing fermentation for 2-4 days. Apocynum venetum is beaten by a beating machine or rolled by a softening machine, washed with water and dehydrated to obtain fibers. Compared with the prior art, the method has the advantages that the alkali consumption is low, the energy consumption is low, high-concentration organic polluted wastewater is changed into special apocynum venetum organic biological trace element potash fertilizer which can be used for irrigating the apocynum venetum field, no wastewater is generated basically, organic matter, beneficial soil microbial florae, trace elements, potash fertilizer and the like are added for the apocynum venetum field, and the degumming wastewater difficult to treat is changed into sustainably used organic biological fertilizer which can be cyclically utilized for a long term.

Owner:XINJIANG ALTAY PREFECTURE GAUBAO KENDER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com