Preparation method of rapid in-situ growth ultra-thin wear-resistant coating on the surface of aluminum alloy special-shaped parts

An in-situ growth and wear-resistant coating technology, which is applied in anodic oxidation and other directions, can solve the problems of easy wear of the film layer, and achieve the effects of environmental protection, improved corrosion resistance, and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

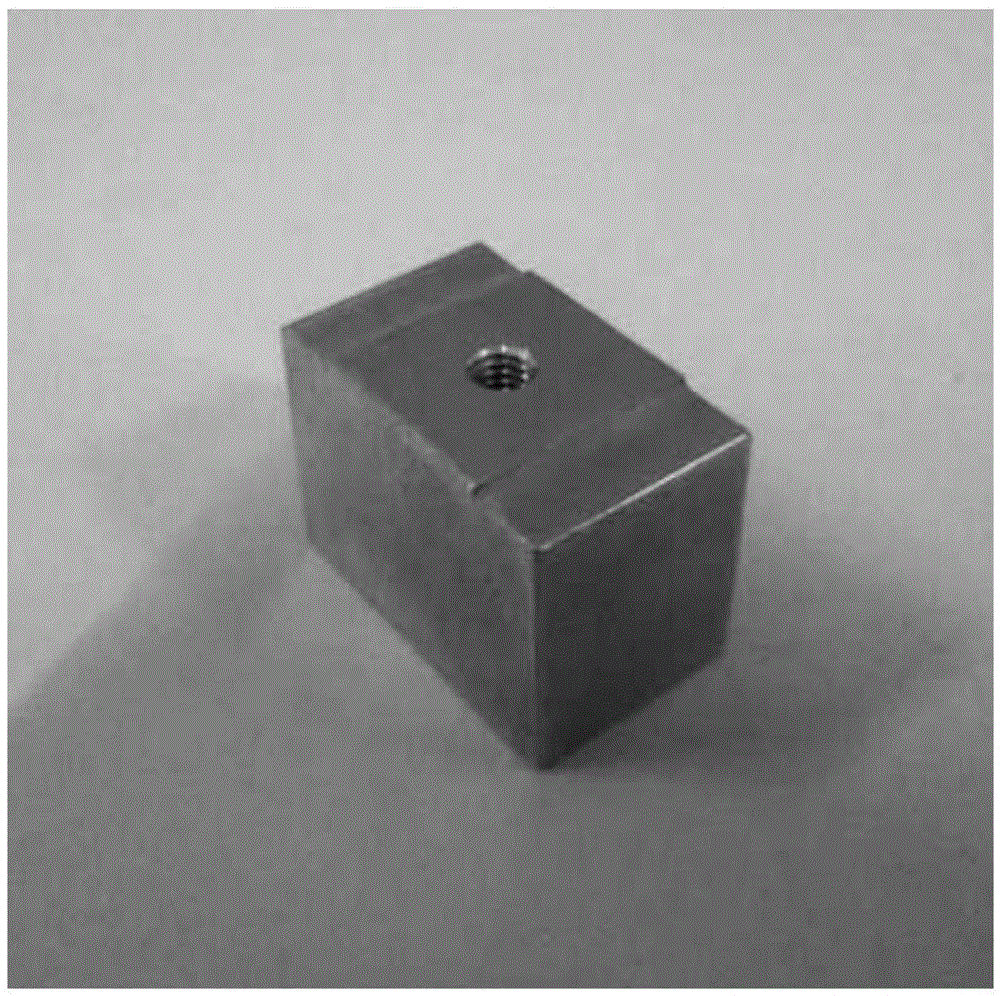

[0024] Specific implementation mode 1: The preparation method of rapid in-situ growth of ultra-thin wear-resistant coating on the surface of aluminum alloy special-shaped parts according to this implementation mode is carried out according to the following steps:

[0025] 1. Surface pretreatment of LY12 aluminum alloy special-shaped parts: immerse LY12 aluminum alloy special-shaped parts in an aqueous solution of sodium hydroxide with a concentration of 35g / L-65g / L, keep it at a temperature of 50°C-60°C for 30s-60s, and take it out Rinse with clean water first, then rinse with distilled water, and dry;

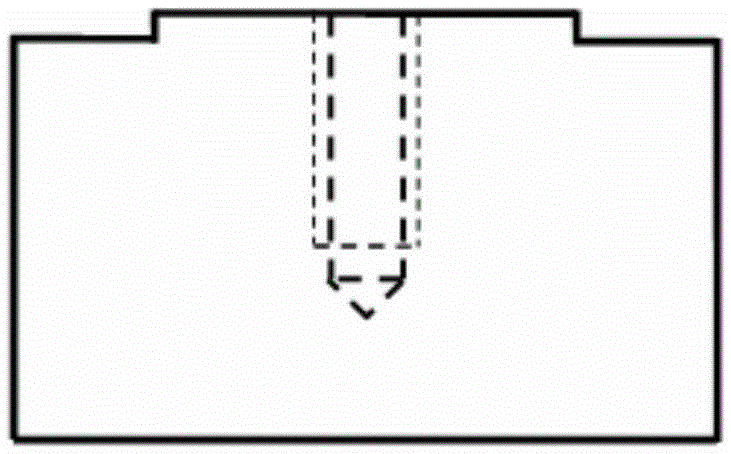

[0026]2. Preparation of electrolyte: according to the main film-forming agent concentration of 10g / L-50g / L, the auxiliary film-forming agent concentration of 1g / L-10g / L, and the pH regulator concentration of 1g / L-5g / L, the reaction can be adjusted stably The agent concentration is 50ml / L~300ml / L, and the surfactant concentration is 0.1g / L~5g / L. Weigh the main film-forming agen...

specific Embodiment approach 2

[0029] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, LY12 aluminum alloy special-shaped parts are immersed in an aqueous sodium hydroxide solution with a concentration of 40g / L-60g / L, at a temperature of 55°C-58°C Hold down for 40s ~ 50s. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Embodiment 3: This embodiment differs from Embodiment 1 in that in Step 1, the special-shaped LY12 aluminum alloy is immersed in an aqueous sodium hydroxide solution with a concentration of 50 g / L, and kept at a temperature of 56° C. for 45 seconds. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com