Glue-permeation-free plant protein sucrose-based environment-friendly adhesive for plywood as well as preparation method and application of glue-permeation-free plant protein sucrose-based environment-friendly adhesive

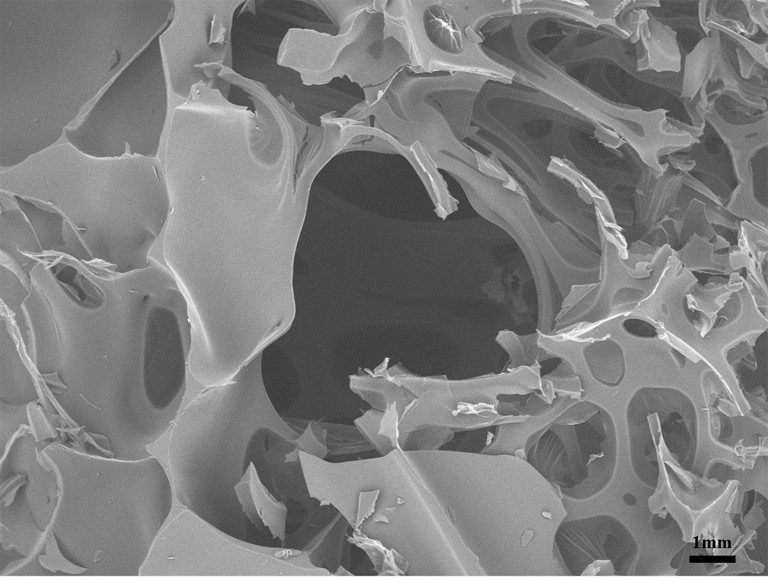

A plant protein and plywood technology, applied in the preparation of animal glue or gelatin, protein adhesives, adhesives, etc., can solve the problem of no dense glue layer, large holes on the surface of SADP adhesive, and cross-linked structure of adhesive Insufficient tightness and other problems, to achieve moderate viscosity, improve glue penetration defects, improve thermal curing rate and bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A vegetable protein sucrose-based environmental-friendly adhesive for glue-free plywood, comprising the following components in parts by weight: 100 parts of sucrose; 20 parts of ammonium dihydrogen phosphate; 3 parts of sodium metabisulfite; 2 parts of sodium carboxymethylcellulose; 0.03 parts of sodium dodecylbenzenesulfonate; 4 parts of boric acid; 3 parts of potassium hydroxide; 0.5 parts of citric acid; 10 parts of defatted soybean protein; 10 parts of dephenolized cottonseed protein and 27 parts of water.

[0035] The solid content of the adhesive is 80.0%, and the viscosity is 670 Pa·s.

[0036] Described water is distilled water.

[0037] A preparation method of a vegetable protein sucrose-based environmental-friendly adhesive for glue-free plywood, comprising the following steps:

[0038] Step 1, mixing sucrose, citric acid and water, and stirring at a low speed for 0.3 hours at room temperature;

[0039] Step 2, adding ammonium dihydrogen phosphate to the re...

Embodiment 2

[0051] The difference between this embodiment and embodiment 1 is only:

[0052] A non-penetrating vegetable protein sucrose-based environmental-friendly adhesive for plywood, comprising the following components in parts by weight: 100 parts of sucrose; 40 parts of ammonium dihydrogen phosphate; 4 parts of sodium metabisulfite; 4 parts of sodium carboxymethylcellulose; 1 part of sodium dodecylbenzenesulfonate; 5 parts of boric acid; 5 parts of potassium hydroxide; 2 parts of citric acid; 25 parts of defatted soybean protein; 25 parts of dephenolized cottonseed protein and 55 parts of water.

[0053] The solid content of the adhesive is 87.1%, and the viscosity range is 1280mPa·s.

[0054] A preparation method of a vegetable protein sucrose-based environmental-friendly adhesive for glue-free plywood, comprising the following steps:

[0055] Step 1, mixing sucrose, citric acid and water, and stirring at a low speed for 0.5 hours at room temperature;

[0056] Step 2, adding amm...

Embodiment 3

[0068] A vegetable protein sucrose-based environmental-friendly adhesive for glue-free plywood, comprising the following components by weight: 100 parts of sucrose; 30 parts of ammonium dihydrogen phosphate; 3 parts of sodium pyrosulfite; 4 parts of sodium carboxymethylcellulose; 0.05 parts of sodium dodecylbenzenesulfonate; 4.5 parts of boric acid; 4 parts of potassium hydroxide; 1 part of citric acid; 20 parts of defatted soybean protein; 15 parts of dephenolized cottonseed protein and 40 parts of water.

[0069] The solid content of the adhesive is 83.4%, and the viscosity range is 915mPa·s.

[0070] A preparation method of a vegetable protein sucrose-based environmental-friendly adhesive for glue-free plywood, comprising the following steps:

[0071] Step 1, mixing sucrose, citric acid and water, stirring at 80°C for 1 hour at low speed;

[0072] Step 2, adding ammonium dihydrogen phosphate to the reaction system, and stirring at a low speed of 90°C for 1 hour;

[0073] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com