Geopolymer coating material for rust prevention and corrosion prevention of steel bars and manufacturing and using method thereof

A technology of anti-rust, anti-corrosion, and coating materials, applied in cement production, etc., can solve problems such as poor weather resistance, gradual aging, high temperature and humidity sensitivity of curing, and achieve the effect of improving durability and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0014] A geopolymer coating material for antirust and anticorrosion of steel bars, which is composed of the following materials: 90 parts of metakaolin, 10 parts of ordinary Portland cement, 10 parts of potassium hydroxide, 70 parts of potassium silicate, and 65 to 105 parts of water Parts, 160-200 parts of natural fine sand, high-performance polycarboxylate water reducer with an amount of 1.2% of the total weight of metakaolin and ordinary Portland cement, and an amount of 1.2% of the total weight of metakaolin and ordinary Portland cement per unit volume 0.25% by weight polypropylene fibers.

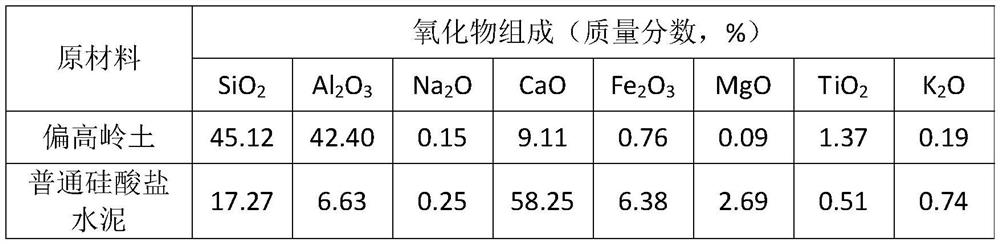

[0015] Among them, metakaolin and ordinary Portland cement (P·O 42.5) that meet the national standard are used as mineral precursors, and their chemical compositions are shown in Table 1. Alkaline activator adopts commercially available high-purity potassium hydroxide solid (the mass fraction of KOH is 98.6%) and potassium water glass solution (SiO 2 The mass fraction is 25.8%, K 2 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com