Application of low-ammonia or ammonia-free latex in domestic rubber gloves

A rubber gloves and household technology, applied in the field of rubber products, can solve problems such as restricting the sustainable development of the latex industry, and achieve the effects of improving elasticity and other properties, avoiding aging, and improving tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] In some embodiments, the nano calcium carbonate is modified nano calcium carbonate; preferably, the raw materials for preparing the modified nano calcium carbonate include nano calcium carbonate, vinyl silsesquioxane, and functionalized hyperbranched polyethylene Further preferably, the preparation method of the modified nano-calcium carbonate includes the following steps:

[0054] Add 10 parts by weight of nano calcium carbonate and 1-2 parts by weight of functionalized hyperbranched polyethylene into a high-speed mixer, stir and mix at 70°C for 45 minutes, then heat up to 210°C, and add (0.5~1.5 weight Parts) polyphosphoric acid solution of vinyl silsesquioxane (CAS: 69655-76-1, purchased from Suzhou Silicon New Material Co., Ltd.) and 0.004~0.008 parts by weight of initiator are added to the above mixed system, and the reaction is kept warm After 3 to 5 hours, the system is cooled to room temperature, poured into acetone solution, washed, filtered, and dried.

[0055] Pr...

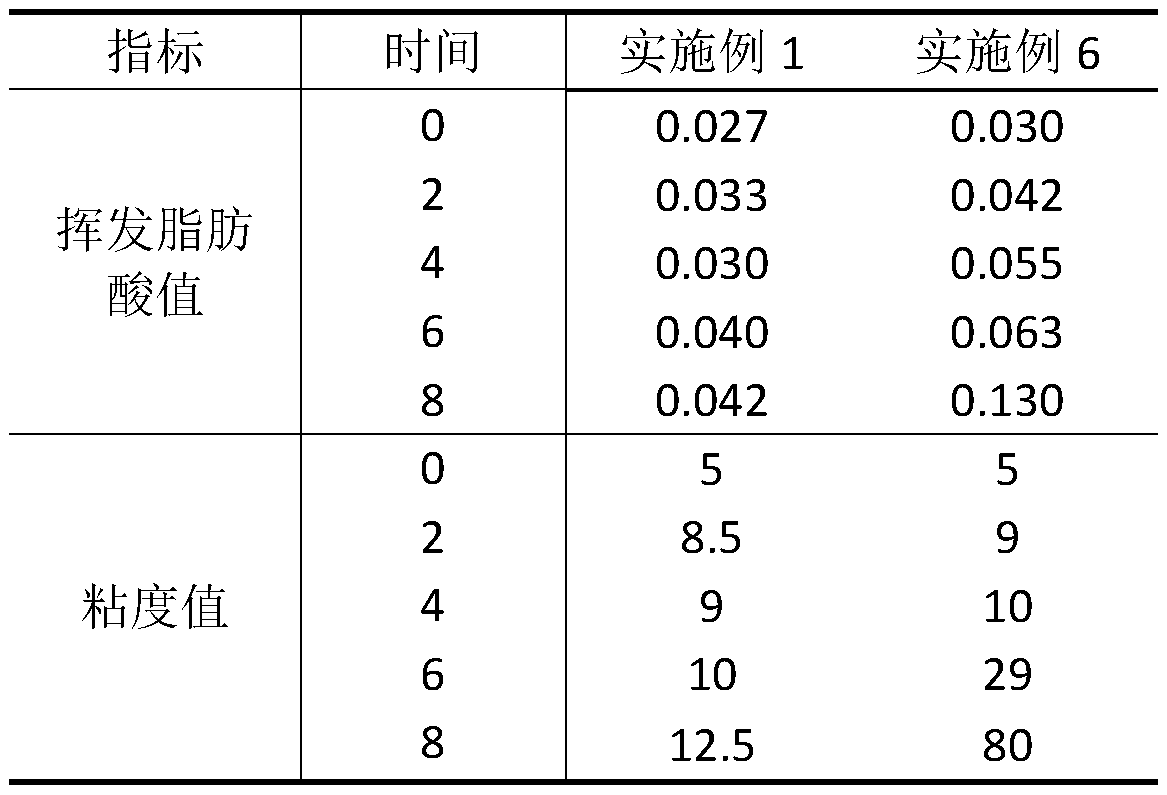

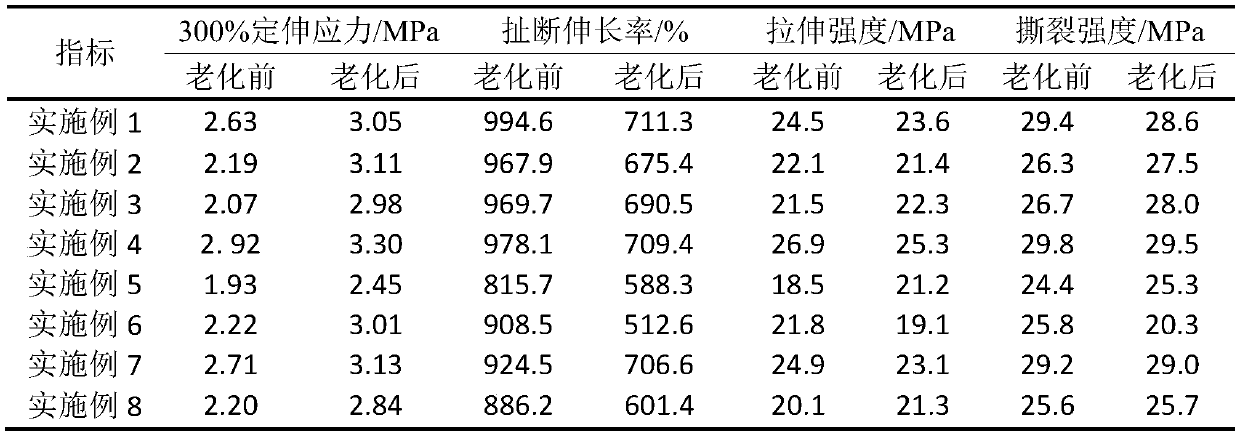

Embodiment 1

[0078] Example 1 A household rubber glove is provided. The raw materials for preparation include natural rubber latex 100, casein 0.25, mixed dispersion 3, potassium hydroxide 0.8, surfactant 0.12, filler 7, and auxiliary agent 0.3 in parts by weight.

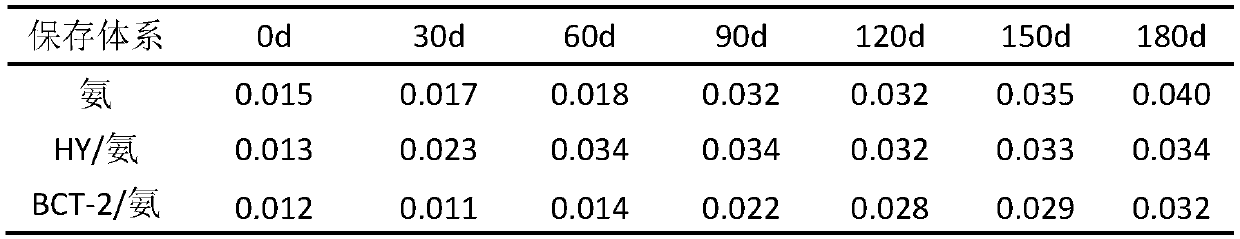

[0079] The filler is conventional calcium carbonate; the additive is a red pigment; the surfactant is a RO(CH 2 CH 2 O) n A polyether surfactant with H structure, where R is a C16 aliphatic carbon chain and n is 18; the natural rubber latex is a natural fresh rubber latex (harvested from rubber trees) after being preserved without ammonia, and then concentrated by centrifugation, The obtained concentrated natural rubber latex is obtained by HY method without ammonia storage. The specific process includes:

[0080] The bactericide and alkaline stabilizer in the preservation system are respectively formulated into 10wt% aqueous solution. The natural fresh latex is preliminarily added to the rubber bucket with a bactericide of 0.12wt% ...

Embodiment 2

[0086] Example 2 A household rubber glove is provided. The raw materials for preparation include natural rubber latex 100, casein 0.1, mixed dispersion 1, potassium hydroxide 0.1, surfactant 0.1, filler 2, and auxiliary agent 0.3 in parts by weight.

[0087] The filler is conventional calcium carbonate; the additive is a red pigment; the surfactant is a RO(CH 2 CH 2 O) n A polyether surfactant with H structure, where R is a C14 aliphatic carbon chain and n is 15; the natural rubber latex is a natural fresh rubber latex (harvested from rubber trees) after being preserved without ammonia, and then concentrated by centrifugation, The obtained concentrated natural rubber latex is obtained by BCT-2 method without ammonia storage. The specific process includes:

[0088] The bactericide and alkaline stabilizer in the preservation system are respectively formulated into 10wt% aqueous solution. The natural fresh latex is preliminarily added to the rubber bucket with a bactericide of 0.12wt%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com