Preparation method and application of large-scale porous aramid fiber microfiber diaphragm

A technology for pre-oxidizing aramid and aramid chopped fibers, which is applied in fiber types, fiber treatment, electrochemical generators, etc. It can solve the problems of low heat resistance temperature, insufficient diaphragm strength, and poor wettability, and prevent short circuits. phenomenon, improvement of service life and safety, and growth-inhibiting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

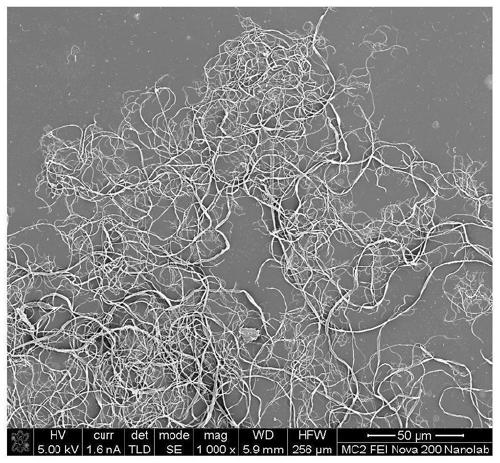

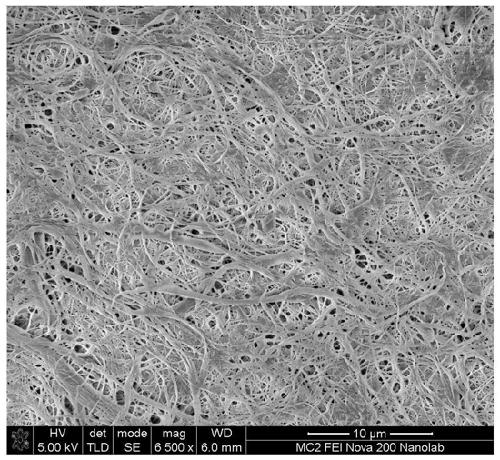

[0023] Specific implementation mode 1: This implementation mode records a method for preparing a large-scale porous aramid microfiber diaphragm, and the specific steps of the method are:

[0024] Step 1: Pre-oxidation process of aramid microfiber:

[0025] Add aramid chopped fibers into a DMSO reaction vessel containing potassium hydroxide and soak for 2 days; due to the strong alkalinity of potassium hydroxide, hydrogen ions in the microfibers inside the aramid chopped fibers will be captured , and weaken the interaction force between the fibers and microfibrils, so that it is easy to peel off the microfibrils on a large scale.

[0026] Step 2: Stripping of aramid microfibers:

[0027] Wash the mixed solution obtained in step 1 with pure dimethyl sulfoxide, remove excess potassium hydroxide, and disperse the pre-oxidized aramid chopped fibers after removing excess potassium hydroxide in dimethyl sulfoxide, Control the concentration of aramid chopped fibers in dimethyl sulfo...

specific Embodiment approach 2

[0030] Embodiment 2: The method for preparing a large-scale porous aramid microfiber diaphragm described in Embodiment 1, in step 1, the mass ratio of the aramid chopped fiber to potassium hydroxide is 1:1-1.5 ; The mass ratio of the aramid chopped fiber to dimethyl sulfoxide is 1:10-20.

specific Embodiment approach 3

[0031] Specific embodiment three: a method for preparing a large-scale porous aramid microfiber diaphragm described in specific embodiment one, in step two, the mass ratio of the pre-oxidized aramid chopped fiber to dimethyl sulfoxide is 1 ~3:100.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com