Method for preparing graphene

A graphene and graphene technology, applied in the field of graphene preparation, can solve the problems of small specific surface area and limited graphene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

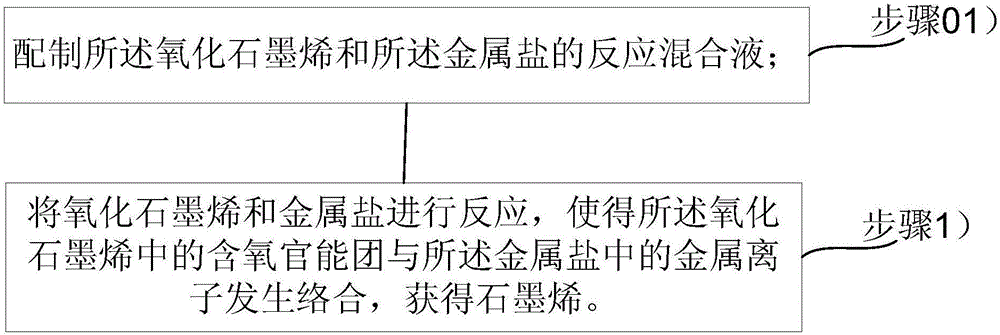

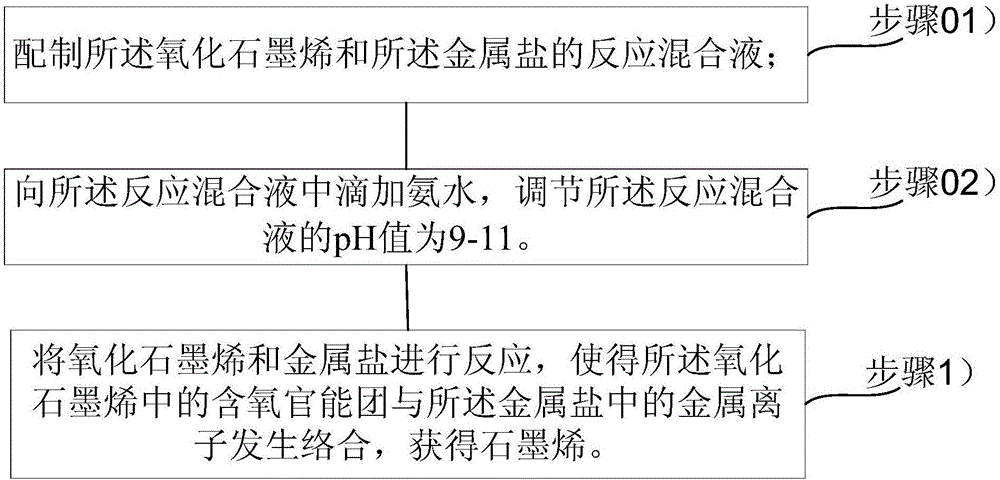

[0034] The embodiment of the present invention provides a kind of preparation method of graphene, see figure 1 ,include:

[0035] Step 1) reacting graphene oxide and metal salt, so that oxygen-containing functional groups in the graphene oxide are complexed with metal ions in the metal salt to obtain graphene.

[0036] Among them, graphene oxide is the oxide of graphene, commonly in the form of powder, flake and solution; graphene oxide is generally obtained by oxidation of graphite with strong acid, and the most common method is: using potassium permanganate in concentrated sulfuric acid After the oxidation reaction with graphite powder, brown graphite flakes with derivatized carboxylic acid groups on the edge and mainly phenolic hydroxyl groups and epoxy groups on the plane are obtained. The graphite flakes are peeled off by ultrasonic or high-shear vigorous stirring. Graphene.

[0037] Wherein, the oxygen-containing functional group may be carboxyl group, hydroxyl group a...

Embodiment 1

[0080] The embodiment 1 uses the method provided by the embodiment of the present invention to prepare graphene.

[0081] Specifically include:

[0082] S1) Prepare graphene oxide aqueous solution with a concentration of 0.05g / L and a metal salt solution with a concentration of 1g / L respectively, wherein the metal ion in the metal salt is Cu 2+ 、Ni 2+ , Zn 2+ and Al 3+ ;

[0083] Specifically, add a certain amount of graphene oxide into water, and disperse it by ultrasonic for 180 minutes to obtain a graphene oxide aqueous solution; disperse a certain amount of metal salt in ethanol, and stir for 30 minutes to obtain a metal salt solution;

[0084] S2) preparing the reaction mixture of the graphene oxide and the metal salt;

[0085] Specifically, the metal salt solution is added to the graphene oxide aqueous solution at a rate of 10 L / min, and stirred while adding to make it evenly mixed to obtain a reaction mixture, wherein the graphene oxide and the metal salt The mass...

Embodiment 2

[0089] The embodiment 2 adopts the method provided by the embodiment of the present invention to prepare graphene.

[0090] Specifically include:

[0091] S1) Prepare graphene oxide aqueous solution with a concentration of 1.0g / L and a metal salt solution with a concentration of 10g / L respectively, wherein the metal ion in the metal salt is Cu 2+ and Ni 2+ ;

[0092] Specifically, adding a certain amount of graphene oxide into water, and ultrasonically dispersing for 10 minutes to obtain a graphene oxide aqueous solution; dispersing a certain amount of metal salt in ethanol, and stirring for 10 minutes to obtain a metal salt solution;

[0093] S2) preparing the reaction mixture of the graphene oxide and the metal salt;

[0094] Specifically, the metal salt solution is added to the graphene oxide aqueous solution at a speed of 30 L / min, and stirred while adding to make it evenly mixed to obtain a reaction mixture, wherein the graphene oxide and the metal salt The mass ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com