Pectin graft copolymer as well as preparation method and application thereof

A technology of graft copolymer and copolymerization reaction, applied in the field of pectin graft copolymer and its preparation, to achieve the effects of weakening hydrogen bond force, increasing antioxidant activity and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

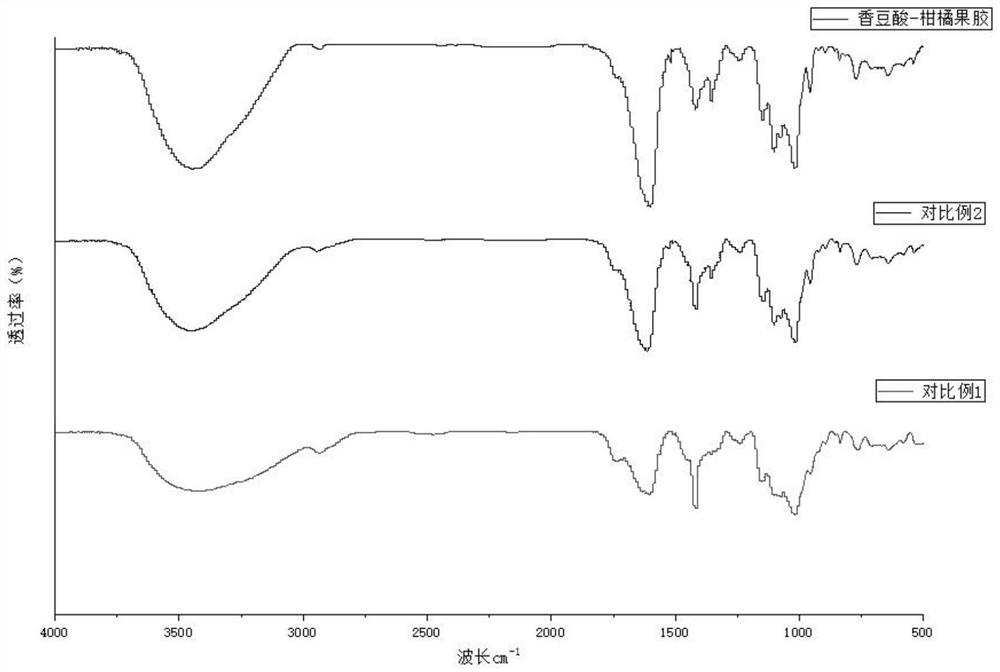

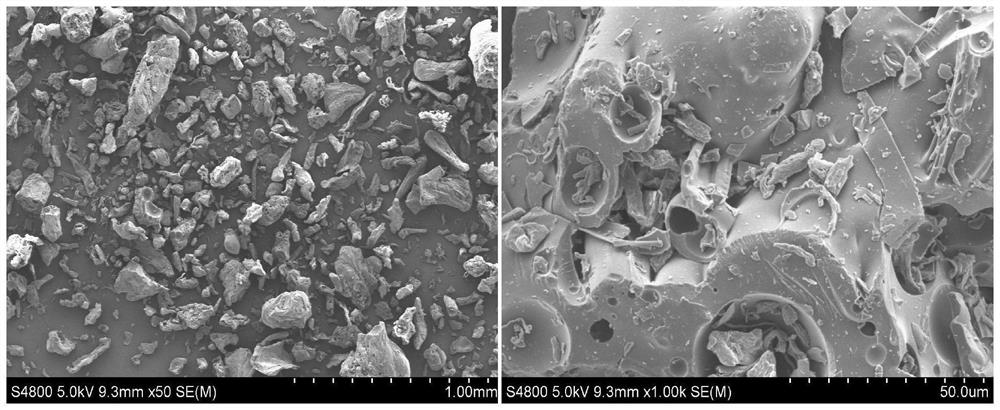

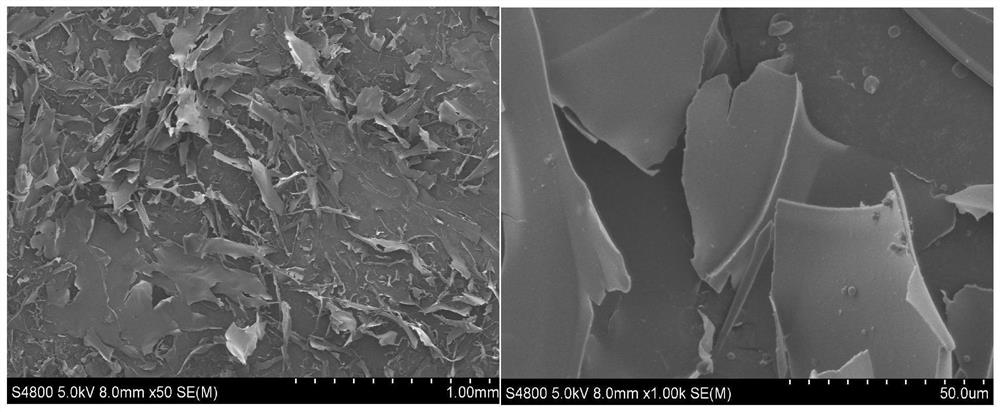

Image

Examples

preparation example Construction

[0030] The invention provides a preparation method of pectin graft copolymer, comprising the following steps:

[0031] Mix pectin, coumaric acid, ascorbic acid and solvent to obtain a mixed solution;

[0032] carrying out ultrasonic-microwave degradation treatment on the mixed solution to obtain a degradation treatment solution;

[0033] The degradation treatment solution and the hydrogen peroxide solution are mixed to carry out a graft copolymerization reaction to obtain a pectin graft copolymer.

[0034] In the present invention, pectin, coumaric acid, ascorbic acid and solvent are mixed to obtain a mixed solution. In the present invention, the pectin is preferably citrus pectin, and the molecular weight of the citrus pectin is preferably 100-200KDa; the present invention has no special requirements on the source of the citrus pectin, and commercially available citrus pectin or You can extract by yourself. In the present invention, the solvent is preferably an acetic acid...

Embodiment 1

[0047] Accurately weigh 0.1 g of citrus pectin and dissolve it in 50 mL of 1% acetic acid solution, then add ascorbic acid and 1 g of coumaric acid, control the concentration of ascorbic acid in the mixed solution to be 0.075 mol / L, and mix the mixture with sodium hydroxide and hydrochloric acid. The pH value of the solution was adjusted to 6.0, and ultrasonic-microwave degradation treatment was carried out for 1 min under the condition of ultrasonic power of 50W and microwave power of 480W to obtain a degradation treatment solution. Nitrogen gas was slowly introduced into the reaction flask containing the degradation treatment solution, and hydrogen peroxide solution was added to start the reaction after 60 min. The concentration of hydrogen peroxide in the reaction system was controlled to be 0.075 mol / L, and the reaction was continued for 2 h under nitrogen conditions. The reacted mixture was poured into a dialysis bag with a molecular weight of 14,000 Da, dialyzed with deio...

Embodiment 2

[0049] Accurately weigh 0.1 g of citrus pectin and dissolve it in 50 mL of 1% acetic acid solution, then add ascorbic acid and 1 g of coumaric acid, control the concentration of ascorbic acid in the mixed solution to be 0.15 mol / L, and mix the mixture with sodium hydroxide and hydrochloric acid. The pH value of the solution was adjusted to 6.0, and the ultrasonic-microwave degradation treatment was carried out for 3 min under the condition of ultrasonic power of 50W and microwave power of 482W to obtain a degradation treatment solution. Nitrogen gas was slowly introduced into the reaction flask containing the degradation treatment solution, and hydrogen peroxide solution was added to start the reaction after 60 min. The concentration of hydrogen peroxide in the reaction system was controlled to be 0.075 mol / L, and the reaction was continued for 2 h under nitrogen conditions. The reacted mixture was poured into a dialysis bag with a molecular weight of 14,000 Da, dialyzed with d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com