Light-weight mesoporous composite aerogel material and preparation method thereof

A technology of composite airgel and composite sol, which is applied in chemical instruments and methods, wave energy or particle radiation processing materials, colloid chemistry, etc., can solve the problems of low thermal conductivity, high cost, high pore volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

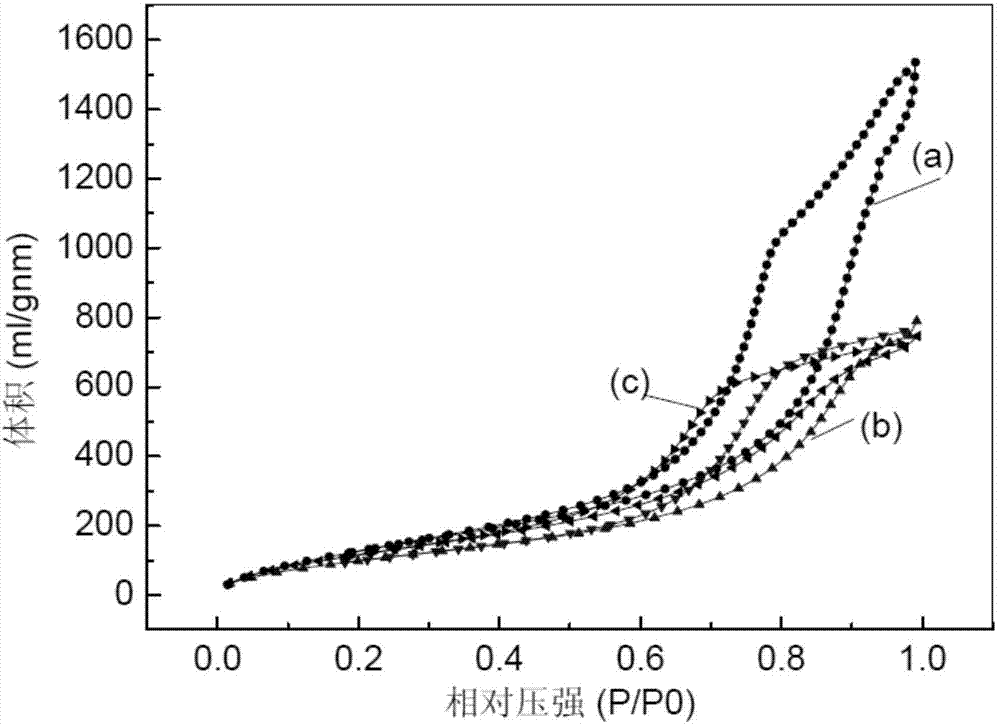

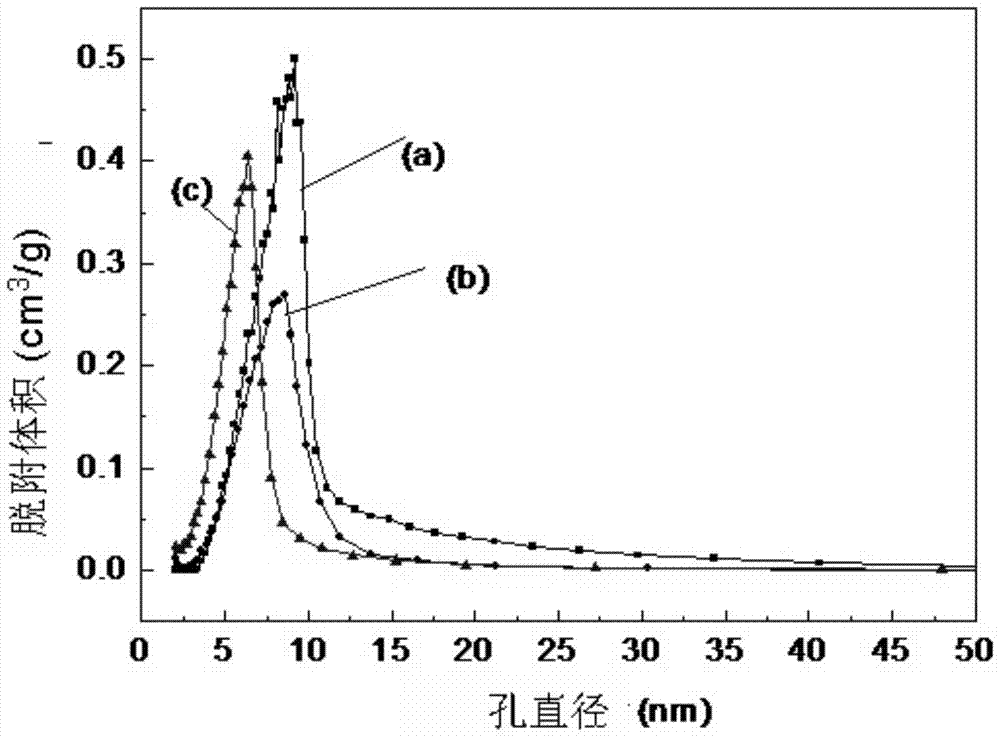

[0047] This example discloses a light mesoporous Cs 0.3 WO 3 / SiO 2 Composite airgel material, its preparation method comprises the following steps:

[0048] ① Preparation of Cs 0.3 WO 3 powder dispersion;

[0049] 2.5g of Cs with visible light transmission and near-infrared light absorption and shielding functions 0.3 WO 3 Disperse the powder in 100ml of water, adjust pH=7, add 520g of zirconia balls with a particle size of 1mm, mill in a ball mill for 1h, add 2.0wt% polyvinyl alcohol dispersant, and obtain Cs through ultrasonic oscillation and magnetic stirring 0.3 WO 3 Nanoparticle dispersion;

[0050] ② Preparation of Cs 0.3 WO 3 / SiO 2 Composite sols and gels:

[0051] Use deionized water to press V for industrial water glass with modulus = 3.38 工业水玻璃 :V 去离子水 =1:4 ratio dilution, and then use strong acidic styrene cation exchange resin for ion exchange to obtain a silicic acid solution with pH=2~3; take 10ml Cs 0.3 WO 3 Dispersion, fully mixed with 50ml si...

Embodiment 2

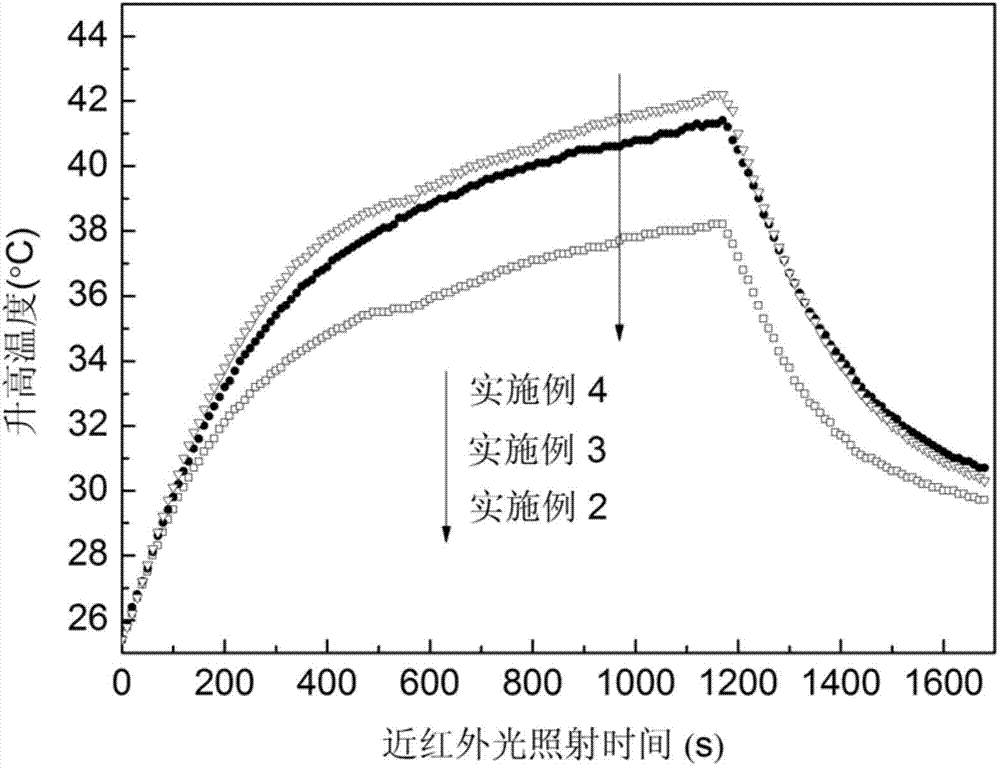

[0057] This example discloses a light mesoporous Cs 0.3 WO 3 / SiO 2 Composite airgel material, its preparation method comprises the following steps:

[0058] ① Preparation of Cs 0.3 WO 3 powder dispersion;

[0059] 2.0g of Cs with visible light transmission and near-infrared light shielding functions 0.3 WO 3 Disperse the powder in 100ml of water, adjust pH=7, add 510g of zirconia balls with a particle size of 1mm, mill in a ball mill for 1h, add 2.0wt% polyvinyl alcohol dispersant, and obtain Cs through ultrasonic oscillation and magnetic stirring 0.3 WO 3 nanoparticle dispersion.

[0060] ② Preparation of Cs 0.3 WO 3 / SiO 2 Composite sols and gels:

[0061] Use deionized water to press V for industrial water glass with modulus = 3.38 工业水玻璃 :V 去离子水 =1:4 ratio dilution, and then use strong acidic styrene cation exchange resin for ion exchange to get silicic acid solution with pH=2~3; take 10ml Cs 0.3 WO 3 Dispersion, fully mixed with 80ml silicic acid solution ...

Embodiment 3

[0067] This example discloses a light mesoporous Cs 0.3 WO 3 / SiO2 Composite airgel material, its preparation method comprises the following steps:

[0068] ① Preparation of Cs 0.3 WO 3 powder dispersion;

[0069] 3.0g of Cs with visible light transmission and near-infrared light shielding functions 0.3 WO 3 Disperse the powder in 100ml of water, adjust pH=7, add 515g of zirconia balls with a particle size of 1mm, mill in a ball mill for 0.5h, add 2.5wt% polyvinyl alcohol dispersant, and obtain Cs through ultrasonic oscillation and magnetic stirring 0.3 WO 3 nanoparticle dispersion.

[0070] ② Preparation of Cs 0.3 WO 3 / SiO 2 Composite sols and gels:

[0071] Use deionized water to press V for industrial water glass with modulus = 3.38 工业水玻璃 :V 去离子水 =1:4 ratio dilution, and then use strong acidic styrene cation exchange resin for ion exchange to get silicic acid solution with pH=2~3; take 10ml Cs 0.3 WO 3 Dispersion, fully mixed with 80ml silicic acid solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com