High-temperature-resistant ceramic coating and preparation method thereof

A technology of high temperature resistant ceramics and coatings, applied in the direction of fireproof coatings, polyurea/polyurethane coatings, coatings, etc., to achieve the effects of improving comprehensive performance, excellent high temperature resistance, excellent high temperature resistance and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

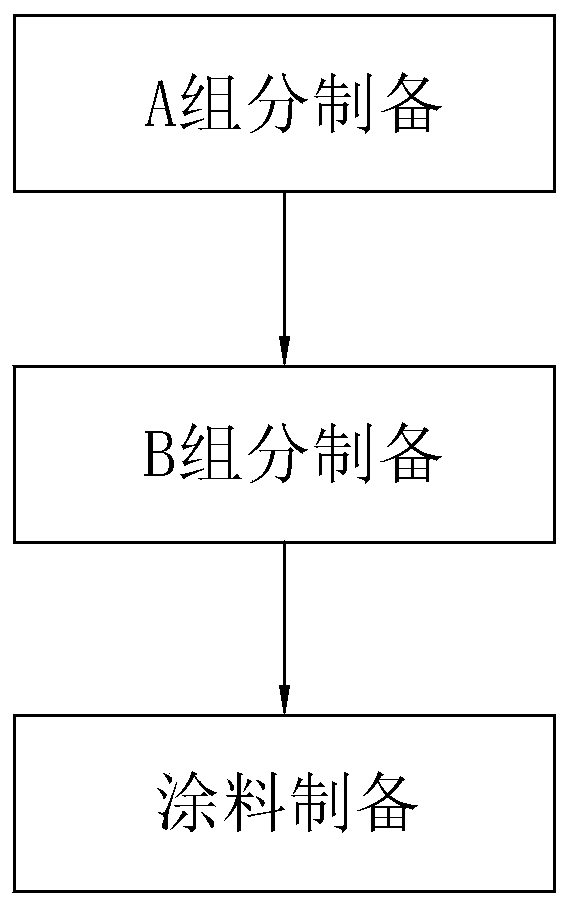

Method used

Image

Examples

Embodiment 1

[0046] A high-temperature-resistant ceramic coating, comprising component A and component B with a mass ratio of 1:1.

[0047] A component comprises the raw material of following weight portion:

[0048] 25 parts of modified silane;

[0049] 3 parts of water-based polyurethane, brand PU7106, purchased from Shanghai Belt New Material Technology Co., Ltd.;

[0050] 1 part of leveling agent, the leveling agent is polydimethylsiloxane;

[0051] 0.3 parts of formic acid;

[0052] Potassium hydroxide 0.1 parts.

[0053] B component comprises the raw material of following weight portion:

[0054] 50 parts of silica sol, silica sol includes 30wt% particle diameter of 5 μm silica sol A and 70wt% particle diameter of 20 μm silica sol B, silica sol A and silica sol B are alkaline, pH value is 9.5, silica content 50%;

[0055] 5 parts of mica powder, particle size 50μm;

[0056] Silica powder 15 parts, particle size 30μm;

[0057] Graphene 2.5 parts, monolayer ratio greater than 8...

Embodiment 2

[0069] A high-temperature-resistant ceramic coating, comprising component A and component B with a mass ratio of 1:1.

[0070] A component comprises the raw material of following weight portion:

[0071] 30 parts of modified silane;

[0072] 5 parts of water-based polyurethane, brand PU7106, purchased from Shanghai Belt New Material Technology Co., Ltd.;

[0073] 1.5 parts of leveling agent, the leveling agent is polydimethylsiloxane;

[0074] 0.5 parts of formic acid;

[0075] Potassium hydroxide 0.2 parts.

[0076] B component comprises the raw material of following weight portion:

[0077] 60 parts of silica sol, silica sol includes 40wt% particle diameter of 5 μm silica sol A and 60wt% particle diameter of 30 μm silica sol B, silica sol A and silica sol B are alkaline, pH value is 9.5, silica content 50%;

[0078] 10 parts of mica powder, particle size 50μm;

[0079] Silica powder 20 parts, particle size 30μm;

Embodiment 3

[0092] A high-temperature-resistant ceramic coating, comprising component A and component B with a mass ratio of 1:1.

[0093] A component comprises the raw material of following weight portion:

[0094] 28 parts of modified silane;

[0095] 4 parts of water-based polyurethane, grade PU7106, purchased from Shanghai Belt New Material Technology Co., Ltd.;

[0096] 1.2 parts of leveling agent, the leveling agent is polydimethylsiloxane;

[0097] 0.4 parts of formic acid;

[0098] Potassium hydroxide 0.15 parts.

[0099] B component comprises the raw material of following weight portion:

[0100] 55 parts of silica sol, silica sol includes 35wt% particle diameter of 5 μm silica sol A and 65wt% particle diameter of 25 μm silica sol B, silica sol A and silica sol B are alkaline, pH value is 9.5, silica content 50%;

[0101] 8 parts of mica powder, particle size 50μm;

[0102] Silica powder 18 parts, particle size 30μm;

[0103] 3 parts of graphene, single-layer ratio greate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com