Method for preparing capacitive pressure transducer

A pressure sensor, capacitive technology, applied in the manufacture of microstructure devices, processes for producing decorative surface effects, coatings, etc. Easy-to-achieve, simple-to-craft effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above objects, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

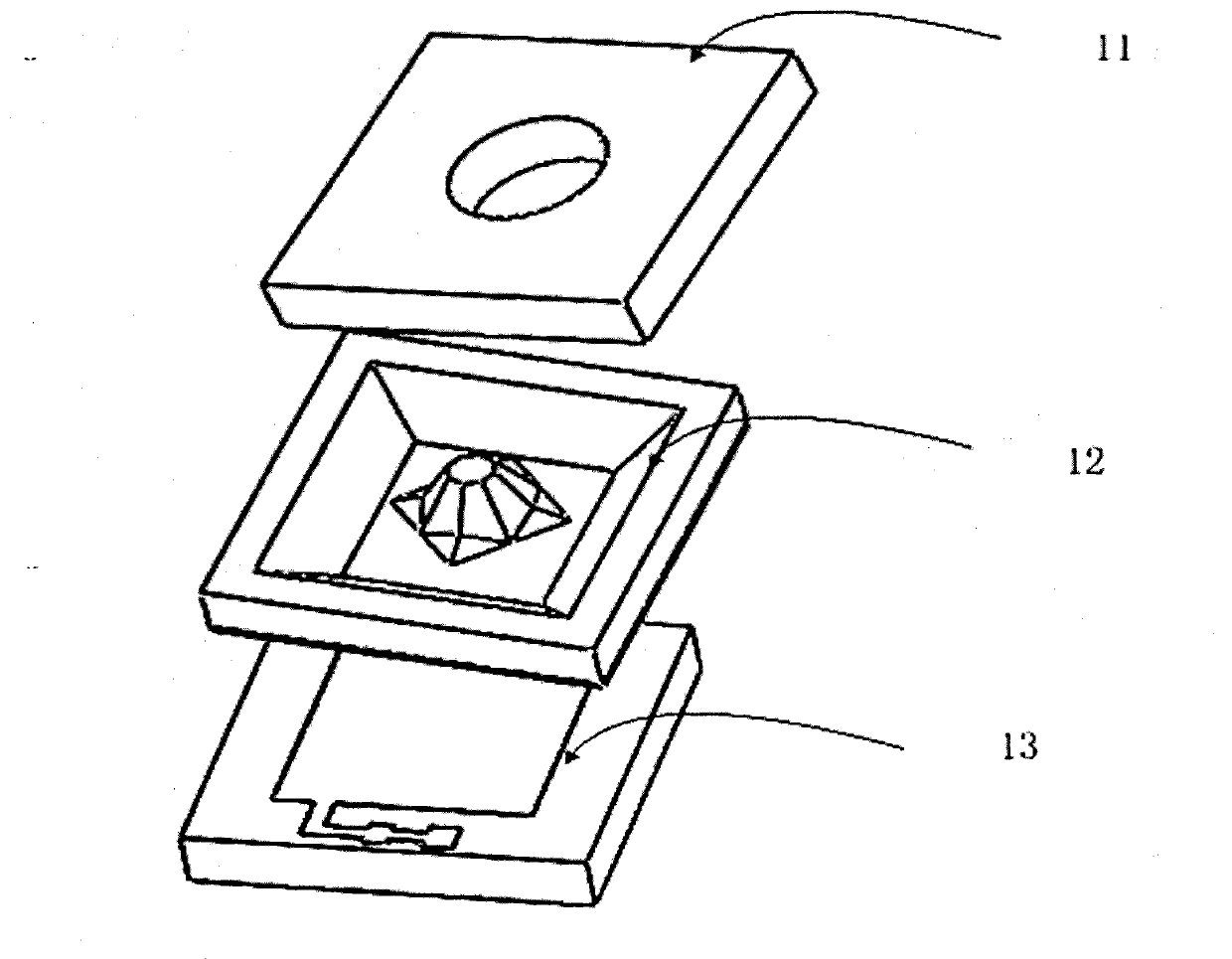

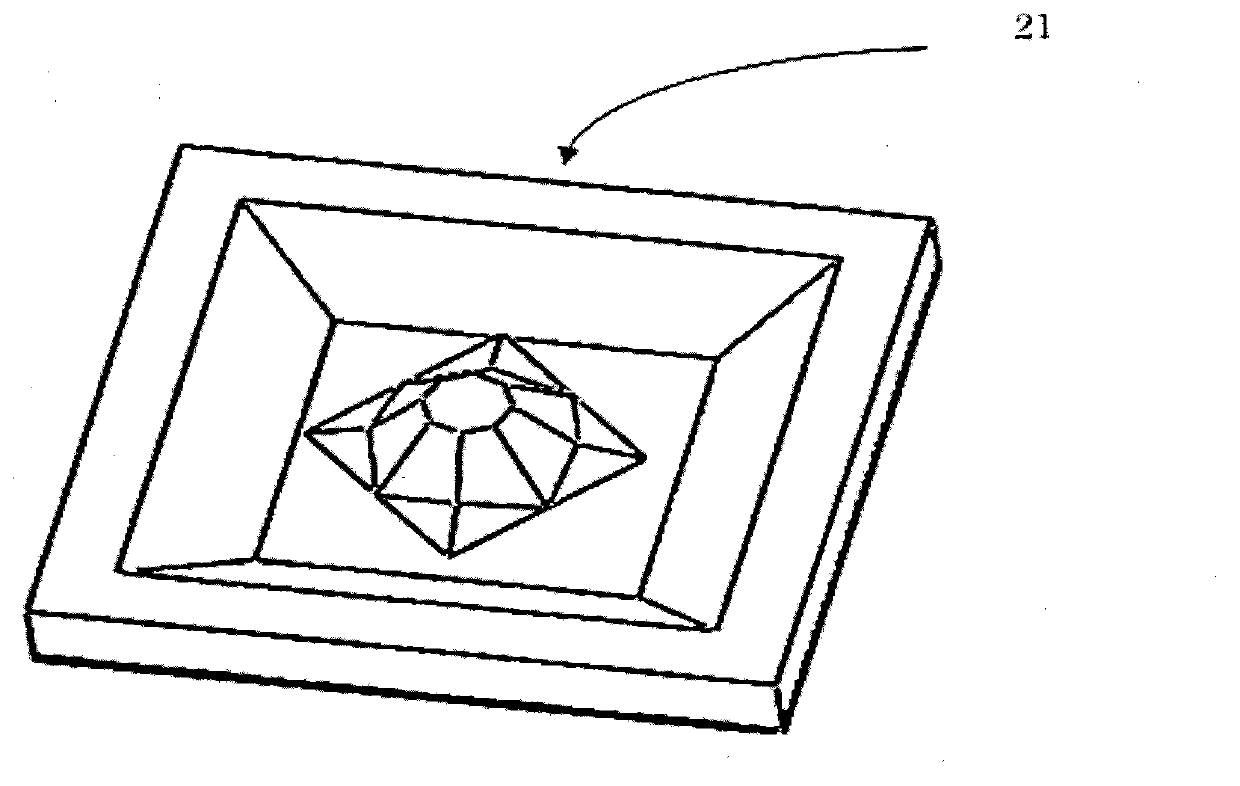

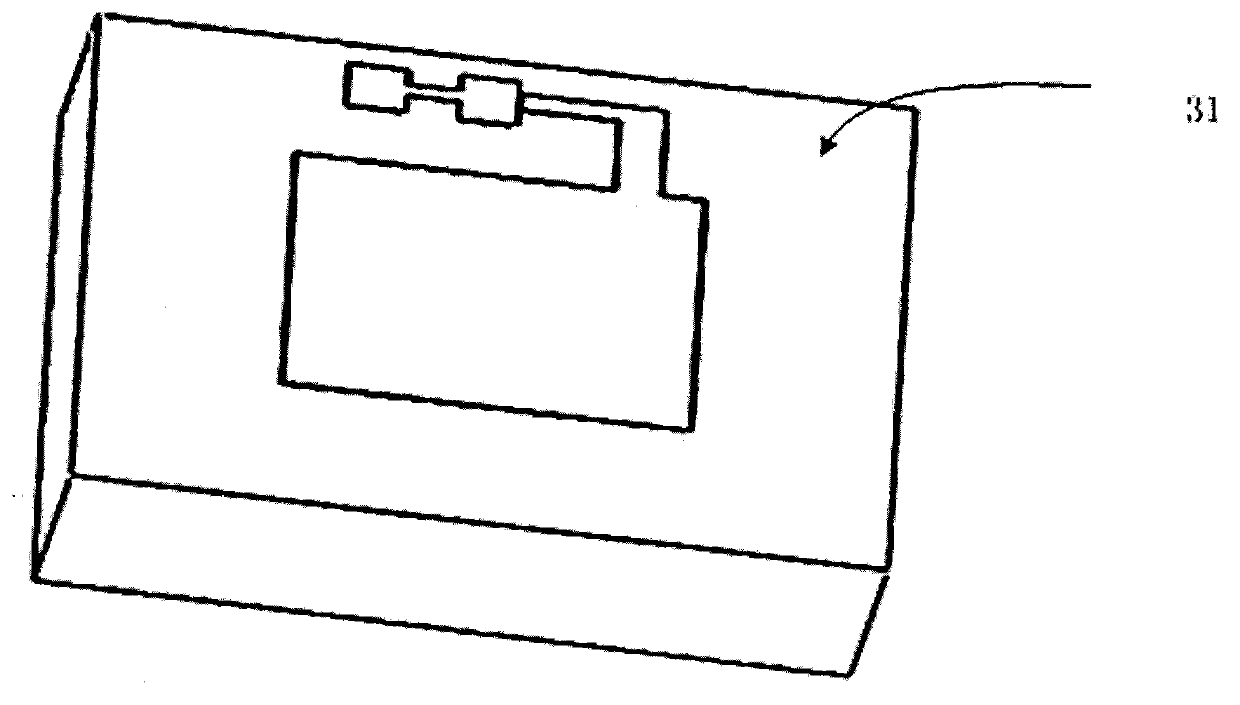

[0027] like figure 1 The whole consists of sensitive diaphragm, glass electrode and perforated glass. The process steps are as follows:

[0028] Thermal oxygen 2000-5000 angstroms on 4 inches (100) silicon wafers, and protect the front side with glue.

[0029] For the first photolithography, use hydrofluoric acid solution to etch silicon oxide, and use tetramethylammonium hydroxide solution or potassium hydroxide solution to etch out a capacitance gap of 2-4um. This process uses 25% tetramethylammonium hydroxide The solution is etched at a temperature of 60 degrees; after the etching is completed, Cr / Au300-400 angstrom / 1500-2000 angstrom is sputtered, and the second photolithography is performed, and the electrode is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com