Patents

Literature

69results about How to "Excellent chemical resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polycarbonate/polyester composition and preparation method thereof

InactiveCN101787195AExcellent chemical resistanceGood low temperature impact resistanceChemistryCompound (substance)

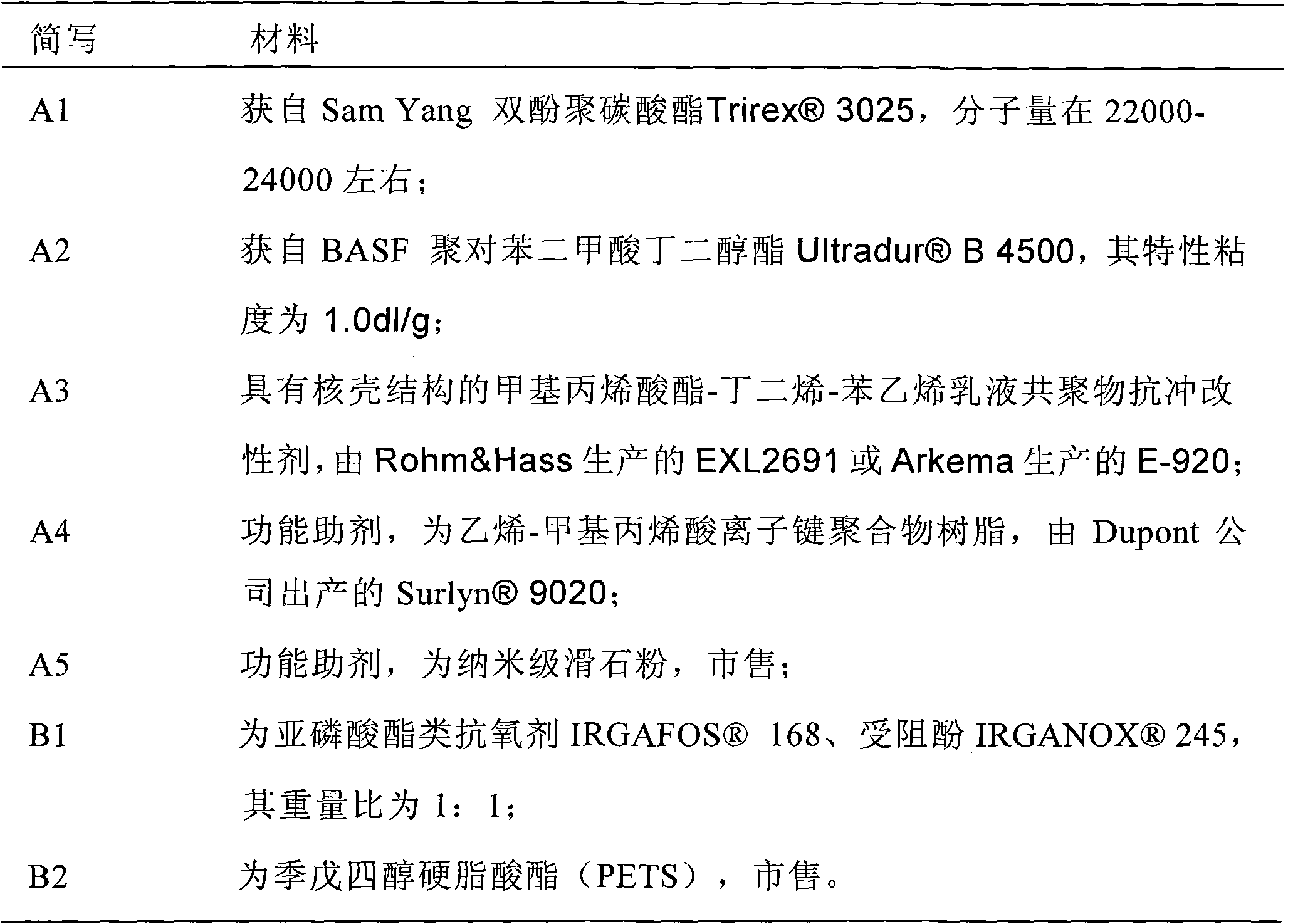

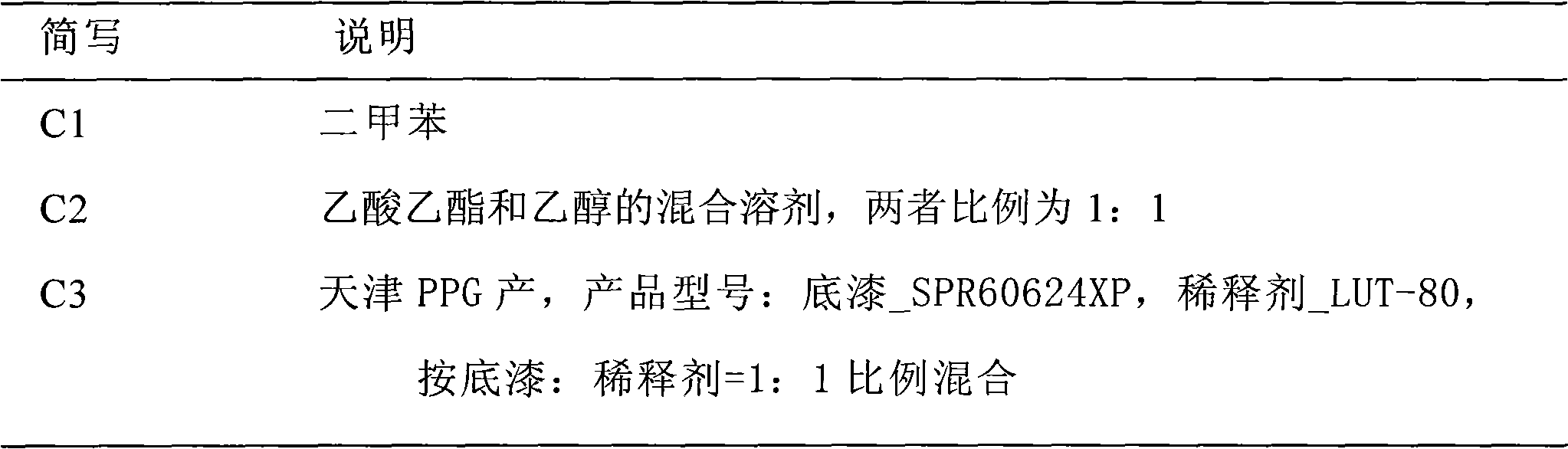

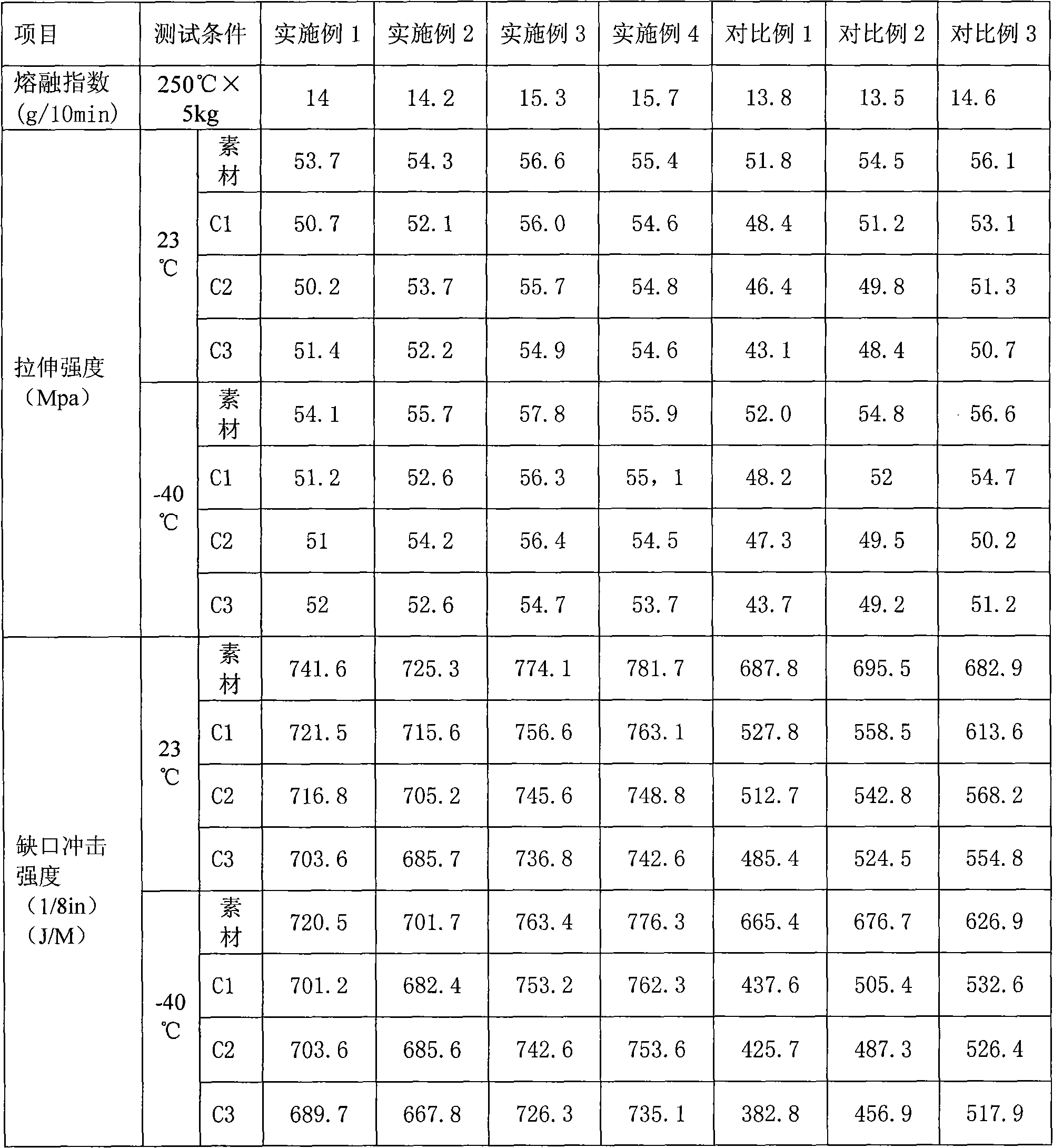

The invention relates to a polycarbonate / polyester composition and a preparation method thereof. The composition comprises the following components by wt%: 50-80wt% of polycarbonate, 10-30wt% of polybutylene terephthalate (PBT), 5-15wt% of toughening agents, 1-5wt% of functional agents, 0.1-1wt% of antioxidant and 0.1-2wt% of lubricants. The method comprises the following steps: proportioning according to the components, then proportionally charging the PBT and the functional agents into a high mixing machine to be premixed and carrying out extrusion pelletization on the premixed materials in an extruder to obtain functional master batches; and then fully mixing the rest components with the master batches in the high mixing machine and then carrying out extrusion pelletization on the mixture in a double-screw extruder to obtain the product. Compared with the prior art, the composition has excellent resistance to chemicals and low temperature impact resistance and simultaneously improves the mechanical properaty of the materials.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

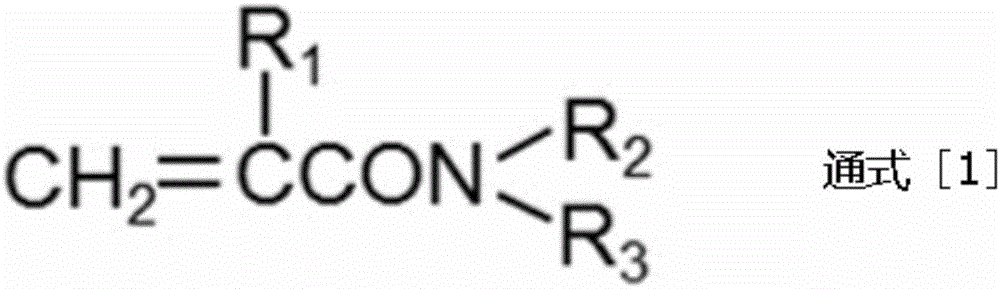

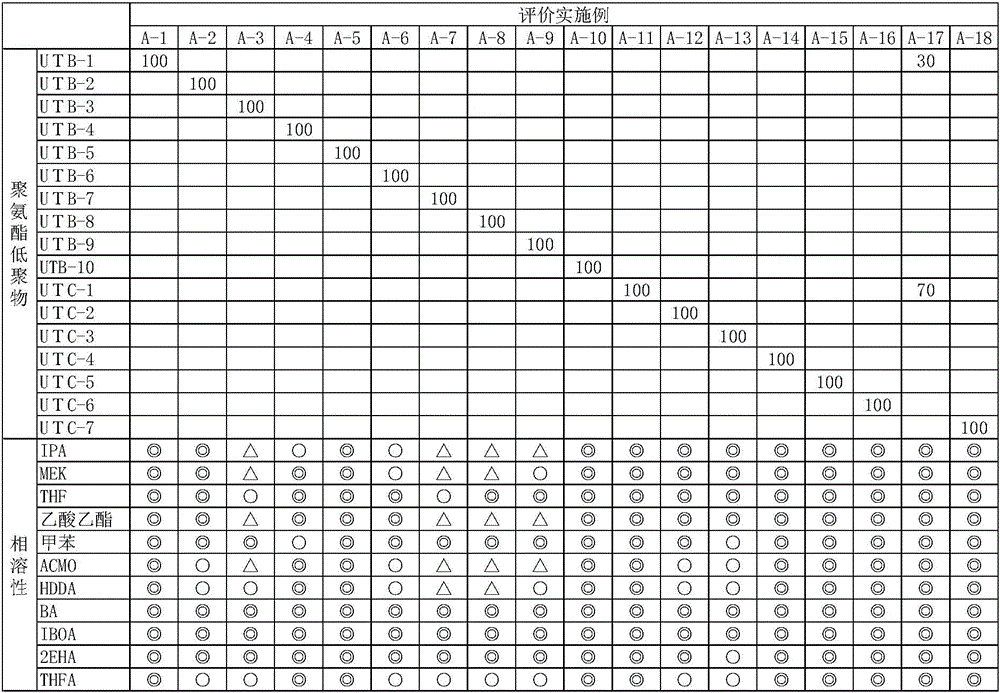

Urethane oligomer and active energy ray curable resin composition containing same

ActiveCN106029727AGood compatibilityExcellent chemical resistancePolyureas/polyurethane adhesivesInksChemistryOligomer

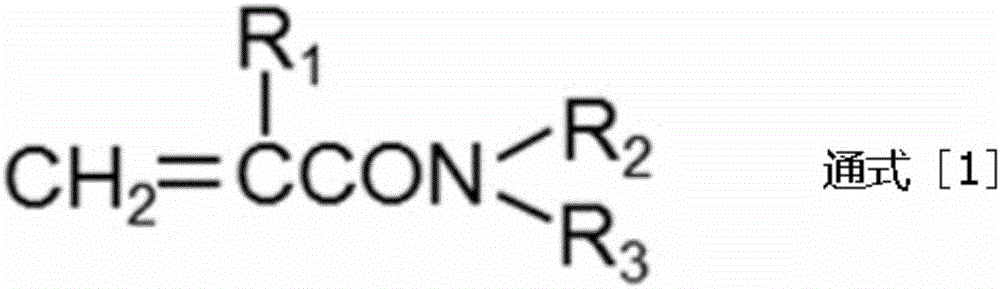

The purpose of the present invention is to provide a (meth)acrylamide-based urethane oligomer which has excellent compatibility with organic solvents and general purpose acrylic monomers and oligomers and a high curing speed when irradiated with active energy rays; and to provide an active energy ray curable resin composition, and a formed product thereof, which contains said urethane oligomers, has excellent adhesion, moisture resistance and surface curability and has low curing shrinkage. By using a (meth)acrylamide-based urethane oligomer having a carbonate skeleton, a diene skeleton or a hydrogenated diene skeleton in the molecule and containing 5 wt% or less of a component having one or more (meth)acrylamide groups and a molecular weight of less than 1000 (excluding (meth)acrylamide compounds (A) having a hydroxyl group), it is possible to obtain an oligomer which has excellent compatibility with organic solvents and general purpose acrylic monomers and oligomers and high curability, and to obtain an active energy ray curable resin composition which contains said oligomer and has excellent adhesion, tack resistance, moisture resistance and shrinkage resistance.

Owner:科捷化成品公司

Glove having excellent chemical resistance and composition for said glove

An emulsion composition for producing a glove, the composition containing: (1) a carboxylated acrylonitrile-butadiene elastomer, comprising 30 to 40% by weight of acrylonitrile residues and 3 to 8% by weight of unsaturated carboxylic acid residues, having an elemental sulfur content detected by neutralization titration of a combusted product of the elastomer of not more than 1% by weight of the elastomer weight, and having a Mooney viscosity (ML(1+4) (100° C.)) of 100 to 220, and (2) a poly(acrylonitrile-butadiene) having a styrene-equivalent weight-average molecular weight of 7,000 to 500,000, wherein the weight ratio of component (1) / component (2) is from 70 / 30 to 90 / 10. Also provided is a glove which, as a result of comprising the emulsion composition, exhibits excellent chemical resistance and superior flexibility.

Owner:KOSSAN

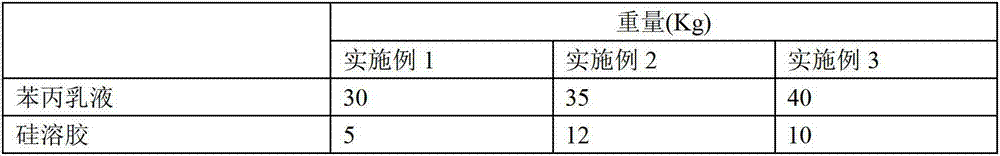

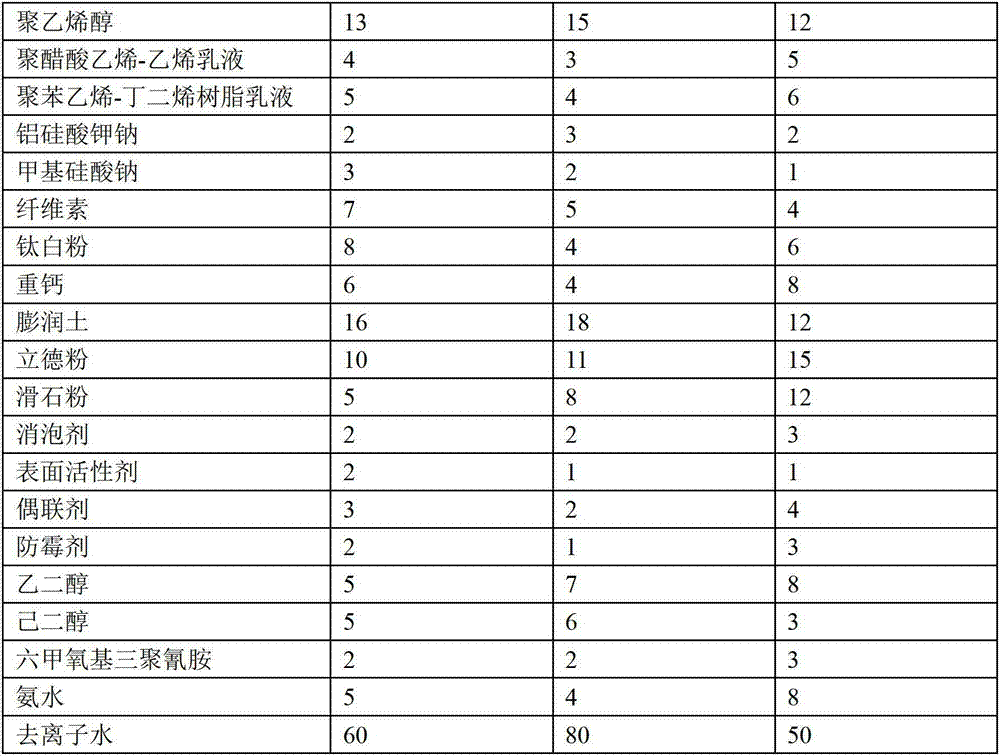

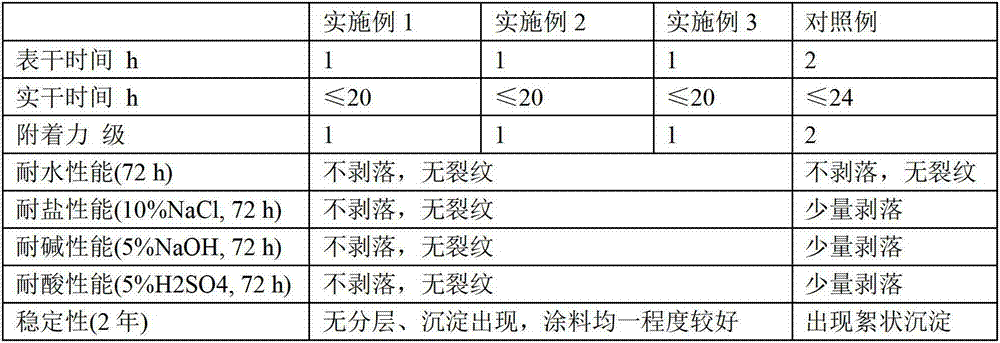

High-stability composite coating

InactiveCN102876145AStrong adhesionExcellent chemical resistanceCoatingsSal ammoniacStyrene-butadiene

The invention provides a styrene acrylic emulsion-silica sol composite coating, and belongs to the technical field of coatings. The composite coating comprises the following components in part by weight: 30-40 parts of styrene acrylic emulsion, 5-12 parts of silica sol, 12-15 parts of polyvinyl alcohol, 3-5 parts of polyvinyl acetate-ethylene emulsion, 4-6 parts of styrene-butadiene resin emulsion, 2-3 parts of sodium potassium aluminosilicate, 1-3 parts of methyl sodium silicate, 4-7 parts of cellulose, 4-8 parts of titanium dioxide, 4-8 parts of triple superphosphate, 12-18 parts of bentonite, 10-15 parts of lithopone, 5-12parts of talcum powder, 2-3 parts of defoamer, 1-2 parts of surfactant, 2-4 parts of coupling agent, 1-3 parts of mildew inhibitor, 5-8 parts of ethylene glycol, 3-6 parts of hexanediol, 2-3 parts of hexamethoxyl melamine, 4-8 parts of ammonia and 50-80 parts of deionized water. The composite coating has the advantages of excellent adhesion, chemical reagent resistance and water resistance and long shelf life.

Owner:WUJIANG TIANYUAN PLASTIC

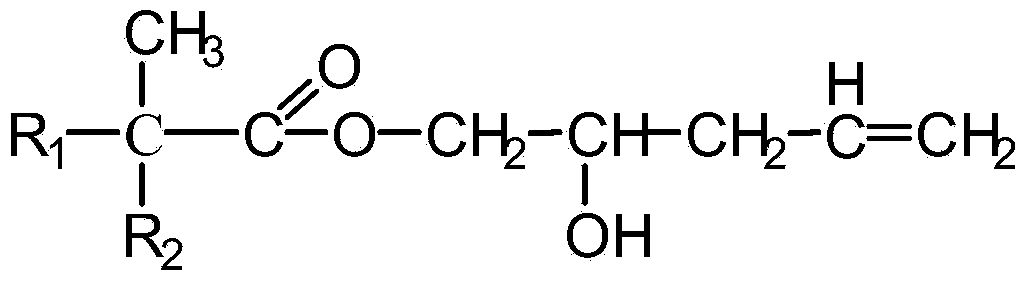

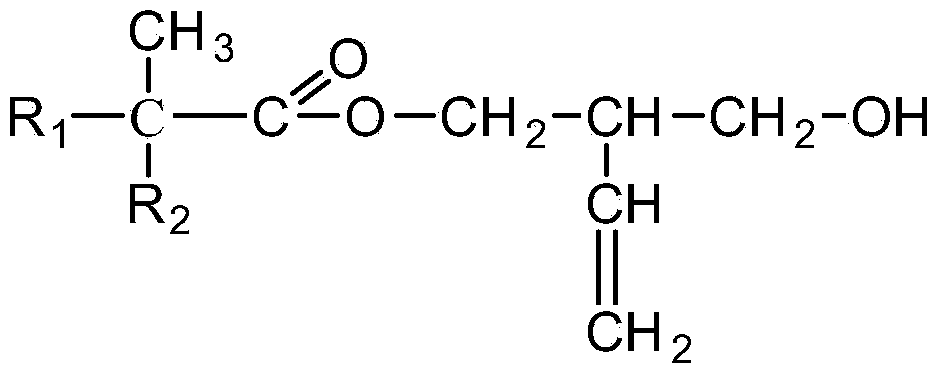

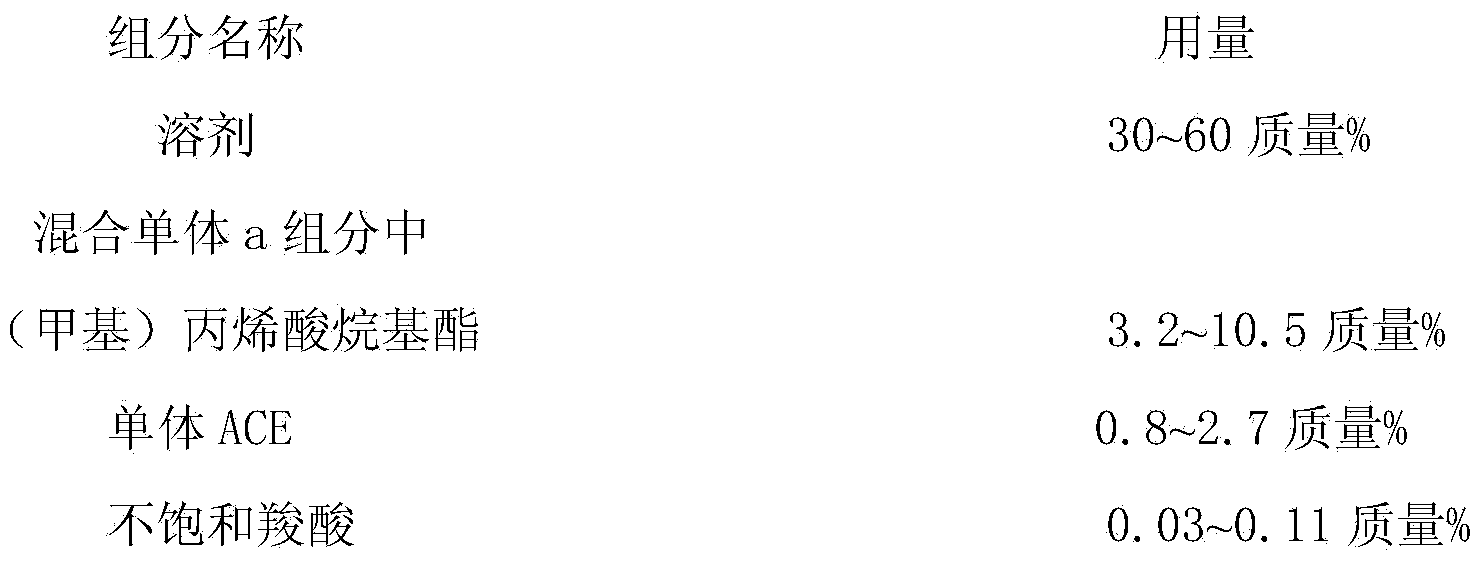

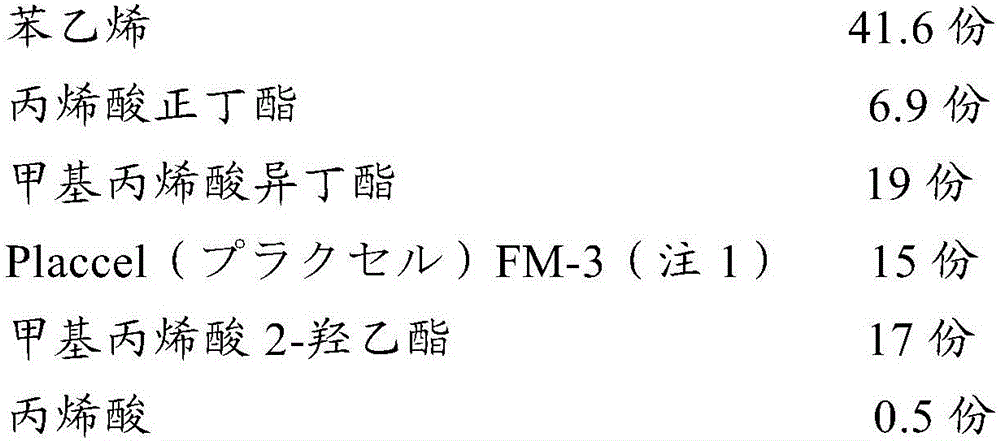

Preparation method of hydroxy acrylic resin for recoatable polyurethane coating

ActiveCN103709312AGood weather resistanceExcellent chemical resistancePolyurea/polyurethane coatingsAngiotensin-converting enzymeIsocyanate

The invention discloses a preparation method of hydroxy acrylic resin for a recoatable polyurethane coating. According to the method, hydroxy acrylic resin is copolymerized by adopting a two-step segmentation method, and a monomer angiotensin converting enzyme (ACE) with internal plasticization is led to a polymer chain segment. The hydroxy acrylic resin is used as a base stock of the coating, cured and crosslinked with polyisocyanate. The prepared recoatable polyurethane coating has excellent weather fastness and corrosion resistance, good chemical resistance and excellent mechanical property. The coating is greatly applied to heavy-duty coating as the finishing coat.

Owner:SHANGHAI HUAYI FINE CHEM CO LTD

Water-based polyurethane varnish and method for preparing same

InactiveCN102733198AImprove mechanical propertiesImprove hydrolysis resistanceFibre treatmentWater basedPolycarbonate

The invention relates to a water-based polyurethane varnish and a method for preparing the same. The Water-based polyurethane varnish is prepared from the following raw materials: polycarbonate diol, diisocyanate, bismuth sulfonic acid based catalyst, carboxyl-containing diol, small-molecule diol, a tertiary-amine compound, acetone, antioxidant 1010, deionized water, an amine chain extender, propylene glycol carbonate and bis-terminal hydroxyl-polyether modified silicone oil. The process for preparing the water-based polyurethane varnish comprises the following steps: (1) dehydrating the polycarbonate diol; (2) synthesizing a prepolymer; (3) neutralizing the prepolymer; (4) extending chains and emulsifing; (5) distilling; and (6) compounding: adding and stirring the propylene glycol carbonate or bis-terminal hydroxyl-polyether modified silicone oil into the obtained water-based polyurethane emulsion to obtain the water-based polyurethane varnish coated on the surface of leather.

Owner:SHANDONG TIANQING TECH DEV

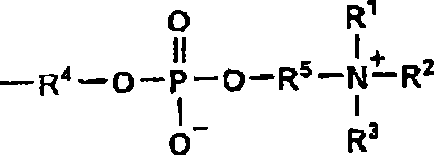

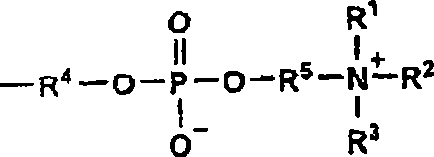

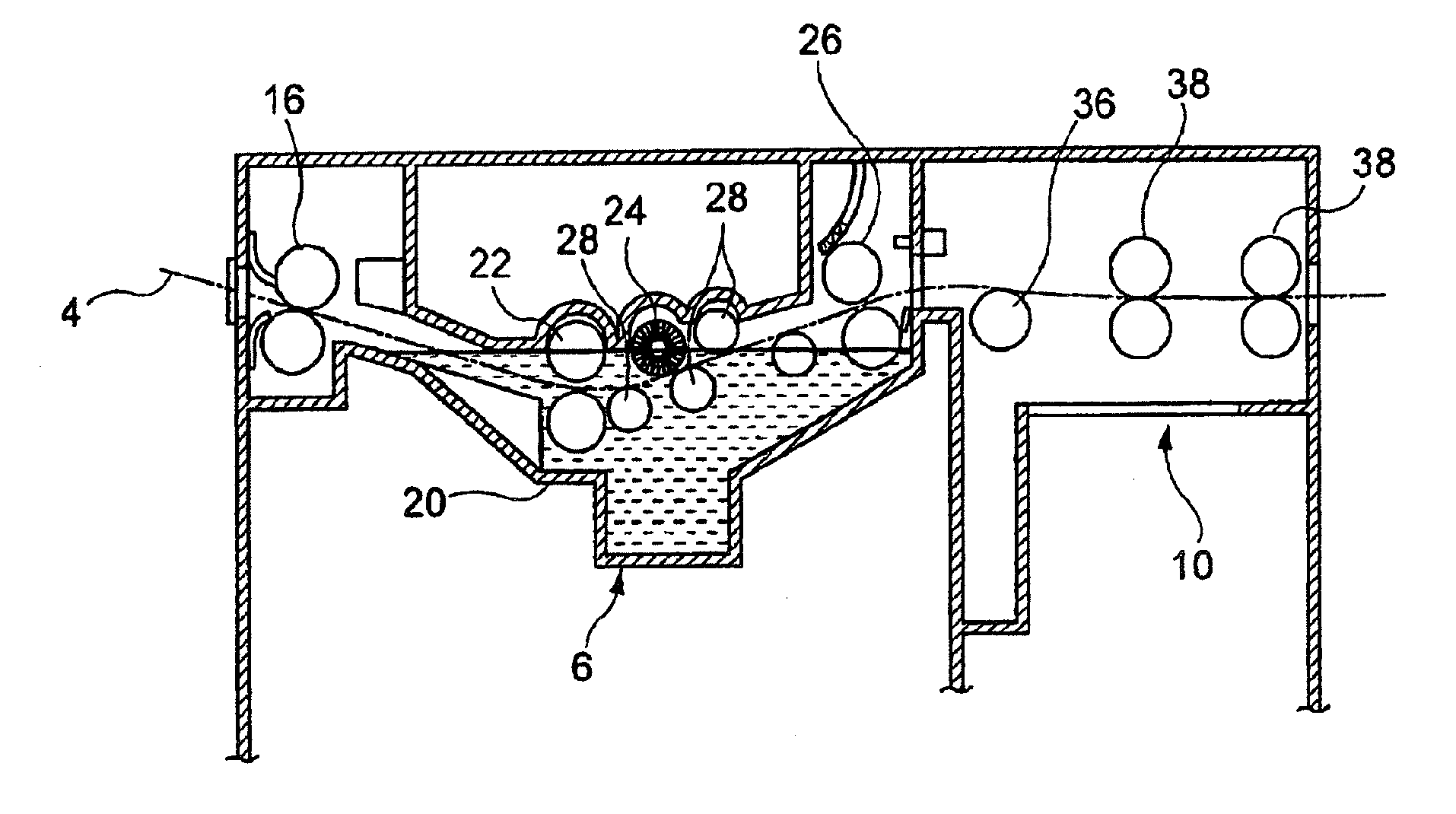

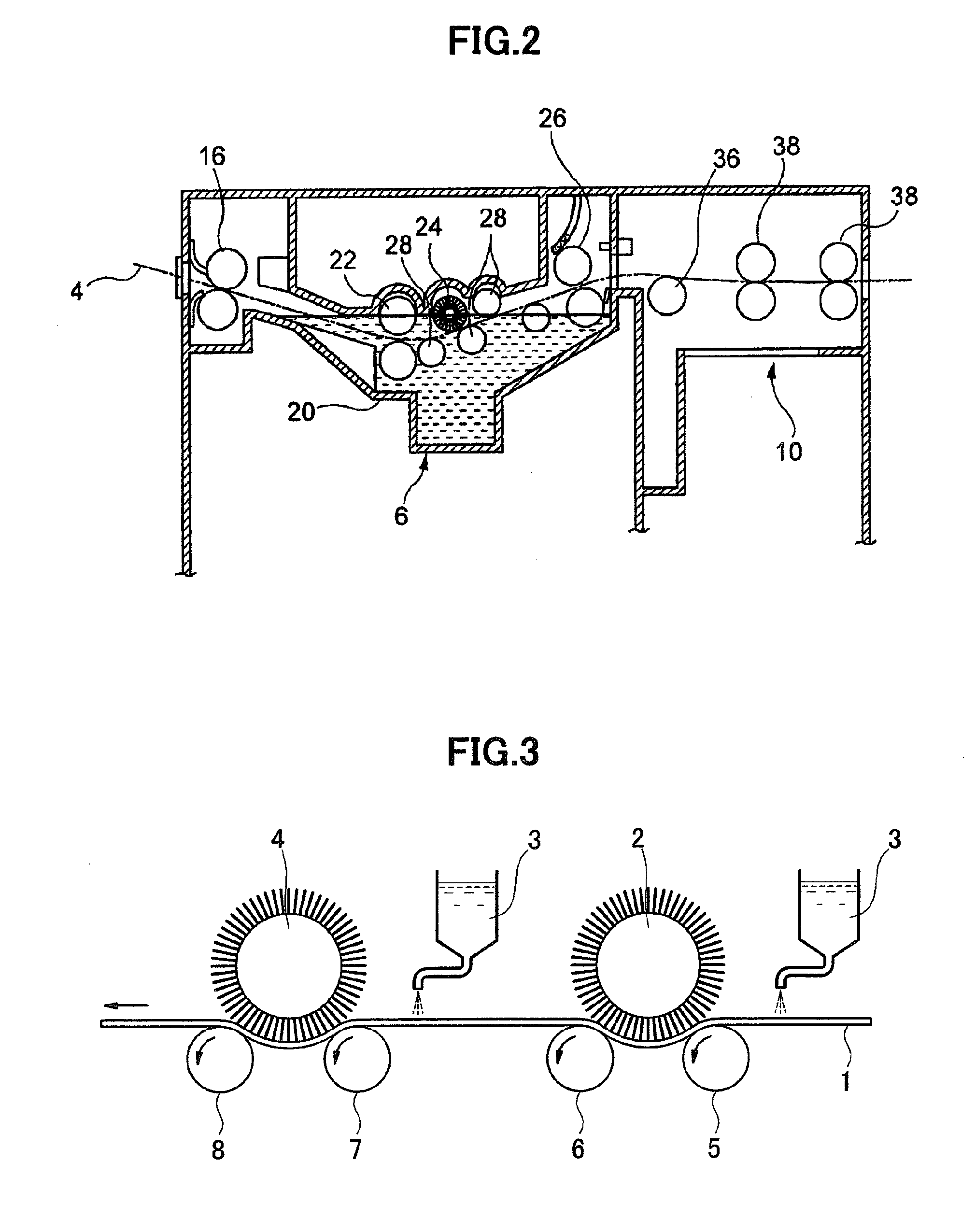

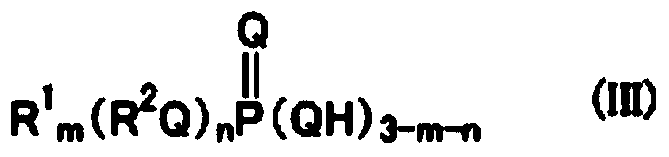

Offset printing plate, offset printing plate material, support for offset printing plate and offset printing method

InactiveCN101466554AExcellent printing resistanceExcellent chemical resistancePlate printingFoil printingWater solubleEngineering

An objective is to provide a planographic printing plate material exhibiting excellent properties such as printing durability, resistance to chemicals and anti-stain at the beginning of printing via restart of printing, and also a planographic printing plate exhibiting excellent properties such as printing durability, resistance to chemicals and anti-stain at the beginning of printing via restart of printing. Disclosed is a planographic printing plate comprising a support and provided thereon, an image portion and a non-image portion, wherein the non-image portion comprises a water-soluble phosphobetaine compound.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

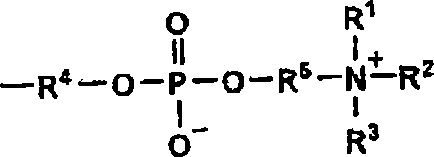

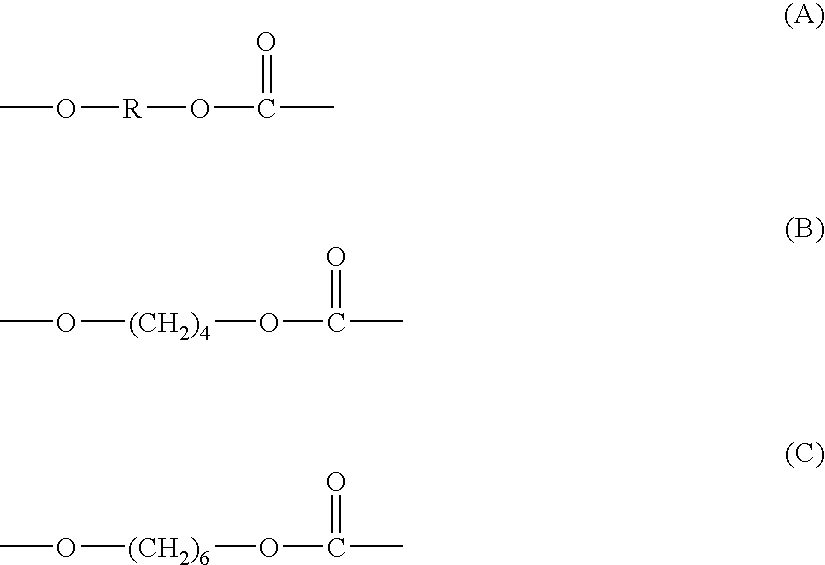

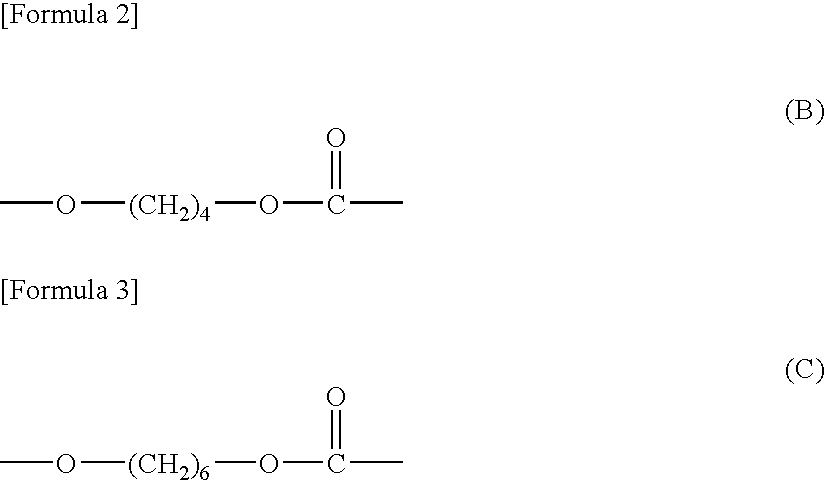

Polycarbonate diol

ActiveUS20100261852A1Excellent chemical resistanceHigh elongationPolyurea/polyurethane coatingsPolycarbonateRepeat unit

A polycarbonate diol comprising repeating units represented by the following formula (A) and a terminal hydroxy group, 60-100 mol % of the repeating units represented by the formula (A) being repeating units represented by the following formula (B) or (C). The amount of the repeating units represented by the formula (B) is 60-100 mol % based on the total amount of the repeating units represented by the formula (A). The polycarbonate diol has a terminal primary OH ratio of 95% or higher. (A) (In the formula, R represents a C2-12 divalent aliphatic or alicyclic hydrocarbon.)

Owner:ASAHI KASEI KOGYO KK

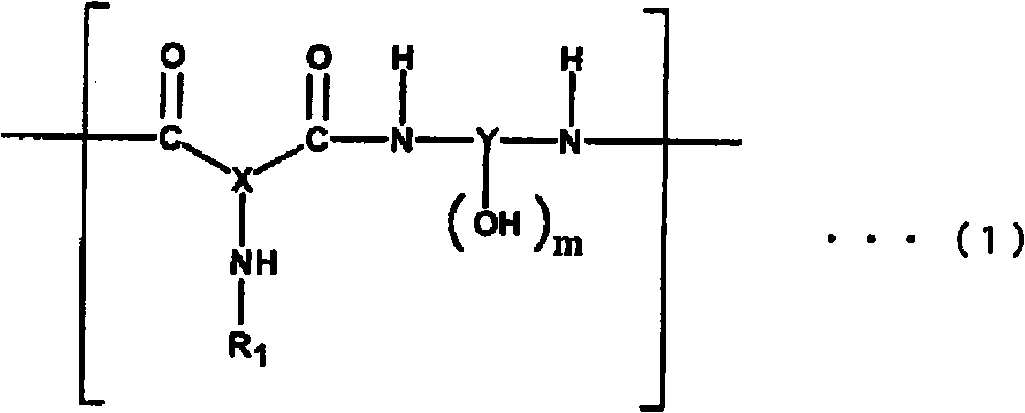

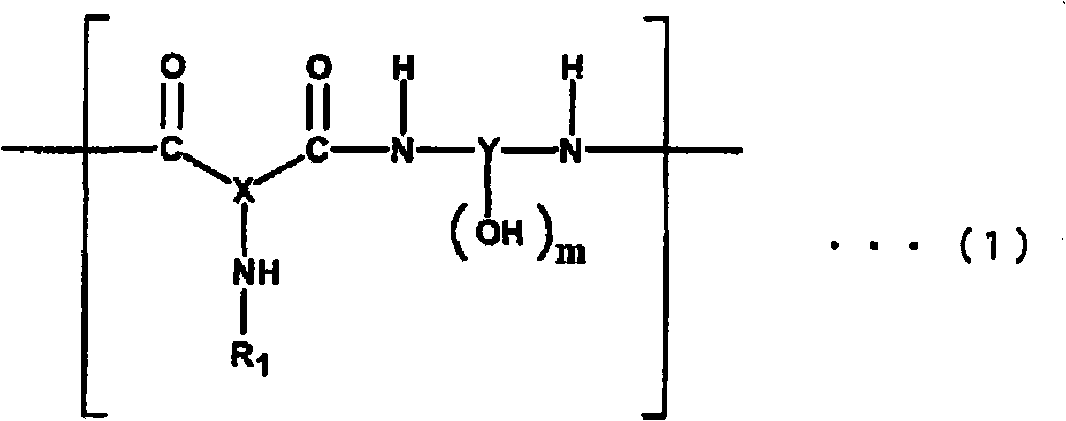

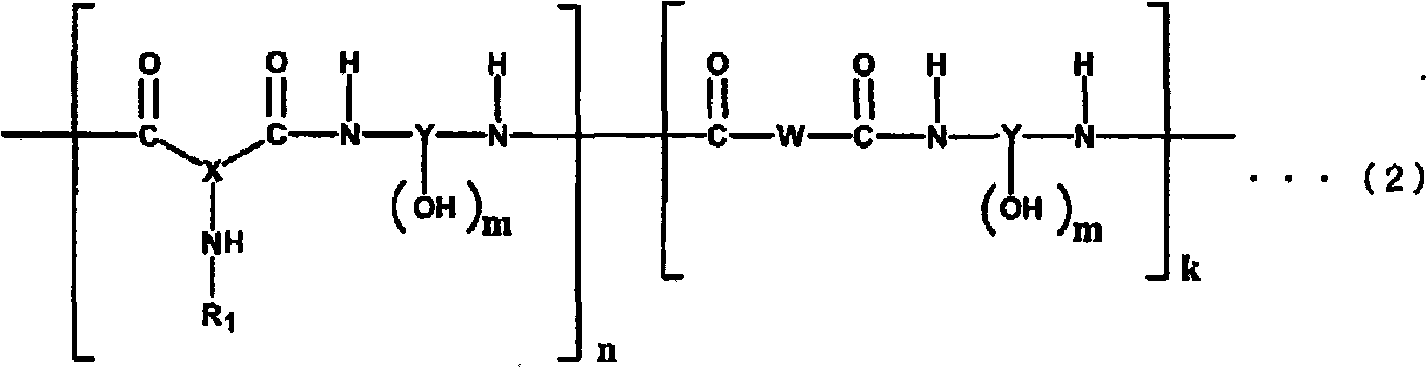

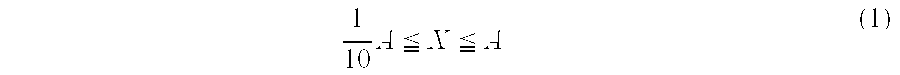

Polyamide resin, photosensitive resin composition, method for forming cured relief pattern, and semiconductor device

ActiveCN101809064AExcellent chemical resistanceGood chemical resistancePhotomechanical apparatusSemiconductor/solid-state device manufacturingChemistryPolyamide

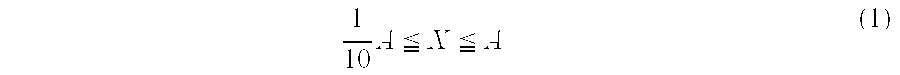

Disclosed is a photosensitive resin composition having excellent photosensitive characteristics, which provides a resin film with excellent film characteristics even when the resin film is formed under heating / curing conditions such as at 200 DEG C or less. A polyamide resin used in the photosensitive resin composition is also disclosed. The polyamide resin contains structural units represented by formula (1) with a repetition number of 2-150 which is within the range of 80-100% of the total number of the structural units constituting the polyamide resin. [In formula (1), X represents a trivalent organic group having 6-15 carbon atoms; m represents 0 or 2; Y represents a divalent organic group having 6-35 carbon atoms when m = 0, and represents a tetravalent organic group having 6-35 carbon atoms when m = 2; and R1 represents an aliphatic group having at least one radically polymerizable unsaturated linking group with 5-20 carbon atoms, which may contain an atom other than carbon atoms].

Owner:ASAHI KASEI KK

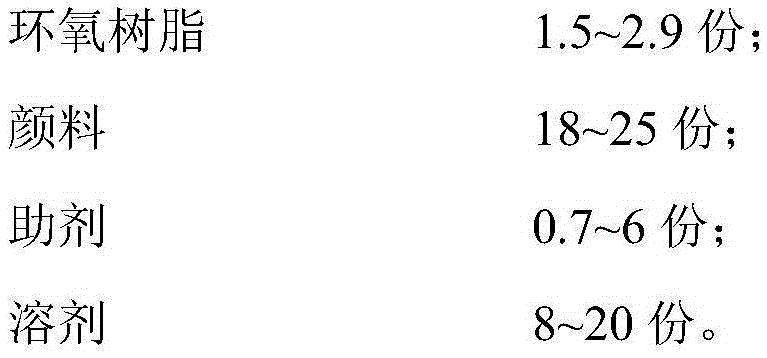

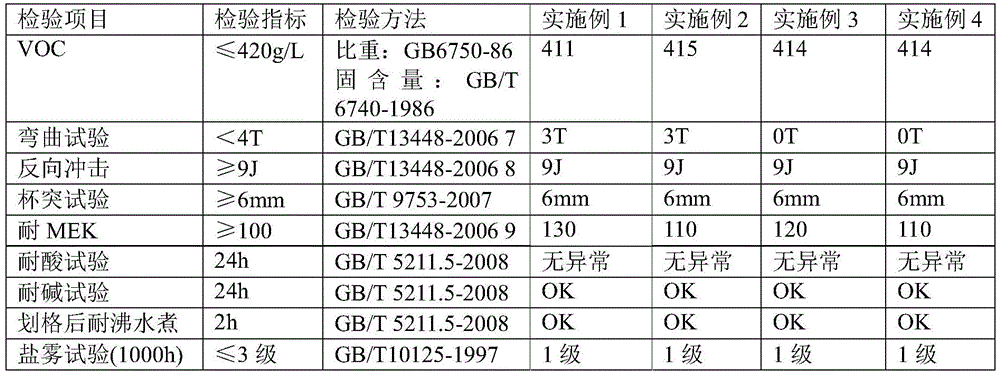

Thick plate polyurethane primer and preparation method thereof

InactiveCN105602435AGood flexibilityHigh resistance to salt sprayAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyPolyester

The invention discloses a thick plate polyurethane primer which comprises the following ingredients in parts by weight: 17-35 parts of polyester resin, 2-6 parts of amino resin, 2-6 parts of isocyanate, 1.5-2.9 parts of epoxy resin, 18-25 parts of pigment, 0.7-6 parts of an auxiliary agent and 8-20 parts of a solvent. The invention also discloses a preparation method of the thick plate polyurethane primer. The T bend of the thick plate polyurethane primer provided by the invention can reach 0T without cracks, the flexibility is good, and a paint peeling phenomenon is avoided in a processing process; the salt spray resistance is high; by virtue of cooperation of the thick plate polyurethane primer and a polyester topcoat with common performances, the salt spray test achieves grade 1 within 1000 hours; the adhesive force with a substrate and the adhesive force with the topcoat are superior to those of traditional epoxy primer and polyester primer. Compared with the traditional primer, the thick plate polyurethane primer provided by the invention has relatively excellent adhesive force, flexibility and chemical corrosion resistance.

Owner:NIPPON PAINT TIANJIN

Room-temperature-cured epoxy resin cast cushion block and preparation method thereof

InactiveCN102372464ASolve the problem of inconvenient constructionSolve sticky surfaceEpoxyToughening

The invention belongs to a filling material used for fixing equipments, and especially relates to a room-temperature-cured epoxy resin cast cushion block and a preparation method thereof. According to existing technologies, the fixation of machineries with relatively large weights requires a large amount of bolts, such that the operation is difficult; in an environment with severe corrosion, fixing bolts are likely to be corroded, and the strengths of the bolts are reduced. The a room-temperature-cured epoxy resin cast cushion block provided by the invention is composed of, by weight: 100 parts of epoxy resin, 0 to 20 parts of a toughening agent, 0 to 3 parts of a diluent, 50 to 100 parts of active silicon micro-powder, 5 to 25 parts of an active crystal whisker material, 0 to 3 parts of titanium dioxide, 0 to 3 parts of a pigment, 0 to 1 part of an antifoaming agent, and 5 to 15 parts of a curing agent. The invention is advantaged in that: the surface properties of the product provided by the invention are stable, the product is not easy to contract, and the service life of the product is long. The cushion block can be cured under room temperature, such that the preparation method is simple. With the cushion block, the equipment can be firmly fixed, and requirements under vessel rocking and corrosion conditions can be satisfied.

Owner:SHANGHAI TITANOS IND

Production method for fluorocarbon powder coating

InactiveCN107805425AGood weather resistanceExcellent chemical resistancePowdery paintsPolyester coatingsFluorocarbonPowder coating

The invention provides a method for preparing a fluorocarbon powder coating, a method for preparing a fluorocarbon powder coating, comprising the following steps: one is to prepare a PVDF fluorocarbon powder coating composition A comprising PVDF fluorocarbon resin; two The first is to prepare FEVE fluorocarbon powder coating composition B containing FEVE fluorocarbon resin; the third is to dry mix the PVDF fluorocarbon powder coating composition A and FEVE fluorocarbon powder coating composition B.

Owner:遵义春华新材料科技有限公司

Improved mobile electronic parts

InactiveUS20160114563A1Excellent chemical resistanceImprove ductilitySynthetic resin layered productsPrinted circuit manufactureMobile electronicsMagnesium

A mobile electronic part comprising: (i) a shaped metal part, at least part of the surface thereof being coated with at least one polymer layer (L), wherein the metal is selected from a group consisting of magnesium, aluminum and alloys of these metals, and wherein said polymer layer (L) comprises at least one polymer selected from an aromatic polyamide-imide polymer [(PAI) polymer, herein after] or a poly(ethersulfone) polymer [(PESU) polymer herein after], and (ii) a thermoplastic resin composition layer [layer (T), herein after] fixed to the at least one polymer layer (L) of said shaped metal part wherein said composition comprises at least one thermoplastic polymer [polymer (T), herein after].

Owner:SOLVAY SPECIALTY POLYMERS USA LLC

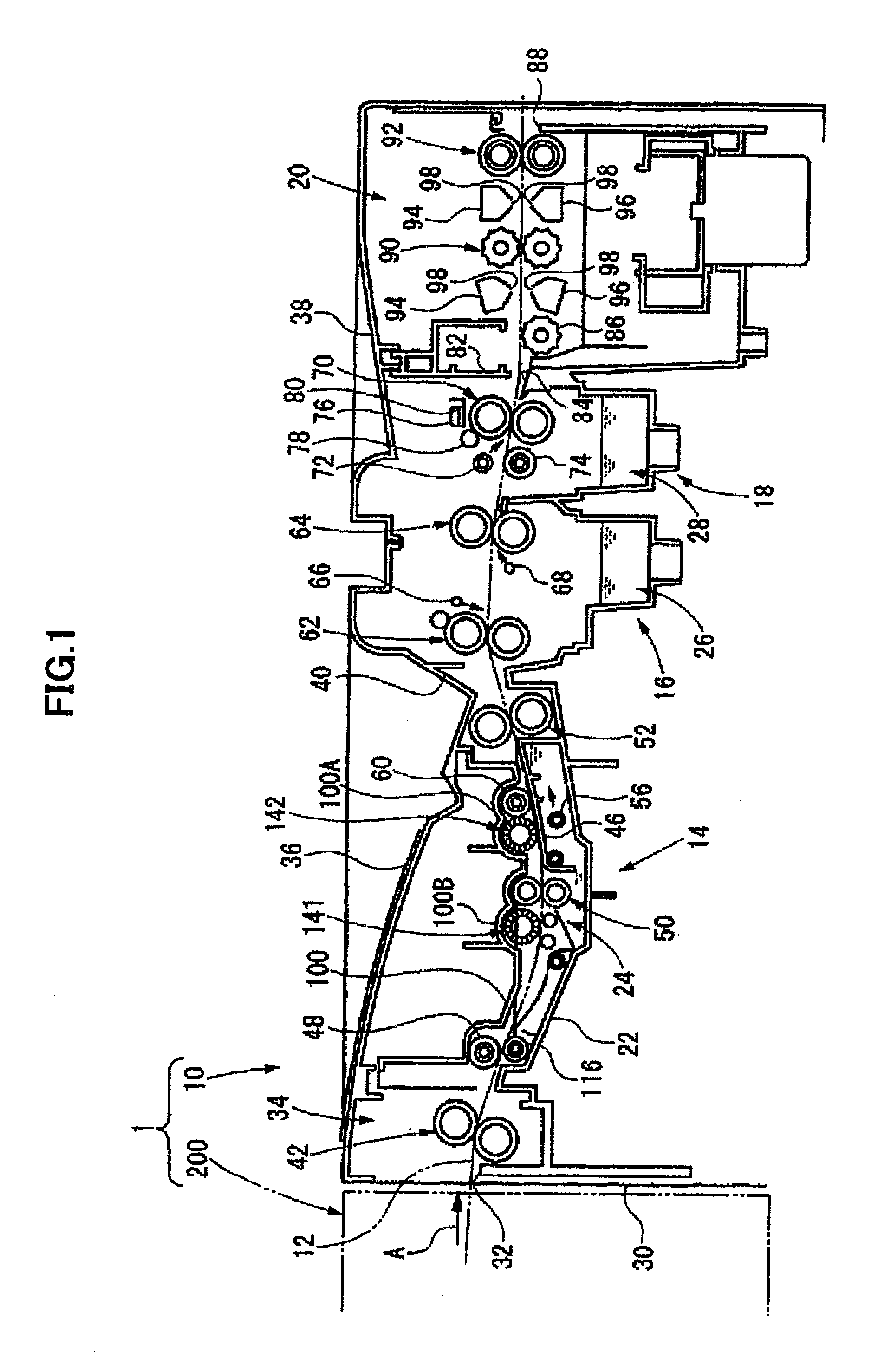

Lithographic printing plate precursor, lithographic printing plate platemaking method, and polymerizable monomer

ActiveUS20110174179A1Excellent chemical resistanceSatisfactory printing durabilityOrganic chemistryOrganic compound preparationImage recordingRadical polymerization

There is provided a lithographic printing plate precursor that enables image recording using a laser and that provides an excellent scumming resistance and an excellent developability while maintaining a satisfactory printing durability. Also provided are a platemaking method, and a novel polymerizable monomer. A lithographic printing plate precursor has a support, and an image recording layer disposed thereon and containing a radical polymerization initiator and a polymerizable monomer that has a sulfonamide group and at least two ethylenically unsaturated groups; a lithographic printing plate platemaking method uses this lithographic printing plate precursor; and a polymerizable monomer has a sulfonamide group and at least two ethylenically unsaturated groups.

Owner:FUJIFILM CORP

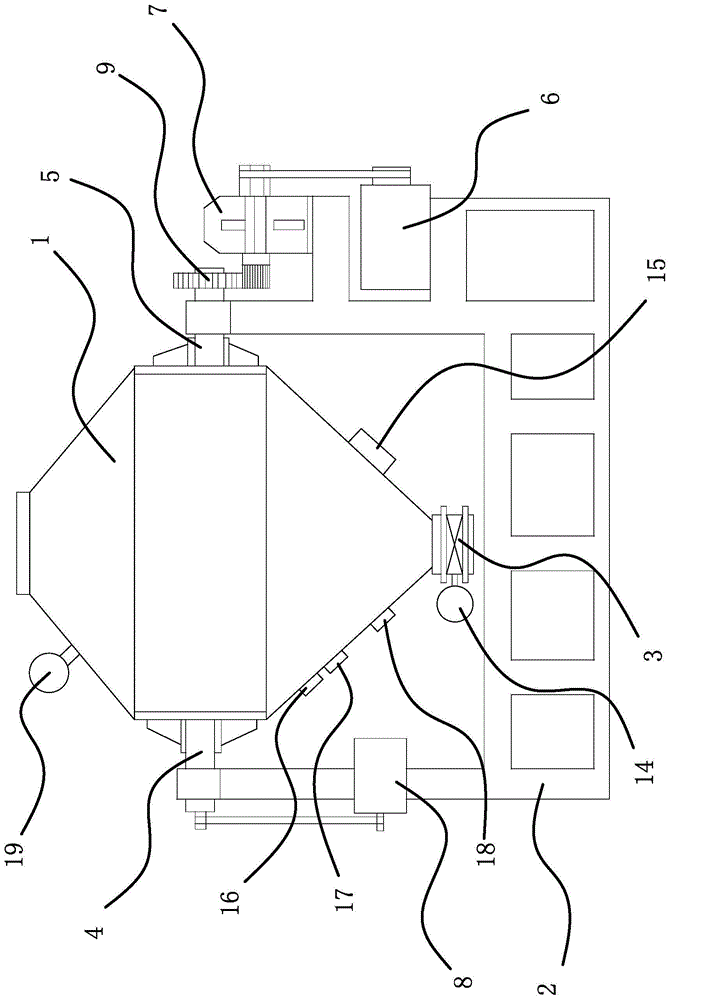

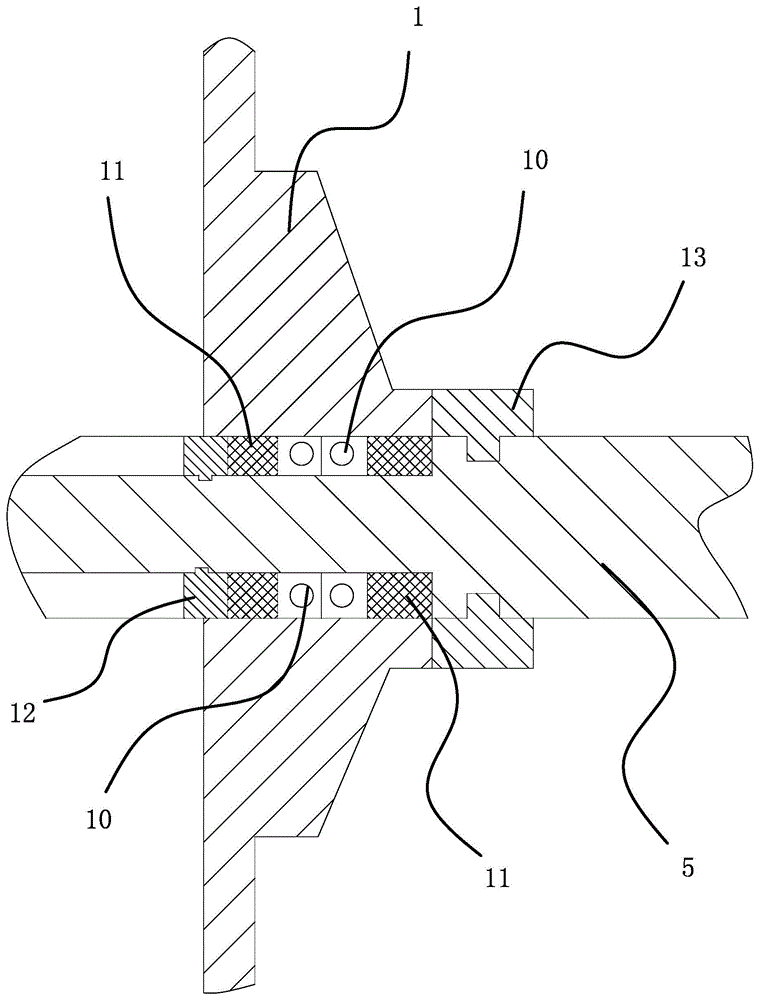

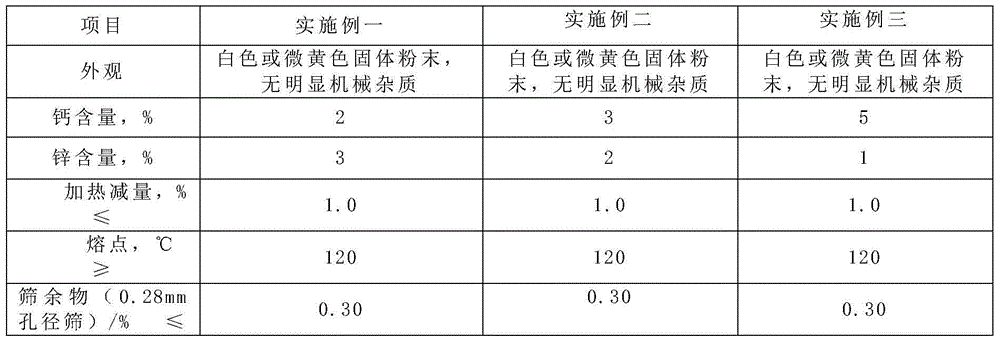

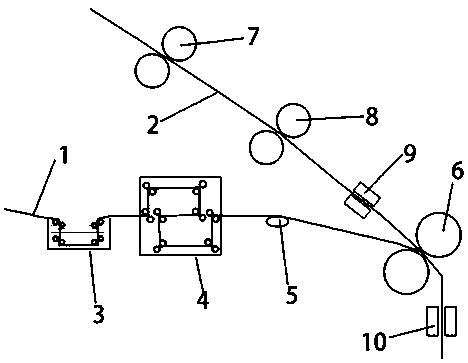

Powder blending technology of PVC reinforcing agent and sealed powder blending machine

The invention provides a powder blending technology of a PVC reinforcing agent and a sealed powder blending machine, which belong to the technical field of chemical industry. The powder blending technology comprises the following steps: mixing 7-10 parts of hydrotalcite, 3-5 parts of zine stearate, 2-3 parts of calcium stearate, 34-40 parts of lubricant and 15-20 parts of calcium carbonate according to the mass part, adding in the sealed powder blending machine, stirring for 40-50 minutes at temperature of 25-35 DEG C, wherein the inward turning of the sealed powder blending machine is 400-450 rotation / minute, and the outward turning is 7-12 rotation / minute. In the sealed powder blending machine, the stirring speed is slow due to stirring at normal temperature, plasticizing phenomenon is not generated, volatilization of the material component can not be effectively controlled, service life of the product is prolonged, and product toughness is increased.

Owner:HAINING LONGDA NEW MATERIAL CO LTD

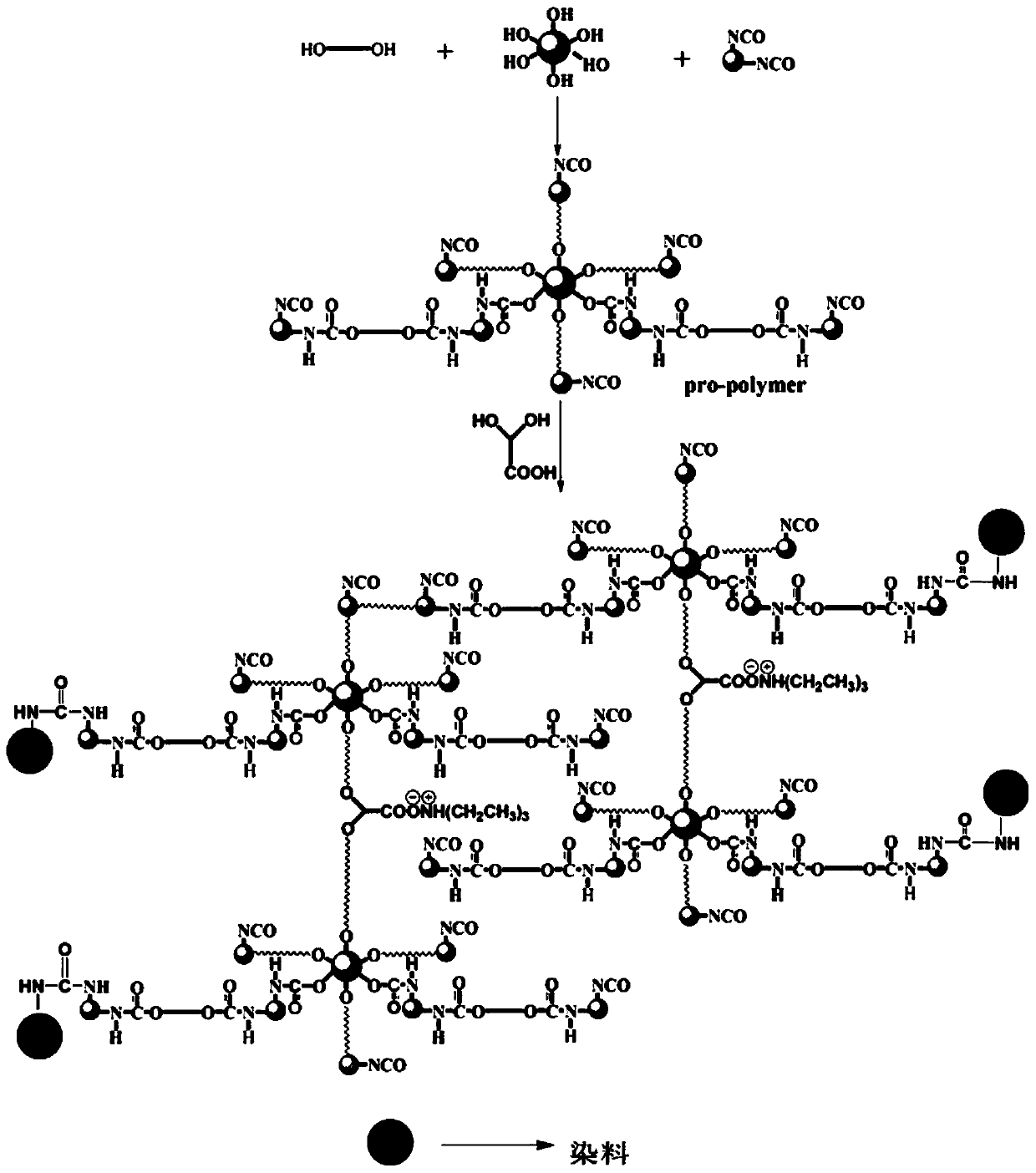

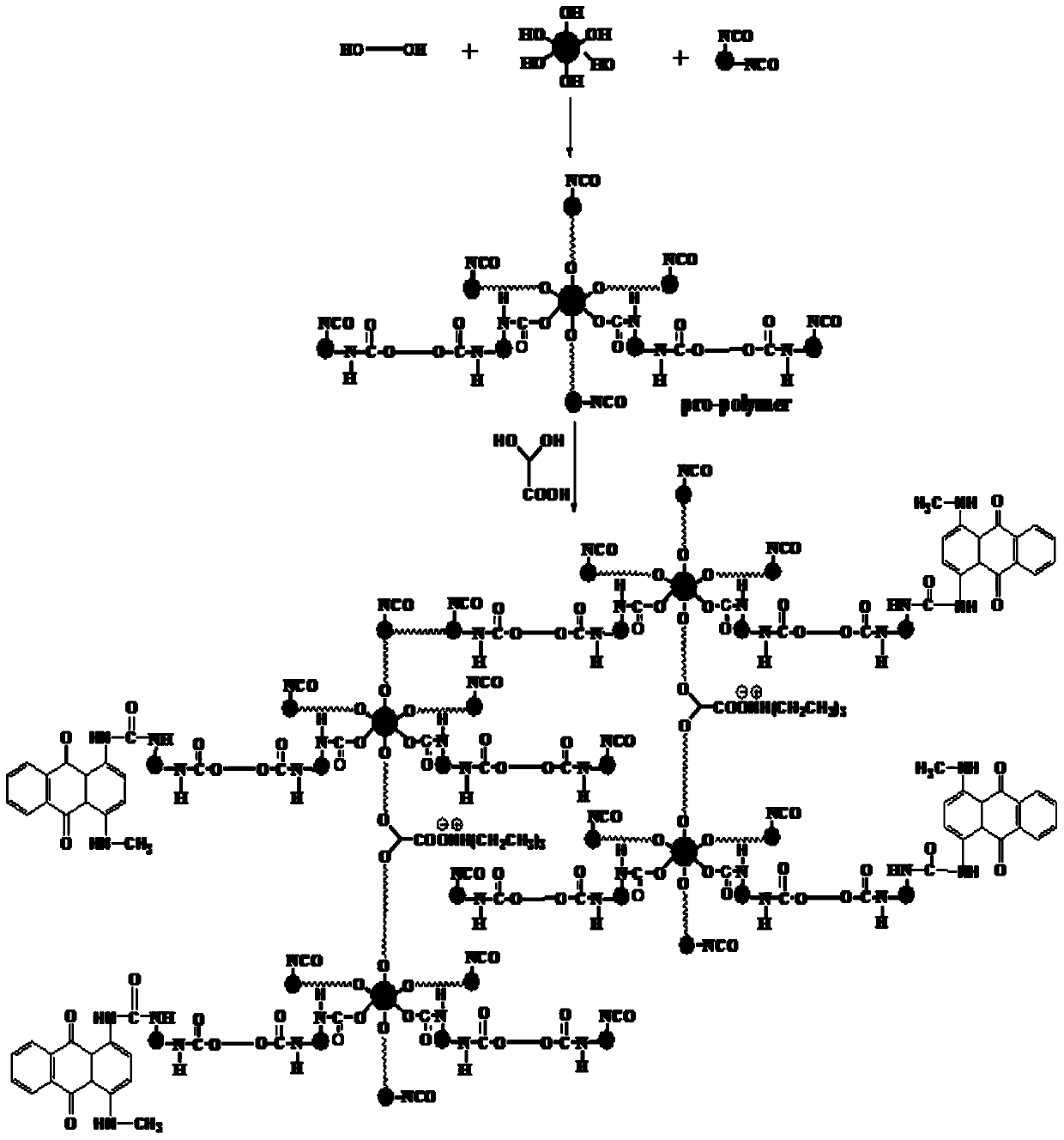

Dendritic waterborne polyurethane-based high-molecular dye and preparation method thereof

The invention discloses a preparation method of a dendritic waterborne polyurethane-based high-molecular dye, a polymer polyol and a dendritic polyester polyol are subjected to dehydration treatment for 2-3 hours under the conditions that the temperature is 100-110 DEG C and the vacuum degree is less than or equal to 0.1 mpa; under the protection of nitrogen, the dendritic polyester polyol, polyisocyanate and a catalyst are sequentially added into a reaction container for reacting for 3-8 hours at the temperature of 90-95 DEG C; the polymer polyol and a solvent are added for reacting at 80-90DEG C for 2-3 hours; a hydrophilic chain extender and a catalyst are added for reacting at 70-80 DEG C for 2-3 hours; a small molecular dye and a solvent are added for reacting for 2-3 hours at the temperature of 60-80 DEG C; after cooling to 30-50 DEG C, a neutralizer is added reacting for 30-60 minutes; a salt forming agent is added, and dispersing is performed for 20-30 minutes at a high speed;and in a rotary evaporator, rotary stirring is performed to remove the solvent at the temperature of 75-80 DEG C to obtain the dendritic waterborne polyurethane-based high-molecular dye the dye; andthe dendritic waterborne polyurethane-based high-molecular dye the dye has the characteristics of high temperature resistance, chemical resistance and corrosion resistance.

Owner:浙江材华科技有限公司

Color modified flame retardant PET (polyethylene terephthalate) and PC (polycarbonate) composite material and preparation method thereof

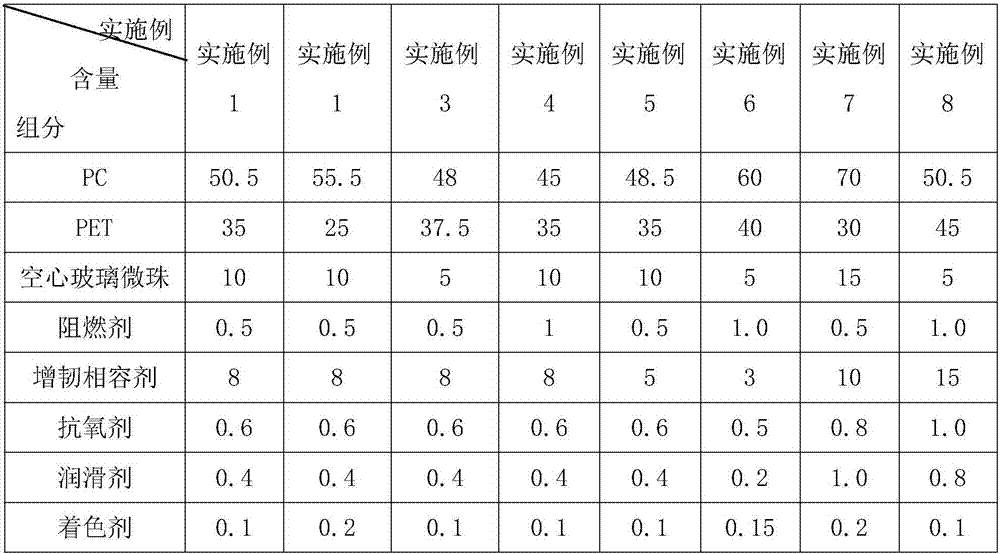

InactiveCN106977893AImprove flame retardant performanceGood compatibilityPolyethylene terephthalatePolyethylene terephthalate glycol

The invention discloses a color modified flame retardant PET (polyethylene terephthalate) and PC (polycarbonate) composite material and a preparation method thereof. The color modified flame retardant PET and PC composite material is prepared from the following raw materials in parts by weight: 45 to 70 parts of PC, 30 to 45 parts of PET, 5 to 15 parts of hollow glass microspheres, 0.5 to 1.0 part of flame retardants, 3 to 15 parts of toughening compatilizers, 0.5 to 1 part of antioxidizers, 0.2 to 1 part of lubricating agents and 0.1 to 0.2 part of coloring agents, wherein the color agents are one or several of anthraquinone organic transparent dyestuff and anthraquinone type organic transparent purple dyestuff. The good flame retardant effect is achieved; meanwhile, good color and transparency are realized.

Owner:NINGBO ZHETIE DAPHOON CHEM

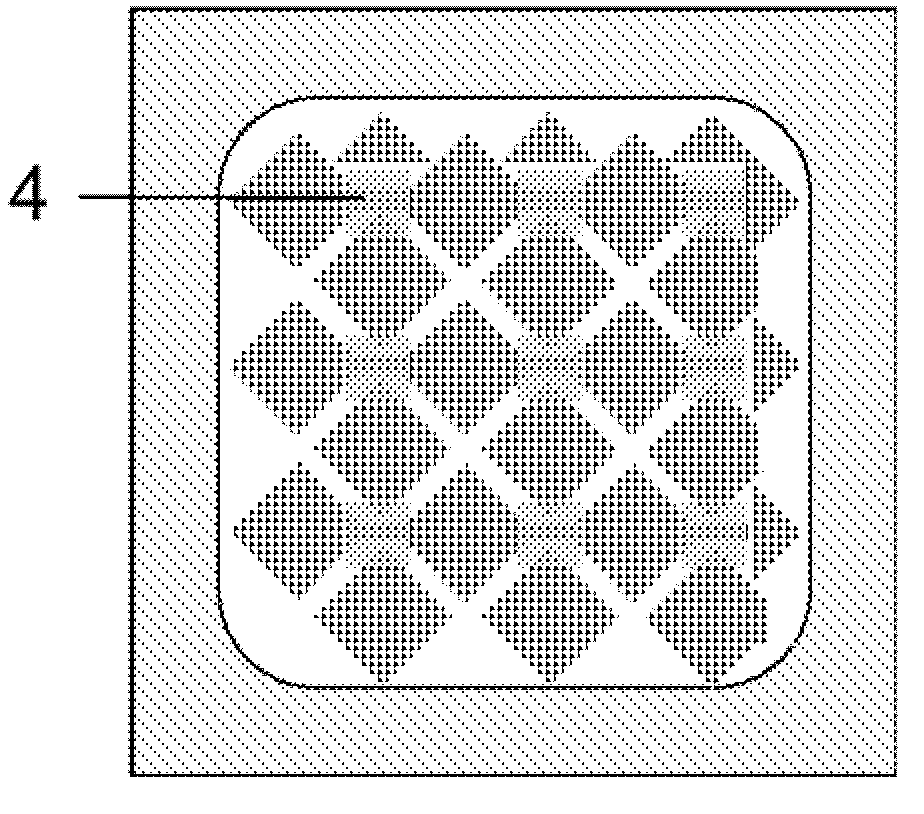

Optical connection structure and optical connection method

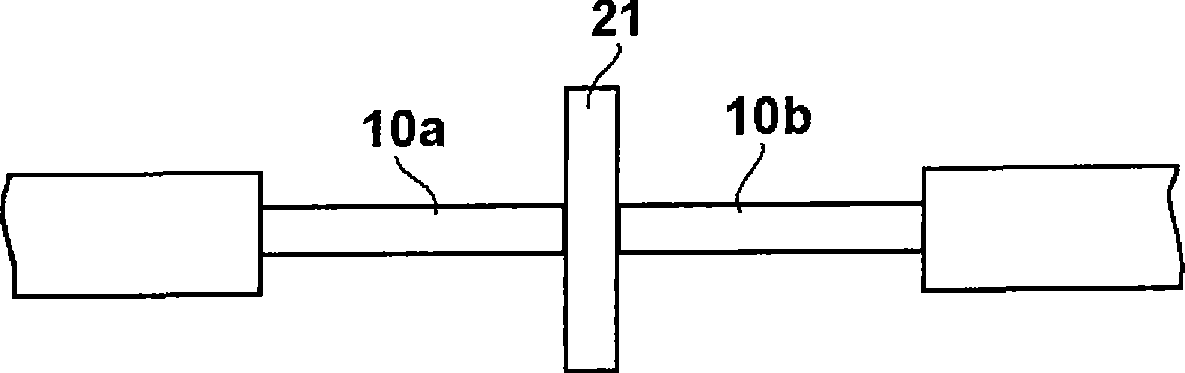

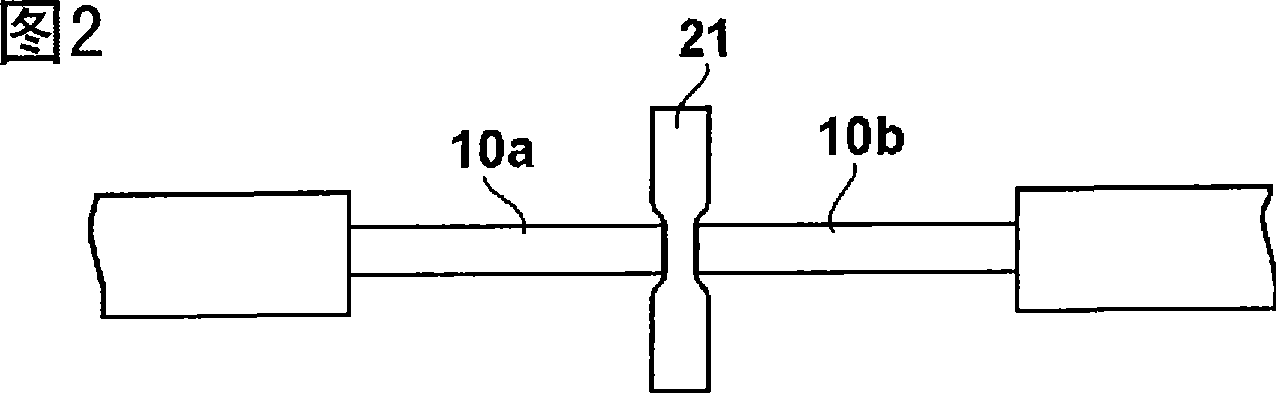

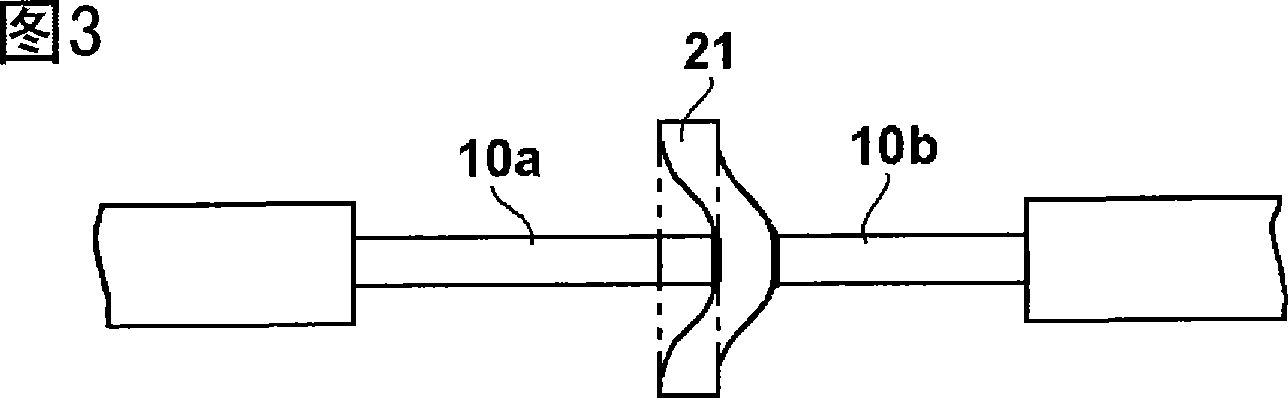

ActiveCN1882861AExcellent heat retentionImprove insulation performanceCoupling light guidesRefractive indexEngineering

There are provided an optical connection structure and an optical connection method capable of holding an optical fiber in a close contact state with a simple structure and easily mounting and detaching the optical fiber while enabling connection having an excellent optical stability. The optical connection structure includes a solid-state adhesive connection member having a refraction factor conformance as a single layer sandwiched between end surfaces of opposing optical transmission media or between the optical transmission media and the optical part. It is preferable that the solid-state adhesive connection member be formed by silicone resin or acryl resin.

Owner:TOMOEGAWA PAPER CO LTD

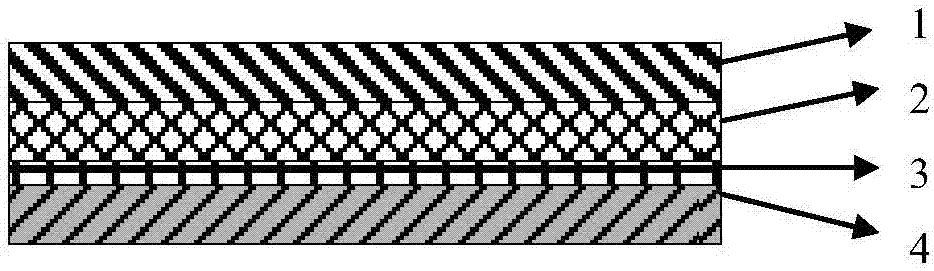

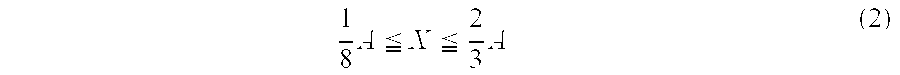

Novel lithium ion battery aluminum plastic soft packaging film

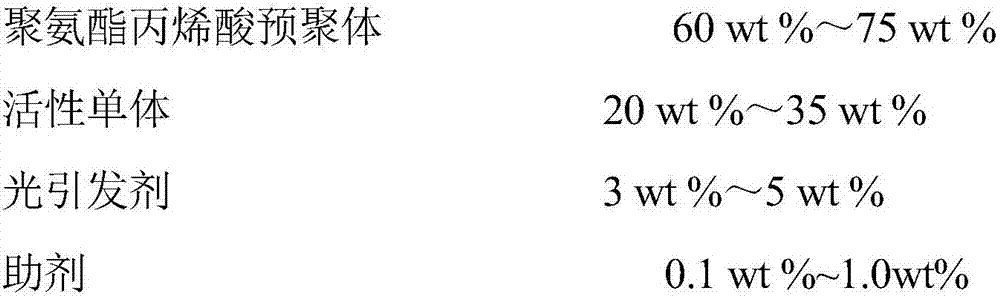

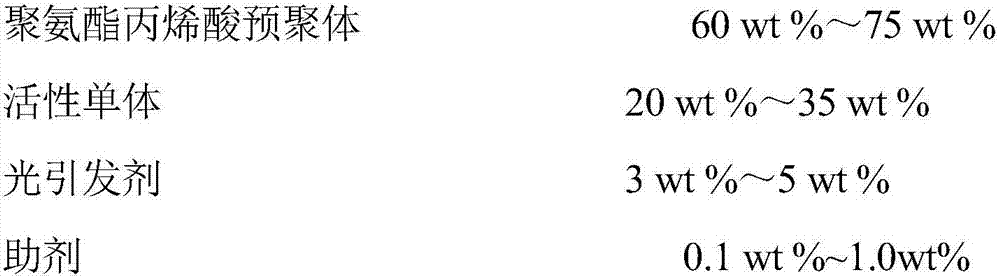

ActiveCN107134547ALayer structure is simpleExcellent chemical resistanceSecondary cellsCell component detailsAdhesive glueChemistry

The invention relates to a novel lithium ion battery aluminum plastic soft packaging film which is sequentially provided with a heat-tolerant protection layer, an aluminum foil layer, an adhesive glue layer and a thermoplastic resin film layer from outside to inside. Polyurethane-acrylate ultraviolet curing paint is cured through ultraviolet light to form a coating which is provided with the heat-tolerant protection layer, the polyurethane-acrylate ultraviolet curing paint comprises, in weight percentage, 60wt%-75wt% of polyurethane-acrylate pre-polymers, 20wt%-35wt% of active monomers, 3wt%-5wt% of photo-initiators and 0.1wt%-1.0wt% of additives. A heat-tolerant resin layer of the aluminum plastic soft packaging film is a polyurethane-acrylate resin layer cured by the ultraviolet light, the aluminum foil layer is directly coated with the heat-tolerant resin layer, use of the adhesive glue layer is decreased, and an interlayer structure of the aluminum plastic soft packaging film is simpler.

Owner:乐凯胶片股份有限公司

Preparation method of water-based adhesive for paper products

InactiveCN108531113AHigh strength chemical resistanceExcellent chemical resistanceNon-macromolecular adhesive additivesGraft polymer adhesivesPrepolymerSolvent

The invention discloses a preparation method of water-based adhesive for paper products, belonging to the technical field of chemical supplies. According to the preparation method, toluene diisocyanate, poly(caprolactone)diol and dimethylolpropionic acid are used as main raw materials; a molecular chain of epoxy resin contains secondary hydroxyl groups and epoxy groups which can react with -NCO groups, the residual -NCO groups in a polyurethane prepolymer are enabled to react with the secondary hydroxyl groups on epoxy resin molecules, and the epoxy resin is grafted on polyurethane molecules,so that the water resistance and solvent resistance of the aqueous polyurethane are improved; furthermore, hydrophobic acrylate is also introduced into polyurethane segments; by means of acrylate modification, the crosslinking degree of the system is improved, and the water resistance of the waterborne polyurethane is improved. The preparation method provided by the invention solves the problem that most of the traditional water-based adhesive adopts water-based polyurethane at present, and the molecular chain of the water-based polyurethane contains ionic groups, has a linear structure and isseldom cross-linked and branched, so that the traditional water-based adhesive is poor in chemical resistance and water resistance.

Owner:张剑

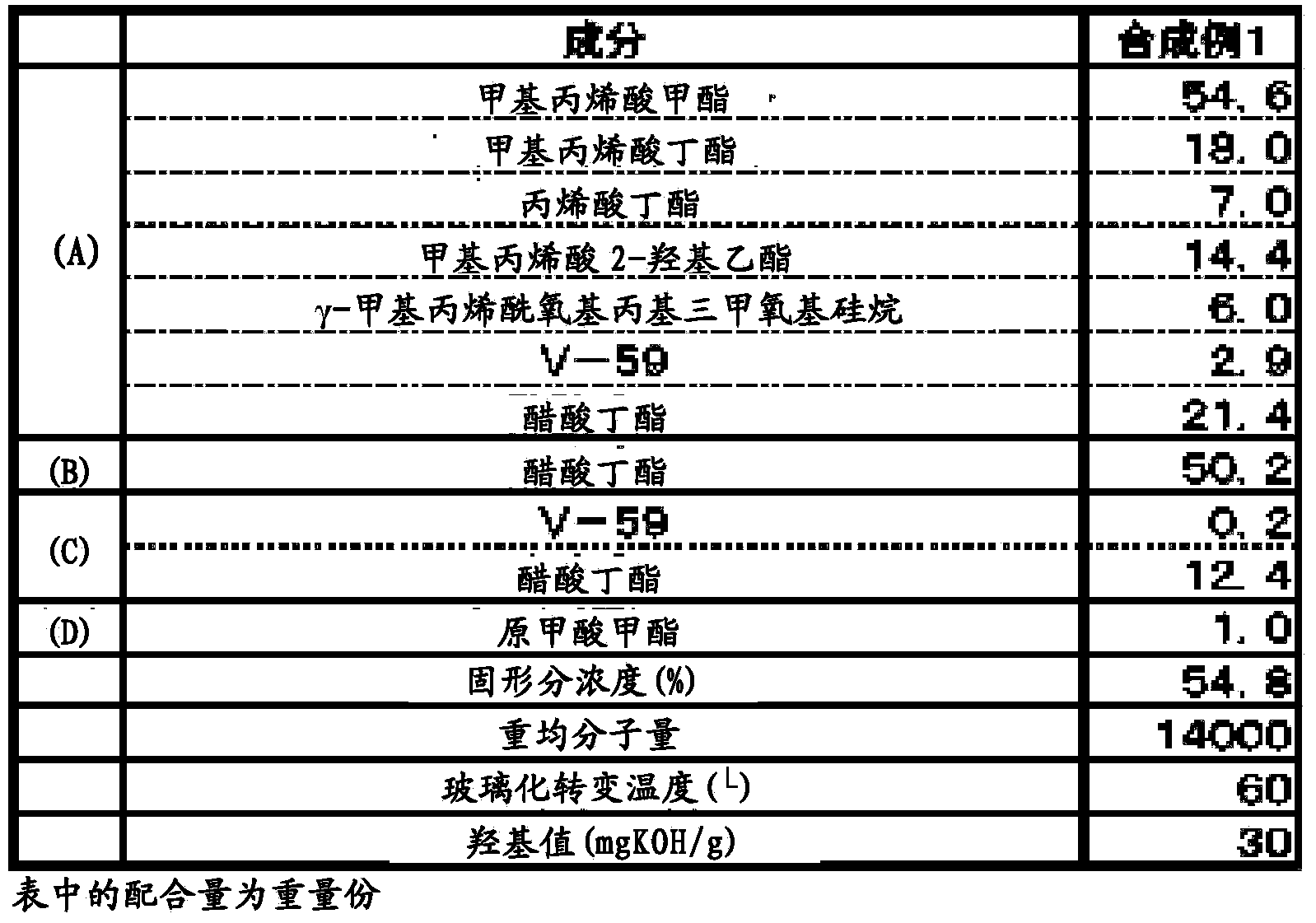

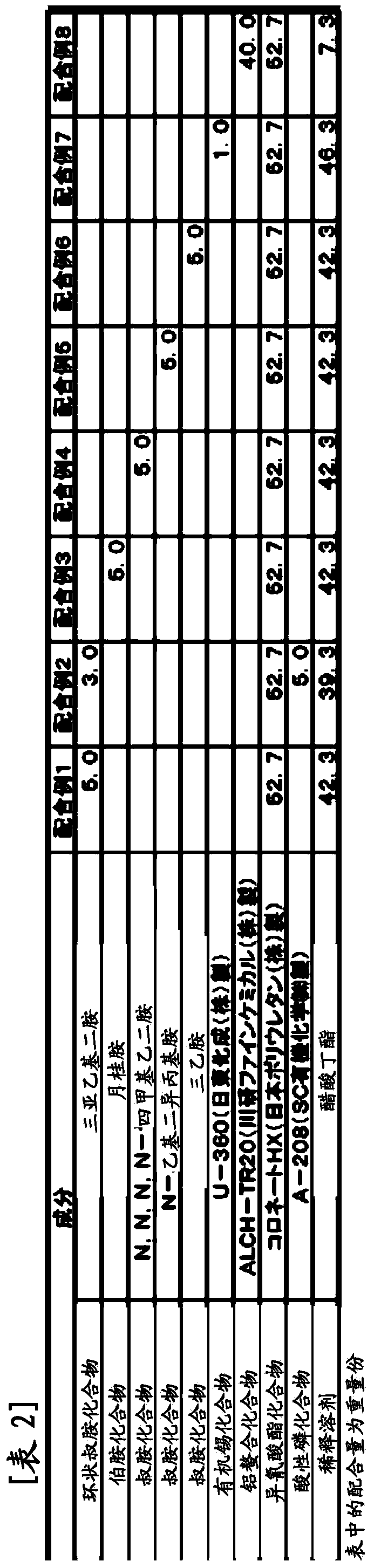

Multiple-package curable coating material composition, method for forming coating film, and coated article

InactiveCN103459528AExcellent chemical resistanceExcellent adhesionLiquid surface applicatorsPolyurea/polyurethane coatingsIsocyanate compoundAcrylic resin

The purpose of the present invention is to provide a multiple-package curable coating material composition which is capable of forming a coating film that has excellent chemical resistance, excellent non-adhesiveness, good adhesion, good processability and good appearance at the same time. A multiple-package curable coating material composition of the present invention is composed of (1) an acrylic resin coating material and (2) a curing agent. This multiple-package curable coating material composition is characterized in that: (1) the acrylic resin coating material has a coating film-forming component that contains a vinyl copolymer (A) having a hydroxyl group, and the vinyl copolymer (A) having a hydroxyl group additionally has a hydrolyzable silyl group; and (2) the curing agent contains an isocyanate compound (B) and a cyclic tertiary amine compound (C) that does not have an active hydrogen group.

Owner:KANEKA CORP

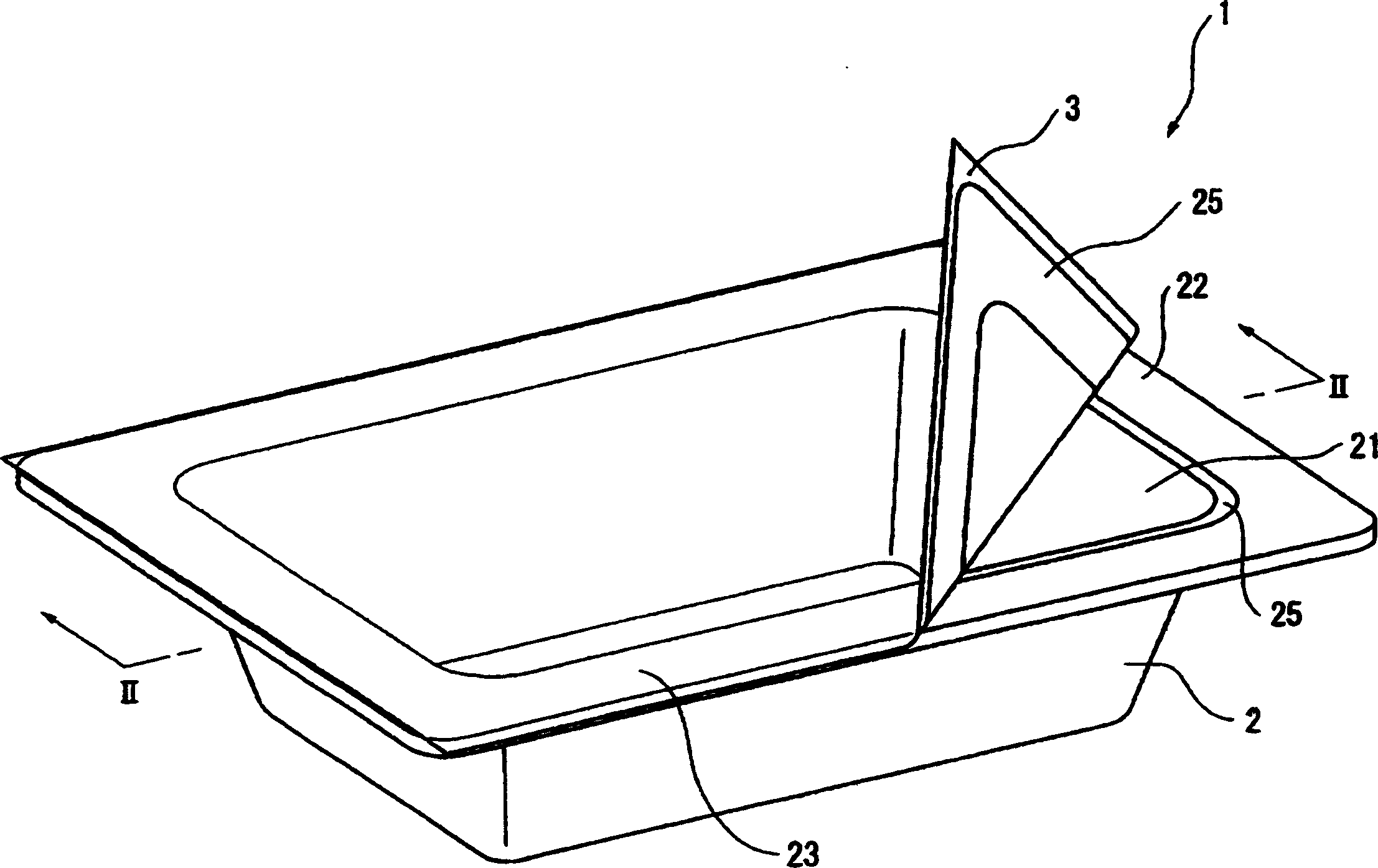

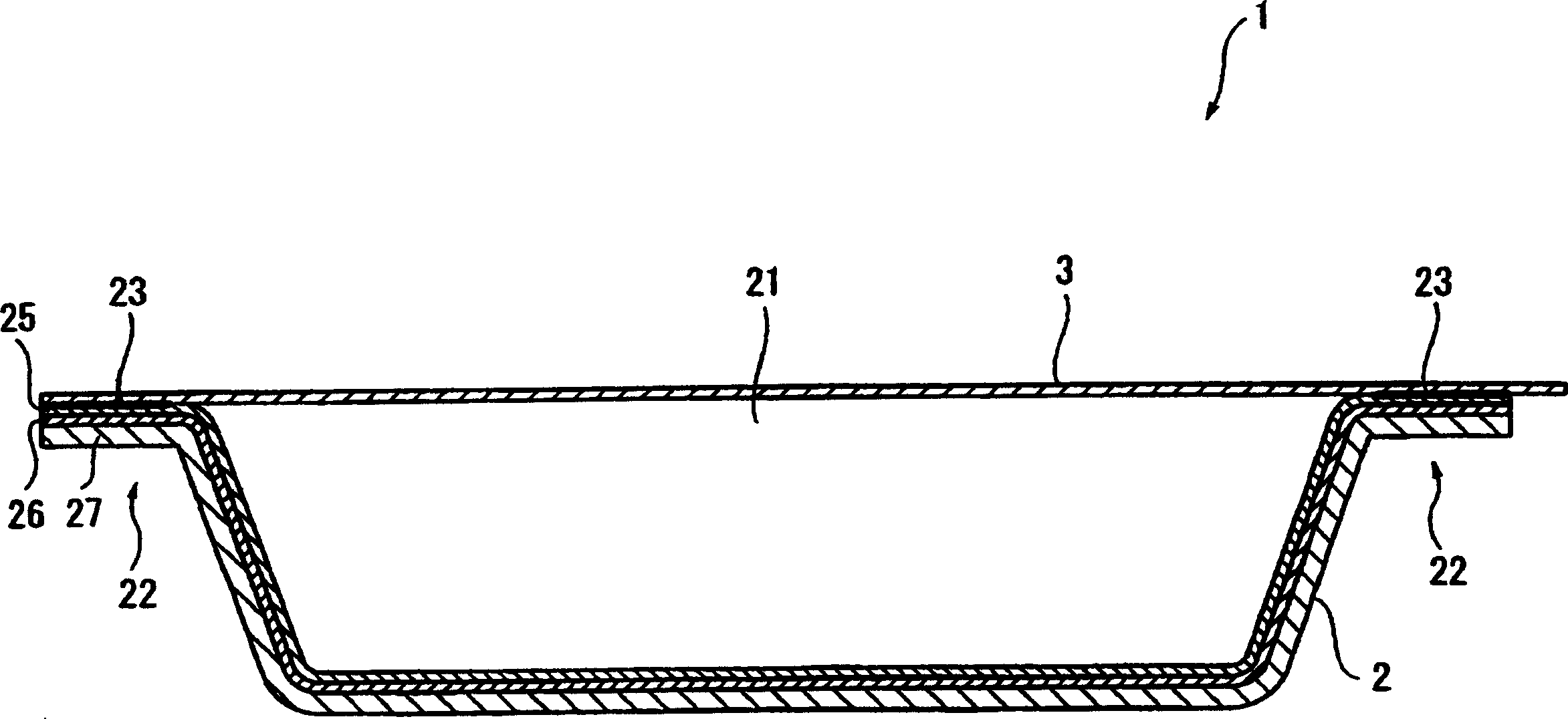

Packaging body for sterilization

InactiveCN1890162AEasy to openExcellent chemical resistanceFlexible coversWrappersTemperature treatmentBiomedical engineering

A packaging body for sterilization selectable with an emphasis placed on the heat sealability thereof with a sheet for sterilization without limiting the selection of a thermoplastic resin forming the innermost layer of a multi-layer packaging body unit. In a sterilization treatment, the packaging body for sterilization can sufficiently cope with a high temperature treatment such as a steam treatment, and there are no possibilities of the adhesion and the stain of an adhesive agent thereonto in the high temperature treatment. The packaging body is formed by heat-sealing the multi-layer packaging body unit (2) formed of the thermoplastic resin to the sheet (3) for sterilization. The packaging body (1) for sterilization is characterized in that when the sheet (3) for sterilization is peeled off from the multi-layer packaging body unit (2) for unsealing, the layers of the multi-layer packaging body unit (2) including at least the innermost layer (25) are moved to the sheet (3) for sterilization and peeled off.

Owner:IDEMITSU UNITECH CO LTD

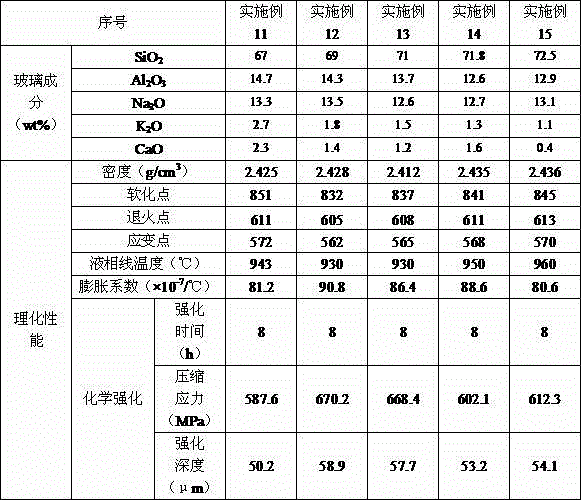

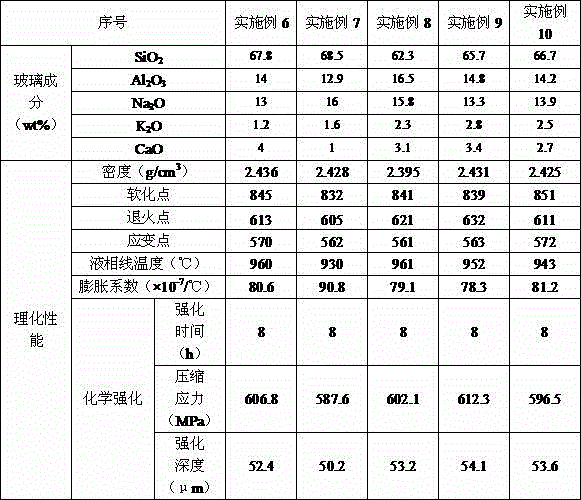

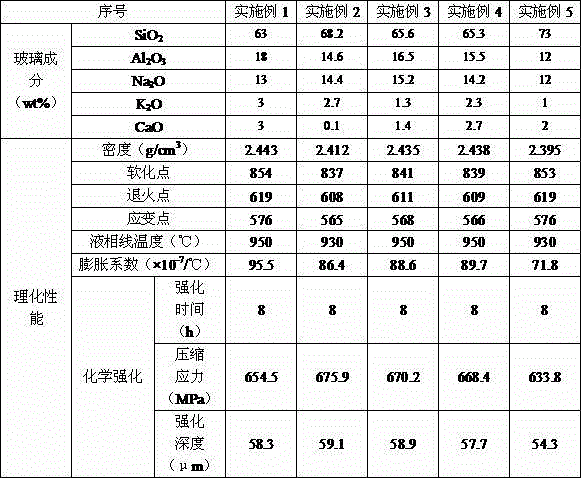

Prescription of cover plate glass for light touch screen

The invention discloses a prescription of a cover plate glass for a light touch screen. Experiments show that the major ingredients of the cover plate glass contain SiO2, Al2O3, Na2O, K2O and CaO, for the glass prepared according to the prescription provided by the invention, the aim of improving the coefficient of thermal expansion is realized by regulating the contents of the ingredients in the prescription, and simultaneously, improving the coefficient of thermal expansion of the glass by using the large proportion of metals containing Ba and Sr is avoided; in the prescription provided by the invention, CaO is selected instead of MgO, the MgO is not added, devitrification tendency of the glass can be lowered, the high-temperature viscosity can be lowered, melting is facilitated, and after being enhanced chemically, the glass can effectively prevent the impact and the scratch damage to the protective screen surface of the touch products, and prolong the service life of the products with touch screens.

Owner:TUNGHSU GRP

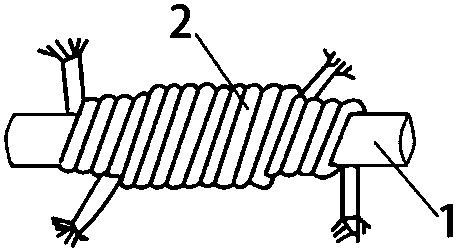

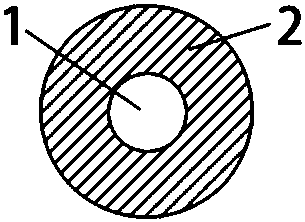

Pre-oxidized fiber core spun yarn and manufacturing method thereof

ActiveCN110453330AImprove flame retardant performanceImprove thermal stabilityFibre typesConjugated synthetic polymer artificial filamentsTextile technologyFiltration

The invention discloses a pre-oxidized fiber core spun yarn and a manufacturing method thereof, and belongs to the technical field of textiles. The manufacturing method of the pre-oxidized fiber corespun yarn comprises the following steps that common polyacrylonitrile resin is mixed with high-isotacticity polyacrylonitrile resin to obtain mixed resin; the mixed resin and dimethylformamide are placed under a high temperature condition for mixing, then filtration is carried out, and a spinning solution is obtained; firstly, the spinning solution is treated into a nascent fiber, and pre-oxidation treatment and spinning processing are performed in sequence to obtain a pre-oxidized filament; then, after a gelatin sizing agent is used for performing sizing pretreatment on the pre-oxidized filament, drying treatment is carried out; finally, a staple fiber rough yarn is used for wrapping the dried pre-oxidized filament, twisting and desizing are carried out in sequence, and the pre-oxidized fiber core spun yarn can be obtained. The obtained pre-oxidized fiber core spun yarn not only has high flame retardancy and excellent thermal stability, but also has higher mechanical strength and suitable textile processing performance.

Owner:义乌市恒达织带有限公司 +1

Preparation method of water-base alicyclic isocyanate modified polyester light-cured resin

ActiveCN105713178AGood storage stabilityImprove wear resistancePolyurea/polyurethane coatingsWater basedDimethylaniline N-oxide

The invention relates to a preparation method of a water-base alicyclic isocyanate modified polyester light-cured resin. The water-base alicyclic isocyanate modified polyester light-cured resin is prepared from 1 to 3% of a hyperbranched polyester, 5 to 12% of an acrylic monomer containing hydroxyl, 10 to 18% of an alicyclic isocyanate monomer, 0.02 to 0.3% of dibutyltin dilaurate, 10 to 20% of maleic anhydride, 4 to 10% of N,N-dimethylaniline, 3 to 5% of sodium hydroxide, and 40 to 65% of deionized water; wherein the hyperbranched polyester is obtained via synthesis of DMPA with TMP in the presence of a catalyst. The water-base alicyclic isocyanate modified polyester light-cured resin possesses excellent storage stability; coating films obtained under action of a photoinitiator possesses excellent water resistance, hardness, aging resistance, chemical resistance, and stain resistance, high glossiness, excellent wear resistance, high adhesive force, high fullness, and excellent impact resistance. The water-base alicyclic isocyanate modified polyester light-cured resin can be widely applied to surface radiation coating and protection of wood, metal, zinc alloy, aluminium alloy, magnesium alloy, and plastic products.

Owner:揭阳市万美塑料粉沫有限公司

Modified polyoxyalkylene polyamine

A modified polyoxyalkylene polyamine obtained by addition reaction of a polyoxyalkylene polyamine and an alkenyl group-containing compound has a low viscosity and it provides, when used as a curing agent for epoxy resin, an epoxy resin composition which can provide an epoxy resin cured product having excellent chemical resistance.

Owner:MITSUBISHI GAS CHEM CO INC

Heat-curable coloring composition, cured film, touch panel provided with said cured film, and method for producing touch panel using said heat-curable coloring composition

ActiveCN104822771AGood heat resistanceExcellent chemical resistanceSemiconductor/solid-state device manufacturingInput/output processes for data processingTouch panelPhthalocyanine

The objective of the present invention is to provide a heat-curable coloring composition having superior chemical resistance while having high heat resistance, and that is such that cissing problems do not arise even if a common light-sensitive transparent material or the like is applied to a formed cured film. The heat-curable coloring composition contains: (A) an inorganic pigment or a phthalocyanine pigment, (B) a polysiloxane obtained from the co-hydrolysis-condensation of alkoxy silane compounds including a specific range of compounds, and (C) an organic solvent.

Owner:TORAY IND INC

Protective paint for power equipment and preparation method thereof

InactiveCN107245272AImprove heat resistanceGood chemical resistanceFireproof paintsAnti-corrosive paintsPower equipmentElectric power

The invention discloses protective paint for power equipment and belongs to the technical field of protective paint. The protective paint is prepared from the following raw materials in parts by weight: 30 to 40 parts of fluorocarbon resin, 12 to 15 parts of amino resin, 20 to 30 parts of silicon resin, 1 to 2 parts of bentonite, 3 to 5 parts of aluminum powder, 5 to 8 parts of titanium boride, 8 to 10 parts of aluminum triphosphate, 6 to 9 parts of nano silicon dioxide, 3 to 5 parts of nano montmorillonite, 1 to 2 parts of titanium dioxide, 1 to 2 parts of defoaming agent, 0.5 to 0.8 part of flatting agent, 3 to 4 parts of dispersing agent, 1 to 3 parts of corrosion inhibitor and 10 to 20 parts of water. The invention further discloses a preparation method of the protective paint for the power equipment. The protective paint disclosed by the invention has strong adhesive ability, rust prevention, high temperature resistance and corrosion resistance and can effectively protect the outdoor power equipment.

Owner:合肥市闵葵电力工程有限公司

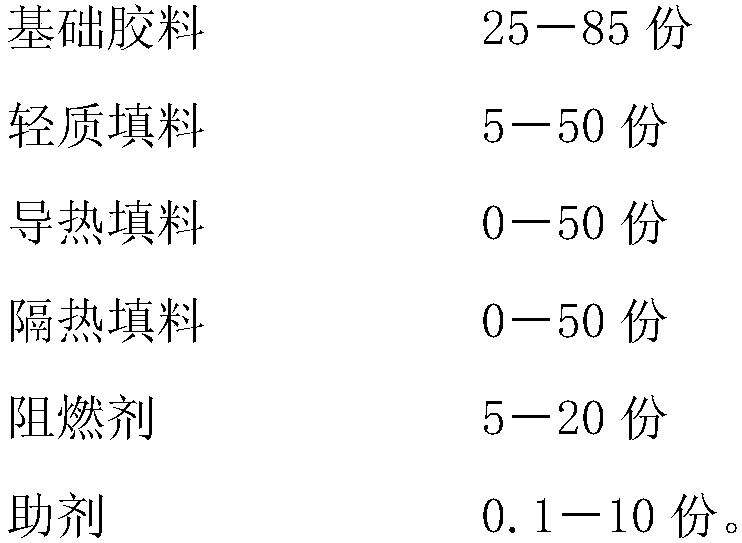

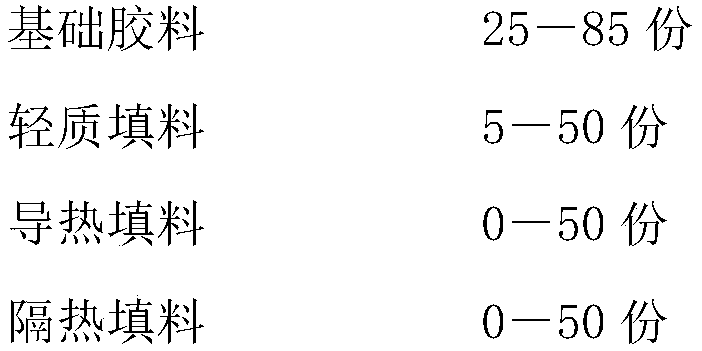

Light polyurethane-polyurea pouring sealant and preparation method thereof

InactiveCN108192558AExcellent chemical resistanceHigh compressive strengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyureaSealant

The invention relates to the technical field of polyurethane and polyurea, in particular to a light polyurethane-polyurea pouring sealant and a preparation method thereof. The polyurethane-polyurea pouring sealant disclosed by the invention has the comprehensive performance of light weight (less than or equal to 1.0g / cm<3>), superior chemical tolerance, heat conductivity or heat insulation property, flame retardance, light weight and the like. By adopting light filler which has higher compressive strength, permanent deformation caused by a foaming material can be effectively lowered.

Owner:苏州聚联电子材料有限公司

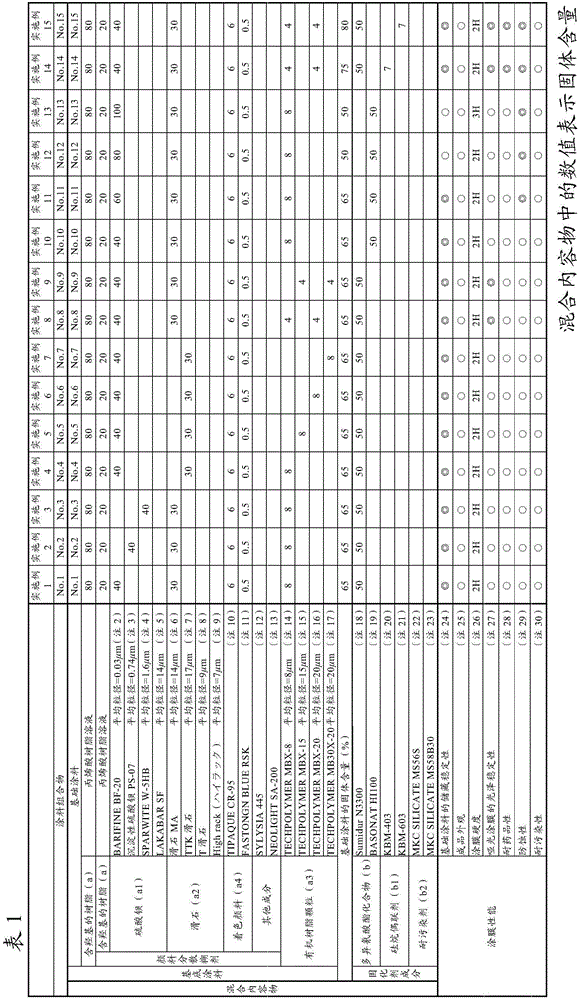

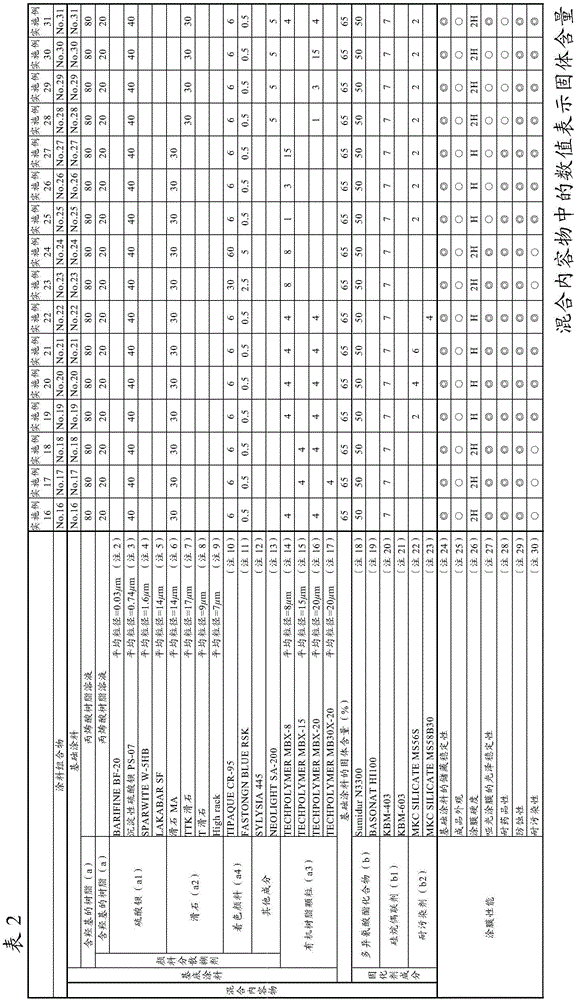

Coating composite

ActiveCN106519938AExcellent chemical resistanceGood corrosion resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsIsocyanateTalc

The invention relates to a coating composite capable of forming a coating film with excellent finished product appearance, coating hardness, gloss stability of low-gloss coating, drug-resistance and erosion-resistance. The coating composite contains hydroxyl-containing resin (a), barium sulfate (a1) with an average particle size of 0.01-2.0[mu]m, soapstone (a2) with an average particle size of over 10 [mu]m, organic resin particles (a3) and coloring pigment (a4) and a polyisocyanate compound (b). With the solid content of the hydroxyl-containing resin (a) as the reference of 100 mass parts, the coating composite contains 1-130 mass parts of barium sulfate (a1), 1-50 mass parts of soapstone (a2), 0.1-20 mass parts of organic resin particles (a3), 1-100 mass parts of coloring pigment (a4) and 10-60 mass parts of polyisocyanate compound (b).

Owner:KANSAI PAINT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com