Preparation method of hydroxy acrylic resin for recoatable polyurethane coating

A technology of hydroxyacrylic and polyurethane coatings, which is applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems that do not involve resin synthesis, etc., and achieve the effects of good chemical resistance, wide use, and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

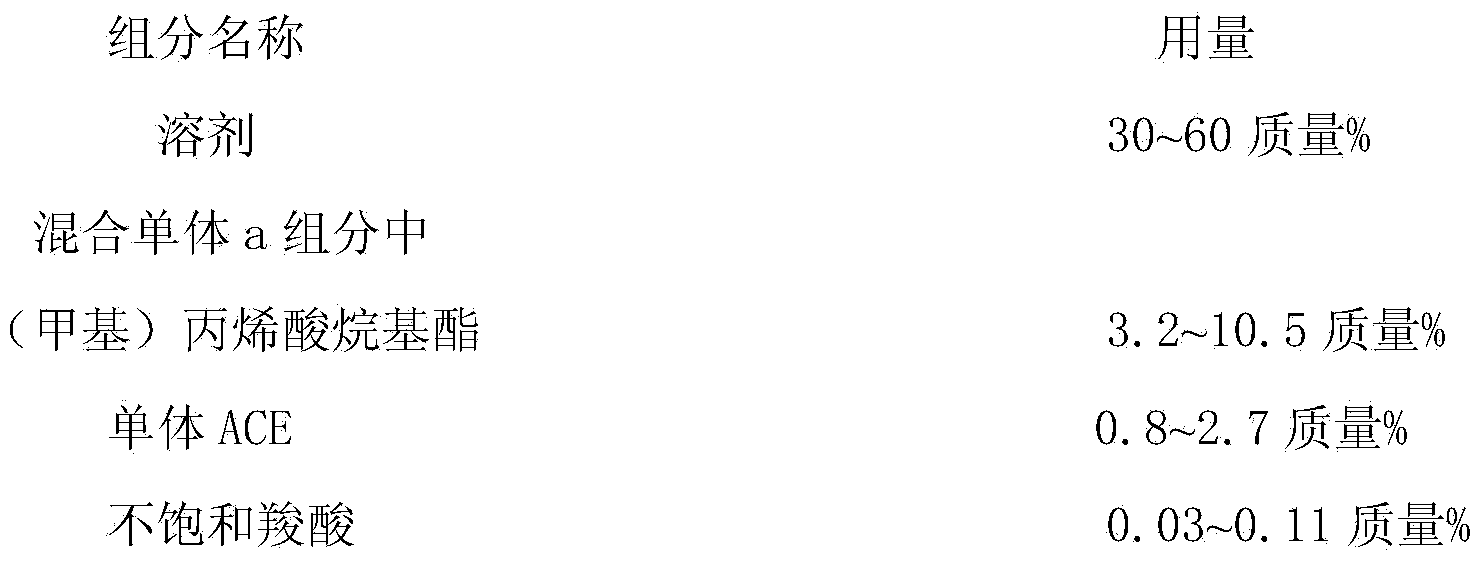

Method used

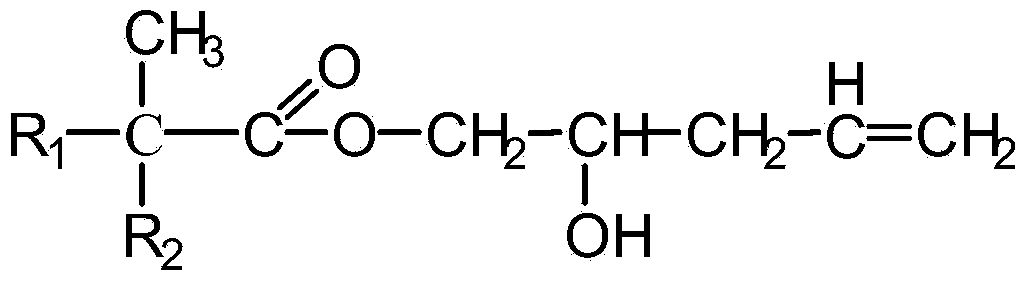

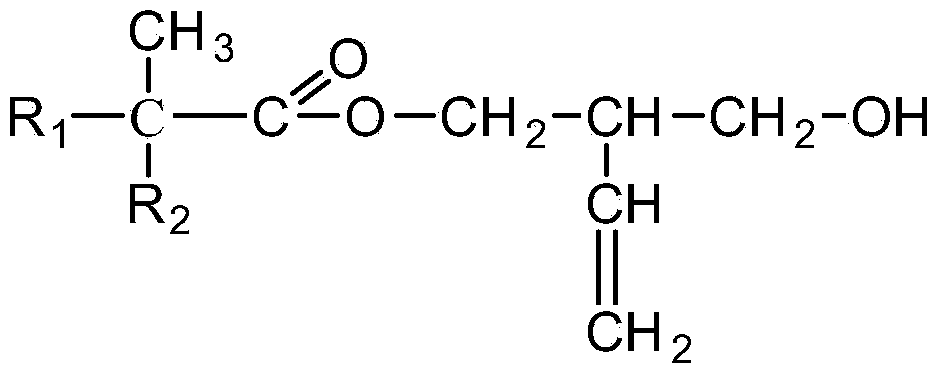

Image

Examples

Embodiment 1

[0037] Add 770g of glycidyl tert-carbonate, 4g of trinonylphenyl phosphite, and 0.5g of stannous octoate into the reactor, heat it to 90°C, keep it warm for 30 minutes, raise the temperature to 105-110°C, and start adding 227g of acrylic acid dropwise. 0.1g of p-hydroxyanisole mixture, control the dropping rate uniformly, and drop it in about 1 hour. After dripping, keep warm for 2 to 3 hours, and measure the acid value. If the acid value is higher than 5 mgKOH / g, the temperature is raised to 120° C. until the acid value is lower than 5 mgKOH / g, then the reaction is terminated to obtain the product monomer ACE.

Embodiment 2

[0039]Add 200g of xylene into the reactor, blow nitrogen, stir and raise the temperature to 126-132°C, start to drop 17.5g of butyl acrylate, 31.2g of methyl methacrylate, and 10.5g of the monomer ACE prepared in Example 1 , a mixture of 0.4g acrylic acid and 0.4g tert-butyl peroxybenzoate, control the dropping speed evenly, finish dropping the mixture in about 40 minutes, and start adding 87.7g butyl acrylate and 156g methyl methacrylate dropwise immediately after dropping , 37.6g hydroxyethyl acrylate, the mixture of monomer ACE, 2g acrylic acid and 2g tert-butyl peroxybenzoate prepared in 53.5g embodiment 1, dropwise at a constant speed, dropwise in 3 hours, after insulation for 1 hour , add 1.2g tert-butyl peroxybenzoate, continue to keep warm for 2-3 hours, cool down to 80°C, add 200g xylene to dilute, stir and disperse to obtain colorless and transparent hydroxyacrylic resin. The parameter index of embodiment 1 sees the following table:

[0040] Table 1

[0041] ...

Embodiment 3

[0043] Add 200g of xylene into the reactor, blow nitrogen, stir and raise the temperature to 126-132°C, start to add dropwise 18g of butyl acrylate, 30g of methyl methacrylate, 10.5g of the monomer ACE prepared in Example 1, 0.4 The mixture of 1g acrylic acid and 0.4g tert-butyl peroxybenzoate, control the dropping rate uniformly, drop the mixture in about 40 minutes, start to drop 90g butyl acrylate, 150g methyl methacrylate, 42g acrylic acid immediately after dropping Hydroxypropyl ester, the monomer ACE that 53.5g embodiment 1 makes, the mixture of 2g acrylic acid and 2g tert-butyl peroxybenzoate, add dropwise at a constant speed, finish dripping in 3 hours, after keeping warm for 1 hour, add 1.2 g tert-butyl peroxybenzoate, continue to keep warm for 2 to 3 hours, cool down to 80°C, add 200g xylene to dilute, stir and disperse to obtain a colorless and transparent hydroxyacrylic resin. The parameter index of embodiment 2 sees the following table:

[0044] Table 2

[0045]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solid acid value | aaaaa | aaaaa |

| Solid acid value | aaaaa | aaaaa |

| Solid acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com