Patents

Literature

89results about How to "Low flexibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

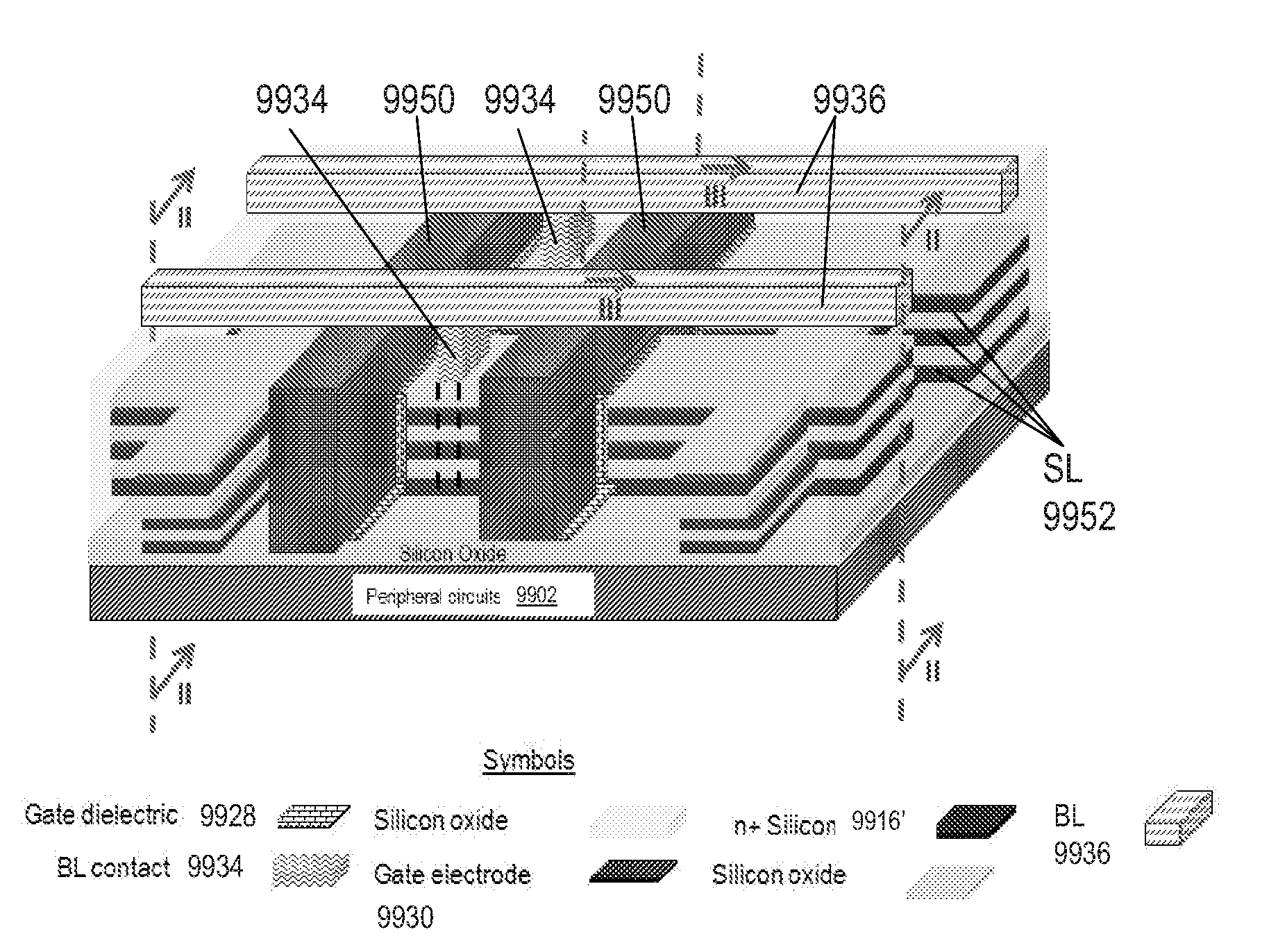

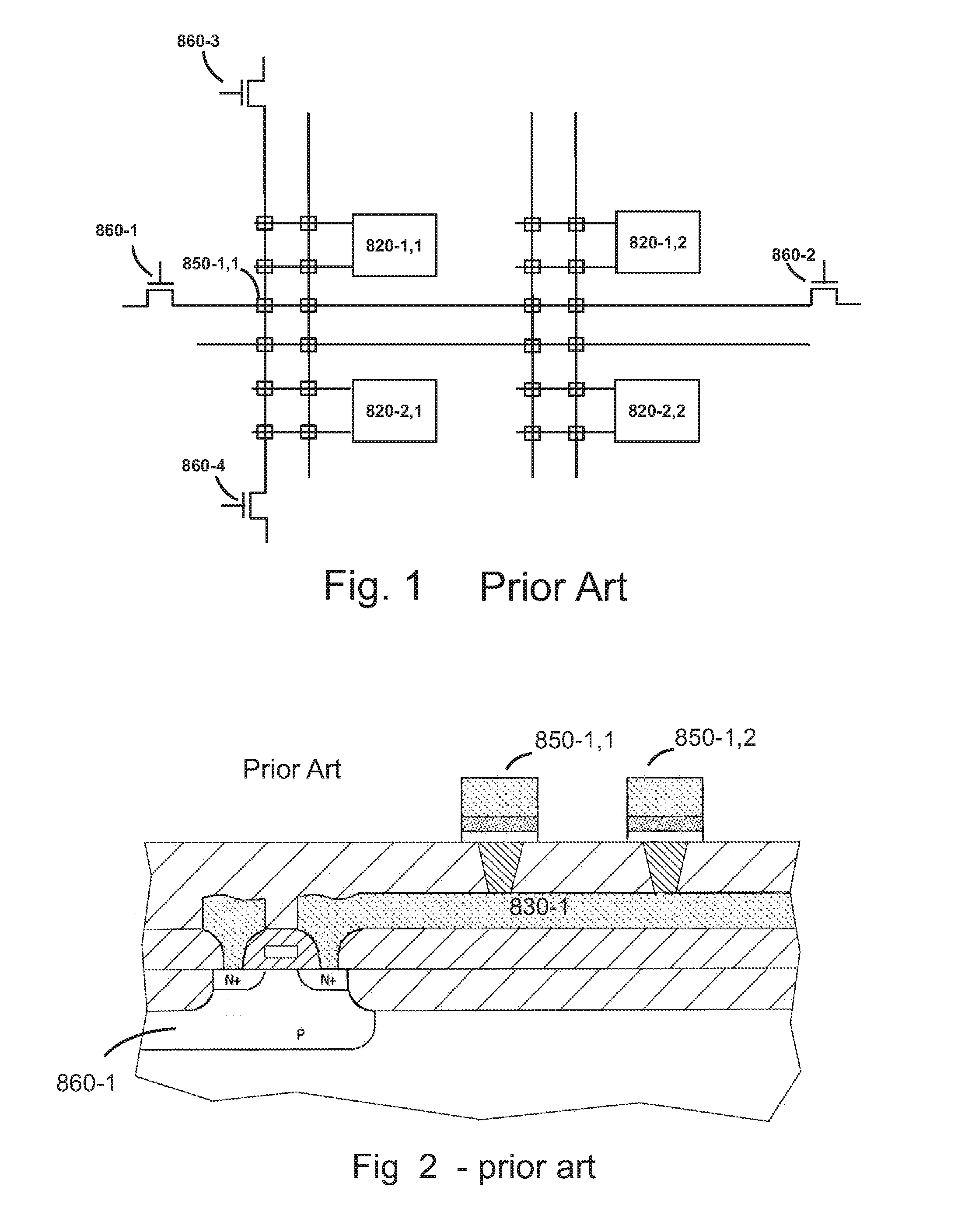

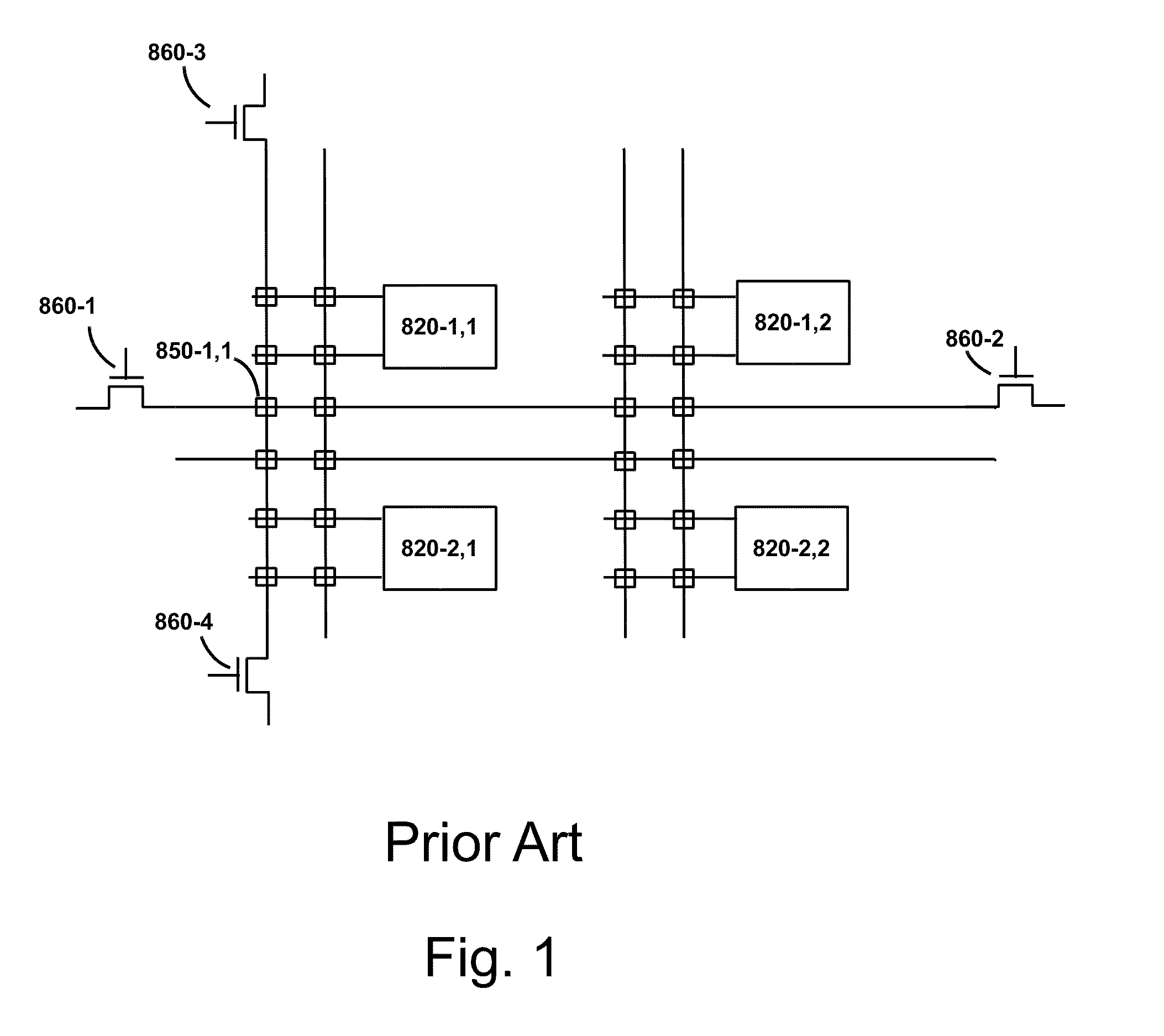

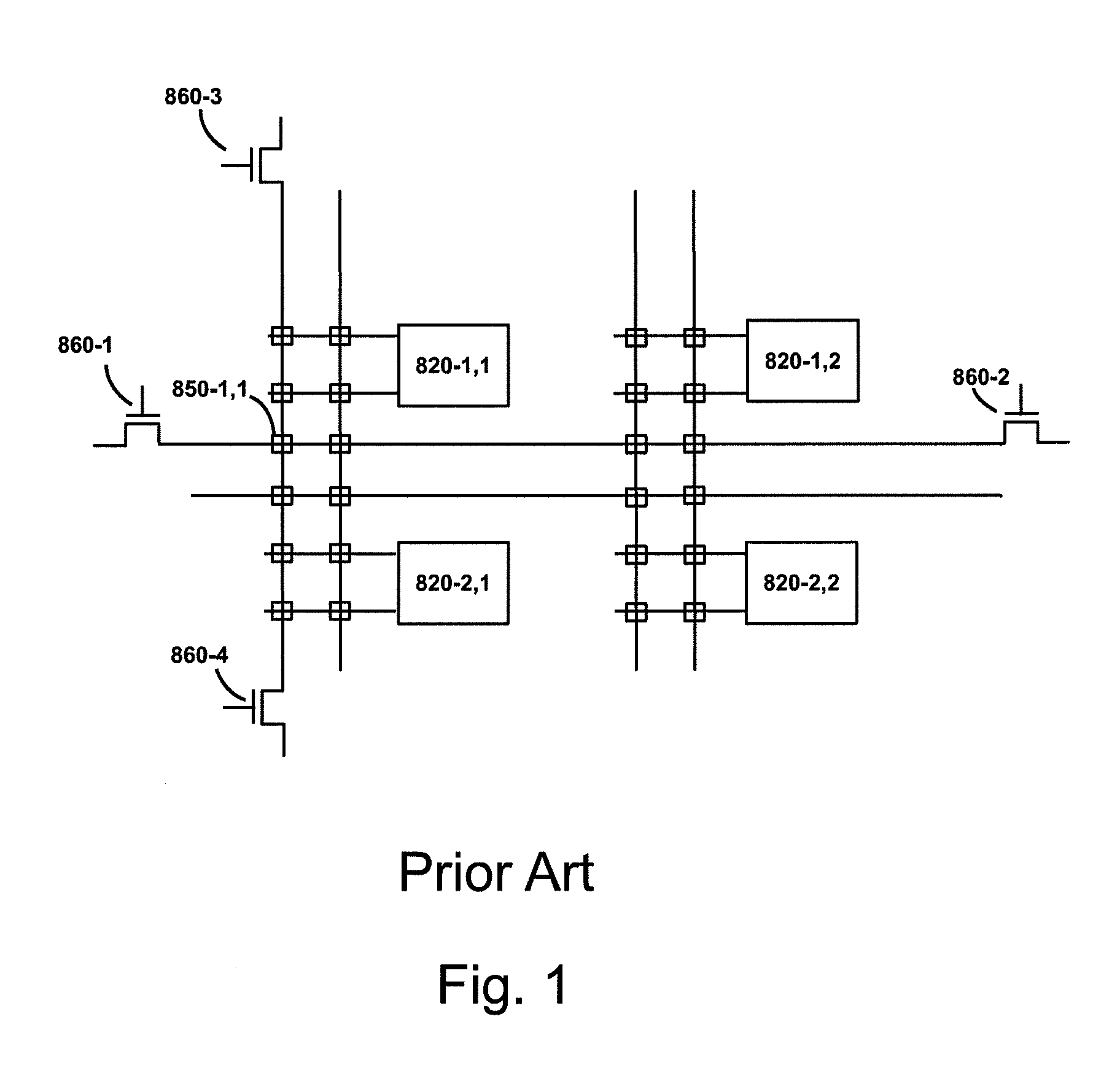

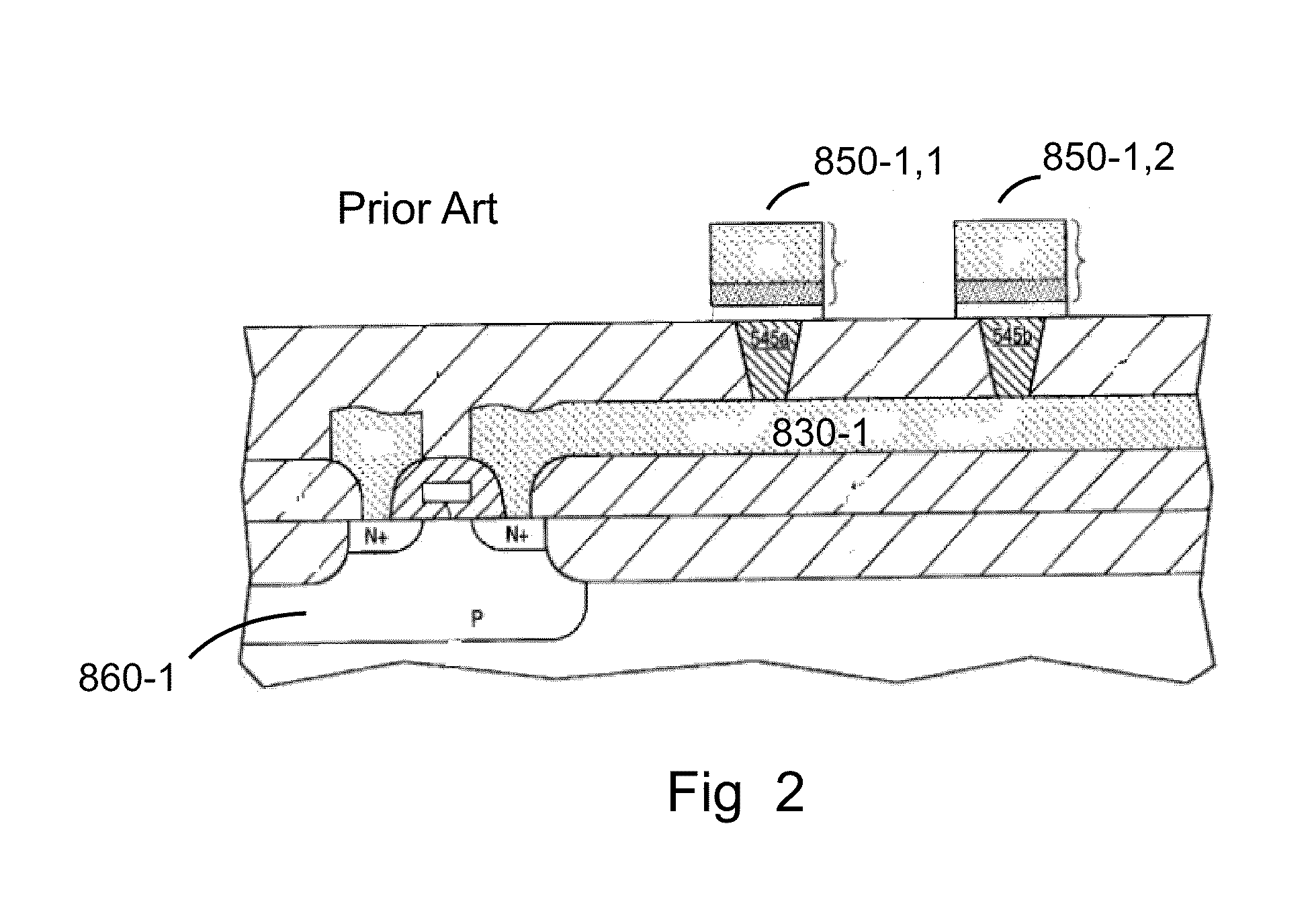

System comprising a semiconductor device and structure

ActiveUS20110121366A1High mask-set costLow flexibilityTransistorSemiconductor/solid-state device detailsPhysicsSemiconductor

A semiconductor device includes a first single crystal silicon layer including first transistors, a first alignment mark, and at least one metal layer overlying the first single crystal silicon layer for interconnecting the first transistors; a second layer overlying the at least one metal layer, wherein the second layer includes a plurality of second transistors; and a connection path connecting the first transistors and the second transistors and including at least a first strip, a second strip, and a through via connecting the first strip and the second strip, wherein the second strip is substantially orthogonal to the first strip and wherein the through via is substantially away from both ends of the first strip and both ends of the second strip.

Owner:SAMSUNG ELECTRONICS CO LTD

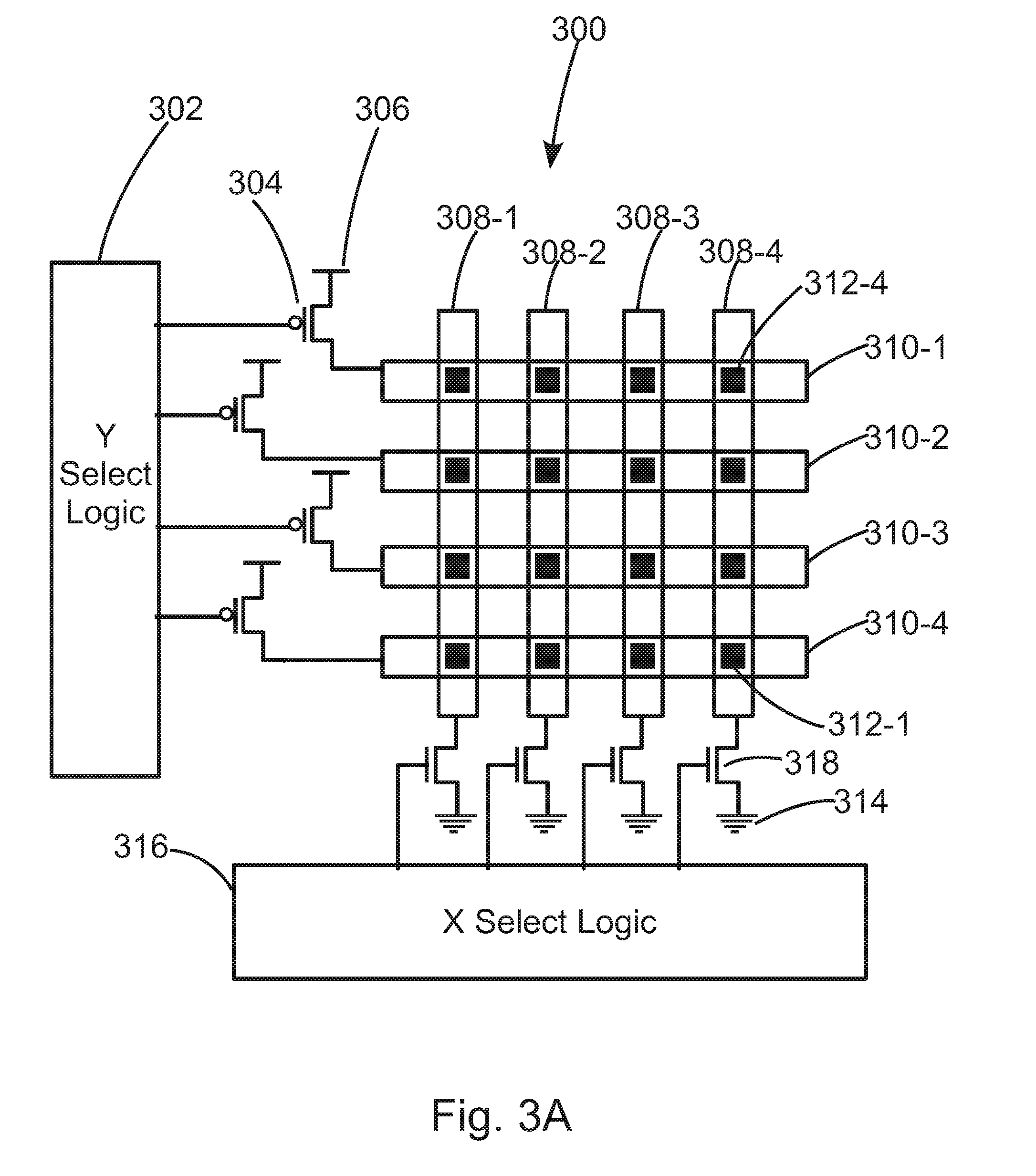

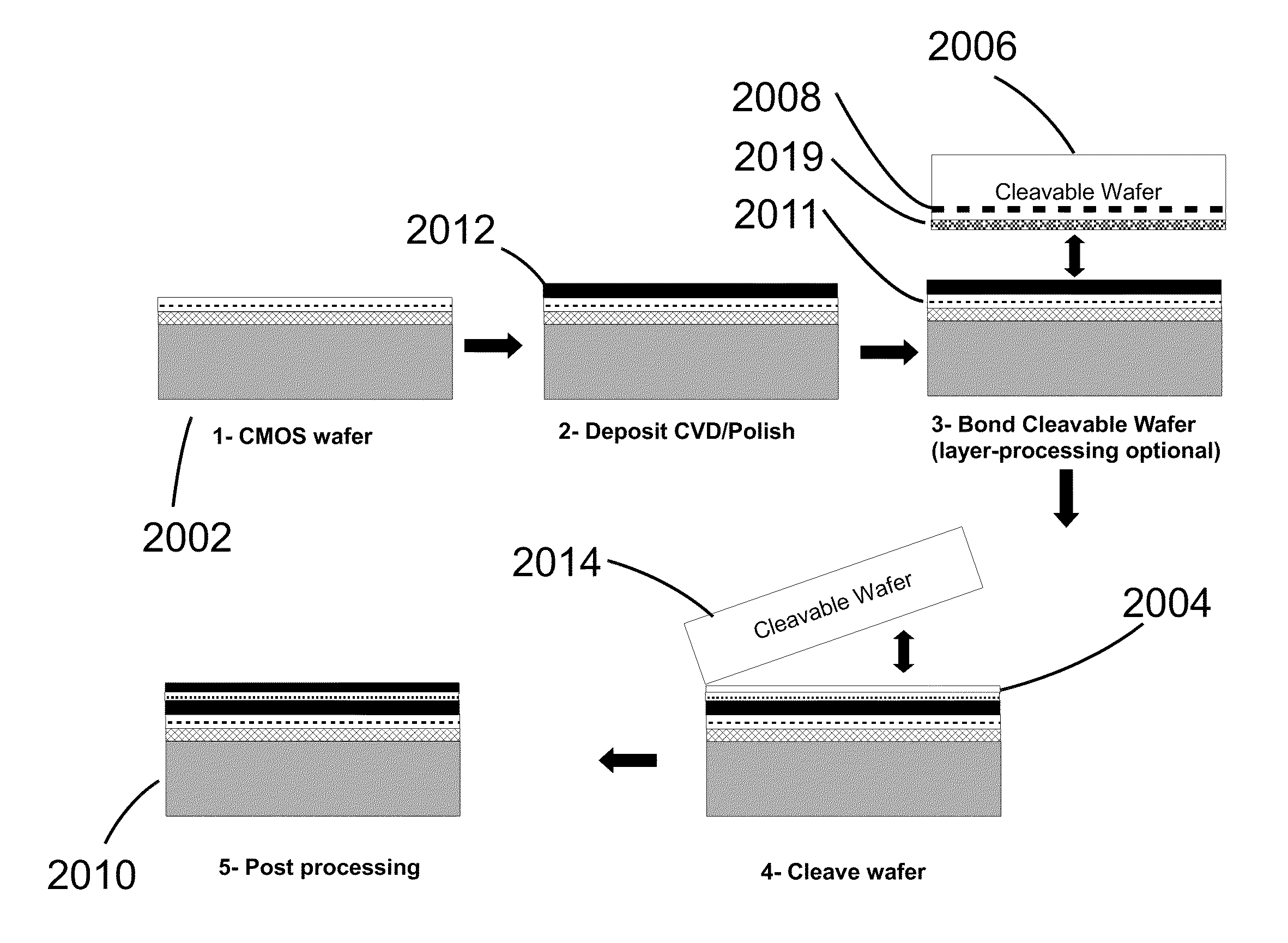

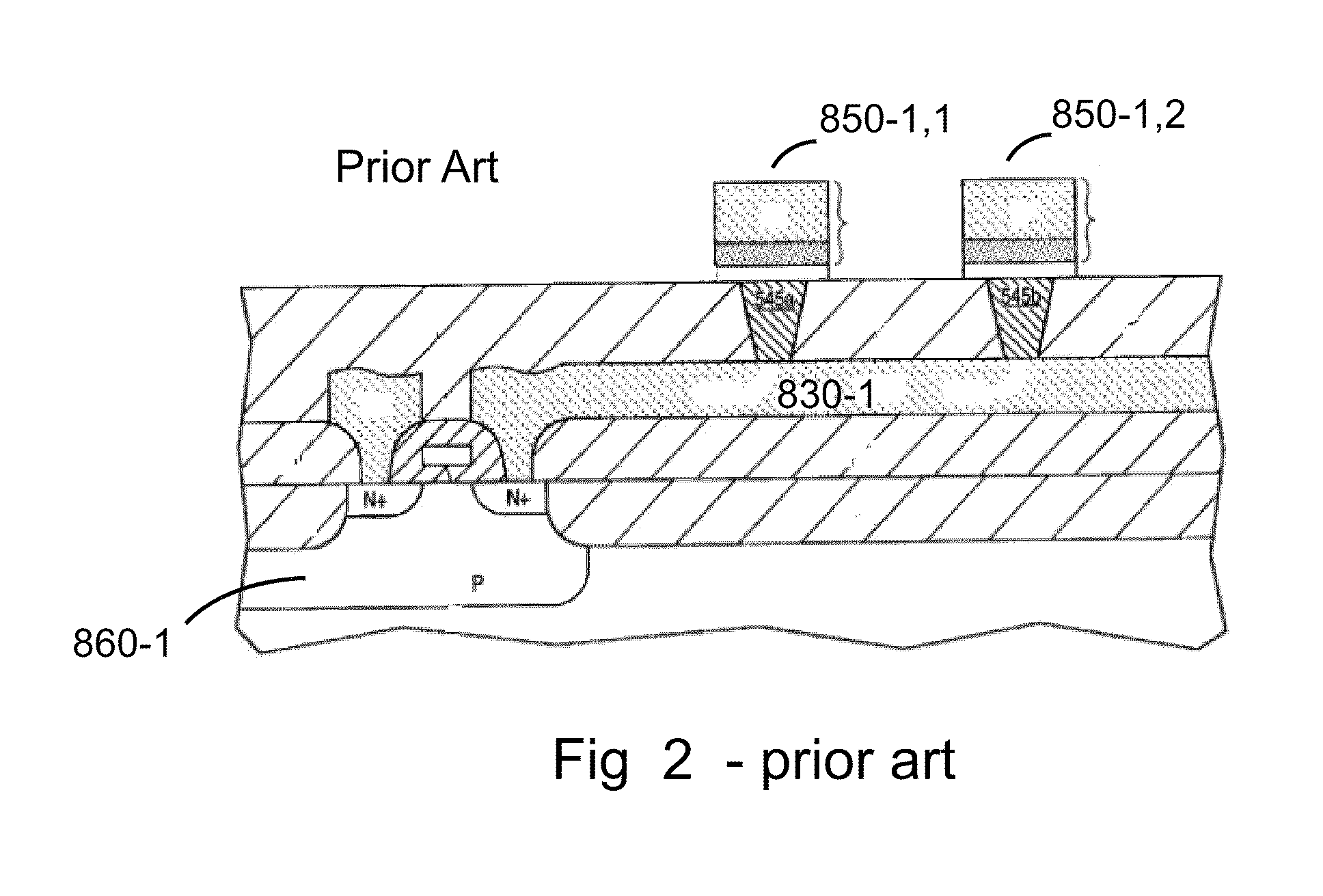

Method for fabrication of a semiconductor device and structure

ActiveUS8058137B1High mask-set costLow flexibilityTransistorSemiconductor/solid-state device detailsSingle crystalSemiconductor

A method of manufacturing a semiconductor wafer, the method including: providing a base wafer including a semiconductor substrate, metal layers and first alignment marks; transferring a monocrystalline layer on top of the metal layers, wherein the monocrystalline layer includes second alignment marks; and performing a lithography using at least one of the first alignment marks in a first direction and at least one of the second alignment marks in a second direction.

Owner:SAMSUNG ELECTRONICS CO LTD

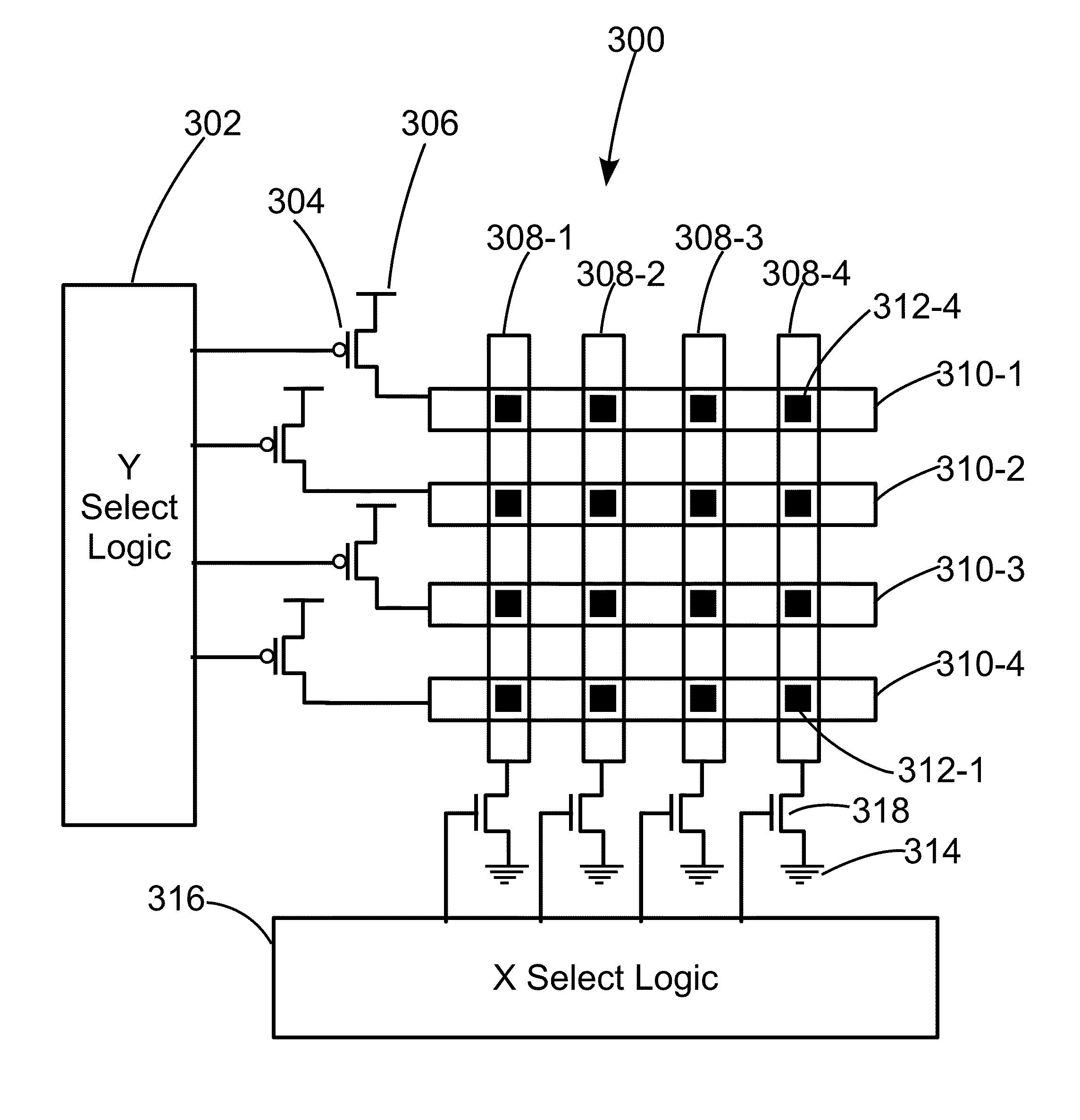

Method for fabrication of a semiconductor device and structure

InactiveUS20110199116A1Low flexibilityReduce high cost of manufacturingSemiconductor/solid-state device detailsSolid-state devicesEngineeringInput/output

A Configurable device comprising, a logic die connected by at least one through silicon-via (TSV), to an input / output (I / O) die.

Owner:MONOLITHIC 3D

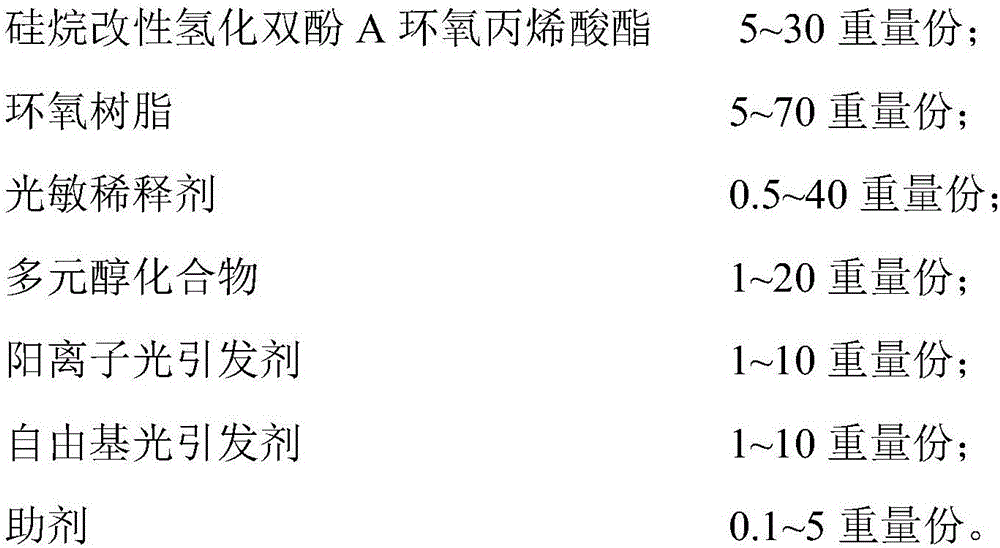

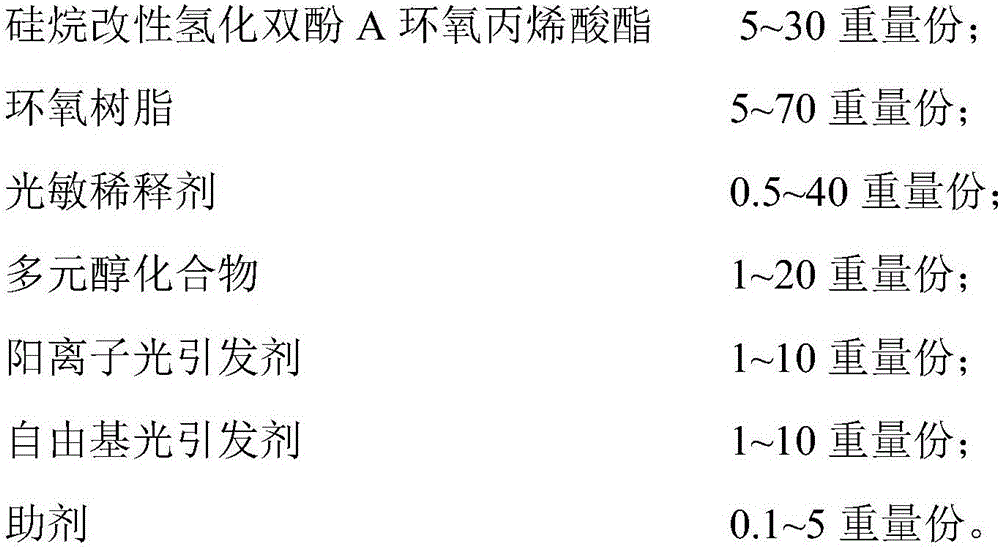

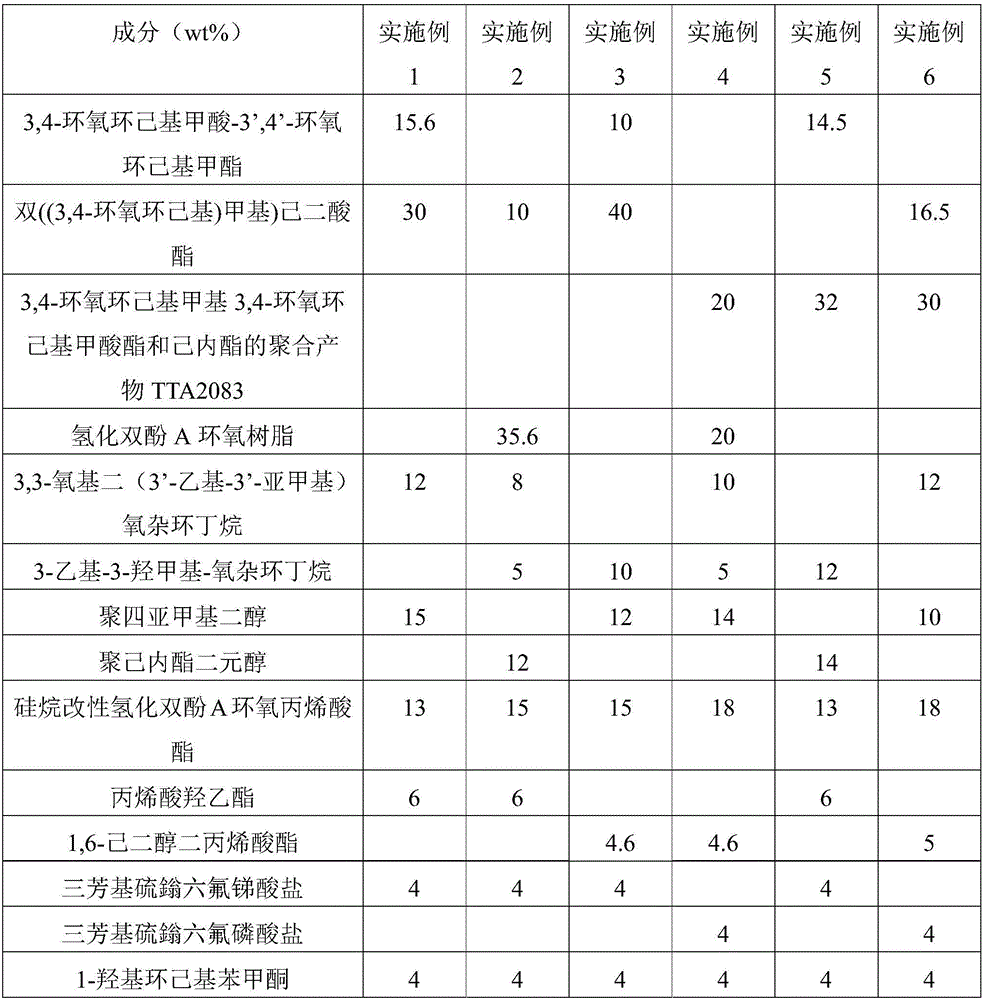

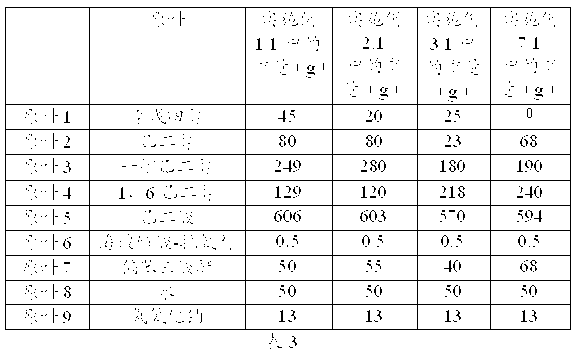

Rubber-type light curing 3D printing material and preparation method thereof

The invention discloses a rubber-type light curing 3D printing material and preparation method thereof. The rubber-type light curing 3D printing material is prepared from the following raw materials: silane-modified hydrogenated bisphenol A epoxy acrylate, epoxy resin, a photosensitive diluent, a polyol compound, a cationic photoinitiator, a free radical photoinitiator and an auxiliary agent. Compared with the prior art, the silane-modified hydrogenated bisphenol A epoxy acrylat as a prepolymer is added into the 3D printing material, so that the tensile elongation at break of the light curing 3D printing material is greatly improved, and the light curing 3D printing material has excellent elasticity, toughness and softness. In addition, the hardness of the light curing 3D printing material can be adjusted through the change of the ratio of the raw materials, different products with the Shore A hardness of 30 to 95 are obtained, and different requirements can be met. The rubber-type light curing 3D printing material has the advantages of high elasticity, high toughness, low hardness, high flexibility, high forming precision and high gloss.

Owner:HANGZHOU LEYI NEW MATERIAL TECH CO LTD

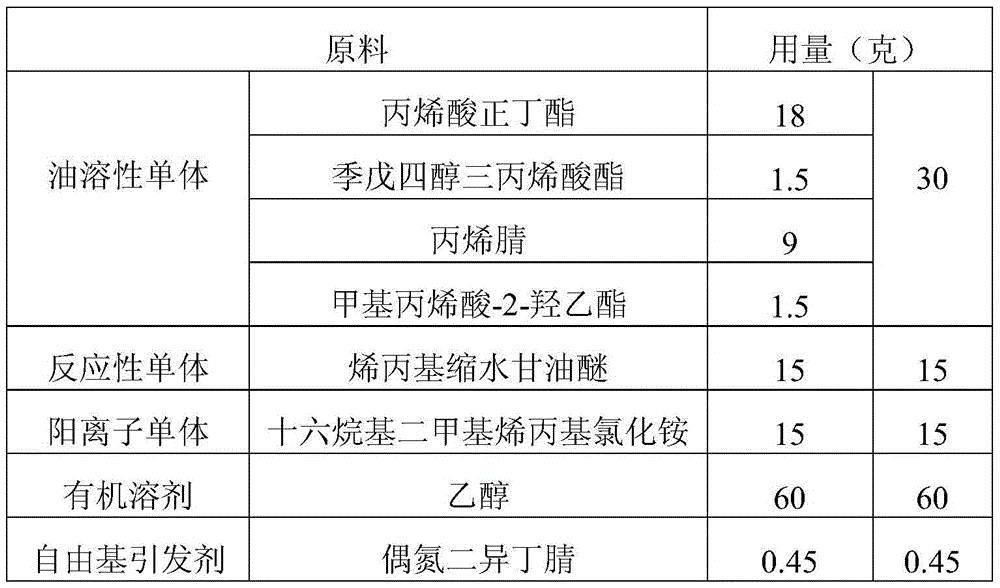

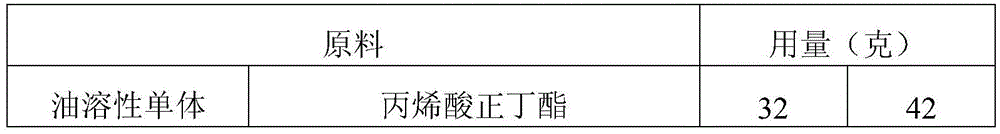

Cationic color fixing agent and preparation method and application thereof

The invention provides a cationic color fixing agent and a preparation method and application thereof. The cationic color fixing agent is obtained by polymerization reaction of an oil-soluble monomer, a cationic monomer and a reactive monomer in a solvent under the action of a radical initiator, wherein the oil-soluble monomer is one or the combination of several of styrene, acrylonitrile and acrylate; the cationic monomer is one or the combination of acryloxyethyl alkyl quaternary ammonium salt and / or allyl alkyl quaternary ammonium salt; the reactive monomer is one or the combination of several of allyl glycidyl ether, hydroxyl-containing acrylics, vinyl trimethoxy silane, vinyl triethoxy silane, acrylamide, crylic acid and methacrylic acid. The cationic color fixing agent is insoluble in water and can be dissolved in a weak polar solvent and / or non-polar solvent; besides, after non-aqueous solvent dyeing of reactive dyes, the cationic color fixing agent can be directly used in the on-going fixing process without washing.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Glove having excellent chemical resistance and composition for said glove

An emulsion composition for producing a glove, the composition containing: (1) a carboxylated acrylonitrile-butadiene elastomer, comprising 30 to 40% by weight of acrylonitrile residues and 3 to 8% by weight of unsaturated carboxylic acid residues, having an elemental sulfur content detected by neutralization titration of a combusted product of the elastomer of not more than 1% by weight of the elastomer weight, and having a Mooney viscosity (ML(1+4) (100° C.)) of 100 to 220, and (2) a poly(acrylonitrile-butadiene) having a styrene-equivalent weight-average molecular weight of 7,000 to 500,000, wherein the weight ratio of component (1) / component (2) is from 70 / 30 to 90 / 10. Also provided is a glove which, as a result of comprising the emulsion composition, exhibits excellent chemical resistance and superior flexibility.

Owner:KOSSAN

Graphene/aluminium oxide nano-composite tanning agent and preparation method thereof

ActiveCN104745736AIncrease hydrolysisIncrease the aggregation abilityTanning treatmentAluminium chlorideP-Toluenesulfonic acid

The invention discloses a graphene / aluminium oxide nano-composite tanning agent. The graphene / aluminium oxide nano-composite tanning agent is prepared from the following materials in parts by mass: 40-50 parts of a graphene oxide nano-slice dispersion liquid, 25-30 parts of aluminium chloride, 0.5-1 parts of p-toluenesulfonic acid, 20-25 parts of alkalizer solution and 0.5-1 parts of a dispersant. The invention further discloses a preparation method for the graphene / aluminium oxide nano-composite tanning agent, wherein when the solid dosage of the graphene / aluminium oxide nano-composite tanning agent is 5% of a tare, the shrinkage temperature of leather tanned by the graphene / aluminium oxide nano-composite tanning agent achieves 112 DEG C, the absorption rate of the tanning agent achieves 95%, the shrinkage temperature is hardly lowered when the tanned leather is washed for 10 times, and lowered by 5% when the tanned leather is washed for 20 times, and the softness, elasticity, fullness and the like of the tanned leather approximate to those of chrome-tanned leather.

Owner:安徽翰邦科技咨询有限公司

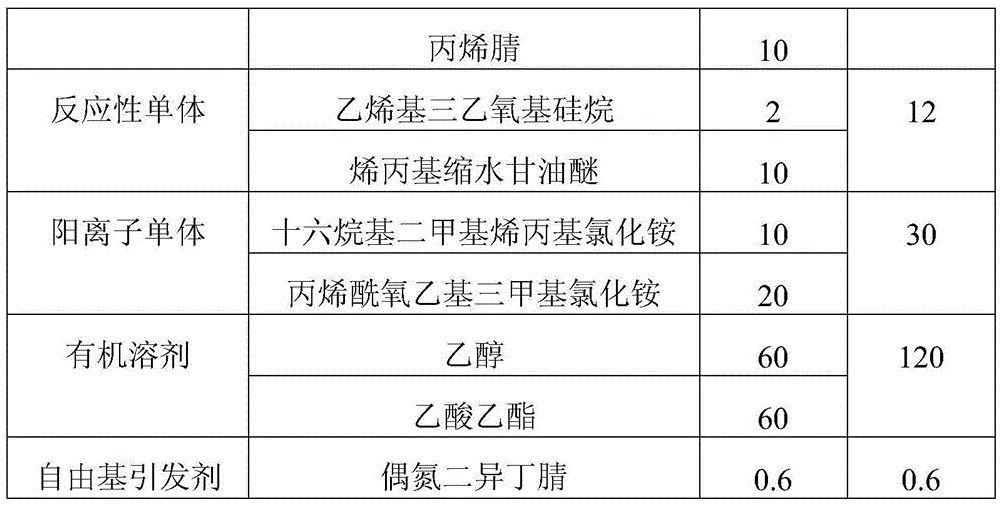

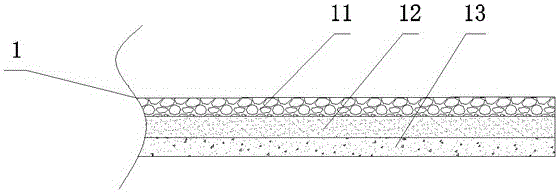

Stereo hot air non-woven fabric production method

ActiveCN104988660AReduce fluffinessLow flexibilityNon-woven fabricsWoven fabricStructural engineering

The invention discloses a stereo hot air non-woven fabric production method comprising the following steps of an opening procedure, a carding procedure, a hot air shaping procedure, stereo shaping procedure and a rolling procedure. In the fourth step, a pair of concave and convex rollers engaged with each other and capable of heating is included; temperature of the concave roller reaches more than 45 DEG C when a plane hot air non-woven fabric enters the stereo fixing concave roller. Rolling equipment and unrolling equipment as well as transportation procedures are prevented compared with the secondary stereo fixing method, so energy consumption is reduced, cost is reduced and production efficiency is improved; secondary pollution to the material can be prevented; and effects to non-woven fabric fluffiness and softness due to multi-time rolling tension force can be reduced.

Owner:XIAMEN YANJAN NEW MATERIAL CO LTD

High-performance composite thermal interface material and preparation method thereof

InactiveCN110387217AHigh thermal conductivityImprove thermal conductivityHeat-exchange elementsLiquid metalTemperature difference

The invention relates to a high-performance composite thermal interface material and a preparation method thereof. The high-performance composite thermal interface material is prepared from liquid metal and ceramic particles in a high-temperature fusion mode; the thermal interface material is sheet metal with the thickness being less than 0.1 mm, and the grain size of the ceramic particles is 600nm-20 [mu]m. The melting point of the thermal interface material is the same as the melting point of the liquid metal, the thermal conductivity is high, conductive thermal resistance is reduced, and ductility and softness are good; the high-performance composite thermal interface material can be applied to chip heat dissipation and large-power devices such as IGBT and replaces silicone grease withlow thermal conductivity, the temperature difference between a chip and a heat dissipater is reduced, and heat is quickly dissipated; and the high-performance composite thermal interface material isstable in performance, and can be manufactured into interface materials with various shapes and sizes.

Owner:YUNNAN ZHONGXUAN LIQUID METAL TECH CO LTD

Non-woven composite gauze sheet for surgery

ActiveCN106671504AReduces hair lossWill not cause lossNon-adhesive dressingsLayered productsSocial benefitsHair falling

A non-woven composite gauze sheet for surgery comprises a non-woven gauze sheet and a gauze sheet, and is characterized in that the non-woven gauze sheet and the gauze sheet are composited, a bamboo fiber gauze layer and a dressing layer are composited on the gauze sheet, and the dressing layer is formed by compositing an antibacterial layer, a healing-promoting layer and a bleeding-stopping layer. The non-woven composite gauze sheet for surgery has the effects of being strong in water-absorbing power, free of loose thread and hair falling, capable of blending with advanced surgical sensors, strong medical function and the like, and has extremely high social benefit and economic benefit.

Owner:湖北唯美医疗用品有限公司

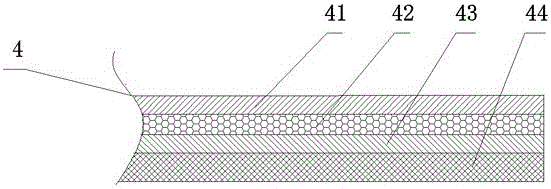

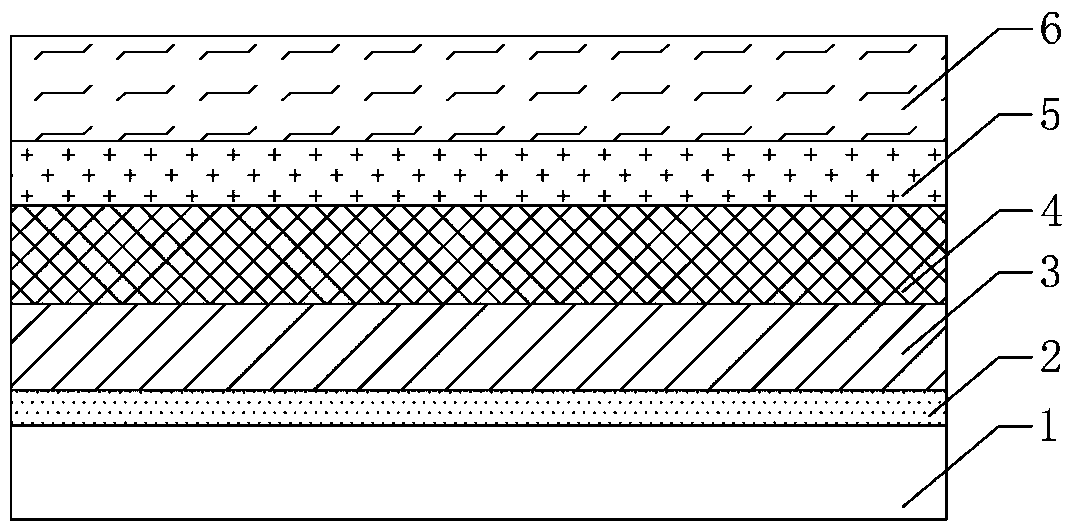

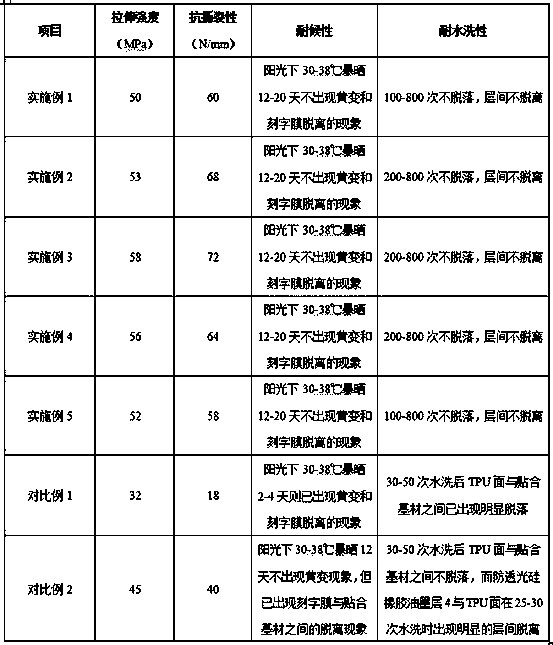

High-elasticity silicone rubber lettering film and preparation method and application method thereof

ActiveCN108610997AIncrease elasticityAvoid deformationPolyureas/polyurethane adhesivesInksRubber materialPolymer science

The invention relates to the technical field of thermal transfer printing lettering film, and in particular, relates to a high-elasticity silicone rubber lettering film and a preparation method and anapplication method thereof. The high-elasticity silicone rubber lettering film comprises a load-bearing substrate, a release layer, a surface layer silicone rubber ink layer, an anti-photopermeable silicone rubber ink layer, an adhesive interfacial agent layer and a TPU hot melt adhesive film which are connected from bottom to top successively; the adhesive interfacial agent layer is prepared from an adhesive interfacial agent, and the adhesive interfacial agent is an adhesive interfacial agent containing dual-resin components. The silicone rubber lettering film has the advantages of both thesilicone rubber material and the TPU material, has good elasticity, tearing strength, weatherability, yellowing resistance, water washing resistance and other comprehensive properties, has layers noteasy to separate, is not easy to discolor or fade by sunlight exposure, and has the water-washing fading rate not less than 0.5%, is not easy to dye when being mixed and washed with materials with other colors, and is high in stability, easy to bond with a variety of materials, high in bonding strength, not easy to peel off, good in stability, delicate in hand feeling, good in aesthetic degree, and long in service life.

Owner:卢汉军

Compound non-woven fabric gauze swab for surgical operation

InactiveCN105311671AStrong water absorptionStrong medical functionNon-adhesive dressingsSynthetic resin layered productsWoven fabricBiomedical engineering

A compound non-woven fabric gauze swab for surgical operation comprises a non-woven fabric piece and a gauze piece and is characterized in that the non-woven fabric piece and the gauze piece are compounded, the gauze piece is compounded with a bamboo fiber gauze layer and a dressing layer, and the dressing layer is formed by compounding a bacteriostatic layer, a healing promoting layer and a hemostatic layer. The compound non-woven fabric gauze swab has the advantages that the gauze swab has strong water-absorbing capacity, threads do not loose, no lint falls, and the gauze swab can be integrated with an advanced operation sensor, has a good medical functionality and the like and has very high social benefits and economic benefits.

Owner:周坤友

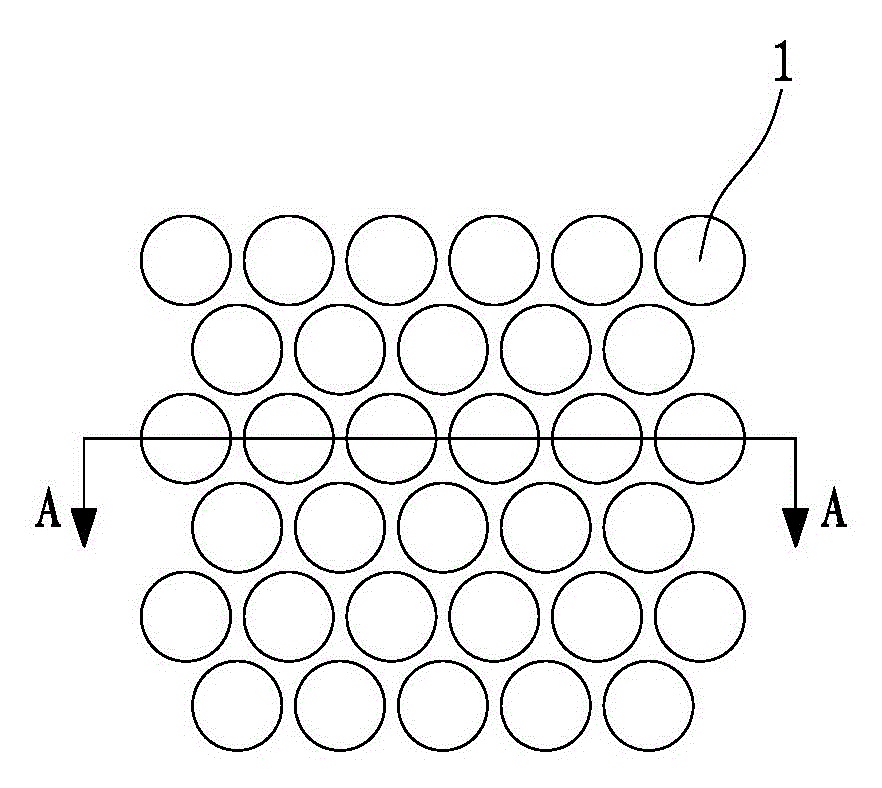

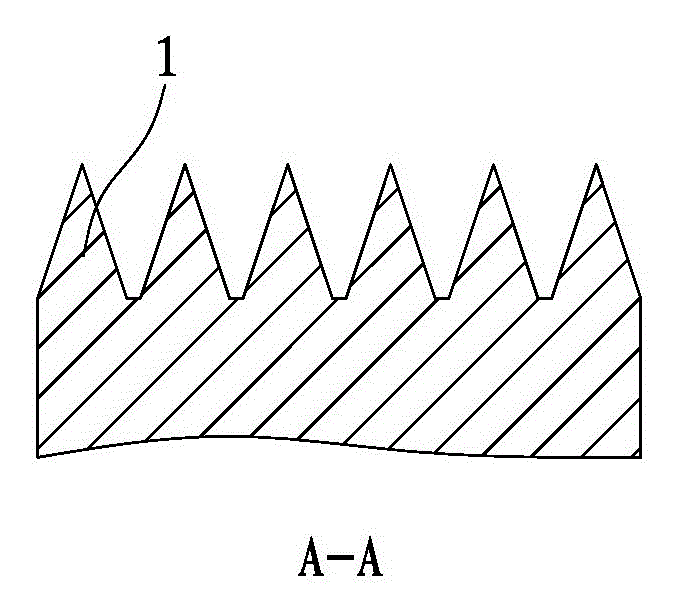

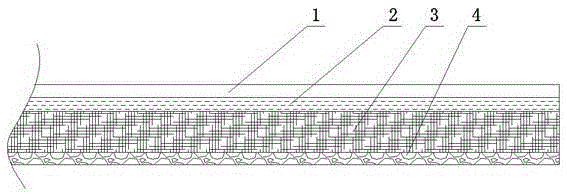

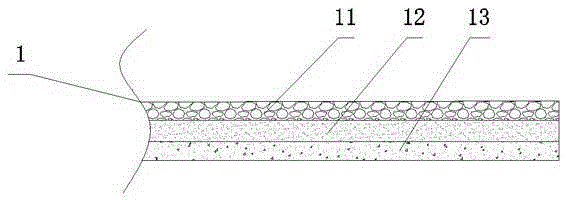

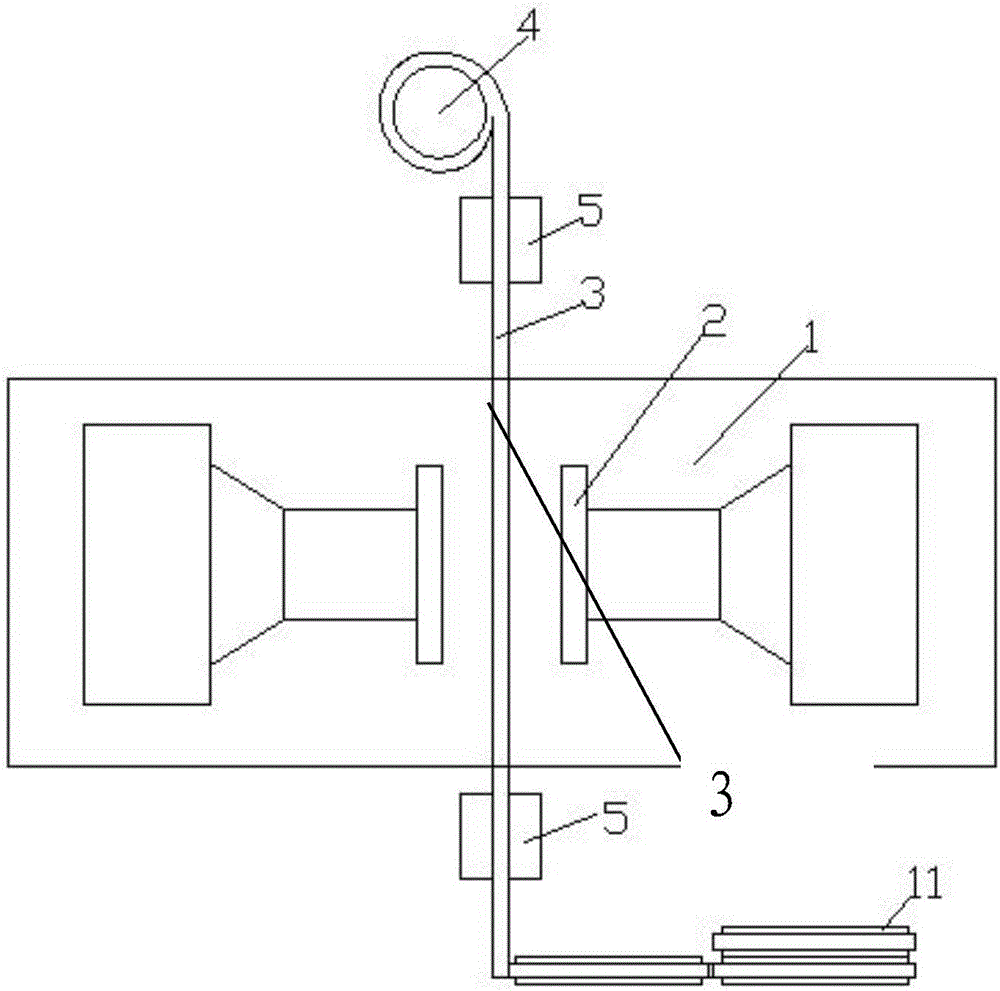

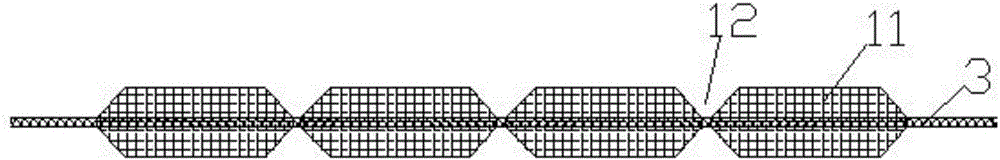

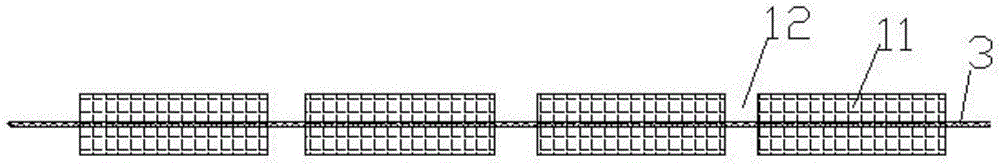

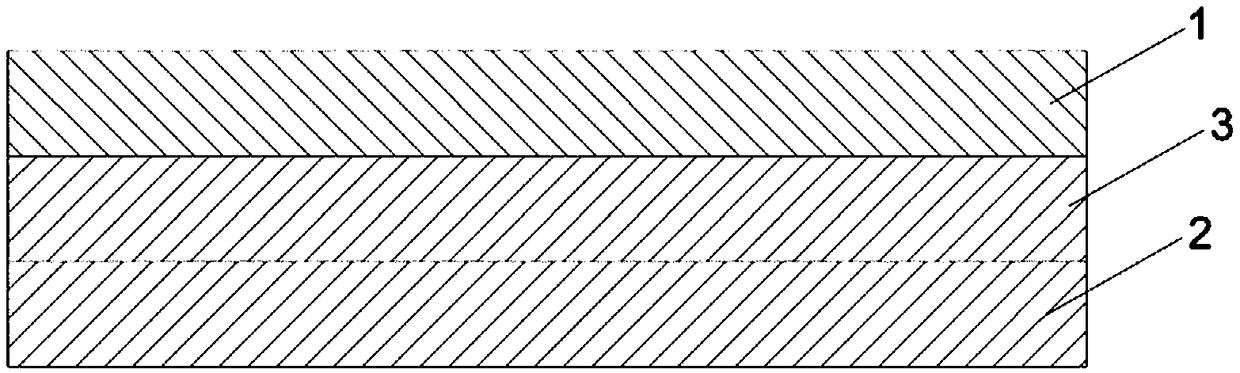

Preparing technology for flexible bullet-proof and piercing-proof structure

ActiveCN106003759AExcellent bulletproof and anti-stab performanceImproved flexibility propertiesTextileInjection moulding

The invention relates to a preparing technology for a flexible bullet-proof and piercing-proof structure. The preparing technology specifically comprises the following preparing steps that firstly, a protection composite particle material is prepared; secondly, base cloth is laid between two sets of injection molds of an injection molding machine, the protection composite particle material is arranged on the two sides of the base cloth in an injection molding manner through the injection molds at the same time, the protection composite particle material is subjected to hot melting, seeps into a base cloth layer and then is cured to form a two-face protection material layer, mold opening is conducted, after the base cloth of an injection molding part is downwards transmitted, the base cloth is tensioned, and then injection molding is conducted; and thirdly, a flexible gap is machined. The structure of the product prepared through the preparing technology has excellent bullet-proof and piercing-proof performance and also has improved flexibility performance. A thermoplastic material and an enhanced material composite material are arranged on the adopted base cloth in an injection molding manner, the thermoplastic material and the enhanced material composite material are subjected to hot melting, seep into the base cloth layer and then are cured to form the two-face protection material layer, gaps among particles of the thermoplastic material and the enhanced material composite material can be eliminated, and the structure is compact and has more excellent bullet-proof and piercing-proof performance; and in addition, the preparing technology is simple, and the production efficiency is high.

Owner:SUZHOU GAOJIA PROTECTION TECH CO LTD

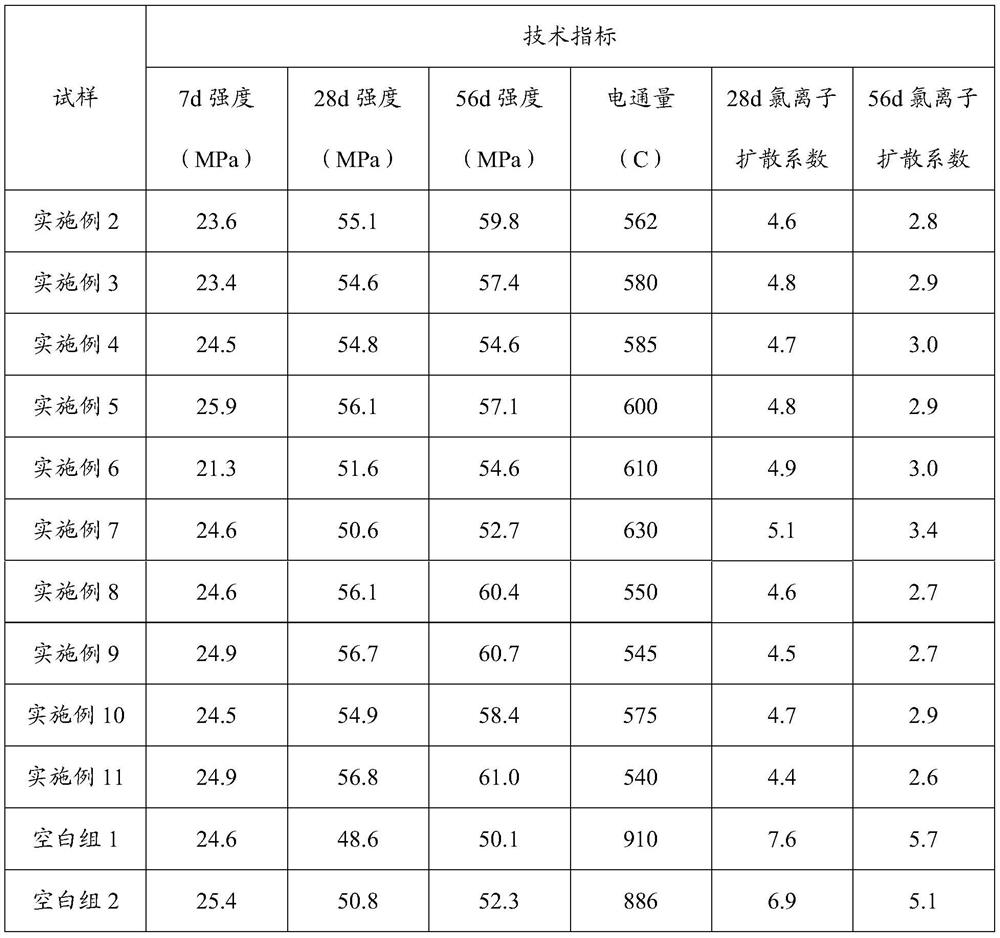

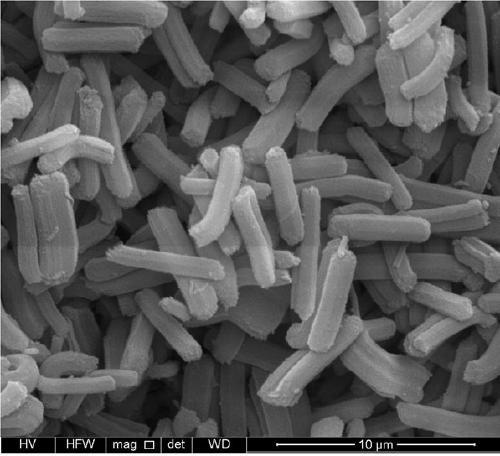

Filled plant fiber, preparation method thereof, and high-strength plastic wave-absorbing concrete

InactiveCN111606616AHigh strengthImprove stress resistanceSolid waste managementPlant fibreWater reducer

The invention discloses a filled type plant fiber. The filled plant fiber takes a hollow tubular plant fiber as a pipe and an alkali-resistant filler as a core material. A preparation method of the filled plant fiber comprises the following steps: soaking the plant fiber in an alkali-resistant filler dispersion, taking out the plant fiber, cooling, drying, and cutting to obtain the filled plant fiber. A high-strength plastic wave-absorbing concrete is prepared from, by weight, 20 to 50 parts of the filled plant fiber, 200 to 300 parts of cement, 100 to 150 parts of coal ash, 20 to 50 parts ofan expanding agent, 700 to 800 parts of sands, 950 to 1100 parts of gravel, 5.8 to 6.8 parts of a water reducing agent, 0.35 to 0.70 part of an air entraining agent and 120 to 180 parts of water. Thefilled plant fiber is good in alkali resistance, good in pressure resistance and high in breaking strength, the bonding force between the filled plant fiber and a cement-based cementing material can be improved, and then the compactness, stability and durability of the concrete are improved.

Owner:中铁二局第二工程有限公司

PVC and PET anti-scratch printing sheet material

InactiveCN110240725AImprove stabilityAvoid degradation of physical and mechanical propertiesPolyester coatingsDecompositionChemistry

The invention discloses a PVC and PET anti-scratch printing sheet material. Chloroethylene resin and polyethylene glycol terephthalate are used as raw materials; through a series of processing, the printing sheet material is prepared; organic tin stabilizing agents are used; high temperature decomposition of chloroethylene resin is avoided; the stability is improved; the physical and mechanical performance reduction is avoided; bis(2-ethylhexyl) phthalate is used; the plasticity and the softness of vinyl chloride resin are improved; the fragility is reduced; the processing formation is easy; photocuring paint is used, so that the wear-resisting performance of the printing sheet material is improved; the anti-scratch function is realized; the adhesive force is improved; during the printing, falling cannot occur; nanometer silicon dioxide and nanometer negative ions are used for improving the corona resistance of the photocuring paint; through corona treatment, the adhesive force of the sheet material is improved. The manufactured sheet material cannot be easily scratched; during the printing, the falling cannot easily occur; the wear-resisting performance of the sheet material body is greatly improved; the service life is prolonged.

Owner:ZHEJIANG ZHONGBANG PLASTIC CO LTD

Anti-wrinkle skin makeup preparation combined by natural plant essence and active mineral substances and preparation method for anti-wrinkle skin makeup preparation c

InactiveCN102579316AGood for healthWith beautyCosmetic preparationsToilet preparationsBaical Skullcap RootPrecipitation

The invention relates to an anti-wrinkle skin makeup preparation combined by natural plant essence and active mineral substances. The anti-wrinkle skin makeup preparation comprises tourmaline and argenon which serve as the active mineral substances and ginseng, glossy ganoderma, white poria, prepared tuber of multiflower knotweed, pearl powder, baical skullcap root, lightyellow sophora root, root of red-rooted salvia and peach seed which serve as natural plants. A preparation method comprises the following steps of: washing the prepared tuber of multiflower knotweed, the baical skullcap root and the like, immersing, performing reflux extraction under reduced pressure, concentrating, performing alcohol precipitation, filtering, and extracting supernate; washing the ginseng, the glossy ganoderma and the white poria, performing reflux by ethanol, percolating, and extracting a concentrated solution; preparing a pearl powder hydrolytic solution by using the pearl powder; grinding the tourmaline and the argenon into mineral powder; and mixing the supernate, the concentrated solution and the hydrolytic solution uniformly, filtering, extracting supernate, adding the supernate into the mineral powder, stirring and immersing to obtain the anti-wrinkle skin makeup preparation. The anti-wrinkle skin makeup preparation exerts the effects of moistening, antiallergy, repair, balancing, radical resistance, wrinkle improvement, anti-aging, the promotion of cytothesis and collagen synthesis; and the anti-wrinkle skin makeup preparation has an obvious curative effect, and is safe and reliable, a formula is scientific, a preparation method is unique, a treatment course is short, and quick response is ensured.

Owner:SHAANXI YUZE COSMETICS

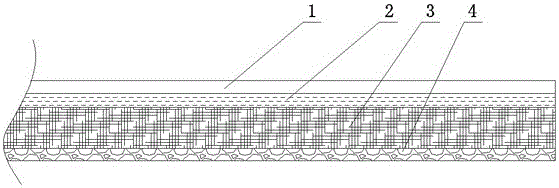

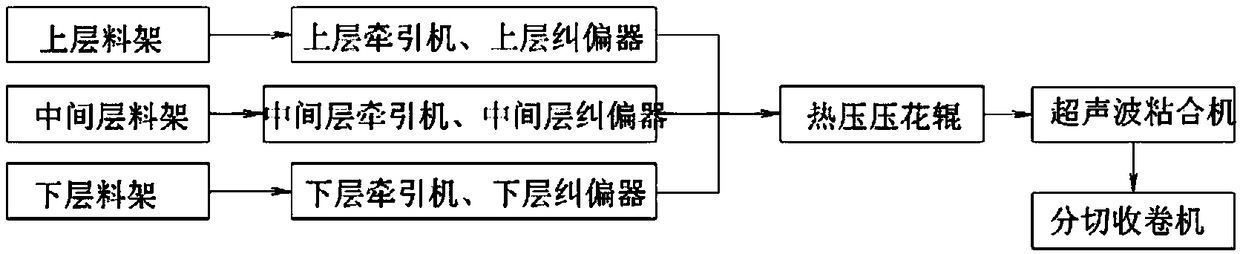

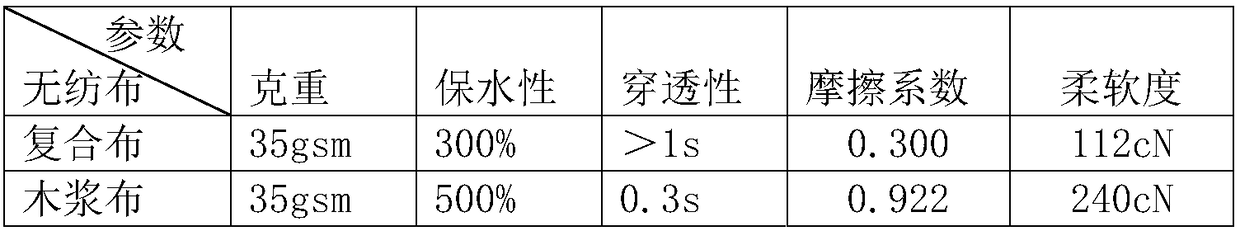

Three-layered compound non-woven fabric as well as processing equipment and processing technology thereof

InactiveCN108859385AEffective protectionPrevent leakageSpectales/gogglesLamination ancillary operationsKnurlingPulp and paper industry

The invention relates to a raw material for hygienic products and in particular relates to a three-layered compound non-woven fabric and processing equipment thereof. The three-layered compound non-woven fabric comprises an upper layer, a middle layer and a lower layer, which are compounded together, wherein the upper layer and the lower layer are PP Polypropylene) particle anti-sticking layers; the middle layer is a long fiber wood pulp layer; the two PP particle anti-sticking layers are used for covering the long fiber wood pulp layer, are knurled through a hot-pressing knurling roller and then are hotly adhered through an ultrasonic adhesion machine. The three-layered compound non-woven fabric adopts a sandwich type structure and the sandwich type structure can be used for effectively preventing wood pulp fibers from leaking out, so that the penetration performance of a product is effectively improved and dirt penetration is effectively prevented; the water retention performance islower than a wood pulp fabric; the three-layered compound non-woven fabric can be used for reducing residues of liquid in a glasses wiping process, and the friction coefficient and the flexibility arerelatively low; a wiped material can be effectively protected; the three-layered compound non-woven fabric is especially suitable for producing glasses wet tissues and has important meaning on application of glasses wet tissue products.

Owner:浙江欣富无纺布科技有限公司

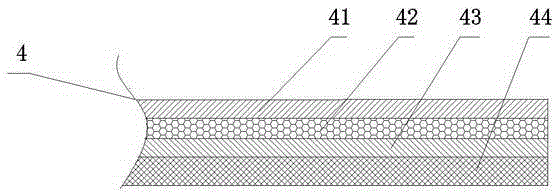

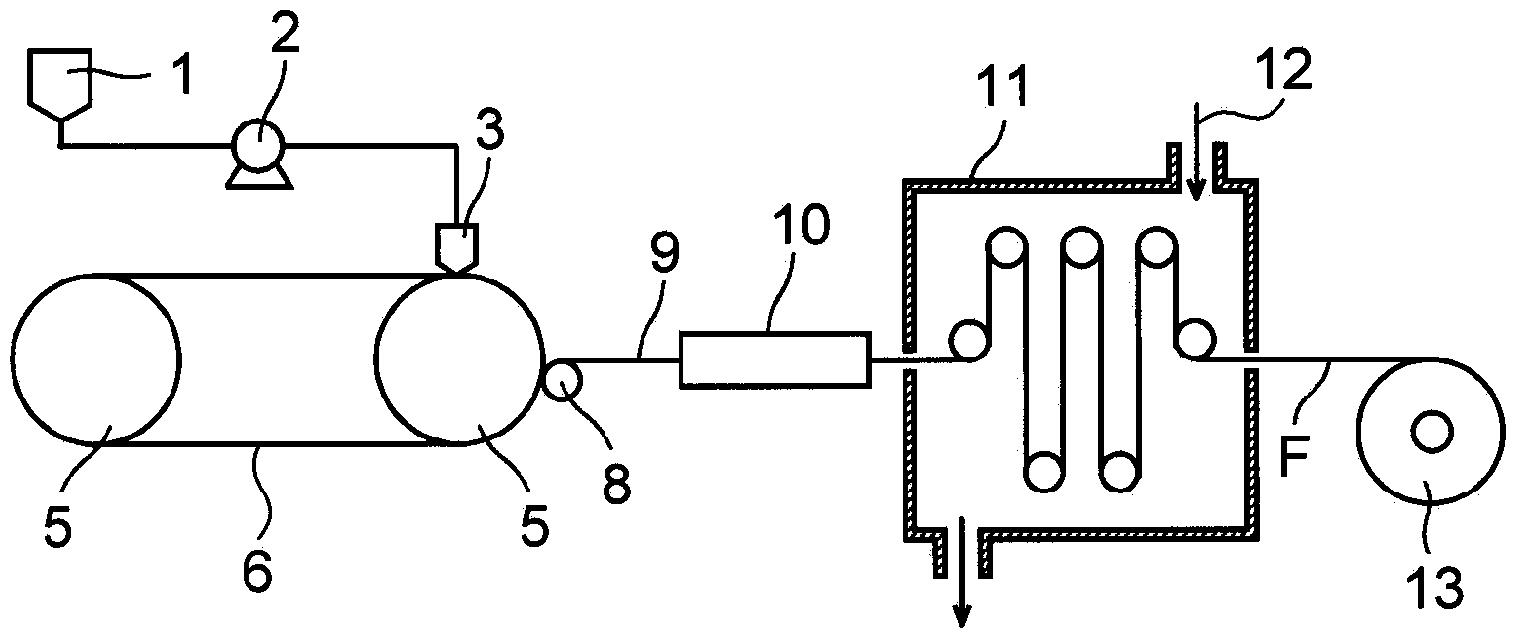

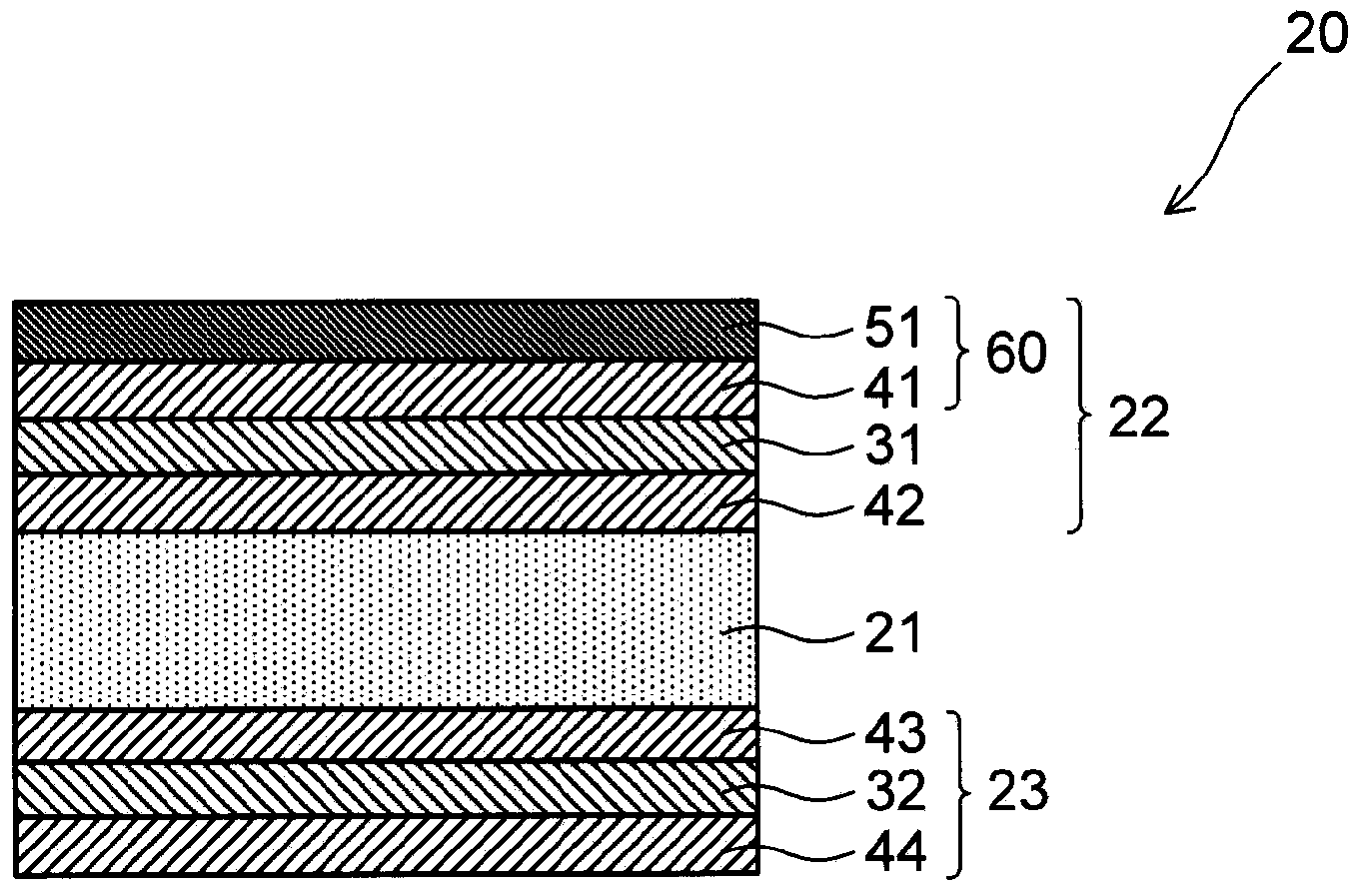

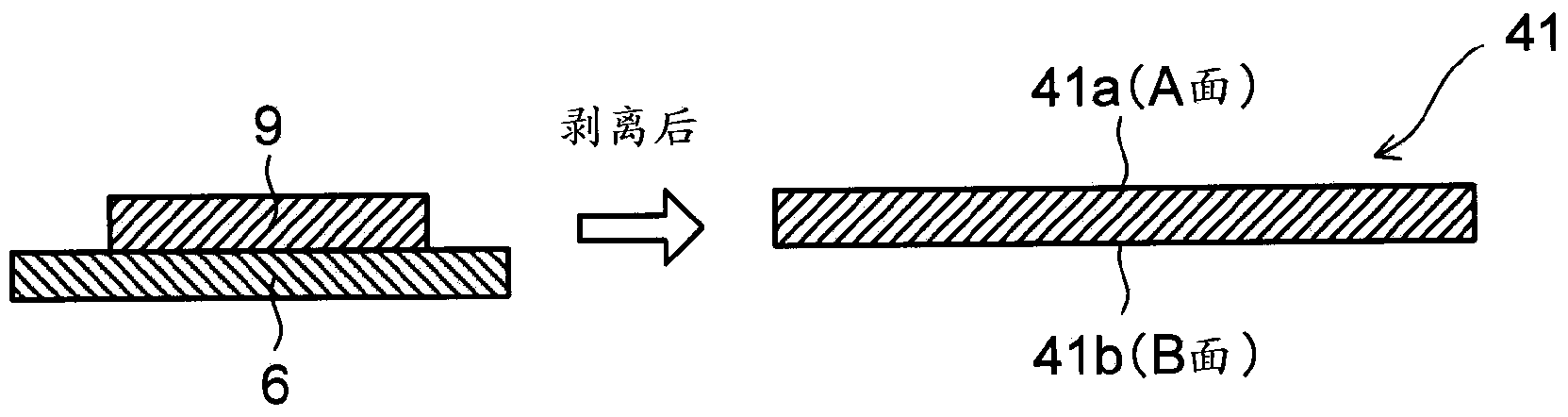

Process for production of hard coat film

ActiveCN104245156ALow flexibilityInhibition of exudationSynthetic resin layered productsCellulosic plastic layered productsCellulose ester membranePlasticizer

This process includes applying a hard coat layer (51) to a thin optical film (such as a cellulose ester film (41)) which is formed by a solution casting method and has a thickness of 15 to 30 [mu]m and which contains not only 1 to 20wt% of a plasticizer having a property of being more densely distributed on a side that has acted as the support side in a casting process for film formation but also silica fine particles as a matting agent, wherein the hard coat layer (51) is applied onto a side such that the silica fine particle concentration on the side is higher than the overall average silica fine particle concentration of the thin optical film.

Owner:KONICA MINOLTA INC

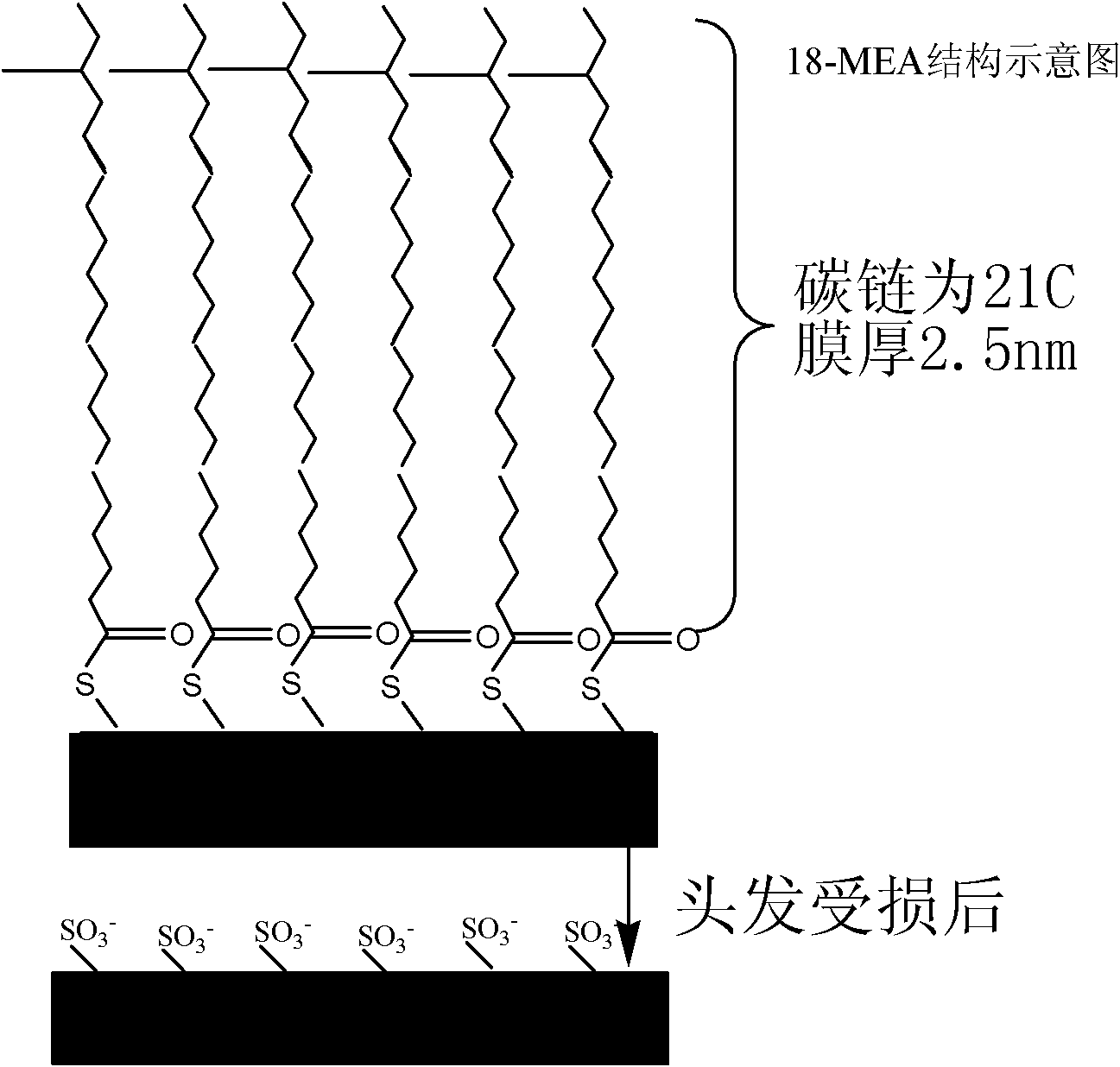

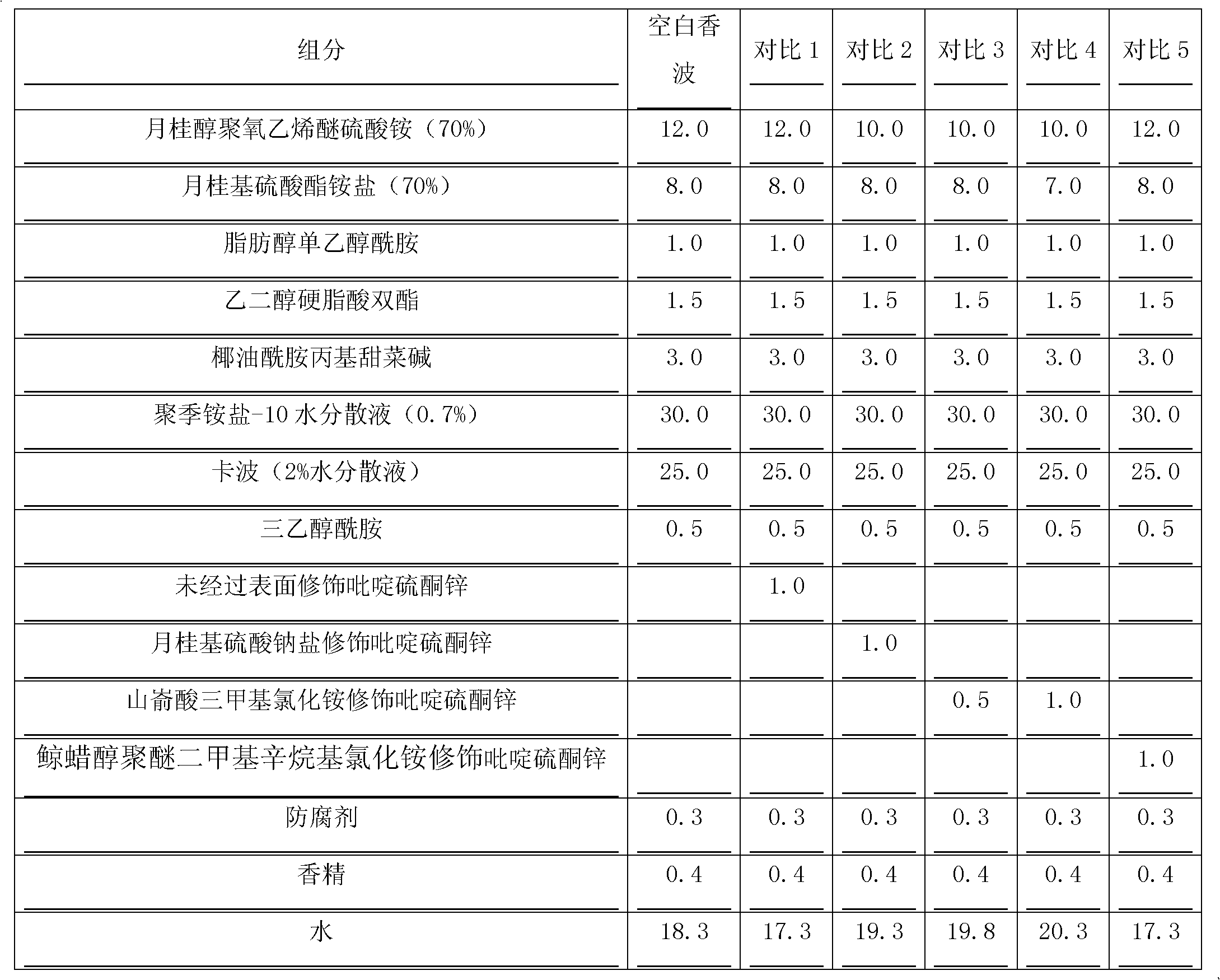

Surface-modified pyridine thioketone salt and application thereof

InactiveCN102180829AImprove lipophilicityImprove astringencyCosmetic preparationsHair cosmeticsThioketonePyridine

The invention relates to a dandruff removing and sterilizing component commonly used in the field of daily use chemicals and discloses a surface-modified pyridine thioketone salt and application thereof. The surface-modified pyridine thioketone salt is prepared by the following steps of: dispersing a monovalent or multivalent pyridine thioketone salt which is subjected to surface modification by a surfactant into a solvent; adding a surfactant at the surface modification temperature of 40-100 DEG C; stirring fully and uniformly; ageing for 1-3 hours; lowering the temperature to 40-60 DEG C; filtering; and drying filter residues. By adopting the surface-modified pyridine thioketone salt, the fungus killing time of pyridine thioketone salt particles on the surfaces of scalps and hairs can be prolonged effectively, dandruff removing and itching relieving effects are enhanced, the phenomena of hair dryness and withering after dandruff removing shampoo is used for washing can be effectively eliminated, the hair conditioning effect is enhanced, and damaged hairs can be repaired.

Owner:南京枫华投资管理有限公司

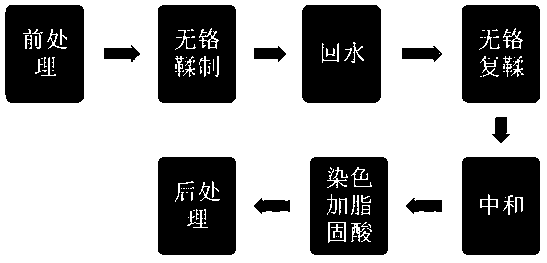

Environment-friendly chromium-free leather retanning method

ActiveCN111321260AImprove flatnessGood flexibilityTanning treatmentPre-tanning chemical treatmentCelluloseCarboxymethyl cellulose

The invention provides an environment-friendly chromium-free leather retanning method. The dyeing uniformity and strength of the leather are further improved, and the durability of the leather is improved. The retanning fullness and the filling property of the leather are improved, so that the leather with obviously higher cutting yield is obtained; a traditional retanning agent is designed into astrip-shaped microcapsule form, good filling performance is realized, the flatness of the leather is improved; in addition, the grain defects of the leather are well repaired, and the retanning agentcan be released for a long time under stress or heating through the design of the microcapsules, so that the obtained leather product is more durable; through cooperation of carboxymethyl cellulose,non-chromium metal and acrylic polymers, dyeing is brighter and more uniform, the tinting strength of the surface of the leather is improved, the color fading phenomenon is basically avoided, and theleather can be endowed with better properties such as bacterium resistance and mildew resistance according to needs. The leather process disclosed by the invention is green and environment-friendly, not only does not discharge chromium, but also reduces the use of dyes, and the microcapsule-shaped retanning agent is beneficial to recycling and has good social and economic benefits and applicationvalues.

Owner:河南中牛实业有限公司

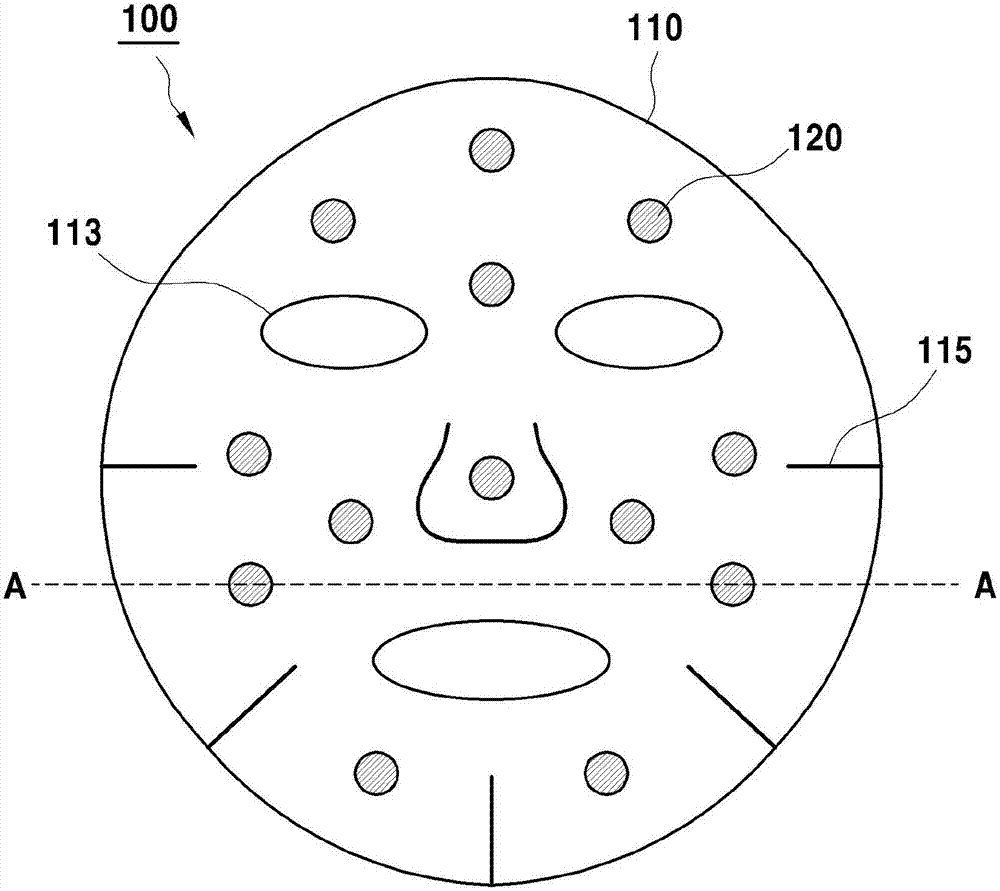

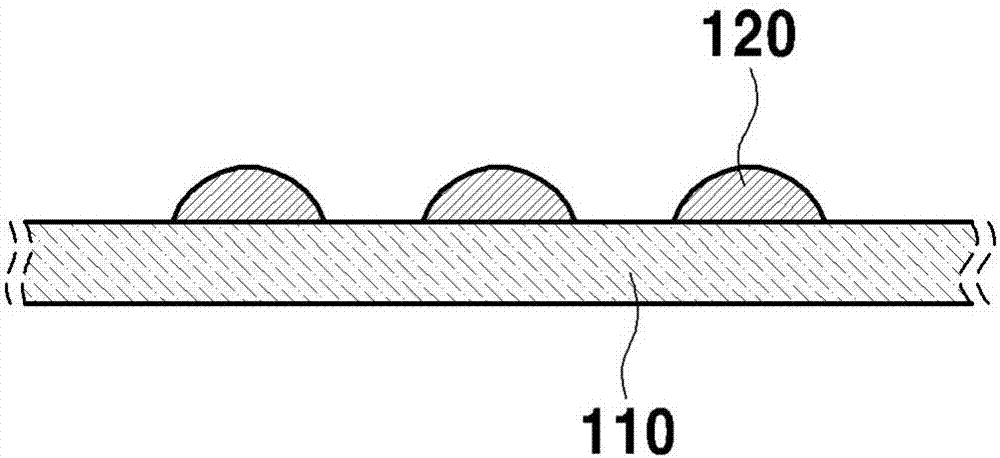

Mask pack having solid-phase nutritional components

InactiveCN106924055AReduce ventilationLow flexibilityCosmetic preparationsToilet preparationsEngineeringNutritional content

Owner:ENC

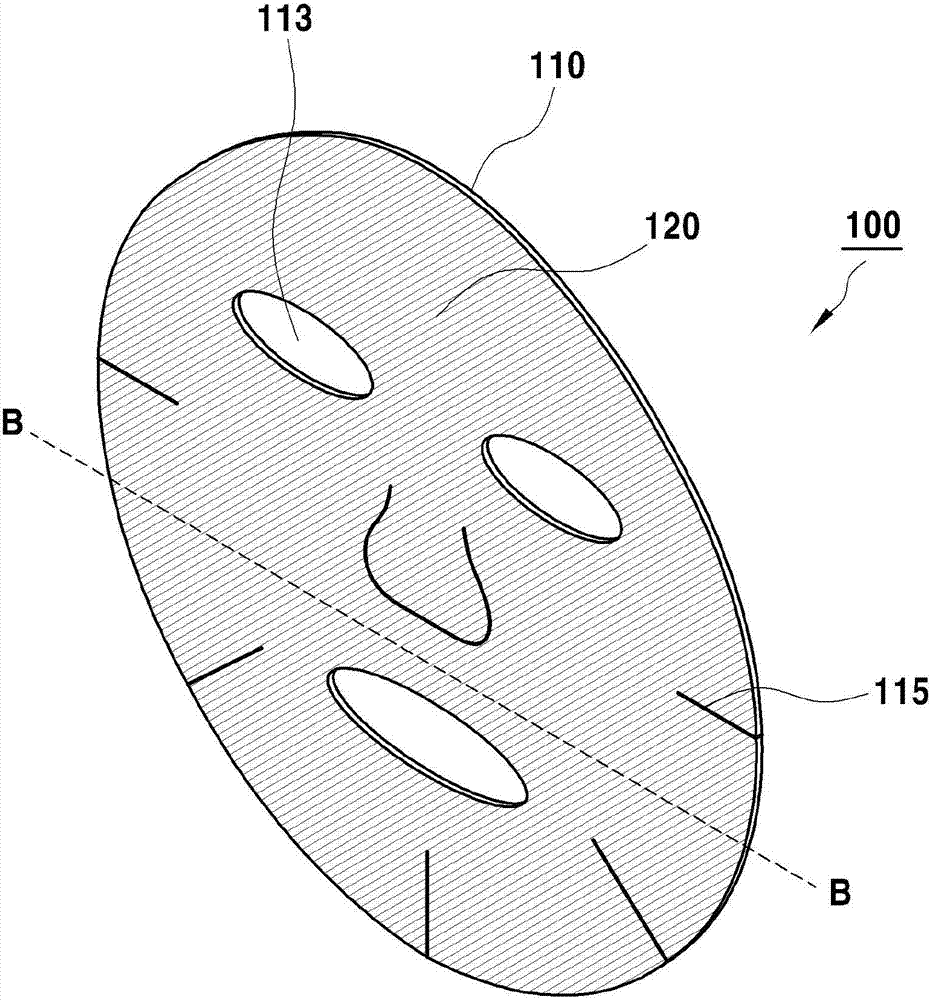

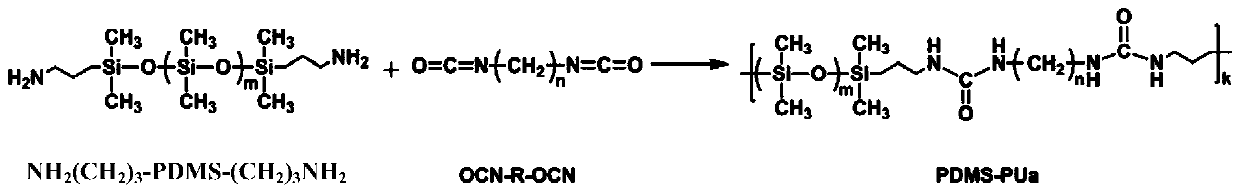

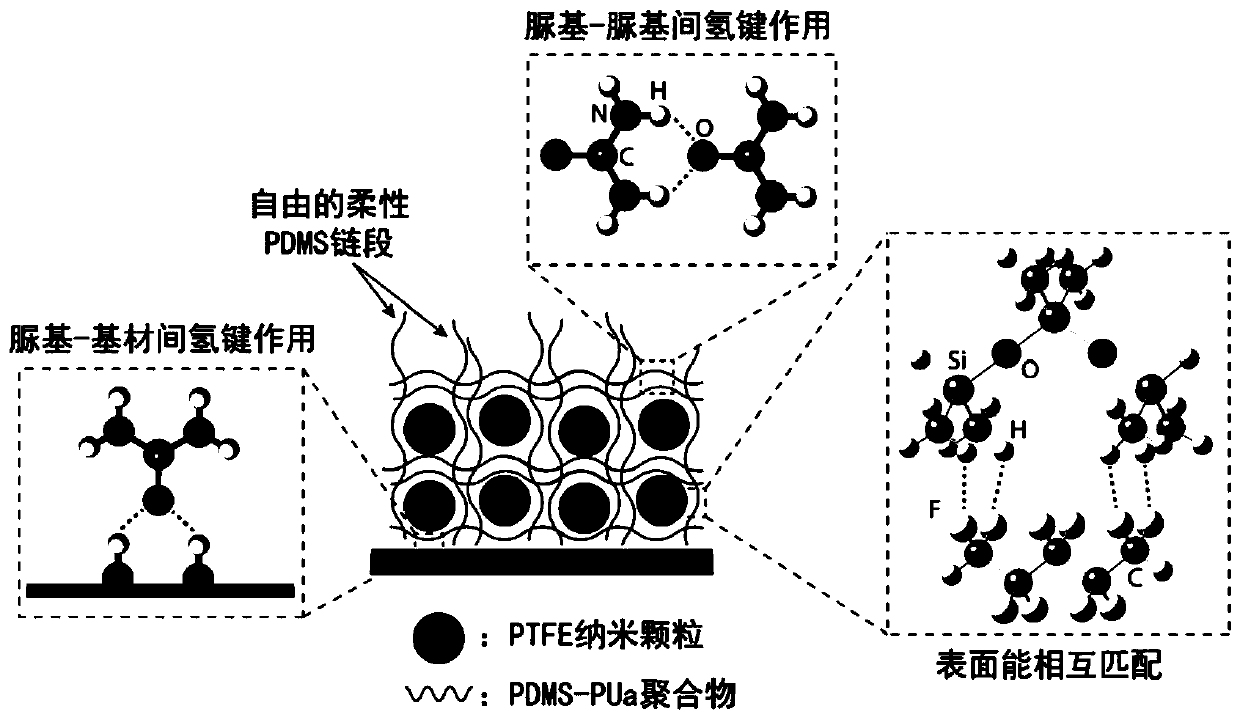

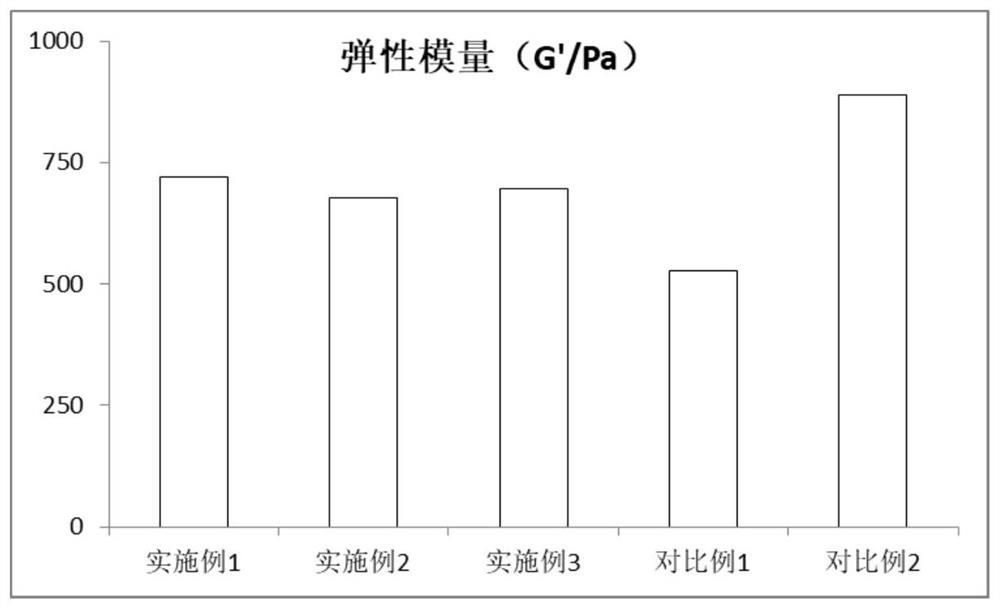

Antifouling coating material and preparation method and application thereof

ActiveCN110804380AImprove mechanical propertiesGood adhesionAntifouling/underwater paintsPaints with biocidesPolymer scienceOrganic solvent

The invention provides an antifouling coating material and a preparation method and application thereof, the coating material comprises the following raw materials: PDMS-PUa, PTFE nanoparticles and anorganic solvent A, and the coating material is obtained by mixing and crosslinking PTFE dispersion liquid dispersed in the organic solvent A and PDMS-PUa. The antifouling coating material and an antifouling material prepared from the antifouling coating material disclosed by the invention have relatively good flexibility and fluidity, a glossy surface and a low elastic modulus, The antifouling property is achieved while good mechanical property is guaranteed, certain self-repairing property is achieved, service life of antifouling material can be prolonged, durable and efficient antifouling purpose is achieved, and a wide application prospect is achieved.

Owner:NAT INNOVATION INST OF DEFENSE TECH PLA ACAD OF MILITARY SCI

Subzero treatment process of copper material

InactiveCN103614677ASolve the problem of offsetting electrical performance effectsLow flexibilityHardnessCopper

The invention discloses a subzero treatment process of a copper material. The subzero treatment process comprises the following steps: (1) dehumidifying, namely, dehumidifying and drying the to-be-treated copper material; (2) cooling, namely, putting the dried copper material into subzero equipment, and controlling the subzero equipment by using a computer so as to reduce the temperature linearly, wherein the reduction speed is 0.5-1 DEG C / minute, and the temperature is reduced to be minus 190 DEG C to minus 196 DEG C from normal temperature; (3) performing heat preservation, namely performing heat preservation for greater than or equal to 2 hours at minus 190 DEG C to minus 196 DEG C according to the size of the material; (4) raising the temperature, namely, linearly and slowly raising the temperature back to be the normal temperature in a balance circulation mode. Compared with the prior art, the subzero treatment process has the advantages that the problems that only the physical properties of a copper tissue are changed and the electric property influence is counteracted after subzero treatment are solved; according to the practical application situation, materials with different hardness and tension forces are treated by controlling the heat preservation time at minus 190 DEG C to minus 196 DEG. The copper material treated by the process can be applied to audios and liners, and the sound quality can be greatly improved.

Owner:上海田伏电子科技有限公司

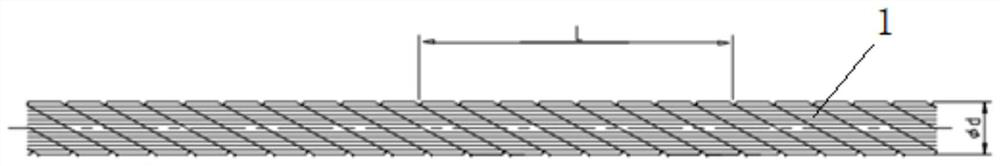

Elevator steel wire rope

The invention discloses an elevator steel wire rope. The elevator steel wire rope comprises a rope body, and the rope body is formed by wrapping and twisting one rope core with a plurality of outer-layer strands and a plurality of inner-layer strands; the lay length of the outer-layer strands is 7.5-8.5 times of the strand diameter of the outer-layer strands; the lay length of the inner-layer strands is 7.5-8.5 times of the strand diameter of the inner-layer strands; the lay length of the inner-layer strands is the same as the lay length of the outer-layer strands; and the lay length of the rope body is 6.55-6.60 times of the rope diameter of the rope body. The lay length of the elevator steel wire rope is increased, and gaps between strands in the elevator steel wire rope are increased; meanwhile, the lay length of the strands is reduced to counteract softness reduction after the lay length of the elevator steel wire rope is increased, and therefore the phenomenon that the strands protrude when the elevator steel wire rope passes through a traction wheel and a guide wheel is prevented, shaking is avoided, and the security is improved.

Owner:WUXI UNIVERSAL STEEL ROPE

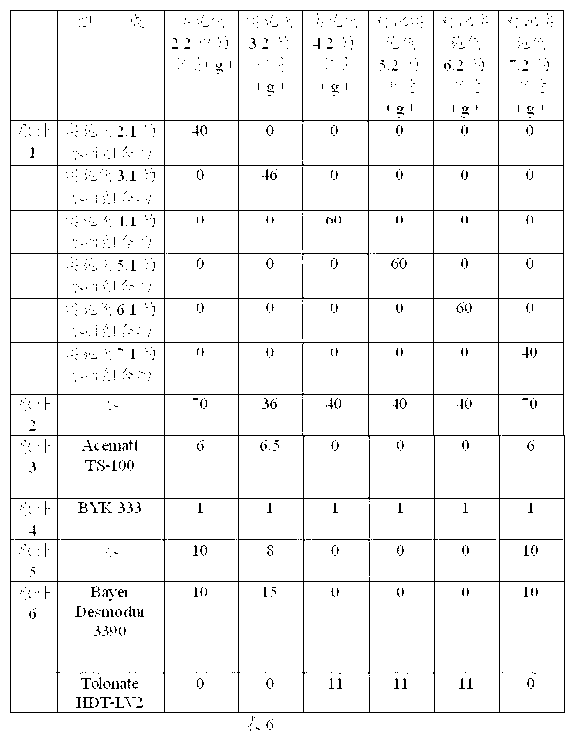

Polyester, aqueous composition including polyester and preparation method of aqueous composition, double-component paint including aqueous composition and preparation method of double-component paint

The invention provides polyester, which is good in stability, excellent in chemical resistance and capable of improving the safety performance. The polyester disclosed by the invention can be stored for one month or more under a temperature higher than the normal temperature, and therefore, the polyester is beneficial to improving the capacity, planning the product in a more reasonable manner and promoting the improvement of production efficiency. Meanwhile, the invention further provides an aqueous composition including the polyester as well as a double-component paint including the aqueous composition. The quality is better in compassion with the existing product, so that smoothness of a finished product is increased, the surface of the finished product is smoother, and therefore, the practical application and more extensive popularization are facilitated, and a remarkable promoting effect is achieved for promoting the industrial technology progress.

Owner:科思创树脂制造(佛山)有限公司

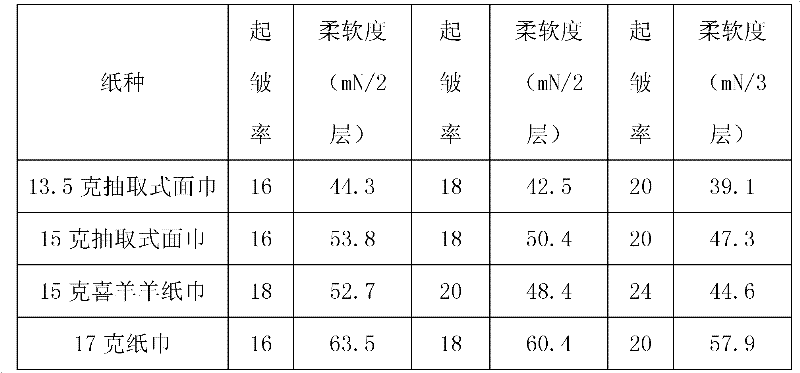

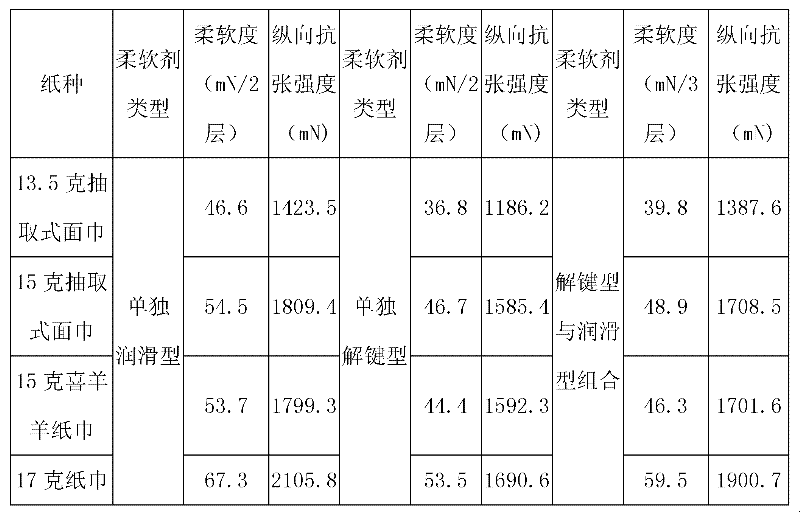

Manufacturing method for improving softness of tissue paper

The invention discloses a manufacturing method for improving the softness of tissue paper. The method comprises the following steps of: sorting, pulping, filling, making paper, scraping the paper, squeezing and drying, and also comprises a step of selecting and adding a softener, wherein a fluffer and refiner series connection free pulping method is adopted and the range of a tackifying coefficient is strictly controlled in the pulping process, and an appropriate scraper angle is selected and the crepe ratio of the paper is adjusted in the paper scraping process. Compared with the prior art, the method has the advantages that: the softness and handfeel of a paper product are obviously improved while the paper product has high strength, the softness of paper towel raw paper is lower, the handfeel of the raw paper is better and the strength of the paper product is slightly influenced when processing conditions are met, and the satisfaction of a consumer with the product is obviously improved.

Owner:WEIANJIE CARE PROD CHINA CO LTD

Biodegradable plastic product material

The invention relates to a biodegradable plastic product material being composed of, by weight, 30-60% of a biodegradable material and 50-70% of polypropylene plastic, wherein the biodegradable material includes soya bean protein and starch according to the ratio of 1:3. Compared with a conventional synthetic plastic product, the biodegradable synthetic material is better than the common synthetic plastic products in light transmittance, oxygen permeability, heat resistance, toughness, softness, elasticity, tensile strength and anti-aging property. In addition the biomass synthetic plastic is greatly reduced in production cost. The biodegradable plastic product material needs 5-8 months for being completely decomposed in soil into high-quality organic fertilizers.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

Biodegradable plastic sole material and preparation method thereof

InactiveCN109181086AGood moisture-proof and water-proofImprove toughnessSolesFoaming agentWear resistance

The invention discloses a biodegradable plastic sole material and a preparation method thereof. The biodegradable plastic sole material is prepared from the following raw material components in partsby weight: 80-100 parts of EVA aggregates, 20-30 parts of high-density polyethylene, 25-35 parts of ethylene-acrylate copolymers, 10-30 parts of ethylene-octene copolymers, 30-40 parts of modified poplar powder, 5-8 parts of activator mixture, 2-4 parts of talcum powder, 2-4 parts of foaming agent and 3-5 parts of crosslinking agent. A sole prepared according to a formula has good dampproof and waterproof effects and also has good toughness, wear resistance and slip resistance, and the plastic sole is degradable so that environment pollution can be avoided.

Owner:ANHUI TONGLI NEW MATERIALS

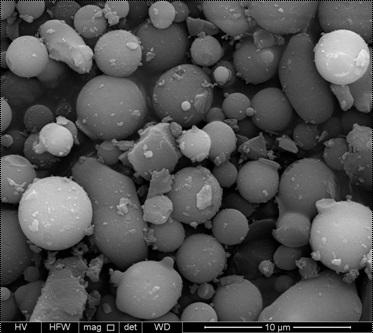

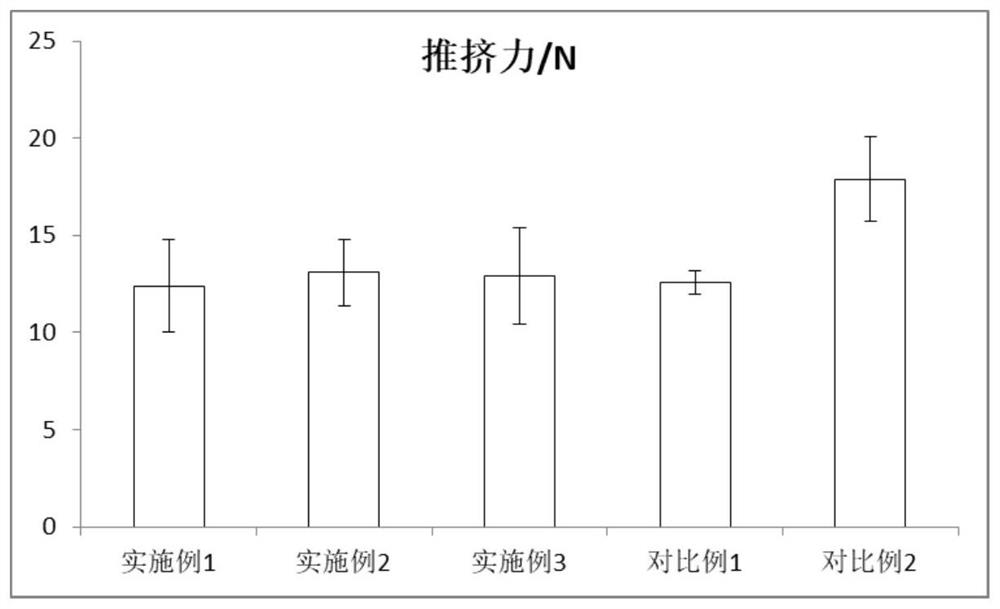

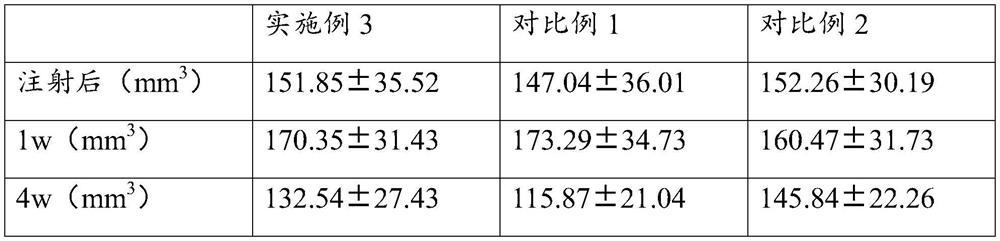

Gradient degradation skin filler and preparation method thereof

ActiveCN114177352AExcellent rheological propertiesImprove deformation resistancePharmaceutical delivery mechanismTissue regenerationPolymer scienceMicrosphere

The invention discloses a gradient degradation skin filler and a preparation method thereof, and relates to the field of tissue filling and medical biological materials. In the filling agent disclosed by the invention, a gel matrix phase serving as a carrier is subjected to secondary crosslinking, so that primary crosslinking gel particles with relatively high crosslinking degree can be uniformly dispersed in a matrix material with relatively low crosslinking degree, and a gel particle matrix formed by the filling agent is high in central crosslinking degree and low in peripheral crosslinking degree; in addition, by compounding degradable or non-degradable microspheres, self collagen regeneration is stimulated. The filler prepared by the secondary crosslinking process has excellent rheological mechanical properties, not only has deformation resistance and durability endowed by high-crosslinking-degree gel, but also has softness and natural aesthetics brought by low-crosslinking-degree gel.

Owner:西安德诺海思医疗科技有限公司

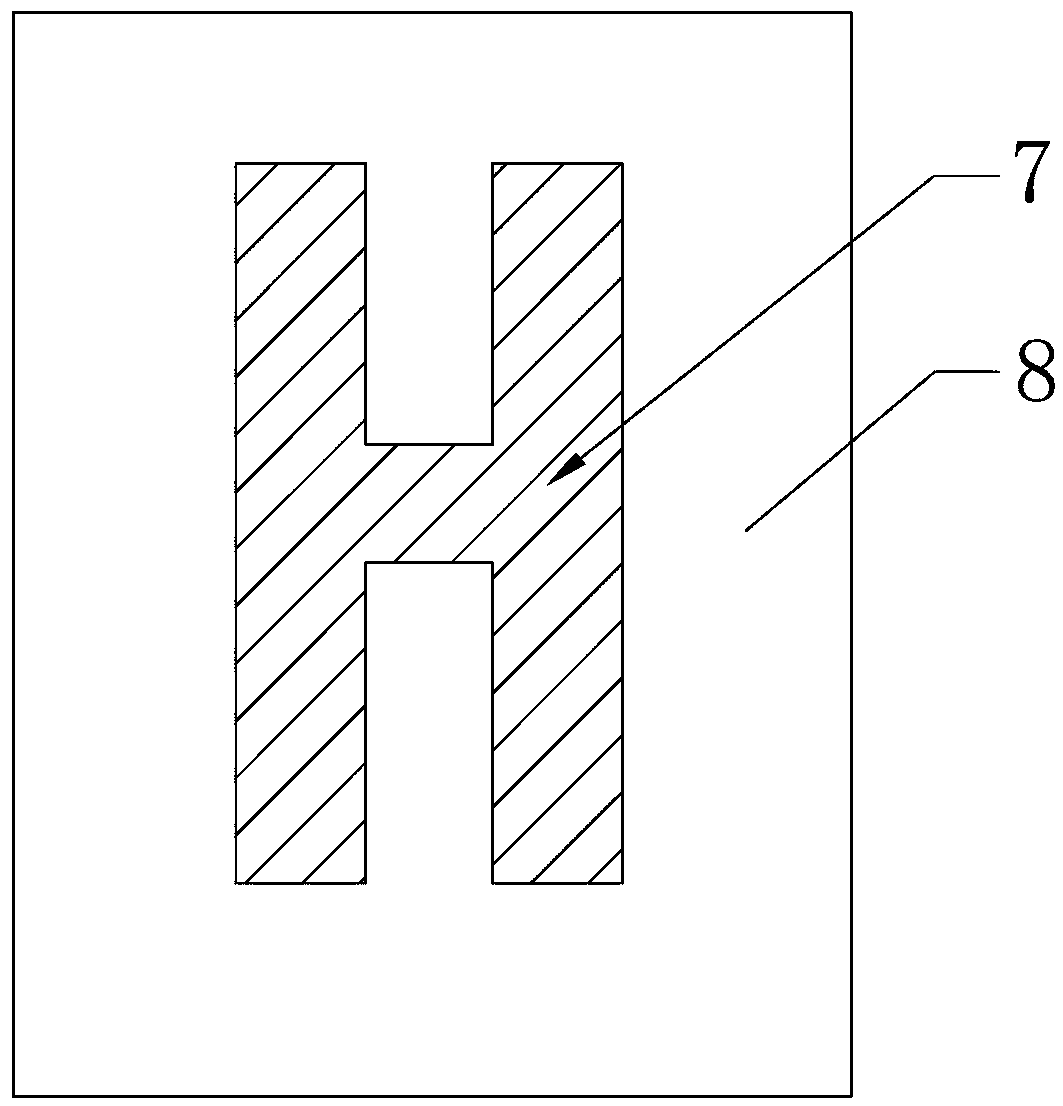

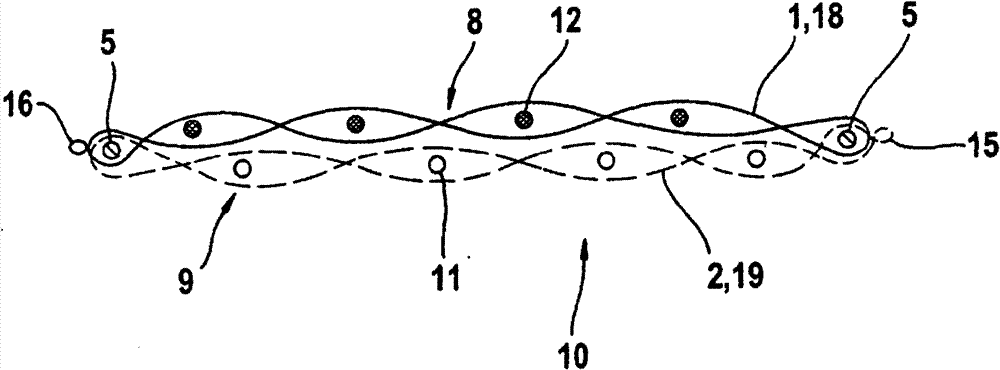

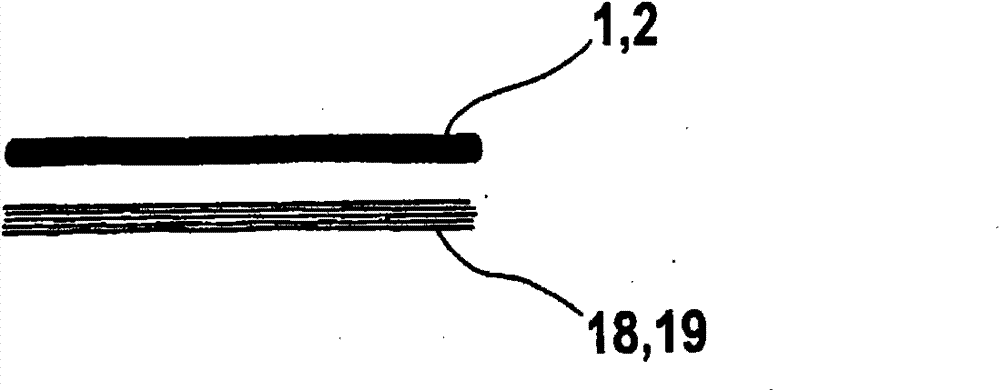

Method for producing a woven fabric and woven fabric produced thereby

ActiveCN101772599BUnaffected by mechanical and especially temperatureImprove lateral stabilityMulti-ply fabricsPolymer sciencePolymer chemistry

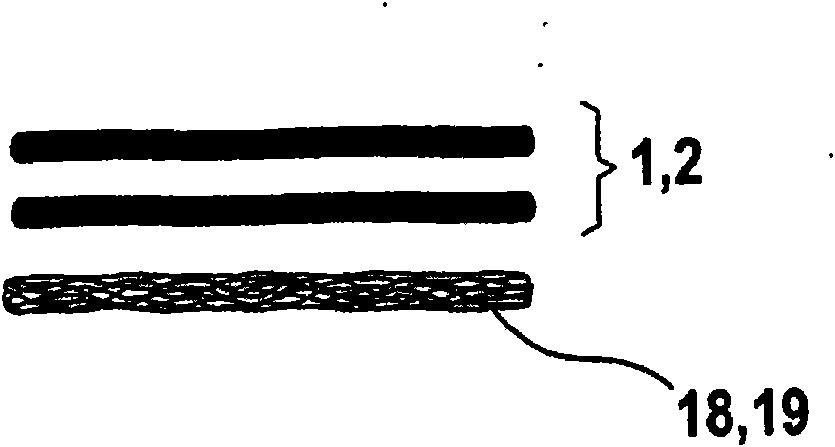

The invention relates to a method for producing a woven fabric (8, 9), the woven fabric (8, 9) comprising at least one monofil or monofil-like weft thread made of highly shrinkable material and warp threads made of low-shrinkage material, characterized in that at least one multifil weft thread (18, 19) running in the same shed is woven together with the at least one monofil or monofil-like weft thread (1, 2) during the weaving process.

Owner:IPROTEX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com