Three-layered compound non-woven fabric as well as processing equipment and processing technology thereof

A non-woven fabric and layer composite technology, applied in the field of raw materials for hygiene products, can solve the problems of low water absorption rate, unsatisfactory, and easy-to-wear products, etc., to prevent dirt from penetrating, improve penetration performance, and prevent leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

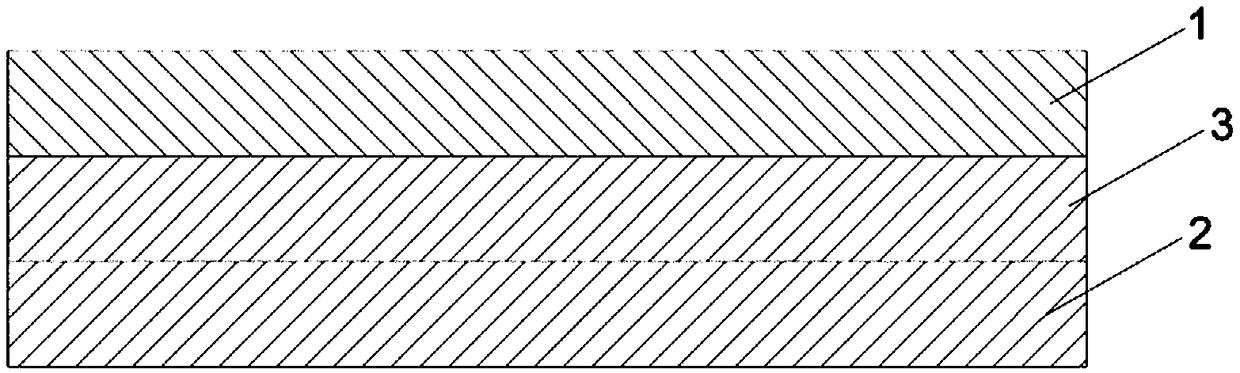

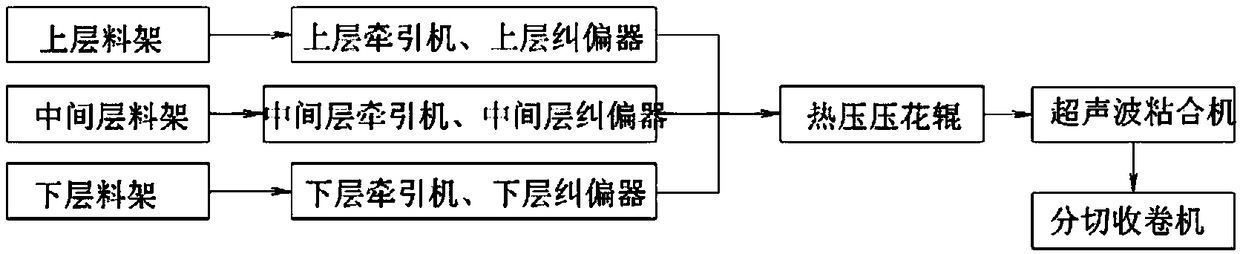

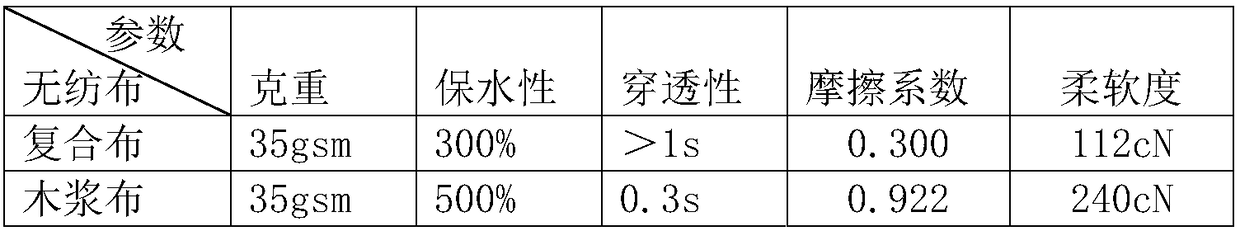

[0021] Such as figure 1 As shown, a three-layer composite non-woven fabric includes an upper layer 1, a middle layer 3 and a lower layer 2 that are combined together. The upper layer 1 and the lower layer 2 are both PP particle anti-sticking layers, and the middle layer 3 is a long-fiber wood pulp layer. Two layers of PP particle anti-sticking layer wrap the long-fiber wood pulp layer in the middle, emboss it with a hot embossing roller, and then heat it with an ultrasonic bonding machine. The grammage of the PP particle anti-sticking layer is 10gsm, and the grammage of the long-fiber wood pulp layer is 15gsm. The non-woven fabric has a grammage of 38gsm, a water retention of 300%, a penetrability>1s, a softness of 200mN, a coefficient of friction<0.3, and a softness of 112cN.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com